Beruflich Dokumente

Kultur Dokumente

ERIKS - Neoprene 60-Compound 329301 White

Hochgeladen von

HerpadianaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ERIKS - Neoprene 60-Compound 329301 White

Hochgeladen von

HerpadianaCopyright:

Verfügbare Formate

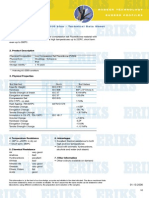

RUBBER TECHNOLOGY RUBBER PROFILES

N e o p re n e 6 0 - c o m p o u n d 3 2 9 3 0 1 w h i t e - Te c h n i c a l D a t a S h e e t 1. Introduction The ERIKS Neoprene 60 329301 compound is made of Polychloroprene and is an excellent weathering resistant compound. Standard profile quality.

2. Product Description

Chemical Composition Physical form Colour Storage stability * : : : : Polychloroprene Rubber Cord / Extrusions White 6 years

* : Following DIN 7716 conditions

3. Physical Properties Test Method Hardness Specific Weight Tensile Strength at break Elongation at break Compression Set 22h/100C, on slab Heat Ageing, 168h/70C Change Tensile strength Elongation Change Hardness Change Norm DIN 53505 DIN 53479 DIN 53504 DIN 53504 DIN 53517 NFT 46002 -15% -7% +3 Test Values 60 5 Shore A 1,47 min. 7 MPa min. 450% max. 20%

4. Temperature Resistance -35 to +100C TR10 (low temp.): -40C

6. Advantages Extremely good weathering resistance Resistance to non-concentrated acids Good flame resistance

5. Chemical Resistance Alkali : good Air : very good Alcohol : very good Fats : good Mineral oils : good Vegetable oils : fair Esters : poor Ozone : very good Steam : fair Water : very good

7. Other Information Also FDA 177.2600 on request. Precision cord on request. Tolerances in compliance with DIN 7715 E2/ ISO 3302-1 E2.

This information is, to the best of our knowledge, accurate and reliable to the date indicated. The above mentioned data have been obtained by tests we consider as reliable. We dont assure that the same results can be obtained in other laboratories, using different conditions by the preparation and evaluation of the samples.

01.04.2006

6

Das könnte Ihnen auch gefallen

- Epdm 70-Compound 55914 - Technical Data SheetDokument1 SeiteEpdm 70-Compound 55914 - Technical Data SheetKek Siang MingNoch keine Bewertungen

- ERIKS - Genuine Viton GF 75-Compound 514141Dokument1 SeiteERIKS - Genuine Viton GF 75-Compound 514141HerpadianaNoch keine Bewertungen

- ERIKS - Genuine Viton-Compound 514206Dokument1 SeiteERIKS - Genuine Viton-Compound 514206HerpadianaNoch keine Bewertungen

- ERIKS - NBR 70-Compound 366301Dokument1 SeiteERIKS - NBR 70-Compound 366301HerpadianaNoch keine Bewertungen

- Eriks - Epdm 70-Compound 559301Dokument1 SeiteEriks - Epdm 70-Compound 559301HerpadianaNoch keine Bewertungen

- ERIKS - FVMQ Silicone 80 614010 BlueDokument1 SeiteERIKS - FVMQ Silicone 80 614010 BlueHerpadianaNoch keine Bewertungen

- BELZONA 1111 Product Specification SheetDokument2 SeitenBELZONA 1111 Product Specification Sheetsibi_s_rajNoch keine Bewertungen

- ERIKS - Datasheet - FKM 70-Compound 514308Dokument1 SeiteERIKS - Datasheet - FKM 70-Compound 514308DarkedgeNoch keine Bewertungen

- Pyrocrete 241Dokument2 SeitenPyrocrete 241Carboline2013Noch keine Bewertungen

- 4011 TDDokument2 Seiten4011 TDFernando HalaburaNoch keine Bewertungen

- 105 Ta D411-350Dokument3 Seiten105 Ta D411-350isaacalvareztejanoNoch keine Bewertungen

- Punto de Fluidez - ASTM D97-11Dokument5 SeitenPunto de Fluidez - ASTM D97-11Chäz XdNoch keine Bewertungen

- Kalrez 0090 Data SheetDokument2 SeitenKalrez 0090 Data SheetGambeatNoch keine Bewertungen

- MaterialsDokument3 SeitenMaterialsmakakkNoch keine Bewertungen

- Eriks Epdm 70 Compound 55985Dokument2 SeitenEriks Epdm 70 Compound 55985chethanNoch keine Bewertungen

