Beruflich Dokumente

Kultur Dokumente

Stripping and Servicing The Theoben Rapid 7111

Hochgeladen von

graham4877Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Stripping and Servicing The Theoben Rapid 7111

Hochgeladen von

graham4877Copyright:

Verfügbare Formate

Stripping and servicing the Theoben Rapid 7

BUDDY BOTTLE REMOVAL

This procedure should be well known to all Rapid users. Unscrew the bottle about half a turn and then dry fire about half a dozen shots. Repeat this step three or four times until no air is expelled on firing. This is known as 'bleeding the action'.

If the bottle were to be unscrewed with the action fully pressurised, a loud 'POP' would be heard from the inlet valve. This high speed discharge of air can damage the buddy bottle O ring.

STOCK REMOVAL

The stock is held in place by 2 Allen bolts, to the front and rear of the trigger

guard. The rear bolt is 3/4" 2BA, front is 1" 1/4" UNF. Allen key sizes: 5/32" & 1/8" respectively.

INLET VALVE

To remove the inlet valve, first clamp the action in a vice (use a rag or cloth to protect the action). There are 2 milled flats on either side of the valve and you will need a 21mm spanner on here. The inlet valves are usually very tight to prevent the unit being unscrewed on removal of the buddy bottle.

If the valve is too tight to remove by hand (as is usually the case), 'shock' it loose by tapping the end of the spanner with a hammer to 'crack' it loose, then unscrew by hand.

There is an 'O' ring at the top of the thread (015 Ni 90), this should be replaced and a small amount of Molykote 33 applied to the new ring.

VALVE BLANKING PLUG

The valve blanking plug is located above the inlet valve, Allen key size is 3/16". This should be removed and the 'O' ring replaced (015 Ni 90).

EXHAUST VALVE REMOVAL

On the right hand side of the action there is a 4BA grub screw, just in front of the breech area.

This should be removed first. The grub screw aligns the transfer ports and secures the valve inside the action.

With the rifle pointing downwards, cock and fire the action. The exhaust valve should drop out of the top hole in the front of the action (from where you removed the blanking plug).

SERVICING THE VALVE

There are two types of exhaust valve on the Mk I Rapids, a metal valve (stainless steel), and a black Acetal valve (fitted to all models produced in '99 or later).

To service the metal valve

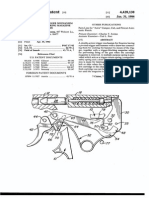

The metal valve comprises two sections, the body and the cap. To remove the cap, you will have to slide a collet over the valve cap, and clamp in a vice (not too tight, or the cap will be distorted). A small rod should be inserted into the transfer port of the valve body for use as a lever to unscrew the cap.

With the cap removed, the white 008 seal can be replaced together with the 011 Ni 90 'O' ring. Apply a small amount of Molykote 33 to the seals and reassemble the valve.

Pick off the 'O' ring around the external circumference of the valve. It is located in a small undercut at the front of the valve body. Replace the 'O' ring and apply Molykote 33.

The last 'O' ring to be changed is on the tail of the valve body. After applying a small amount of Molykote 33, the valve is ready to be replaced.

To service the black acetal valve

This is a one piece valve and is usually completely replaced on a service.

The unit only has two external 'O' rings, one around the external circumference of the body and one at the tail.

EXHAUST VALVE STEM

There may be either one or two 'O' rings on the valve stem, depending on which type you have. The 'O' ring(s) should be picked off and replaced and a small amount of Molykote 33 applied to the new ones.

HAMMER/SPRING & INERTIA WEIGHT ASSEMBLY

This assembly is accessed through the rear of the action. Unscrew the stainless cap at the rear, and then remove parts as follows: Hammer spring guide (if applicable), hammer spring, and finally the hammer (containing the washer, inertia weight and return spring).

The hammer should be reassembled dry, as any lubrication will cause drag, slowing its travel, thus reducing power.

BARREL REMOVAL

First you will need to remove the front scope mount.

Beneath the front mount, you will find a small (2BA 3/16") grub screw, which is the barrel locating screw. This should be removed.

All that remains is to loosen off the barrel clamp (2BA 3/4" Allen bolt), then the barrel can slide free of the action.

NOTE. On the barrel there is a blind hole at the top for location, the transfer port

is on the underside.

It is essential to align properly the 2BA grub screw in the blind hole, so that the transfer port is not obstructed, thus restricting the airflow.

BUDDY BOTTLE

Finally, all that remains is to change the buddy bottle 'O' ring (111 Ni90), and apply a small amount of Molykote 33.

