Beruflich Dokumente

Kultur Dokumente

Ewf - Technical Sheet - Calculation of Preheat Temperature For Butt Welds

Hochgeladen von

Dries VandezandeOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ewf - Technical Sheet - Calculation of Preheat Temperature For Butt Welds

Hochgeladen von

Dries VandezandeCopyright:

Verfügbare Formate

Pre-heating temperature for butt welding

Fundamentals of preheating

Preheating involves heating the base metal, either in its entirety or just the region surrounding the joint, to specific temperature, The preheat temperature. Heating may be continued during the welding process, b t f ldi but frequently th preheat tl the h t form's sufficient to maintain the desired temperature through out the weld.

Heat Input

It can be see that an increase of heat input (Q) during welding permits a reduction of preheat temperature.

Calculation of preheat temperature

The effect of chemical composition characterized by the carbon equivalent (CET) ,the plate thickness (d),the hydrogen content of the weld metal (HD), and heat input (Q) can be combined by the formula given below to calculate the preheat temperature:

Hydrogen scale

The hydrogen scale to be used for any arc welding process depend mainly on the g p p y diffusible hydrogen content. The effect of hydrogen content, HD, of the weld metal in accordance with ISO3690 on pre-heat temperature can calculate using the following expression:

Graphical determination of preheat temperature

The relationship between preheat temperature and plate thickness, for selected heat input and carbon equivalent can be represented:

preheat temperature (c) e

Combined thickness

When heating a joint to be welded, the EN1011 code requires that the combined thickness should be determined as the sum of parent metal thicknesses averaged over a distance of 75 mm from weld line.

Base material

The influence of the chemical composition on the cold cracking behavior of steel is characterized by mean of carbon equivalent (CET).The effect of carbon and other individual alloying element is given by

Legend: 1-preheat temperature 2-plate thickness

plate thickness (mm)

If the carbon equivalent and heat input in the diagram do not agree with the actual values, the inferred preheat temperature shall be corrected A correction of 7 5C has corrected. 7.5 C to be made for every 0.01% difference in carbon equivalent. The correction for heat input can obtained in expression noted before.

Das könnte Ihnen auch gefallen

- ST 35.8 (Germany / DIN) : Material PropertiesDokument3 SeitenST 35.8 (Germany / DIN) : Material Propertiesmohammad zareiNoch keine Bewertungen

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Dokument15 SeitenFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaNoch keine Bewertungen

- Evaluation of 8090 and Weldalite-049 Aluminum-Lithium AlloysDokument39 SeitenEvaluation of 8090 and Weldalite-049 Aluminum-Lithium Alloysskylancer-3441Noch keine Bewertungen

- Material Information Sheet For Plates: Erndtebrücker EisenwerkDokument2 SeitenMaterial Information Sheet For Plates: Erndtebrücker EisenwerkAhmad KamilNoch keine Bewertungen

- JIS B2311 Steel Butt Welding Pipe Fittings For Ordinary UseDokument24 SeitenJIS B2311 Steel Butt Welding Pipe Fittings For Ordinary Usense mcxNoch keine Bewertungen

- b2020-Tdc-Fas-004 Fasteners r3Dokument2 Seitenb2020-Tdc-Fas-004 Fasteners r3Ramalingam PrabhakaranNoch keine Bewertungen

- Astm A106 Ts EnglDokument4 SeitenAstm A106 Ts EnglxaviereduardoNoch keine Bewertungen

- Astm A179 PDFDokument1 SeiteAstm A179 PDFgaminNoch keine Bewertungen

- Esab Buddy TIG400iDokument2 SeitenEsab Buddy TIG400iJeganeswaranNoch keine Bewertungen

- ST 37Dokument7 SeitenST 37rendra.farisrNoch keine Bewertungen

- Closure Data PEDokument2 SeitenClosure Data PEjowarNoch keine Bewertungen

- 2062Dokument17 Seiten2062hswed91100% (1)

- EN 13480-3 Straight Pipes PDFDokument1 SeiteEN 13480-3 Straight Pipes PDFmasatusNoch keine Bewertungen

- QCF312 WPQRDokument2 SeitenQCF312 WPQRminhnnNoch keine Bewertungen

- D.P.transmitter Spriano 47B ManualDokument22 SeitenD.P.transmitter Spriano 47B ManualBruno100% (1)

- S275JR PDFDokument1 SeiteS275JR PDFEmrahCayboylu100% (1)

- Project HSE Requirements ManualDokument14 SeitenProject HSE Requirements ManualHamid MansouriNoch keine Bewertungen

