Beruflich Dokumente

Kultur Dokumente

Lab 5 Full Report

Hochgeladen von

tirahanafiOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lab 5 Full Report

Hochgeladen von

tirahanafiCopyright:

Verfügbare Formate

Lab5: Production of Acetic Anhydride 1.

2012

PROCEDURE

Methodology for production of acetic anhydride using Aspen Plus for:

1. First, the Aspen plus user interface is opened and Aspen plus blank simulation is chosen. 2. RPlug reactor model is dragged one by one from the unit operation model toolbar at the bottom of process flow sheet onto the flow sheet. RPlug is chosen as the reactor used in this experiment is plug flow reactor (PFR). 3. Inlet stream and outlet streams are attached to the reactor. Each stream and model block is renamed. 4. Setup, components, properties, streams, and blocks inputs from data browser are filled with related information and values.

Table 1: Input information and Values Reaction Or CH3COCH3 CH2CO+ CH4 A B+C Vapour phase cracking of acetone to produce ketene and methane Conditions Feed Temperature Pressure Length Diameter Kinetic rA = kCA (first order reaction with respect to acetone) Adiabatic reactor Reaction type LHHW 8000 kg/hr 1035 K 1.6 atm ~3m ~1m Vapour

1|Page

Lab5: Production of Acetic Anhydride Rate constant, k Activation energy, E Driving force Term 1 1.125 To 1000 K 67999 cal/mol Reactant: exponent to 1 Products:

2012

acetone

ketene

and

methane exponent to 0 Driving force Term 2 All exponents and

constant B, C, D = 0 Constant A = -1000000

5.

Next button is pressed as for running the simulation process.

6. Step 5 until 6 is are repeated by manipulate the diameter, length and number of tubes of reactor.

2.0

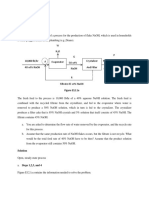

PROCES FLOW DIAGRAM (PFD)

Figure 2: Production of acetic anhydride.

2|Page

Lab5: Production of Acetic Anhydride

2012

3.0

WORKBOOK

Table 3.1: Stream results for production of acetic anhydride.

PRODUCTION OF ACETIC ANHYDRIDE Stream ID From To Phase Substream: MIXED Mole Flow CH3COCH3 CH2CO CH4 Total Flow Total Flow Total Flow Temperature Pressure Vapor Frac Liquid Frac Solid Frac Enthalpy Enthalpy Enthalpy Entropy Entropy Density Density Average MW Liq Vol 60F l/min cal/mol cal/gm cal/sec cal/mol-K cal/gm-K mol/cc gm/cc kmol/hr kg/hr l/min K atm kmol/hr 137.7410 0.0 0.0 137.7410 8000.000 1.21855E+5 1035.000 1.600000 1.000000 0.0 0.0 -29235.24 -503.3612 -1.1186E+6 -17.68577 -.3045068 1.88395E-5 1.09420E-3 58.08004 169.8718 109.4326 28.30834 28.30834 166.0493 8000.000 1.29843E+5 914.8328 1.600000 1.000000 0.0 0.0 -24251.17 -503.3612 -1.1186E+6 -11.30441 -.2346362 2.13141E-5 1.02688E-3 48.17846 190.3017

3|Page

FEED PFR VAPOR

OUTLET PFR VAPOR

Lab5: Production of Acetic Anhydride

2012

Table 3.1: Stream results for production of acetic anhydride for manipulated diameter (7m) and length (5m).