REBUILD

Rebuild in reverse order. Points to watch out for:

Make sure the exhaust valve is properly aligned (4BA grub screw to the blind hole). When replacing the 4BA grub screw, screw it down until it contacts the valve body, then back off 1/4 turn. Replace the valve assembly and the valve blanking plug BEFORE you replace the inlet valve, which sits on top of the blanking plug.

When refitting the buddy bottle, make sure the rifle is cocked and the bolt is locked down in the REARWARD position. This removes hammer spring tension from the exhaust valve allowing the stem to seat properly, thus sealing air pressure within the rifle.

If you fail to do this, you will most probably have all the air from your buddy bottle leak right through the action and out of the barrel.

CHRONOGRAPH

You should now check the rifle over a chronograph and adjust the power accordingly via the stainless adjuster at the rear of the action.

WARNING! Do not attempt to adjust the rifle above 12ft.lbs as the exhaust valve stem is designed to back up against the valve blanking plug and bend itself, should too much force be exerted upon it by the hammer. The stem will no longer sit concentrically on the valve seat, and subsequently all the air from the buddy bottle will be exhausted through the barrel, rendering the rifle useless!

Das könnte Ihnen auch gefallen

- Rapid Range Servicing InstructionsDokument2 SeitenRapid Range Servicing Instructionsgraham4877Noch keine Bewertungen

- A Treatise on Staff Making and Pivoting: Containing Complete Directions for Making and Fitting New Staffs from the Raw MaterialVon EverandA Treatise on Staff Making and Pivoting: Containing Complete Directions for Making and Fitting New Staffs from the Raw MaterialNoch keine Bewertungen

- Rapid Range Technical Information SheetDokument2 SeitenRapid Range Technical Information Sheetgraham487767% (3)

- Punching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesVon EverandPunching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesNoch keine Bewertungen

- Barrel RemovalDokument2 SeitenBarrel Removalgraham4877Noch keine Bewertungen

- Rapid Mk1 Pressure IndicatorDokument1 SeiteRapid Mk1 Pressure Indicatorgraham4877Noch keine Bewertungen

- Rapid Bolt Assembly InstuctionsDokument1 SeiteRapid Bolt Assembly Instuctionsgraham4877Noch keine Bewertungen

- Cleaning Your Barrel With A Pull ThroughDokument1 SeiteCleaning Your Barrel With A Pull Throughgraham4877Noch keine Bewertungen

- RAPIDID TRIGGER Standard Sporter Trigger For The Rapid RangeDokument1 SeiteRAPIDID TRIGGER Standard Sporter Trigger For The Rapid Rangegraham48770% (1)

- QB78 TuneDokument11 SeitenQB78 TuneSadBoiH0urs 1100% (1)

- Rapid Field Target SpecsDokument1 SeiteRapid Field Target Specsgraham4877Noch keine Bewertungen

- M48 Disassembly ReassemblyDokument7 SeitenM48 Disassembly ReassemblypoinkerNoch keine Bewertungen

- 870 Detent Staking PunchDokument1 Seite870 Detent Staking PunchZardoz10900% (1)

- The GOLD MEDAL TRIGGER The Field Target Trigger For The Rapid RangeDokument1 SeiteThe GOLD MEDAL TRIGGER The Field Target Trigger For The Rapid Rangegraham4877Noch keine Bewertungen

- DP Series Build SheetDokument49 SeitenDP Series Build SheetJoe Creole100% (1)

- AKT020 Rivet Jaws InstructionsDokument12 SeitenAKT020 Rivet Jaws InstructionsDale WadeNoch keine Bewertungen

- Step Type Target CrownDokument5 SeitenStep Type Target Crownlbaraldi100% (1)

- Product Instructions - Flat Bending Jig InstructionsDokument34 SeitenProduct Instructions - Flat Bending Jig InstructionsDale WadeNoch keine Bewertungen

- VZ 58 Shell DeflectorDokument15 SeitenVZ 58 Shell DeflectoromikamiNoch keine Bewertungen

- MD Profiler Instruction ManualDokument11 SeitenMD Profiler Instruction ManualTatiana Trenogina100% (1)

- Manuale CZ200Dokument11 SeitenManuale CZ200gatto61Noch keine Bewertungen

- STEN / 76: 9mm Sub Machine Gun SuppressorDokument6 SeitenSTEN / 76: 9mm Sub Machine Gun SuppressorIngo Quander100% (1)

- BSA Scorpion & T10Dokument2 SeitenBSA Scorpion & T10Pera DjetlicNoch keine Bewertungen