- 20G Boiler Steel Pipe PDFDokument5 Seiten20G Boiler Steel Pipe PDFHeza FirdausNoch keine Bewertungen

- Oil Gas Construction Factory L.L.CDokument2 SeitenOil Gas Construction Factory L.L.CRenny DevassyNoch keine Bewertungen

- Soft Magnetic Iron Parts Fabricated by Powder Metallurgy (P/M) TechniquesDokument4 SeitenSoft Magnetic Iron Parts Fabricated by Powder Metallurgy (P/M) TechniquesEduardoNoch keine Bewertungen

- Compresor EinhellDokument1 SeiteCompresor Einhellmih4iNoch keine Bewertungen

- Jun 2018 153707867T2JQPG3GPFRDokument61 SeitenJun 2018 153707867T2JQPG3GPFRANIL KUMARNoch keine Bewertungen

- E1 Technical Data Sheet - ShortDokument2 SeitenE1 Technical Data Sheet - ShortOmaiyio M. SaginiNoch keine Bewertungen

- Asme Ix Int Vol26Dokument17 SeitenAsme Ix Int Vol26Julio CastilhosNoch keine Bewertungen

- Stainless Steel Bars and Shapes: Standard Specification ForDokument8 SeitenStainless Steel Bars and Shapes: Standard Specification ForkrkmurthyNoch keine Bewertungen

- Hydro TestDokument1 SeiteHydro TestMilan BanerjeeNoch keine Bewertungen

- API 5L GR.B SteelDokument2 SeitenAPI 5L GR.B SteelYosua Rielys PNoch keine Bewertungen

- Sensitization of Inconel 625Dokument9 SeitenSensitization of Inconel 625nantha kumarNoch keine Bewertungen

- Rationalise List Welding ConsumablesDokument19 SeitenRationalise List Welding ConsumablesMayank SadaniNoch keine Bewertungen

- Ss Grade 50 - Galvanized Steel Coils & SheetsDokument1 SeiteSs Grade 50 - Galvanized Steel Coils & SheetshealgoseNoch keine Bewertungen

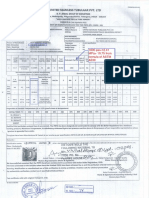

- Mill Test Certificate: Customer Name/Address StampDokument1 SeiteMill Test Certificate: Customer Name/Address StampD S Sagar TripuramalluNoch keine Bewertungen

- List of en Standards: SR No Code/Standard DescriptionDokument4 SeitenList of en Standards: SR No Code/Standard DescriptionAnilNoch keine Bewertungen

- Is 210Dokument16 SeitenIs 210Debopriyo GhoshNoch keine Bewertungen

- Wps For Aluminium WeldingDokument8 SeitenWps For Aluminium WeldingMohammed MusaNoch keine Bewertungen

- Astm A 335Dokument8 SeitenAstm A 335Ruben Dario Espinoza Vasquez100% (1)

- ASTM F1545 Plastic Lined Pipe 0803Dokument6 SeitenASTM F1545 Plastic Lined Pipe 0803JabranYounasNoch keine Bewertungen

- Global Marketing For Tube & Pipe: JIS G3457 Arc Welded Carbon Steel PipesDokument7 SeitenGlobal Marketing For Tube & Pipe: JIS G3457 Arc Welded Carbon Steel PipesNurzed MunkhbayarNoch keine Bewertungen

- Flange 8 Inch RTJDokument3 SeitenFlange 8 Inch RTJreniNoch keine Bewertungen

- Buried Pipes and Fittings Painting SpecDokument5 SeitenBuried Pipes and Fittings Painting SpecRohan Sharma50% (2)

- PWHT ReportsDokument1 SeitePWHT ReportsKarthikNoch keine Bewertungen

- Weld History SheetDokument2 SeitenWeld History SheetAjin S100% (1)

- Commented - 8' PIPE TCDokument1 SeiteCommented - 8' PIPE TCAqib Khan VCSPNoch keine Bewertungen

- QAP Seamless PipeDokument2 SeitenQAP Seamless PipeashokkahirwarNoch keine Bewertungen

- Iso 15552 2004 en PDFDokument8 SeitenIso 15552 2004 en PDFashokkumarNoch keine Bewertungen

- MTC, Annexure & Tally Sheet PDFDokument23 SeitenMTC, Annexure & Tally Sheet PDFashish.mathur1Noch keine Bewertungen

- Assure Solutions: Hydro Test ReportDokument1 SeiteAssure Solutions: Hydro Test ReportKailas NimbalkarNoch keine Bewertungen

- CV Painting InsulationDokument3 SeitenCV Painting Insulationhamza brahmiNoch keine Bewertungen