PRODUCTION OF ACETIC ANHYDRIDE Stream ID From To Phase Substream: MIXED Mole Flow CH3COCH3 CH2CO CH4 Total Flow Total Flow Total Flow Temperature Pressure Vapor Frac Liquid Frac Solid Frac Enthalpy Enthalpy Enthalpy Entropy Entropy Density Density Average MW Liq Vol 60F l/min cal/mol cal/gm cal/sec cal/mol-K cal/gm-K mol/cc gm/cc kmol/hr kg/hr l/min K atm kmol/hr 137.7410 0.0 0.0 137.7410 8000.000 1035.000 1.600000 1.000000 0.0 0.0 -29235.24 -503.3612 -17.68577 -.3045068 89.51646 48.22449 48.22449 185.9654 8000.000 824.3684 1.600000 1.000000 0.0 0.0 -21653.97 -503.3612 -8.839555 -.2054815 PFR VAPOR VAPOR FEED OUTLET PFR

1.21855E+5 1.31037E+5

-1.1186E+6 -1.1186E+6

1.88395E-5 2.36531E-5 1.09420E-3 1.01753E-3 58.08004 169.8718 43.01875 204.6751

4|Page

Lab5: Production of Acetic Anhydride

2012

Table 3.1: Stream results for production of acetic anhydride for Multitube (number of tube = 6), diameter (7m) and length (5m).

PRODUCTION OF ACETIC ANHYDRIDE Stream ID From To Phase Substream: MIXED Mole Flow CH3COCH3 CH2CO CH4 Total Flow Total Flow Total Flow Temperature Pressure Vapor Frac Liquid Frac Solid Frac Enthalpy Enthalpy Enthalpy Entropy Entropy Density Density Average MW Liq Vol 60F l/min cal/mol cal/gm cal/sec cal/mol-K cal/gm-K mol/cc gm/cc kmol/hr kg/hr l/min K atm kmol/hr 137.7410 0.0 0.0 137.7410 8000.000 1035.000 1.600000 1.000000 0.0 0.0 -29235.24 -503.3612 -1.1186E+6 -17.68577 -.3045068 1.88395E-5 1.09420E-3 58.08004 169.8718 82.22847 55.51248 55.51248 193.2534 8000.000 789.7417 1.600000 1.000000 0.0 0.0 -20837.35 -503.3612 -1.1186E+6 -8.192211 -.1978966 2.46902E-5 1.02209E-3 41.39642 209.9348

5|Page

FEED PFR VAPOR

OUTLET PFR VAPOR

1.21855E+5 1.30452E+5

Lab5: Production of Acetic Anhydride

2012

4.0

THEORY

There are two ojectives set as guideline while doing this experiment. These objectives are to install and converge a plug flow reactor and to simulate a process involving reaction. As to produce acetic anhydride, the process method used is by the vapour phase cracking of acetone to produce ketene and methane: CH3COCH3 CH2CO+ CH4 This reaction is first order reaction with respect to acetone. The feed condition is 8000 kg/hr of acetone to tabular reactor. The reactor is adiabatic, with inlet T is 1035 K and the pressure is 1.6 atm. Hint: 1. 2. Use SYSOPO of state fluid package.(SI unit) Reactor : ADIABATIC Length: Diameter: 3. 4. 5. Assume 3 m Assume 1 m

Reaction type LHHW Kinetic : Vapour, k: 1.125, To 1000 K, E = 67999 cal/mol Driving force : Term 1 Reactant: acetone exponent to 1 Products: ketene and methane exponent to 0

6.

Driving force : Term 2 All exponents and constant B, C, D = 0 Constant A = -1000000

7.

There length, diameter, number of tubes can be change to achieve specific goal. 6|Page

Lab5: Production of Acetic Anhydride

2012

5.0

1.

Q&A DISCUSSION

What volume required for at least 20 % conversion?

