Beruflich Dokumente

Kultur Dokumente

Testing Lucas Alternators Aug 2013

Hochgeladen von

derryukCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Testing Lucas Alternators Aug 2013

Hochgeladen von

derryukCopyright:

Verfügbare Formate

Testing Lucas Alternators

Some background

Originally I wanted to know if the alternator on my T100 was working. The engine was in bits so I mounted the stator and rotor onto my bench grinder. This ran at about 3000 RPM but my grinder struggled to maintain speed when the stator was connected to a load. I later bought a more powerful three-phase motor and inverter and built a small test rig (on the right.) This rig can drive an alternator from 0 to 4000 RPM under load. The top limit is arbitrary as I dont know the maximum speed of the motor! To make measurements I used a digital multimeter (DM) and a Picoscope (software oscilloscope.) Lucas specifies a 1 Ohm load resistor to test their alternators and initially I made my own from resistance wire. There is a fair amount of heat to dissipate by the load (at least 120W) and after burning my hand a couple of times I fitted a cooler running 200W device below left. I also added a selection of resistors to simulate ignition and lighting loads.

Although I started out to test my own alternator, over time this has changed and I have taken the opportunity to test any alternator I can get my hands on. I have logged the test results at the end of this document.

Testing Lucas Alternators

Stators

Stators are pretty simple devices, just a long length of copper wire wound around coil formers. Generally they will either work or they wont. There were two types latterly produced by Lucas, single-phase and three-phase. You can identify each type by its number of output wires and coils. A single-phase stator has two wires and six coils (below left), while a three-phase stator has three wires and 9 coils (below right).

Confusingly the early single-phase stators also had three wires. This was because they were initially used on 6 volt electrical systems which had no voltage regulation (no zener). To increase alternator output whenever lights were used, extra stator coils (the third wire) were brought into use. These stators can also be used on 12v systems by connecting the green/yellow and green/black wires together to make a two wire single-phase stator. Some even earlier stator types had 5 wires but these were used on AC only bikes. Lucas stators have an ID number and date of manufacture stamped on them. To find your numbers you may have to remove your stator. Aftermarket stators tend to have only a name at best.

Testing Lucas Alternators

Rotors

As far as I can tell there is no difference between single and three-phase rotors. Rotors have identifying numbers and sometimes a date.

The rotor keyway is only required for timing purpose, it is not required to drive the rotor. I never use a key on my rig and only ever just nip up the rotor nut, it never moves. You must use a key if you run a battery-less ignition system (including with a capacitor) or if you use the marks on the rotor for ignition timing. There may be rub marks on your rotor but these are not necessarily a bad thing. However there must be a gap between the rotor and stator, check yours with a feeler gauge. The gap size is not critical but make sure you can get a feeler all the way around. If the rub marks have any depth or formed grooves, check the nearest main bearing for wear.

Magnetism

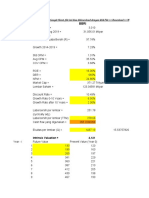

There is a lot of forum talk about how much magnetism a rotor loses over time and what impact this might have on alternator output. I have a collection of old rotors and some are good, some are bad. Shown below two of my old Lucas rotors are very close to a new Wassell on output (C & E), two are close and rotor B wants chucking in the bin. Meter Reading Scope reading Power 1 No load 1 No Output % Ohm Ohm load AC AC Peak Peak Compared to Volts Volts Volts Volts Wassell 12.2 22.1 23.2 58.2 70 10.4 18.8 20.1 51.2 51 14.3 25.3 27.2 63.7 96 14.6 25.9 27.2 63.7 100 14.2 24.8 26.7 61.4 95 12.9 23.2 24.1 60.4 78

ID A B C D E F

Make Lucas Lucas Lucas Wassell Lucas Lucas

Year 11 68

ID 54215824 54212006 ww10105p 54212006 54212006

44 78 5 69

Watts 149 108 204 213 202 166

RPM 3000 3000 3000 3000 3000 3000

Testing Lucas Alternators

I have tested a Sparx high-output rotor and this gave a useful extra 50W output on a single phase stator and 25W extra on a three phase. Take note that this increase would stress a standard zener through overheating. A modern rec/reg should be OK with the extra output though. Power Output % Compared to Wassell 96 100 141

Rotor Lucas Wassell Sparx

Voltage 10.8 11.0 13.1

Watts 117 121 171

I used a two wire stator 47205A with 1 Ohm load at 3000 RPM in this test.