- Wps Sp14 Reva PDFDokument9 SeitenWps Sp14 Reva PDFravi00098Noch keine Bewertungen

- Boq For AS BoilerDokument1 SeiteBoq For AS BoilerGayan ChathurangaNoch keine Bewertungen

- Cathodic Protection BOMDokument4 SeitenCathodic Protection BOManonymous542Noch keine Bewertungen

- Steel Properties Material Grade Comparison ChartDokument1 SeiteSteel Properties Material Grade Comparison Chartgk80823Noch keine Bewertungen

- Dynamic Balancing MachineDokument4 SeitenDynamic Balancing Machine.x100% (1)

- WPS PQR-05Dokument10 SeitenWPS PQR-05Ranjan KumarNoch keine Bewertungen

- 71 Technical Sheet - Pre-Heating Temperature For Butt Welding PDFDokument1 Seite71 Technical Sheet - Pre-Heating Temperature For Butt Welding PDFArul Edwin VijayNoch keine Bewertungen

- ABout Preheat Before WeldingDokument2 SeitenABout Preheat Before WeldingHary Olya AdriansyahNoch keine Bewertungen

- Help Welding Calculation - WeldingDokument14 SeitenHelp Welding Calculation - Weldingahmed100% (1)

- Welcome To Preheat Calculation Program: C.brak@it - Fnt.hvu - NLDokument16 SeitenWelcome To Preheat Calculation Program: C.brak@it - Fnt.hvu - NLKelvin Labarez100% (1)

- Method of Calculating The Cooling Rate in HAZ During WeldingDokument6 SeitenMethod of Calculating The Cooling Rate in HAZ During WeldingahmedNoch keine Bewertungen

- Rumus Welding PDFDokument8 SeitenRumus Welding PDFidienNoch keine Bewertungen

- ESAB ExtractPage32-33DDokument17 SeitenESAB ExtractPage32-33DDries VandezandeNoch keine Bewertungen

- ESAB ExtractPage34-35DDokument16 SeitenESAB ExtractPage34-35DDries VandezandeNoch keine Bewertungen

- ESAB ExtractPage35-36DDokument16 SeitenESAB ExtractPage35-36DDries VandezandeNoch keine Bewertungen

- ESAB ExtractPage39-40DDokument17 SeitenESAB ExtractPage39-40DDries VandezandeNoch keine Bewertungen

- ExtractPage40 41D PDFDokument21 SeitenExtractPage40 41D PDFDries VandezandeNoch keine Bewertungen

- ESAB ExtractPage17-18cDokument9 SeitenESAB ExtractPage17-18cDries VandezandeNoch keine Bewertungen

- ESAB ExtractPage20-21cDokument8 SeitenESAB ExtractPage20-21cDries VandezandeNoch keine Bewertungen

- ExtractPage38 39c PDFDokument8 SeitenExtractPage38 39c PDFDries VandezandeNoch keine Bewertungen

- ESAB ExtractPage29-30cDokument9 SeitenESAB ExtractPage29-30cDries VandezandeNoch keine Bewertungen

- ESAB ExtractPage15-16cDokument9 SeitenESAB ExtractPage15-16cDries VandezandeNoch keine Bewertungen

- ExtractPage40 41c PDFDokument12 SeitenExtractPage40 41c PDFDries VandezandeNoch keine Bewertungen

- ExtractPage35 36c PDFDokument8 SeitenExtractPage35 36c PDFDries VandezandeNoch keine Bewertungen

- Regulators Edge Linemaster Series: Ideal For Industrial Sector UsesDokument4 SeitenRegulators Edge Linemaster Series: Ideal For Industrial Sector UsesDries VandezandeNoch keine Bewertungen

- Regulator/flowmeter Combination OptiflowDokument5 SeitenRegulator/flowmeter Combination OptiflowDries VandezandeNoch keine Bewertungen

- Oxy-Fuel Cutting & Welding Outfits Edge Series and G-Series Kits - ContentsDokument4 SeitenOxy-Fuel Cutting & Welding Outfits Edge Series and G-Series Kits - ContentsDries VandezandeNoch keine Bewertungen

- Regulator/flowmeter Combination OptiflowDokument5 SeitenRegulator/flowmeter Combination OptiflowDries VandezandeNoch keine Bewertungen

- Regulators G Series Regulators: Featuring Tube Overpressure Relief MechanismDokument4 SeitenRegulators G Series Regulators: Featuring Tube Overpressure Relief MechanismDries VandezandeNoch keine Bewertungen

- Iso 15156 2 2003 en FR PDFDokument11 SeitenIso 15156 2 2003 en FR PDFMurad AlmoudiNoch keine Bewertungen