At 1st RUN: % Conversion, X =

X = (28.3084 / 137.7410) x 100% X = 20.55% conversion Volume = (Area) x (length) = (D2/4) x (length) where diameter, D = 1 meter Length, L = 3 meter Volume = ((12)/4) x 3 = 2.36 m3 Therefore, the volume required for at least 20 % conversion is 2.36 m3 At 2nd RUN: Manipulate diameter/length Length=7m Diameter=5m % Conversion, X = (48.2245 / 89.5165) x 100% = 53.87% conversion Volume = ((52)/4) x 7 = 137.44 m3 At 3rd RUN: Manipulate Number of Tube Length=7m Diameter=5m Multitube, no of tube=6 % Conversion, X = (55.5125 / 82.2285) x 100% 7|Page

Lab5: Production of Acetic Anhydride = 67.51% conversion Volume = ((52)/4) x 7 = 137.44 m3 DISCUSSION

2012

There are two ojectives in this experint which are to install and converge a plug flow reactor and to simulate a process involving reaction. Both of these two objective are succesfully done by running the simulation at three different condition. The first condition is where the reactor diameter and length are set at 1m and 3m recpectively. The second condition is where the diamater and length of the reactor are manipulate at 5m and 7m recpectively . Meanwhile, the third condition is where the number of tubes inside the reactor is manipulated with same diameter and length as the second run. The results these three different condition show in table 5.1. Table 5.1: Results of three diffenrent condition 1st RUN 2nd RUN 3rd RUN

Length

= 3m

Length = 7m Diameter = 5m

Length = 7m Diameter = 5m Multi-tubes, no. of tube = 6

Diameter = 1m

% Conversion, X = 20.55% conversion volume = 2.36 m3

% Conversion, X = 53.87% conversion volume = 137.44 m3

% Conversion, X = 67.51% conversion volume = 137.44 m3

Based on calculated results, the highest conversion obtained at the 3rd RUN with conversion of 67.51%. The 1st RUN obtained only 20.55% of conversion and the 2nd RUN obtained 53.87% of conversion. As for volume comparison, the 1st RUN had smallest

8|Page

Lab5: Production of Acetic Anhydride

2012

volume of reactor and for both 2nd RUN and 3rd RUN hand same volume of reactor. From this, it can be said that the increment of diameter and length of the reactor will increase the % conversion of the reaction and the volume of reactor will also increase. However, as to compare the 2nd RUN and 3rd RUN, the % conversion will increase much higher if the reactor used is multi-tubes reactor even by using the same volume of reactor.

9|Page

Das könnte Ihnen auch gefallen

- Team 4 Final PresentationDokument25 SeitenTeam 4 Final Presentationlux0008Noch keine Bewertungen

- PBRDokument19 SeitenPBRdarvyneeNoch keine Bewertungen

- Methanol Reactor ModelDokument11 SeitenMethanol Reactor ModeljoeNoch keine Bewertungen

- Convergence Hints (Aspen)Dokument13 SeitenConvergence Hints (Aspen)Saurabh GuptaNoch keine Bewertungen

- Heat Capacity of Liquids - Critical Review and Recommended ValuesDokument404 SeitenHeat Capacity of Liquids - Critical Review and Recommended ValuesDoris AngNoch keine Bewertungen

- Cumene BDokument6 SeitenCumene BimanchenNoch keine Bewertungen

- Lab 4 SimulationDokument8 SeitenLab 4 SimulationaziziNoch keine Bewertungen

- Assignment 2Dokument3 SeitenAssignment 2Himanshu Aggarwal0% (1)

- 6 - Numerical Methods For Chemical Engineers With Matlab ApplicationsDokument87 Seiten6 - Numerical Methods For Chemical Engineers With Matlab ApplicationsGonzalo1959Noch keine Bewertungen

- Calculation of Bubble and Dew PointDokument9 SeitenCalculation of Bubble and Dew Pointrgopinath5Noch keine Bewertungen

- Growth of Escherichia Coli in A 5 Litre Batch Fermentation VesselDokument15 SeitenGrowth of Escherichia Coli in A 5 Litre Batch Fermentation VesselAs'ad Mughal100% (2)

- Lab 3Dokument16 SeitenLab 3Paen Zulkifli100% (1)

- MATERIAL BALANCE TITLEDokument46 SeitenMATERIAL BALANCE TITLEG Vamsee KrishnaNoch keine Bewertungen