- Sig Mosquito Dis-Assemble and Re-AssembleDokument28 SeitenSig Mosquito Dis-Assemble and Re-Assemblercol8314100% (1)

- Silver Streak and Blue Streak Repair Manual: All Rights Reserved, UJ BackusDokument20 SeitenSilver Streak and Blue Streak Repair Manual: All Rights Reserved, UJ BackusRonNoch keine Bewertungen

- Rapid Rifle Numbers and Approximate AgesDokument1 SeiteRapid Rifle Numbers and Approximate Agesgraham4877Noch keine Bewertungen

- DR Bob's Quick Fill InstructionsDokument3 SeitenDR Bob's Quick Fill Instructionsgraham4877100% (1)

- Stirling Walking Beam EngineDokument13 SeitenStirling Walking Beam EngineTomescu PaulNoch keine Bewertungen

- CZ 200 PCP Air Rifle Manual PDFDokument18 SeitenCZ 200 PCP Air Rifle Manual PDFErikNoch keine Bewertungen

- Forcing Cone and Throat ReamingDokument5 SeitenForcing Cone and Throat Reamingrooster59Noch keine Bewertungen

- AK Builder Rivet Tool InstructionsDokument4 SeitenAK Builder Rivet Tool InstructionsDale WadeNoch keine Bewertungen

- Anschutz 64 Match BoltDokument1 SeiteAnschutz 64 Match BoltAnonymous cCQKlG0RqNoch keine Bewertungen

- Product Instructions - Trigger Guard Rivet Drilling Jig Instructions PDFDokument3 SeitenProduct Instructions - Trigger Guard Rivet Drilling Jig Instructions PDFFrank MeekerNoch keine Bewertungen

- Mini-Lathe - Change Gears Chart For Inch ThreadingDokument4 SeitenMini-Lathe - Change Gears Chart For Inch ThreadingCody McCormackNoch keine Bewertungen

- United States Patent 1111 3,595,128Dokument9 SeitenUnited States Patent 1111 3,595,128rte678Noch keine Bewertungen

- NAA .32 ACP专利 PDFDokument8 SeitenNAA .32 ACP专利 PDFJin SongNoch keine Bewertungen

- Patented June 1, 1901. No. 675,999.: L. HellfritzschDokument4 SeitenPatented June 1, 1901. No. 675,999.: L. HellfritzschСлэйтер Строительная компанияNoch keine Bewertungen

- Ti25 Advanced Composite Steel Lip Magazine For Ruger 10 - 22 byDokument3 SeitenTi25 Advanced Composite Steel Lip Magazine For Ruger 10 - 22 byarizona212Noch keine Bewertungen

- Budischowsky Tp-70Dokument5 SeitenBudischowsky Tp-70JustinNoch keine Bewertungen

- Rapid MK 2 SpecsDokument1 SeiteRapid MK 2 Specsgraham4877Noch keine Bewertungen

- Tap & Drill Chart W - Decimal Inch & MetricDokument10 SeitenTap & Drill Chart W - Decimal Inch & MetricGanesh NatarajanNoch keine Bewertungen

- Bolt Action 4Dokument10 SeitenBolt Action 4browar444100% (1)

- Uzi Semi-Auto Carbine Fixed Stock Installation InstructionsDokument4 SeitenUzi Semi-Auto Carbine Fixed Stock Installation Instructionselvergonzalez1Noch keine Bewertungen

- Crosman 160 Factory Service ManualDokument9 SeitenCrosman 160 Factory Service ManualJust4Him100% (2)

- Page 18Dokument1 SeitePage 18frank1615100% (2)

- Instruction Manual Slavia 634 enDokument14 SeitenInstruction Manual Slavia 634 enzeniek50% (2)

- M1 Garand Barrel Replacement  " New BarrelDokument35 SeitenM1 Garand Barrel Replacement  " New BarrelToschanoNoch keine Bewertungen

- AMT LightningDokument9 SeitenAMT LightningJustinNoch keine Bewertungen

- CarriageDokument25 SeitenCarriageSamir SinghNoch keine Bewertungen

- MT-II LabDokument7 SeitenMT-II LabAjay Vikram0% (1)

- Chimera ManualDokument12 SeitenChimera ManualticocrazyNoch keine Bewertungen

- Old Model B392-OM1Dokument9 SeitenOld Model B392-OM1Just4HimNoch keine Bewertungen

- High Standard-MagazinesDokument3 SeitenHigh Standard-MagazinesBob WilliamsNoch keine Bewertungen

- Ex Reg2ndDokument57 SeitenEx Reg2nddaviddealbaNoch keine Bewertungen

- QB-78 Quik-Tune Removing The StockDokument4 SeitenQB-78 Quik-Tune Removing The StockLaszlo Csok100% (1)