- Catalogo Dixon Oil&GAS Conexoes PDFDokument60 SeitenCatalogo Dixon Oil&GAS Conexoes PDFCarlos SopasNoch keine Bewertungen

- Floating JointDokument0 SeitenFloating JointsugirinNoch keine Bewertungen

- Minerals in Your Home: Activity BookDokument17 SeitenMinerals in Your Home: Activity BookThicc ThighsNoch keine Bewertungen

- STP 556-1974Dokument192 SeitenSTP 556-1974Tim SchouwNoch keine Bewertungen

- Kobel CoDokument4 SeitenKobel CoCesar ZarateNoch keine Bewertungen

- Lesson 3 - Ductile and Brittle FractureDokument80 SeitenLesson 3 - Ductile and Brittle FractureArgexander CarballoNoch keine Bewertungen

- Arcelormittal Crane Rails enDokument6 SeitenArcelormittal Crane Rails enjulius_xNoch keine Bewertungen

- ASTM A325: ScopeDokument2 SeitenASTM A325: ScopetylerstearnsNoch keine Bewertungen

- DM Water Tank SpecificationDokument9 SeitenDM Water Tank SpecificationManish PatelNoch keine Bewertungen

- Acid Dew Point Corrosion ChimneyDokument4 SeitenAcid Dew Point Corrosion Chimneyzementhead100% (1)

- Welding HandbookDokument48 SeitenWelding HandbookMohan Prasad.M93% (27)

- Is 14220-PumpDokument13 SeitenIs 14220-PumpJignesh TrivediNoch keine Bewertungen

- Lass Ndustry: Hapter IXDokument19 SeitenLass Ndustry: Hapter IXPriyank ChaudhariNoch keine Bewertungen

- Welding of Steel PipingDokument8 SeitenWelding of Steel PipingElias EliasNoch keine Bewertungen

- Railway Engineering MCQsDokument14 SeitenRailway Engineering MCQstushark12127Noch keine Bewertungen

- PREN Value (Duplex)Dokument4 SeitenPREN Value (Duplex)onkarNoch keine Bewertungen

- Thyssenkrupp: Elevator Technology Synergy Element Package. Fact SheetDokument15 SeitenThyssenkrupp: Elevator Technology Synergy Element Package. Fact SheetTek tek hapNoch keine Bewertungen

- Magnalenz Induction FurnaceDokument31 SeitenMagnalenz Induction Furnaceassar_metalNoch keine Bewertungen

- Nimoten Plus 535: LOW ALLOY STEEL (Nimoten Series)Dokument1 SeiteNimoten Plus 535: LOW ALLOY STEEL (Nimoten Series)satnamNoch keine Bewertungen

- Product Overview Brochure DOC-B90-EXS006 V11 LowDokument24 SeitenProduct Overview Brochure DOC-B90-EXS006 V11 LowJoão Paulo FioriNoch keine Bewertungen

- Handcraft in Wood and MetalDokument288 SeitenHandcraft in Wood and MetalArtisan Ideas100% (3)

- Metals 164 Tata Steel Jamshedpur 0 PDFDokument41 SeitenMetals 164 Tata Steel Jamshedpur 0 PDFkalaiNoch keine Bewertungen

- Materials For Reformer Furnace Tubes History of EvolutionDokument7 SeitenMaterials For Reformer Furnace Tubes History of EvolutionAPI100% (1)

- k2s-Ng01007551-Gen-ra7754-00004 Specification For Line Pipe Protective Coating RepairDokument15 Seitenk2s-Ng01007551-Gen-ra7754-00004 Specification For Line Pipe Protective Coating Repairadeoye_okunoyeNoch keine Bewertungen

- General Requirements For Alloy and Stainless Steel PipeDokument11 SeitenGeneral Requirements For Alloy and Stainless Steel PipeCesar BernalNoch keine Bewertungen

- Astm-A36 Chapa Grossa Ate 19mmDokument1 SeiteAstm-A36 Chapa Grossa Ate 19mmAndre MelloNoch keine Bewertungen

- 3-A Sanitary Standards For Uninsulated Tanks For Milk and Milk Products, Number 32-03Dokument10 Seiten3-A Sanitary Standards For Uninsulated Tanks For Milk and Milk Products, Number 32-03CHRISTIAN ZAVALANoch keine Bewertungen

- GU-379 Pipeline Emergency Repair ManualDokument76 SeitenGU-379 Pipeline Emergency Repair Manualhappale2002Noch keine Bewertungen

- Cutter Wheel Chart 12 14Dokument4 SeitenCutter Wheel Chart 12 14Pablo CoroNoch keine Bewertungen