- Araldite 2010Dokument6 SeitenAraldite 2010nrd9771Noch keine Bewertungen

- ERIKS - Datasheet - Genuine Viton 70-Compound 514674 BlueDokument1 SeiteERIKS - Datasheet - Genuine Viton 70-Compound 514674 BlueDarkedgeNoch keine Bewertungen

- Technical Data: Three Bond 1104 Liquid GasketDokument4 SeitenTechnical Data: Three Bond 1104 Liquid GasketMochammad irhamNoch keine Bewertungen

- 4105 DatasheetDokument2 Seiten4105 DatasheetAsad NaeemNoch keine Bewertungen

- Complete Top-of-Wall Firestopping Solution!: CP 672 CP 672Dokument4 SeitenComplete Top-of-Wall Firestopping Solution!: CP 672 CP 672Gökhan GülhanNoch keine Bewertungen

- Thermaline 450 PDFDokument2 SeitenThermaline 450 PDFNageswara Rao BavisettyNoch keine Bewertungen

- Epoxy 4044Dokument2 SeitenEpoxy 4044Grzegorz SkrętaNoch keine Bewertungen

- Chemical Resistance GuideDokument36 SeitenChemical Resistance GuideHeiner PalaciosNoch keine Bewertungen

- Eriks - Datasheet - Aflas 75-Compound 223002 PDFDokument1 SeiteEriks - Datasheet - Aflas 75-Compound 223002 PDFVictor Flores ResendizNoch keine Bewertungen

- ERIKS - Datasheet - FKM 75-Compound 514010 WhiteDokument1 SeiteERIKS - Datasheet - FKM 75-Compound 514010 WhiteDarkedgeNoch keine Bewertungen

- NSPure Ni SpecDokument2 SeitenNSPure Ni SpecPieter van der WaltNoch keine Bewertungen

- 000 Bf-610-EngDokument5 Seiten000 Bf-610-EngckarantoniNoch keine Bewertungen

- ERIKS - Kalrez 4079Dokument2 SeitenERIKS - Kalrez 4079hufuentsNoch keine Bewertungen

- Surlyn 1652SR DatasheetDokument3 SeitenSurlyn 1652SR Datasheetbhoopendra singhNoch keine Bewertungen

- Never-Seez® India +91-891-2564393Dokument2 SeitenNever-Seez® India +91-891-2564393Project Sales CorpNoch keine Bewertungen

- Explosive DecompressionDokument11 SeitenExplosive DecompressionAndrey EkkertNoch keine Bewertungen

- Impreglon 410M DataSheetDokument2 SeitenImpreglon 410M DataSheetMehrad LahutiNoch keine Bewertungen

- 3M™ Nitrile High Performance Plastic Adhesive 1099 - 20231109Dokument7 Seiten3M™ Nitrile High Performance Plastic Adhesive 1099 - 20231109Jose Luis MonroyNoch keine Bewertungen

- Loctite Ea 9309.3naDokument5 SeitenLoctite Ea 9309.3naechobravo1Noch keine Bewertungen

- Phenoline 1205 PDS 9-06 PDFDokument2 SeitenPhenoline 1205 PDS 9-06 PDFttr_1947Noch keine Bewertungen

- Hysol Ea 9309Dokument5 SeitenHysol Ea 9309edgmtNoch keine Bewertungen

- Le0563 PDS Re - America en V2 PDS Am - 2 4481 10031804Dokument3 SeitenLe0563 PDS Re - America en V2 PDS Am - 2 4481 10031804Aleksa SaricNoch keine Bewertungen

- Polyclad 975 H PDSDokument2 SeitenPolyclad 975 H PDSLinnie McleodNoch keine Bewertungen

- Epofine 138 - Finehard 998Dokument3 SeitenEpofine 138 - Finehard 998Karishma PrabhuNoch keine Bewertungen

- Jeffamine ED-600 Polyetheramine: Technical BulletinDokument2 SeitenJeffamine ED-600 Polyetheramine: Technical BulletinAnonymous oSf3D0Noch keine Bewertungen

- Epofine 184-Finehard 907 - Acc 062Dokument4 SeitenEpofine 184-Finehard 907 - Acc 062Karishma PrabhuNoch keine Bewertungen

- HysolDokument2 SeitenHysoljorgequijanoNoch keine Bewertungen

- Biotemp: Biodegradable Dielectric Insulating FluidDokument4 SeitenBiotemp: Biodegradable Dielectric Insulating FluidSamuel PakianathanNoch keine Bewertungen