Tight Fit Rotor

While mentioning Sparx, their rotors are now an interference fit on the crankshaft. Until we know different Id suggest using an expanding reamer or hone in the Sparx rotor bore to give yourself a bit of clearance. Rotor Lucas Wassell Sparx Bore size 0.753 0.7525 0.7505 Clearance 0.003 0.0025 0.0005 The crankshaft diameter is 0.750in. All dimensions in inches.

Rotor Offset

A rider said his rotor has a 0.25 (6.35mm) offset from his stator and wondered what effect it would have on output. I did a quick check using a standard Lucas rotor with single-phase 47205a stator running at 3000rpm without and with a load. Voltage No load 33.4 35.5 Voltage 1 Ohm 10.2 10.7 Watts 104.0 114.5 That offset caused a 9% drop in output so worth getting it right. It would be interesting to know if the offset is standard or has been caused by a mismatch of parts ie wrong size spacer or stator

Offset Aligned studs.

Shorted Stator Output

There has been some forum discussion about the power consumption of Lucas alternators, i.e. how much effort does it take to rotate a rotor. Most thought it would be at maximum effort when the output leads are shorted together. However one lone voice declared that the drive power would be at minimum with leads shorted. To test the theory I set the frequency of my inverter to 17Hz (1000 RPM) and noted the output current of the inverter with no load, with a 1 Ohm load and with the stator leads shorted together. To just drive the motor alone (no rotor or stator) the inverter current was 1.9 amps.

Testing Lucas Alternators

The tests showed that minimum power is required with shorted leads. Not surprising then that most modern rec/regs work using this system as the following example Motor current (A) shows: Stator D Stator J http://mastercircuits.blogspot.co.uk/2010/05/motorcycleNo load 3.3 2.9 1 ohm 3.6 3.1 voltage-regulator.html shorted 2.8 2.5 I was surprised at how little difference there is between the no load and 1 ohm load values. If anyone is wondering why the no load values are so high don't forget that you have a set of rotor magnets trying to hang onto the stator poles. Since doing this test I have found Lucas circuit diagrams that show output leads shorted together in some lighting switch positions (Lucas Workshop Instructions, Section L-2, Part E, Page 3 Nov 1960). The following text was included, In the lights off position the alternator output is regulated to a minimum value by the interaction of a magnetic flux set up by the current flowing in the short-circuited coils with the magnetic flux of the rotor the latter flux being distorted and therefore less effective.

Will a shorted stator overheat?

Another forum member suggested that although it takes less power to rotate a shorted stator, over time a shorted stator would still fatally overheat. The accompanying chart shows stator J with its output leads shorted together running with a Lucas rotor at 3000 RPM. After 40 minutes the temperature is stabilising around 80 deg C. The output leads of the stator were only warm to the touch suggesting that the temperature rise is mostly caused by eddy currents. I am not sure what the internal temperature of a Triumph primary chaincase would be after 40 minutes running but I would imagine that it is likely to be 80 deg C or more.

Testing Lucas Alternators

Testing

Finally to give an idea what an alternator is doing have a look at the plot below, the output of stator M. As you can see, with no load the stator output is a straight line. If you double the speed of the rotor you double the output voltage of the stator. With a load, the curve is flattened.

100 90 80 70 60 Peak Volts DC 50 40 30 20 10 0 0 2000 RPM 4000 6000

1 Ohm load No load

Testing your alternator

RM stators are robust things; it is difficult to destroy one. If you are having charging problems it is likely to be something other than a bad alternator. Also if you replace your alternator without first testing it then the chances are you are wasting your money. If your bike suddenly develops a flat battery then to test your alternator: First charge your battery (so you can start your bike and keep it running) Disconnect your stator Measure the stator resistance and compare your readings to mine in the tables below. When measuring very low resistances the meter lead resistance can be higher than the stator resistance so measure the lead resistance first (connect the meter leads together and note the meter reading), then measure your stator resistance and subtract the lead resistance to give actual stator resistance. Remember that with stator resistance results, near enough is good enough. If my stator measures 0.5 Ohm and yours is 0.62 Ohm then that is OK. If you have an infinite or very high stator resistance then you have a broken stator coil or stator lead. Now measure the resistance between the stator lead and the crankcase, it should always be infinite (very high). Start your bike and measure the AC voltage between leads at 3000 RPM (you dont need the 1 Ohm resistor.) Compare your results with mine. Again, being close is good enough. Dont just blip the throttle to make measurements, hold the revs until you get a steady meter reading.