- Ex Up System MaintenanceDokument12 SeitenEx Up System MaintenanceDerek CaseyNoch keine Bewertungen

- Desanblaje y Ensamblaje de Caja 4l60 eDokument20 SeitenDesanblaje y Ensamblaje de Caja 4l60 eDanny Ivan ZambranoNoch keine Bewertungen

- T1002-PSV-1453 Type - 2600Dokument2 SeitenT1002-PSV-1453 Type - 2600Jonson CaoNoch keine Bewertungen

- WNCO Valve's WN-1 Valve MaintenanceDokument5 SeitenWNCO Valve's WN-1 Valve MaintenancethritaNoch keine Bewertungen

- Auto Arc WelderDokument4 SeitenAuto Arc Weldergraham4877Noch keine Bewertungen

- Basic Blacksmithing - David Harries PDFDokument132 SeitenBasic Blacksmithing - David Harries PDFMichele Perrone FilhoNoch keine Bewertungen

- DIY 1000 Watt Wind TurbineDokument9 SeitenDIY 1000 Watt Wind Turbinegraham4877Noch keine Bewertungen

- Rapid Rifle Numbers and Approximate AgesDokument1 SeiteRapid Rifle Numbers and Approximate Agesgraham4877Noch keine Bewertungen

- The GOLD MEDAL TRIGGER The Field Target Trigger For The Rapid RangeDokument1 SeiteThe GOLD MEDAL TRIGGER The Field Target Trigger For The Rapid Rangegraham4877Noch keine Bewertungen

- Alternator ManualDokument16 SeitenAlternator Manualgraham4877Noch keine Bewertungen

- ARKARA Single Bay User ManualDokument35 SeitenARKARA Single Bay User Manualgraham4877Noch keine Bewertungen

- Rapid MFR InfoDokument2 SeitenRapid MFR Infograham4877Noch keine Bewertungen

- ALSAT Manual 0430Dokument11 SeitenALSAT Manual 0430graham4877Noch keine Bewertungen

- Rapid MFRDokument1 SeiteRapid MFRgraham4877Noch keine Bewertungen

- Rapid MK 2 SpecsDokument1 SeiteRapid MK 2 Specsgraham4877Noch keine Bewertungen

- Rapid Bolt Assembly InstuctionsDokument1 SeiteRapid Bolt Assembly Instuctionsgraham4877Noch keine Bewertungen

- RAPIDID TRIGGER Standard Sporter Trigger For The Rapid RangeDokument1 SeiteRAPIDID TRIGGER Standard Sporter Trigger For The Rapid Rangegraham48770% (1)

- Instruction For Fitting A 177 Cal or Fac Rated Inlet or Pressure Indicator AdaptorDokument1 SeiteInstruction For Fitting A 177 Cal or Fac Rated Inlet or Pressure Indicator Adaptorgraham4877Noch keine Bewertungen

- Rapid Field Target SpecsDokument1 SeiteRapid Field Target Specsgraham4877Noch keine Bewertungen

- How To Load Your Rapid Mag CorrectlyDokument1 SeiteHow To Load Your Rapid Mag Correctlygraham4877Noch keine Bewertungen

- BA 5052 - 5109 EnglischDokument9 SeitenBA 5052 - 5109 Englischgraham4877Noch keine Bewertungen

- DR Bob's Quick Fill InstructionsDokument3 SeitenDR Bob's Quick Fill Instructionsgraham4877100% (1)

- Cleaning Your Barrel With A Pull ThroughDokument1 SeiteCleaning Your Barrel With A Pull Throughgraham4877Noch keine Bewertungen

- CHRN InstDokument1 SeiteCHRN Instgraham4877Noch keine Bewertungen

- Match Grade Trigger MFRDokument1 SeiteMatch Grade Trigger MFRgraham4877Noch keine Bewertungen

- Adjusting The Mak4rDokument2 SeitenAdjusting The Mak4rgraham4877Noch keine Bewertungen

- Christopher Sommer - Basic Ring Strength DevelopmentDokument1 SeiteChristopher Sommer - Basic Ring Strength Developmentjvincent6657100% (1)

- Spohn Performance, Inc.: Part# D94-02-TB-DS - Adjustable Front Track BarDokument5 SeitenSpohn Performance, Inc.: Part# D94-02-TB-DS - Adjustable Front Track BarJameson PowersNoch keine Bewertungen