- Fire Fighting Approved EquipmentDokument34 SeitenFire Fighting Approved EquipmentAbdul RaoofNoch keine Bewertungen

- PEER Seals CatalogDokument64 SeitenPEER Seals CatalogRodatecnia Javier100% (1)

- PVDF 2Dokument72 SeitenPVDF 2SamiYousif100% (1)

- Pds Psx700 Jan 2008Dokument3 SeitenPds Psx700 Jan 2008mjayhawk28Noch keine Bewertungen

- Never-Seez® India Call +91-891-6666482Dokument2 SeitenNever-Seez® India Call +91-891-6666482Project Sales CorpNoch keine Bewertungen

- Loctite 243Dokument4 SeitenLoctite 243ablemathew173974Noch keine Bewertungen

- Eriks - VMQ Silicone Profile St-ztt-70-001Dokument1 SeiteEriks - VMQ Silicone Profile St-ztt-70-001HerpadianaNoch keine Bewertungen

- Garlock Stress Saver LiteratureDokument4 SeitenGarlock Stress Saver Literature윤종주Noch keine Bewertungen

- Belzona 1311 Original Specification SheetDokument2 SeitenBelzona 1311 Original Specification SheetSaad IqbalNoch keine Bewertungen

- Loctite 1Dokument2 SeitenLoctite 1Antonio GonzaleNoch keine Bewertungen

- Chemraz 526: Explosive Decompression ResistantDokument0 SeitenChemraz 526: Explosive Decompression Resistantcasda73Noch keine Bewertungen

- Polypropylene Polystone P GreyDokument2 SeitenPolypropylene Polystone P GreyVinaya Almane DattathreyaNoch keine Bewertungen

- TC Colorcode PDFDokument7 SeitenTC Colorcode PDFPatrick MonteroNoch keine Bewertungen

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionVon EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Cryogenics Safety Manual: A Guide to Good PracticeVon EverandCryogenics Safety Manual: A Guide to Good PracticeNoch keine Bewertungen

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesVon EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesBewertung: 3.5 von 5 Sternen3.5/5 (3)

- The Chemistry of Nitrogen: Pergamon Texts in Inorganic ChemistryVon EverandThe Chemistry of Nitrogen: Pergamon Texts in Inorganic ChemistryNoch keine Bewertungen

- MBA14QTDokument15 SeitenMBA14QTsushmaxNoch keine Bewertungen

- Eriks - VMQ Silicone Profile St-sv-60-901Dokument1 SeiteEriks - VMQ Silicone Profile St-sv-60-901HerpadianaNoch keine Bewertungen

- Eriks - VMQ Silicone Profile St-ztt-70-001Dokument1 SeiteEriks - VMQ Silicone Profile St-ztt-70-001HerpadianaNoch keine Bewertungen

- Eriks - HNBR 75-Compound 886301Dokument1 SeiteEriks - HNBR 75-Compound 886301HerpadianaNoch keine Bewertungen

- Eriks - VMQ Silicone Profile St-Ec-60-001Dokument1 SeiteEriks - VMQ Silicone Profile St-Ec-60-001HerpadianaNoch keine Bewertungen

- ERIKS - FKM 70-Compound 514308Dokument1 SeiteERIKS - FKM 70-Compound 514308HerpadianaNoch keine Bewertungen

- ERIKS - FVMQ Silicone 80 614010 BlueDokument1 SeiteERIKS - FVMQ Silicone 80 614010 BlueHerpadianaNoch keine Bewertungen

- RSlogix 500 DescriptionDokument2 SeitenRSlogix 500 DescriptionHerpadianaNoch keine Bewertungen

- Fines GatewayDokument23 SeitenFines GatewayHerpadianaNoch keine Bewertungen

- 23 Retroper CLPDokument2 Seiten23 Retroper CLPHerpadianaNoch keine Bewertungen

- N - Channel 800V - 1.8 - 5A - To-220/To-220Fp Powermesh MosfetDokument10 SeitenN - Channel 800V - 1.8 - 5A - To-220/To-220Fp Powermesh MosfetHerpadianaNoch keine Bewertungen

- Gaskets - Kemchan CatologueDokument3 SeitenGaskets - Kemchan Catologueselvamech1986Noch keine Bewertungen

- 002.0 Surface Sampling TrainingDokument17 Seiten002.0 Surface Sampling TrainingNguyễnTrường100% (1)