If your resistances are OK but your voltage is much lower than mine then you have weak magnets in your rotor.

Testing Lucas Alternators

If your bike passes these tests then you need to look at your rectifier and zener (or your rec/reg for combined units) for your charging problems. There is further guidance here: http://www.scribd.com/doc/152680652/Fault-Finding-Lucas-Motorcycle-Charging-Systems

The log, what it all means

ID - is what I scribed onto a stator as I pulled it from the box so I could refer back if necessary. Type single (1) or three (3) phase Number - is what was stamped onto the stator. I am not sure what the numbers mean and I suspect that you could get the same alternator type but with different numbers for each bike manufacturer. Where it says unknown this refers to a rotor purchased new from eBay and I think of them as a Royal Enfield (India) types of stator rather than of Lucas origin. Year - what was stamped on the stator. Wires - the number of, coming from the stator. Number of laminations - counted. Lead colours - if the majority of lead colour is brown with a thin blue stripe then this is brown-blue in my log. Resistance between leads - in Ohms. As I said previously measuring low value resistance is tricky because part of the resistance you are trying to measure is caused by the meter itself; often the meter lead resistance is greater than the stator resistance. To overcome this in my tests I used the four-wire resistance measuring method, done using two meters (hence four-wire) and a separate power supply. The power supply is used to provide a current flow through the stator being tested and one meter is connected to measure this current flow. If we now measure the voltage across the stator leads we can calculate its resistance (R=V/I). The important point is that with this method the meter lead resistance is of no concern. Using the circuit on the left I adjusted the power supply until 1 amp was flowing through the ammeter; from Ohms law the voltage measured across the stator is the same as the stator resistance. So if I measure 0.5v across the stator coil then its resistance is 0.5 Ohm. Watts - an idea of what the stator output power is likely to be. I have multiplied the meter reading with 1 Ohm load by itself. It is not accurate but a reasonable indication. RPM of the rotor used for the measurement. Meter reading 1 Ohm load volts AC - what my meter measured with a 1 Ohm load. These readings are relative rather than absolute. You need whats known as a true RMS meter for accurate results, my meter isnt but it gives you an idea what to expect. 7

Testing Lucas Alternators

Meter reading no load - as above with 1 Ohm load disconnected. Peak 1 Ohm volts - peak voltage measured on my Picoscope, the dotted lines shown below.

Stator C 4000 RPM 1 Ohm load Meter reading 6.0 volts AC

This is important as it gives an indication of whether at maximum load your battery will be charged. Now a charged 12v battery measures 12.6V across its terminals, so to charge it we need more than 12.6 volts. Looking at the image above you can see the peak voltage is just over 10 volts which isnt enough. Peak no load volts - as can be seen bellow you have plenty of voltage to charge your battery.

Stator C 4000 RPM no load Meter reading 52.1 volts AC

Testing Lucas Alternators

In practice you can never achieve no load as your electrical system will always have a load of some sort (the battery itself, ignition coils, zener diode.) Notes - some remarks. An X in this column indicates the leads I used for measurement on threephase stators. DerryUK August 2013

Testing Lucas Alternators

T Y P E Stator number Y e a r Resistance Between Leads 0.916 0.451 0.484 4.790 0.847 0.851 0.851 0.849 0.858 0.860 0.234 0.529 0.530 0.517 0.519 0.519 0.519 0.829 0.831 0.844 0.704 1.102 2.350 1.092 Meter reading 1 Ohm No load AC AC Volts Volts 5.2 6.7 3.0 3000 1000 2000 3000 4000 3000 3000 1000 2000 3000 4000 3000 5.8 4.5 5.5 5.8 6.0 12.2 7.3 4.9 6.6 7.3 7.7 6.0 4.2 1.0 1.1 1.2 13.2 26.4 75.9 38.0 13.2 26.3 39.4 52.1 22.1 30.0 9.8 19.6 29.2 38.6 37.3 20.4 7.5 16.5 10.1 Scope reading 1 Ohm No load Peak Peak Volts Volts 9.1 11.2 4.5 9.6 7.8 9.1 9.5 10 23.2 12.1 8.5 11.4 12.2 12.8 9.8 6.9 1.7 1.9 1.9 35.5 92.5 203.0 67 22.3 48.0 72.0 96.3 58.2 56.8 16.4 33.5 50.4 67.0 60.3 55.7 30.1 54.9 37.8