- Aspen PlusDokument17 SeitenAspen PlusNéia CostaNoch keine Bewertungen

- Fluid Fluid Reaction KineticsDokument27 SeitenFluid Fluid Reaction KineticsIlyas AzmanNoch keine Bewertungen

- Chemical Engineering Projects Can Be Divided Into Three TypesDokument25 SeitenChemical Engineering Projects Can Be Divided Into Three Typestrungson1100% (1)

- Chemical Reactors: FoglerDokument34 SeitenChemical Reactors: FoglerMike PoulinNoch keine Bewertungen

- FullDokument33 SeitenFullEja RotiKeju100% (2)

- Tugas HysysDokument4 SeitenTugas HysysLisa Septidiana100% (1)

- Glucose To Acrylic AcidDokument2 SeitenGlucose To Acrylic AcidRachel FrenchNoch keine Bewertungen

- Preliminary Design of Dimethyl Ether Production ProcessDokument114 SeitenPreliminary Design of Dimethyl Ether Production ProcessAdesuwa O'sae0% (1)

- CHEMCAD reactor design tutorialDokument4 SeitenCHEMCAD reactor design tutorialErich EscobarNoch keine Bewertungen

- File1 - Laporan 5Dokument48 SeitenFile1 - Laporan 5Bhaskoro AbdillahNoch keine Bewertungen

- Fortran User ModelDokument20 SeitenFortran User ModelkingboboNoch keine Bewertungen

- CSTRDokument12 SeitenCSTRsamueloNoch keine Bewertungen

- HimmelblauDokument17 SeitenHimmelblauadilla nitaaNoch keine Bewertungen

- CHEMCAD Solids Modeling: Define, Electrolytes, AnalogDokument4 SeitenCHEMCAD Solids Modeling: Define, Electrolytes, Analogpetrol1111111111Noch keine Bewertungen

- ASPEN PLUS Example ProblemDokument5 SeitenASPEN PLUS Example ProblemAlbert Powa0% (1)

- New agitated reactor and heat exchanger installation cost estimateDokument2 SeitenNew agitated reactor and heat exchanger installation cost estimateDiego MoralesNoch keine Bewertungen

- Process Description of Paracetamol ManufacturingDokument25 SeitenProcess Description of Paracetamol ManufacturingAllan ChongNoch keine Bewertungen

- Butene-1: Trans-2-Butene, Isobutylene, and ButadieneDokument1 SeiteButene-1: Trans-2-Butene, Isobutylene, and ButadieneYESIKBMARTIN100% (1)

- AnalDokument163 SeitenAnalMilan MoradiyaNoch keine Bewertungen

- Assignment 1Dokument3 SeitenAssignment 1imtiazNoch keine Bewertungen

- Kinetics and Modelling of The S02 To The SO3 ProcessDokument23 SeitenKinetics and Modelling of The S02 To The SO3 ProcessAbdullah KhanNoch keine Bewertungen

- Simulation of Methanol Production From Biomass Gasification in Interconnected Fluidized BedsDokument9 SeitenSimulation of Methanol Production From Biomass Gasification in Interconnected Fluidized BedsKelly TorresNoch keine Bewertungen

- Batch Manufacture of Propylene GlycolDokument6 SeitenBatch Manufacture of Propylene Glycolprassna_kamat1573Noch keine Bewertungen

- Perancangan Proses Kimia 1Dokument15 SeitenPerancangan Proses Kimia 1RantyNoch keine Bewertungen

- GAS PROPERTIES: IDEAL VS REALDokument9 SeitenGAS PROPERTIES: IDEAL VS REALReza Gustarani DaneswariNoch keine Bewertungen

- CHEMICAL ENGINEERING DEPARTMENT COURSE GUIDEDokument70 SeitenCHEMICAL ENGINEERING DEPARTMENT COURSE GUIDEJogi BogiNoch keine Bewertungen

- Simulation of Methanol Synthesis in Packed Bed Reactor Based On Gas From Biomass GasificationDokument9 SeitenSimulation of Methanol Synthesis in Packed Bed Reactor Based On Gas From Biomass GasificationHaris Surya HidayatNoch keine Bewertungen