- SWOT Analysis of India Rubber IndustryDokument6 SeitenSWOT Analysis of India Rubber IndustryKeshav Gupta33% (3)

- Lab ReportDokument9 SeitenLab Reportapi-345342456Noch keine Bewertungen

- Propane - WikipediaDokument10 SeitenPropane - Wikipediaduongbk24 luu quang duongNoch keine Bewertungen

- Isolate II Plasmid Mini Kit Product ManualDokument16 SeitenIsolate II Plasmid Mini Kit Product ManualJesus MiguelezNoch keine Bewertungen

- Character Is at Ion and Engineering Properties of Singapore Residual SoilsDokument26 SeitenCharacter Is at Ion and Engineering Properties of Singapore Residual SoilsChengHian YapNoch keine Bewertungen

- Mind MapDokument1 SeiteMind MapSaurabh SumanNoch keine Bewertungen

- Spe 200369 PaDokument13 SeitenSpe 200369 PaYousif IraqiNoch keine Bewertungen

- FMRC 1612 Polyvinyl Chloride (PVC) Pipe and Fittings For Underground Fire Protection Service PDFDokument30 SeitenFMRC 1612 Polyvinyl Chloride (PVC) Pipe and Fittings For Underground Fire Protection Service PDFdyıldırım_4Noch keine Bewertungen

- The Sugars of Honey-A ReviewDokument14 SeitenThe Sugars of Honey-A ReviewsedianpoNoch keine Bewertungen

- Practical Hints (Sizing)Dokument3 SeitenPractical Hints (Sizing)Amir YasinNoch keine Bewertungen

- Emulsions Part 2. A Little (Theory) Emulsion Stability. Klaus Tauer MPI Colloids and Interfaces Am Mühlenberg, D-14476 Golm, GermanyDokument59 SeitenEmulsions Part 2. A Little (Theory) Emulsion Stability. Klaus Tauer MPI Colloids and Interfaces Am Mühlenberg, D-14476 Golm, GermanyLina WinartiNoch keine Bewertungen

- Lime SWPDokument5 SeitenLime SWPjoy kiddNoch keine Bewertungen

- CapecitabineDokument13 SeitenCapecitabinegd_hbar100% (1)

- Safety Data Sheet: 1. IdentificationDokument10 SeitenSafety Data Sheet: 1. Identificationkrishnadas kotaNoch keine Bewertungen

- Effluent TreatmentDokument21 SeitenEffluent TreatmentRadhika AnandkumarNoch keine Bewertungen

- BT Chuyển hóa HC1Dokument9 SeitenBT Chuyển hóa HC1Nguyễn Khánh LyNoch keine Bewertungen

- AXH1113 - UK - Rev0 - Dumper 4200Dokument88 SeitenAXH1113 - UK - Rev0 - Dumper 4200Cesar BocanegraNoch keine Bewertungen

- Mineral Oil - USP-NFDokument2 SeitenMineral Oil - USP-NFelenitabastosNoch keine Bewertungen

- Fresh Water Generator On ShipsDokument11 SeitenFresh Water Generator On ShipsGuruNoch keine Bewertungen

- Functional Groups ContainingDokument8 SeitenFunctional Groups ContainingViku GuptaNoch keine Bewertungen

- TSWJ2012 471417Dokument9 SeitenTSWJ2012 471417Bertha Felix TarazonaNoch keine Bewertungen

- SABUN Dan DETERGENDokument34 SeitenSABUN Dan DETERGENIsna NurhidayatiNoch keine Bewertungen

- EM MultiVIV OutdoorUnits PDFDokument152 SeitenEM MultiVIV OutdoorUnits PDFPritam NatuskarNoch keine Bewertungen

- Uss ChemistryDokument104 SeitenUss Chemistry07jhasamNoch keine Bewertungen

- Hydrogen Peroxide Production StoryDokument22 SeitenHydrogen Peroxide Production StorySo Maye100% (1)

- 2386 2 PDFDokument18 Seiten2386 2 PDFIndira BanerjeeNoch keine Bewertungen

- 2JelaluK - Laboratory Manual and Review On Clinical Pathology PDFDokument33 Seiten2JelaluK - Laboratory Manual and Review On Clinical Pathology PDFOUR STORYNoch keine Bewertungen

- Drinking Water MOHDokument3 SeitenDrinking Water MOHNur Amanina OmarNoch keine Bewertungen