ID

Wires

Laminations

47197A

67

18

Lead Brown Brown Red Black-white Green-yellow Green-yellow White-green Green-yellow Green-yellow White-green Green-yellow Green-yellow Green-yellow White-green Green-yellow Green-yellow White-green Green-yellow Green-yellow White-green Brown Brown Brown Brown

47252

85

19

C D E

3 1 3

47252 47161A 47244A

89 64 88

3 2 3

21 16 20

colours brown-blue red brown-blue black Yellow Green-black White-green Green-black Green-black White-green Green-black Green-pink Green-black White-green Green-black Green-black White-green Green-black Green-black White-green Green-black Clear Red Purple Mauve

Watts 27 45 9 34

RPM

3000

Notes No connection Stop Lamp Lights Ignition coils X

34 36 149 53

472442

83

20

53 59 36 18 1 1 1

47252A

79

20

1 Unknown

17

3000

10

Testing Lucas Alternators

T y p e 1 Stator number 7188B Y e a r Resistance Between Leads 0.499 3.950 0.400 4.340 0.424 0.597 1.120 1.700 0.735 2.040 1.330 0.531 0.960 Meter reading 1 Ohm No load AC AC Volts Volts 6.5 26.6 2.5 73.8 5.9 16.0 2.8 89.5 6.5 11.1 9.5 22.2 10.8 33.1 Scope reading 1 Ohm No load Peak Peak Volts Volts 10.2 78.2 3.7 225.0 9.8 37.9 4.1 265.0 13.6 31.3 17.6 62.3 17.9 92.4

ID I

Wires 5

Laminations 18

Lead Red Brown Brown Black-white White-green Light green Light green Dark green Green Green White Orange Purple

colours Brown-blue Black-white Black-yellow Black-yellow Green-yellow Mid green Dark green Mid green White Purple Purple Yellow Purple

47205A

69

18

Watts 42 6 35 8 42 90 117

RPM 3000 1000 2000 3000

Notes Marked C15

Unknown

19

Not tested Stator did not fit my rig 71 1 29 92 41 3000 8.4 0.3 5.4 9.6 6.4 27.8 1.9 26.0 23.0 25.8 14.0 1.0 9.0 17.6 11.16 75.1 12.3 67.1 66.2 79.7 Windings In-phase 104.7 101.0 4.6 Windings In-phase Broken leads

Unknown

23

Unknown

32 Orange White-green White-green Green-black White-green Red Red Green Yellow Green-black Green-yellow Green-yellow Green-black+ green-yellow Green Yellow Yellow 149 31 88

3000

47209A

26

1.199 0.584 1.788

3000 129

12.2 5.6 9.4 0

40.1 38.5 1.5

23.9 8.55 14.6 0.38

11.4

38.8

17.9

101.6

472308

73

11

Testing Lucas Alternators

T y p e 3 Stator number Sparx Hi-output Sparx Hi-output Y e a r Resistance Between Leads 0.495 0.497 0.497 0.495 0.497 0.497 Meter reading 1 Ohm No load AC AC Volts Volts 7.9 28.0 Scope reading 1 Ohm No load Peak Peak Volts Volts 12.78 40.9

ID Q

Wires 3

Laminations 20

20

Lead Green-yellow Green-yellow White-green Green-yellow Green-yellow White-green

colours White-green Green-black Green-black White-green Green-black Green-black

Watts 62

RPM 3000

Notes Wassell rotor Sparx hi-output rotor

87

3000

9.32

31.8

15.13

46.2

12

Das könnte Ihnen auch gefallen

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualVon EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualNoch keine Bewertungen

- Alternator Troubleshooting With An OscilloscopeDokument4 SeitenAlternator Troubleshooting With An OscilloscopeVyas SrinivasanNoch keine Bewertungen

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualVon EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualBewertung: 2.5 von 5 Sternen2.5/5 (2)

- DTC Check ClearDokument2 SeitenDTC Check ClearDaniel Mamani ParedezNoch keine Bewertungen

- Ignition System GuideDokument8 SeitenIgnition System GuideJesus ParraNoch keine Bewertungen

- Ignition System: 1988 Toyota CelicaDokument7 SeitenIgnition System: 1988 Toyota CelicaToua Yaj100% (1)

- Electrochemi Toyota Land Cruiser Prado 2004 DemoDokument15 SeitenElectrochemi Toyota Land Cruiser Prado 2004 DemoVinsensius Agus Priyono100% (1)