- Gas Absorption ReportDokument15 SeitenGas Absorption ReportdaabgchiNoch keine Bewertungen

- Comsol Nonisothermal Plug Flow ReactorDokument14 SeitenComsol Nonisothermal Plug Flow ReactorArjun TomerNoch keine Bewertungen

- Zhang Yie Zien. High-Rate Mesophilic Anaerobic Digestion of Palm Oil Mill Effluent (POME) PDFDokument6 SeitenZhang Yie Zien. High-Rate Mesophilic Anaerobic Digestion of Palm Oil Mill Effluent (POME) PDFZainul Fikri TampengNoch keine Bewertungen

- It1.Introduction & History:-: 1.1 Introduction To Cumene:-StructureDokument12 SeitenIt1.Introduction & History:-: 1.1 Introduction To Cumene:-StructureJaymin GoswamiNoch keine Bewertungen

- Thus, This Term Actually Means A in A Constant-Volume System The Measure of Reaction Rate of Component I BecomesDokument23 SeitenThus, This Term Actually Means A in A Constant-Volume System The Measure of Reaction Rate of Component I Becomesalice Annabelle100% (1)

- AMMONIA PROCESS SIMULATIONDokument8 SeitenAMMONIA PROCESS SIMULATIONChecoCastilloNoch keine Bewertungen

- Techno-Economic Modelling and Cost Functions of CO Capture ProcessesDokument11 SeitenTechno-Economic Modelling and Cost Functions of CO Capture ProcessesAlex MarkNoch keine Bewertungen

- CSTRDokument11 SeitenCSTRfarahanisiliasNoch keine Bewertungen

- For Hysys UsersDokument5 SeitenFor Hysys UsersZohaib RanaNoch keine Bewertungen

- TEG-Dehydration Mass and Energy BalanceDokument137 SeitenTEG-Dehydration Mass and Energy BalanceIgnatius Adriel WijayaNoch keine Bewertungen

- Nhóm (Đ.Anh+ Hiếu + Ý) Syngas to MethanolDokument40 SeitenNhóm (Đ.Anh+ Hiếu + Ý) Syngas to MethanolStrong NguyenNoch keine Bewertungen

- Chapter 15 Heat Exchanger NetworksDokument29 SeitenChapter 15 Heat Exchanger NetworksRina Hapsarininggar0% (1)

- Design of Production 2-Ethylhexanol From Propylene and Synthesis GasDokument11 SeitenDesign of Production 2-Ethylhexanol From Propylene and Synthesis Gasعلی محمد قادر خضرNoch keine Bewertungen

- Acetone BDokument9 SeitenAcetone BIrdani IdrisNoch keine Bewertungen

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationVon EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNoch keine Bewertungen

- Dynamic Programming in Chemical Engineering and Process Control by Sanford M RobertsVon EverandDynamic Programming in Chemical Engineering and Process Control by Sanford M RobertsNoch keine Bewertungen

- Practical Chemical Thermodynamics for GeoscientistsVon EverandPractical Chemical Thermodynamics for GeoscientistsNoch keine Bewertungen

- Principles and Case Studies of Simultaneous DesignVon EverandPrinciples and Case Studies of Simultaneous DesignNoch keine Bewertungen

- DesignScript Summary User ManualDokument20 SeitenDesignScript Summary User ManualEsper AshkarNoch keine Bewertungen

- Vodafone Bid HBS Case - ExhibitsDokument13 SeitenVodafone Bid HBS Case - ExhibitsNaman PorwalNoch keine Bewertungen

- CNT SVX15D E4 1111Dokument60 SeitenCNT SVX15D E4 1111Mihai IavorschiNoch keine Bewertungen

- Design of RC Building - ExerciseDokument6 SeitenDesign of RC Building - Exercisesajeerala100% (1)