- P'COLOGYDokument18 SeitenP'COLOGYHeena BhojwaniNoch keine Bewertungen

- Application For Unfreeze Bank Account - Request L 2Dokument1 SeiteApplication For Unfreeze Bank Account - Request L 2Gideon LawalNoch keine Bewertungen

- Owner's Manual: Health Trainer 65T TreadmillDokument30 SeitenOwner's Manual: Health Trainer 65T TreadmillXax Xax XaxNoch keine Bewertungen

- Marketing of Football ClubsDokument6 SeitenMarketing of Football ClubsValle VijayasandeshNoch keine Bewertungen

- Level 1 Gnome ArtificerDokument3 SeitenLevel 1 Gnome ArtificerLauren PolianNoch keine Bewertungen

- Renegade X MR 1000R 2021: With Visco-4LokDokument1 SeiteRenegade X MR 1000R 2021: With Visco-4LokMihai AndreiNoch keine Bewertungen

- Chrono Series - Wikipedia BookDokument95 SeitenChrono Series - Wikipedia BookEdelylaNoch keine Bewertungen

- Date:28 Sept 2015 (Monday) Reporting Time: 0900 HRS: SNO Regno Fullname Father'S Name DOBDokument15 SeitenDate:28 Sept 2015 (Monday) Reporting Time: 0900 HRS: SNO Regno Fullname Father'S Name DOBChitransh SrivastavaNoch keine Bewertungen

- Wing Commander Morningstar Construction Manual: RC Profile PlanesDokument10 SeitenWing Commander Morningstar Construction Manual: RC Profile Planessavall21Noch keine Bewertungen

- The Closed Sicilian Daniel King (PDFDrive)Dokument146 SeitenThe Closed Sicilian Daniel King (PDFDrive)Kshitij DuttaNoch keine Bewertungen

- Manual Muscle TestingDokument29 SeitenManual Muscle TestingImran Ghafoor67% (6)

- 80313AM1P.S550 Exploded Views (D33IST)Dokument12 Seiten80313AM1P.S550 Exploded Views (D33IST)Daniel MuratallaNoch keine Bewertungen

- Facebook Game PDF 16 PagesDokument8 SeitenFacebook Game PDF 16 Pagesscorpion999Noch keine Bewertungen

- Cinderella: A) True or False? Answer The Questions. 1) 2)Dokument1 SeiteCinderella: A) True or False? Answer The Questions. 1) 2)JosesNoch keine Bewertungen

- TS20190505 T2598680513 No Limit Hold'Em TicketDokument81 SeitenTS20190505 T2598680513 No Limit Hold'Em TicketdidadosNoch keine Bewertungen

- 3 Forces and MotionDokument34 Seiten3 Forces and MotionIoryNoch keine Bewertungen

- Skill TestSchdl WebDokument26 SeitenSkill TestSchdl Websunil kumarNoch keine Bewertungen

- 2 English Plus Photocopiable Resources 1 Answer KeyDokument14 Seiten2 English Plus Photocopiable Resources 1 Answer Keykosovare361% (18)

- Foot Position On Leg PressDokument16 SeitenFoot Position On Leg PressA. Samy TAGNoch keine Bewertungen

- Mesterolone:: 83% Unique ContentDokument2 SeitenMesterolone:: 83% Unique ContentovizdikNoch keine Bewertungen

- Home Workouts Encyclopaedia 60 Workout Programs To Stay Active From HomeDokument332 SeitenHome Workouts Encyclopaedia 60 Workout Programs To Stay Active From HomeYmiuchin100% (2)

- Match NumbersDokument30 SeitenMatch NumberswidiNoch keine Bewertungen

- C Hook+Operator+Safety+ManualDokument7 SeitenC Hook+Operator+Safety+ManualAshokNoch keine Bewertungen

- Fluid Mechanics - 2009Dokument18 SeitenFluid Mechanics - 2009Paragmoni KalitaNoch keine Bewertungen

- Fun For Movers On-Line Resources - 2017, 4th - 234pDokument234 SeitenFun For Movers On-Line Resources - 2017, 4th - 234pЮлия Васильева100% (2)

- Fly For Fun Knights Complete Guide Part 2 by RegaxionDokument63 SeitenFly For Fun Knights Complete Guide Part 2 by RegaxionEduardo SalvadorNoch keine Bewertungen

- Sonata For Two Violas (Falck 62) : Viola 1Dokument5 SeitenSonata For Two Violas (Falck 62) : Viola 1cynthiaNoch keine Bewertungen

- Appendix B Submission Form For Potential TDS Activities 2021-22Dokument81 SeitenAppendix B Submission Form For Potential TDS Activities 2021-22Sam YAONoch keine Bewertungen