- DTC P0130 Oxygen Sensor Circuit Malfunction (Bank 1 Sensor 1)Dokument4 SeitenDTC P0130 Oxygen Sensor Circuit Malfunction (Bank 1 Sensor 1)williamNoch keine Bewertungen

- Nissan 1991-1993 Silvia S13 SR20DET, 1991-1995 180SX SR20DETDokument2 SeitenNissan 1991-1993 Silvia S13 SR20DET, 1991-1995 180SX SR20DETElectronica Ave FenixNoch keine Bewertungen

- Identification: Avalon (1999), Camry 3.0L, Camry Solara 3.0L & SiennaDokument54 SeitenIdentification: Avalon (1999), Camry 3.0L, Camry Solara 3.0L & SiennaJuan Carlos Martinez NuñezNoch keine Bewertungen

- Engine Control System: SectionDokument501 SeitenEngine Control System: SectionNilson MaldonadoNoch keine Bewertungen

- Cooling System: Engine - 2Tr-Fe Engine EG-18Dokument2 SeitenCooling System: Engine - 2Tr-Fe Engine EG-18Maxi SardiNoch keine Bewertungen

- Toyota Trouble Code Info PDFDokument6 SeitenToyota Trouble Code Info PDFdhanysiregarNoch keine Bewertungen

- ABS, brake assist, EBD, TRC and VSC systems diagramDokument16 SeitenABS, brake assist, EBD, TRC and VSC systems diagramasfwsvgerNoch keine Bewertungen

- Toyota Corolla 1.8l 2zr (Body Control Module)Dokument2 SeitenToyota Corolla 1.8l 2zr (Body Control Module)Franz DelgadilloNoch keine Bewertungen

- Body + ElectricalDokument259 SeitenBody + Electricalnels26Noch keine Bewertungen

- 3MZ FE PartsDokument10 Seiten3MZ FE PartsDamon Howes100% (1)

- Instrument Panel Analog - Nissan Sentra 1993Dokument8 SeitenInstrument Panel Analog - Nissan Sentra 1993Alessandro BaffaNoch keine Bewertungen

- Tomihawk Tools CatalogueDokument60 SeitenTomihawk Tools CatalogueRosília DomingosNoch keine Bewertungen

- Toyota Diagnostic Trouble Codes Full List Obdii365Dokument2 SeitenToyota Diagnostic Trouble Codes Full List Obdii365kabuye NicholasNoch keine Bewertungen

- Electrical Wiring Diagram: TOYOTA: Hilux Sport RiderDokument60 SeitenElectrical Wiring Diagram: TOYOTA: Hilux Sport RiderThiri HlaingNoch keine Bewertungen

- Engine 1.6L (Steem G16) PDFDokument18 SeitenEngine 1.6L (Steem G16) PDFAry Duran0% (1)

- DTC P0101 Mass Air Flow Circuit Range / Performance Problem: DescriptionDokument3 SeitenDTC P0101 Mass Air Flow Circuit Range / Performance Problem: Descriptioncarlos gil100% (1)

- Ta1248 PDFDokument38 SeitenTa1248 PDFbad_boyz1989Noch keine Bewertungen

- Index for DTCsDokument14 SeitenIndex for DTCsAlex Hernandez100% (1)

- Hybrid System Overview: Section 1Dokument150 SeitenHybrid System Overview: Section 1Cacanaut100% (1)

- Components of The Ignition SystemDokument5 SeitenComponents of The Ignition SystemJaston MwicheNoch keine Bewertungen

- Engine Bay Relay Locations GuideDokument82 SeitenEngine Bay Relay Locations GuidelukasNoch keine Bewertungen

- 4 AfeDokument36 Seiten4 AfeJuan ContrerasNoch keine Bewertungen

- ECM I/O Signals DiagnosticsDokument5 SeitenECM I/O Signals Diagnosticskofo3000Noch keine Bewertungen

- How to Optimize Your Website for Search EnginesDokument49 SeitenHow to Optimize Your Website for Search EnginestfphoenixNoch keine Bewertungen

- ECM Input/Output Components Diagnosis GuideDokument17 SeitenECM Input/Output Components Diagnosis GuideFlorin BodroghinăNoch keine Bewertungen

- Bandas de Tiempo 2005 by PowerGripDokument878 SeitenBandas de Tiempo 2005 by PowerGripIng Jose Amad Nolazco Nunez100% (1)