- Faculty of Engineering and Computing Sciences: Annexure-IDokument2 SeitenFaculty of Engineering and Computing Sciences: Annexure-IAkshay MehtaNoch keine Bewertungen

- ELEN3017A Project Brief 2022 Rev2Dokument3 SeitenELEN3017A Project Brief 2022 Rev2Dick MabhidaNoch keine Bewertungen

- Straight Line MotionDokument12 SeitenStraight Line MotionMZWAANoch keine Bewertungen

- Engg Mechanics Paper Dec 2019 As Per CODokument4 SeitenEngg Mechanics Paper Dec 2019 As Per COPiyush BhandariNoch keine Bewertungen

- MotorDokument33 SeitenMotorLyka LasilasNoch keine Bewertungen

- Canon I Sensys LBP5300 5360Dokument192 SeitenCanon I Sensys LBP5300 5360GonzaloNoch keine Bewertungen

- Huawei Site Design GuidelineDokument7 SeitenHuawei Site Design GuidelineHeru BudiantoNoch keine Bewertungen

- GPT 7000L User: Manual'Dokument26 SeitenGPT 7000L User: Manual'Adel Abo AdamNoch keine Bewertungen

- 0580 w13 QP 41Dokument20 Seiten0580 w13 QP 41Haider AliNoch keine Bewertungen

- SUDOKU DocumentDokument37 SeitenSUDOKU DocumentAmbika Sharma33% (3)

- Free Electron TheoryDokument4 SeitenFree Electron TheoryARGHYADEEP NAGNoch keine Bewertungen

- Materials and Techniques Used For The "Vienna Moamin": Multianalytical Investigation of A Book About Hunting With Falcons From The Thirteenth CenturyDokument17 SeitenMaterials and Techniques Used For The "Vienna Moamin": Multianalytical Investigation of A Book About Hunting With Falcons From The Thirteenth CenturyAirish FNoch keine Bewertungen

- Lecturer Notes On Pipe Sizing BasicsDokument32 SeitenLecturer Notes On Pipe Sizing BasicsTactical Blackhawk BatamNoch keine Bewertungen

- Multistage Amplifier Frequency ResponseDokument29 SeitenMultistage Amplifier Frequency ResponseMuhammad HafizNoch keine Bewertungen

- Cagayan State University: Republic of The PhilippinesDokument21 SeitenCagayan State University: Republic of The PhilippinesblessaNoch keine Bewertungen

- E16 8 2Dokument4 SeitenE16 8 2Branko FerenčakNoch keine Bewertungen

- Dome Enclosure: MoellerDokument3 SeitenDome Enclosure: MoellerLjubomir VasicNoch keine Bewertungen

- Homework Labs Lecture01Dokument9 SeitenHomework Labs Lecture01Episode UnlockerNoch keine Bewertungen

- GD-1884 Manual PDFDokument10 SeitenGD-1884 Manual PDFAnonymous srwHCpANoch keine Bewertungen

- Airy stress function enables determination of stress components in pure beam bendingDokument19 SeitenAiry stress function enables determination of stress components in pure beam bendingmaran.suguNoch keine Bewertungen

- Esolutions Manual - Powered by CogneroDokument31 SeitenEsolutions Manual - Powered by CogneroAll About MusicNoch keine Bewertungen

- Same Denominator or Numerator Worksheet 1Dokument2 SeitenSame Denominator or Numerator Worksheet 1Jenny KimNoch keine Bewertungen

- SMD Meter User's ManualDokument2 SeitenSMD Meter User's ManuallucianoNoch keine Bewertungen

- NMNR5104 Research MethodologyDokument2 SeitenNMNR5104 Research MethodologynadiaNoch keine Bewertungen

- ZTE NODE-B ConnectivityDokument19 SeitenZTE NODE-B ConnectivitySanjeet Doodi100% (7)

- Echotrac Mkiii: Operator'S ManualDokument48 SeitenEchotrac Mkiii: Operator'S ManualKhắc PhongNoch keine Bewertungen