- CorollaDokument3 SeitenCorollaSir-attha Mohd HattaNoch keine Bewertungen

- Accent P0068 MAP (MAF) - Throttle Position Sensor CorrelationDokument6 SeitenAccent P0068 MAP (MAF) - Throttle Position Sensor Correlationflash_24014910Noch keine Bewertungen

- Engine Control: System OutlineDokument14 SeitenEngine Control: System OutlineHernanCalderonDíaz100% (1)

- 1Nz-Fe Engine Mechanical: Service DataDokument3 Seiten1Nz-Fe Engine Mechanical: Service Dataalbert phiriNoch keine Bewertungen

- Toyota Camry IgDokument56 SeitenToyota Camry IgKulasekaran Amirthalingam100% (1)

- P1012-Fuel Pump Delivery Pressure Too High: Theory of OperationDokument2 SeitenP1012-Fuel Pump Delivery Pressure Too High: Theory of OperationYovani AcevedoNoch keine Bewertungen

- DTC P0418 Secondary Air Injection System Relay "A" CircuitDokument4 SeitenDTC P0418 Secondary Air Injection System Relay "A" CircuitOrkhon GanchimegNoch keine Bewertungen

- 2uztrd PDFDokument33 Seiten2uztrd PDFbob loblawNoch keine Bewertungen

- Z18XE SCHDokument3 SeitenZ18XE SCHJan WolnyNoch keine Bewertungen

- Toyota Tundra (2UZ FE) 2002Dokument16 SeitenToyota Tundra (2UZ FE) 2002Isaac Castillo100% (1)

- GM ChargingDokument20 SeitenGM ChargingMihai TacheNoch keine Bewertungen

- Harrop Lc200-1ur InstallDokument22 SeitenHarrop Lc200-1ur InstallArtur ElectroMecânicoNoch keine Bewertungen

- Pin Out Nissan Sensor MAFDokument3 SeitenPin Out Nissan Sensor MAFAlbertiniCongoraAsto100% (1)

- 4afe O2sensor TestDokument3 Seiten4afe O2sensor Testkkg4782Noch keine Bewertungen

- Steering Column Switch PDFDokument26 SeitenSteering Column Switch PDFDaniel OlariNoch keine Bewertungen

- Wiring Diagrams PDFDokument40 SeitenWiring Diagrams PDFtom50% (2)

- 1000 Manual 0407Dokument60 Seiten1000 Manual 0407Dharmesh patelNoch keine Bewertungen

- 007 - Automatic Transmission - 6T40 (MH8 MHH) - Diagnostic Information and ProceduresDokument178 Seiten007 - Automatic Transmission - 6T40 (MH8 MHH) - Diagnostic Information and ProceduresGedas GvildysNoch keine Bewertungen

- 2011 Jeep Liberty Limited 2011 Jeep Liberty Limited: Fig. 73: Transmission Control Output Wiring DiagramDokument7 Seiten2011 Jeep Liberty Limited 2011 Jeep Liberty Limited: Fig. 73: Transmission Control Output Wiring DiagramcarlosNoch keine Bewertungen

- VGRS Actuator MalfunctionDokument3 SeitenVGRS Actuator MalfunctionHenry YogaswaraNoch keine Bewertungen

- Steering Angle Sensor E38 M57Dokument2 SeitenSteering Angle Sensor E38 M57Michal PiratzNoch keine Bewertungen

- AEM Undocumented Settings v1Dokument13 SeitenAEM Undocumented Settings v1Franklyn RamirezNoch keine Bewertungen

- DTC C1554/23 Power Supply Relay Failure DTC C1555/25 Motor Relay Welding FailureDokument3 SeitenDTC C1554/23 Power Supply Relay Failure DTC C1555/25 Motor Relay Welding FailureOswaldo Sierra100% (1)

- 2010 Toyota Prius Repair Manual - Suspension and Alignment - Zero Point CalibrationDokument4 Seiten2010 Toyota Prius Repair Manual - Suspension and Alignment - Zero Point CalibrationsaifNoch keine Bewertungen

- 2004 Corolla Electrical Diagram - Cruise ControlDokument6 Seiten2004 Corolla Electrical Diagram - Cruise ControlNick BaptisteNoch keine Bewertungen

- Toyota OBD CodesDokument2 SeitenToyota OBD Codesnanorutamilan100% (1)

- Fault Finding Lucas Motorcycle Charging Systems Aug 2013Dokument7 SeitenFault Finding Lucas Motorcycle Charging Systems Aug 2013derryukNoch keine Bewertungen

- Two Zeners in The Rectifier BridgeDokument1 SeiteTwo Zeners in The Rectifier BridgederryukNoch keine Bewertungen

- A Lucas Alternator and Zener Charging CircuitDokument8 SeitenA Lucas Alternator and Zener Charging CircuitderryukNoch keine Bewertungen

- Lucas 2MC Capacitor TestsDokument6 SeitenLucas 2MC Capacitor Testsderryuk100% (1)

- Non Triumph RecRegDokument2 SeitenNon Triumph RecRegderryukNoch keine Bewertungen

- TriumphServiceBulletin 092667 No20Dokument2 SeitenTriumphServiceBulletin 092667 No20Norbert SteffensNoch keine Bewertungen

- Digital Regulator For Triumph TwinDokument2 SeitenDigital Regulator For Triumph TwinderryukNoch keine Bewertungen

- Overview of Algorithms For Swarm Intelligence PDFDokument14 SeitenOverview of Algorithms For Swarm Intelligence PDFmenguemengueNoch keine Bewertungen

- Control Valve Packing Guide - PTFE, Graphite, & EPA Compliant Options in 40 CharactersDokument2 SeitenControl Valve Packing Guide - PTFE, Graphite, & EPA Compliant Options in 40 Charactersmilton1987Noch keine Bewertungen

- Math 54 Exam 2 ReviewDokument11 SeitenMath 54 Exam 2 ReviewBea DucaoNoch keine Bewertungen

- Silicon Rubber Laboratory Pre ReportDokument9 SeitenSilicon Rubber Laboratory Pre ReportAdrian Adalberto GarayNoch keine Bewertungen

- Lecture 10, 11, 12 - Chapter 5 Distributed ForcesDokument43 SeitenLecture 10, 11, 12 - Chapter 5 Distributed Forcesrobel metikuNoch keine Bewertungen

- Activity 1Dokument13 SeitenActivity 1Marving ZNoch keine Bewertungen

- Jurnal Row Cropping PK GoshDokument12 SeitenJurnal Row Cropping PK GoshAdek AbangNoch keine Bewertungen

- 5-Mooring Buoy KEMENANGAN BrosurDokument2 Seiten5-Mooring Buoy KEMENANGAN Brosurdody andiNoch keine Bewertungen

- CP R77 Gaia AdminGuideDokument230 SeitenCP R77 Gaia AdminGuideRamiro BojorquezNoch keine Bewertungen

- FUNDAMENTALDokument18 SeitenFUNDAMENTALRachel BasistoNoch keine Bewertungen

- Computer Aided Design and FE Analysis of A PM BLDG Hub MotorDokument6 SeitenComputer Aided Design and FE Analysis of A PM BLDG Hub MotorDebarati DamNoch keine Bewertungen

- Good Practice Guide For Form and Diameter Measurements For Large ShaftsDokument14 SeitenGood Practice Guide For Form and Diameter Measurements For Large ShaftsNg Wei LihNoch keine Bewertungen

- Car Crash LabDokument6 SeitenCar Crash LabMatthew SomervilleNoch keine Bewertungen

- Synergysoft Scheduler SystemDokument40 SeitenSynergysoft Scheduler SystemfelipeNoch keine Bewertungen

- 2005 Carbon SteelDokument65 Seiten2005 Carbon SteelmageshkumarNoch keine Bewertungen

- Worksheet #1g: Hydrostatic Pressure & Archimedes' PrincipleDokument3 SeitenWorksheet #1g: Hydrostatic Pressure & Archimedes' PrincipleLuke NancooNoch keine Bewertungen

- Bagi Yang Masih Awam Memakai Google Sheet, File Ini Bisa Didownload Dengan Klik File Download MS. ExcelDokument67 SeitenBagi Yang Masih Awam Memakai Google Sheet, File Ini Bisa Didownload Dengan Klik File Download MS. Excelwisnu pranata adhiNoch keine Bewertungen

- Course: EC2P001 Introduction To Electronics Lab: Indian Institute of Technology Bhubaneswar School of Electrical ScienceDokument5 SeitenCourse: EC2P001 Introduction To Electronics Lab: Indian Institute of Technology Bhubaneswar School of Electrical ScienceAnik ChaudhuriNoch keine Bewertungen

- 73 Magazine - June 1978Dokument224 Seiten73 Magazine - June 1978Benjamin DoverNoch keine Bewertungen

- Acog Practice Bulletin: Antepartum Fetal SurveillanceDokument12 SeitenAcog Practice Bulletin: Antepartum Fetal SurveillanceMariana Hernandez100% (10)

- High Productivity Scalable Pick-and-Place HandlerDokument2 SeitenHigh Productivity Scalable Pick-and-Place HandlermhafizanNoch keine Bewertungen

- Lecture-SULAMAN SADIQ - TSE-SDH and SONETDokument51 SeitenLecture-SULAMAN SADIQ - TSE-SDH and SONETSulaman SadiqNoch keine Bewertungen

- Aircraft Gas Turbine EnginesDokument9 SeitenAircraft Gas Turbine EnginesmgskumarNoch keine Bewertungen

- SAIVEERA ACADEMY’S GUIDE TO 12TH CHEMISTRY UNIT 1 METALLURGYDokument26 SeitenSAIVEERA ACADEMY’S GUIDE TO 12TH CHEMISTRY UNIT 1 METALLURGYKrish Krishn100% (1)

- SAP PM T - CodesDokument4 SeitenSAP PM T - CodesBujjibabu Katta0% (1)

- Papper Maths Class 8thDokument5 SeitenPapper Maths Class 8thAbdul Basit KhanNoch keine Bewertungen

- AnInvestigationofPhaetonPlanetIIwrite Upv2Dokument14 SeitenAnInvestigationofPhaetonPlanetIIwrite Upv2Divine Zen Love GoddessNoch keine Bewertungen

- Shop Inspection and Test Plan for FRP Water TroughDokument29 SeitenShop Inspection and Test Plan for FRP Water TroughEljo AndsNoch keine Bewertungen

- Circuit Center ValvulaDokument4 SeitenCircuit Center ValvulaLuis Carlos PardoNoch keine Bewertungen

- EvaporationDokument51 SeitenEvaporationPratiksha GoreNoch keine Bewertungen

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterVon EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterNoch keine Bewertungen

- Practical Reservoir Engineering and CharacterizationVon EverandPractical Reservoir Engineering and CharacterizationBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Nuclear Energy in the 21st Century: World Nuclear University PressVon EverandNuclear Energy in the 21st Century: World Nuclear University PressBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionNoch keine Bewertungen

- Renewable Energy: A Very Short IntroductionVon EverandRenewable Energy: A Very Short IntroductionBewertung: 4.5 von 5 Sternen4.5/5 (12)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesVon EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesBewertung: 4.5 von 5 Sternen4.5/5 (21)

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!Von EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!Noch keine Bewertungen

- Biogas Production: Pretreatment Methods in Anaerobic DigestionVon EverandBiogas Production: Pretreatment Methods in Anaerobic DigestionNoch keine Bewertungen

- Grid-Scale Energy Storage Systems and ApplicationsVon EverandGrid-Scale Energy Storage Systems and ApplicationsFu-Bao WuNoch keine Bewertungen

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsVon EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNoch keine Bewertungen

- Fundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsVon EverandFundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsNoch keine Bewertungen

- Industrial Waste Treatment HandbookVon EverandIndustrial Waste Treatment HandbookBewertung: 5 von 5 Sternen5/5 (1)

- Global Landscape of Renewable Energy FinanceVon EverandGlobal Landscape of Renewable Energy FinanceNoch keine Bewertungen

- Idaho Falls: The Untold Story of America's First Nuclear AccidentVon EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentBewertung: 4.5 von 5 Sternen4.5/5 (21)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesVon EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertBewertung: 3 von 5 Sternen3/5 (2)

- Shorting the Grid: The Hidden Fragility of Our Electric GridVon EverandShorting the Grid: The Hidden Fragility of Our Electric GridBewertung: 4.5 von 5 Sternen4.5/5 (2)

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeVon EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeBewertung: 4 von 5 Sternen4/5 (130)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialVon EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNoch keine Bewertungen

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successVon EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Flow Analysis for Hydrocarbon Pipeline EngineeringVon EverandFlow Analysis for Hydrocarbon Pipeline EngineeringNoch keine Bewertungen

- ISO 50001: A strategic guide to establishing an energy management systemVon EverandISO 50001: A strategic guide to establishing an energy management systemNoch keine Bewertungen

- The Way Home: Tales from a life without technologyVon EverandThe Way Home: Tales from a life without technologyBewertung: 4 von 5 Sternen4/5 (45)

- Power Quality in Power Systems and Electrical MachinesVon EverandPower Quality in Power Systems and Electrical MachinesBewertung: 4.5 von 5 Sternen4.5/5 (11)