Beruflich Dokumente

Kultur Dokumente

Modifying The Toyota 3SGE

Hochgeladen von

Badshah PeerOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Modifying The Toyota 3SGE

Hochgeladen von

Badshah PeerCopyright:

Verfügbare Formate

Modifying the 3SG non-turbo engine by Terry OBeirne

Introduction

This 2-part article follows-on from the several part story we wrote about racing an MR2. Most owners are only familiar with bolt-on modifications to turbo engines, so we have prepared this to give an insight on modifying the non-turbo (Naturally Aspirated or NA for short). Some of this information is directly relevant to turbo engines, which of course can produce double these values (albeit with short life).

Engine models

for the period 1995-2002. Mostly used in Carinas, they were tuned to produce around 224kw (300 flywheel HP). Unfortunately, they became quite fragile due to the extreme revs required for NA engines to produce this sort of power. Slightly less power was extracted in lesser classes, for both circuit racing & rallying. In a few countries, the dry-sumped Gen 2 engines with the fabulous Xtrac sequential shift dog type gearbox were fitted into Corolla rally cars for simply awesome performance (see pic below). The Gen 3 engines have been widely used in rally cars, whilst the final version of the Gen 4 saw use for a short time in a couple of Altessas used in the British Touring Car Championship.

Before you get too carried away, you need to understand exactly which engine you are dealing with. Commonly called generations (Gen), the Australian delivered SW20 MR2 came with the Gen 2 engine from Oct89Oct93 & the Gen 3 engine thereafter. No turbo cars, & none with the Gen 4 beams were sold here new. There are several easy identifiers for the NA engines fitted to MR2s

Gen2 Aust spec 117kw@6600rpm (DIN rating) 1-piece, pressed steel sump Gen3 Aust spec 131kw@7000rpm (DIN rating) The sump is 2 pieces, with a large alloy part bolted to the block & a very small pressed steel piece below it The oil filter is down on the alloy intermediate sump The cylinder head has the valve clearance shims under the bucket Gen 4 Not avail in Aust

As for Gen 3

The oil filter is under the exhaust manifold The cylinder head has the valve clearance shims on top of the bucket

As for Gen 3 External mods The cylinder head is Gen 3 type but has variable cam timing on the inlet only. The cam cover is red & has the word beams in silver script.

The Caldina, Celica, GT4, Camry, Carina etc also used the Gen 2, 3 & 4 engines, but with a host of minor differences that make swaps not as simple as they first appear. The Generation 1 engine (2 separate cam covers) was never used in MR2s & is not a direct replacement for the later engines, so I wont mention it any more in this article.

Competition history

In general, individual external modifications on stock 3SG engines, produce such small power gains, that it difficult to prove their worth with simple dyno testing. Testing items like pod filters, high flow mufflers & even extractor type exhausts, invariably show either the same power on the dyno, or such a small change at (maybe only) one rev range, it is within the limits of repeatability of the test process & therefore it is not prudent to make great claims for them. If you are trying to prove the worth of minor changes, you must test them on computer controlled dynos that can accurately reproduce acceleration runs. Simple max power testing is next to useless. (see footnote 1 about dyno results) . 1

The 3SG engine replaced the 3T as the large performance 4 cylinder in Toyotas range in 1988. Almost immediately it found its way into race cars around the world, competing head to head with the best mass-production engines from Europe Fiat, Alfa, Ford etc. The most advanced form of the Gen 2 version was in the Super-Tourers, a world-wide touring car category

Copyright Terry OBeirne Road & Track 2006.

Both chassis & engine dynos have repeatability & accuracy problems that most non specialists are unaware of. Some are integral to the dyno design, whilst others reflect changing atmospheric or vehicle conditions. A 10-15C change in engine oil or water temp between dyno runs, can, for example, produce a noticeable peak power change on many engines. Many operators cannot calibrate their machines & in 99% of cases, they cannot manage the environment.. Better dyno shops apply correction factors to attempt to account for the atmospheric pressure (air density) & temperature), & the very best of them use acceleration runs to try to measure performance over a wider range than just a single max power test. Together, all these issues conspire against reliably measuring changes of only a few HP/kw .

www.roadandtrack.net.au

Page1

Modifying the 3SG non-turbo engine by Terry OBeirne

Having said that, some combinations of the above will definitely yield benefits, but its dangerous to give power predictions as there are so many variables involved. The limiting factor with most bolt-on mods is the capacity of the stock computer to adjust the fuel & ignition values to match what you have done.

Exhaust

that they suck in hot air (less dense) from the engine bay, rather than (relatively) cool air from the intake near the wheel, & you can lose power. We log incoming air temperature & engine bay temps, & even on the hottest Queensland summer day, the factory intake is always several degrees below the engine bay. Air density is proportional to temperature, & it is air density that helps make power. If a cold intake drops the air temp by say 5 C, then the density increase is 1.6%. This is the absolute maximum power increase, & in practise, it will be much less. The next big problem to avoid with pod filters is their very poor mounting arrangement. They wobble around a lot & some of them fatigue the steel or plastic backings they come with. If this results in a cracked fitting or broken hose, then unfiltered air can enter the engine & do considerable harm. Finally, pay special attention to oiling cotton filters like K&N, Final Filter or BMC, or foam ones like Lynx. Over oiling results in power loss by tacky oil deposits building up internally & we know of 1 case where resultant valve stem deposits caused a misfire & the new car dealer refused a warranty claim. We use & recommend a washable flat panel cotton filter inside the Toyota air box because they are re-useable & offer lowest possible resistance yet excellent filtration capacity. By the way, the bulb on one side of the intake pipe is just a resonance chamber designed to remove some annoying hums. Deleting it wont increase power at all, but it helps a little with access around the filter case. Ram air intakes like the TOMS snorkel, dont appear to do any harm, but we have never been able to test one on its own, & of course they cant be properly tested on a dyno. There is a chance that they could drop the incoming air temperature because they suck air further away from the bitumen. Cold , ram charged air can only be a good thing, provided it is filtered properly.

Intake & throttles

The real value in extractor type exhaust manifolds only comes when camshafts & valve springs are changed so that peak torque occurs at higher revs. A simple design formula that appears to work OK is:Primary pipe length in inches =((850 x ED)/rpm)-3 Where RPM is the tuning revs, typically being the max torque engine revs & ED is (180 + exhaust cam opening point BBDC). On a fast road engine with a peak torque point of say 3500rpm, this works out to be 134cm (53), whilst for a race only engine at 5500rpm, it is 91cm (36) We have always found that 4:1 systems work best. The 4:1 device is commonly called a merge collector & these can be purchased pre-made. It impossible to make a 4:1 on a road going MR2 with such long pipes, so you need to compromise with a 4:2:1 system, & get the total of the primary plus secondary pipes to be this length. With this sort of system on a MR2, the pipes run perilously close to the sump so you need physical heat shield in this place. Increased size cat back exhaust systems continue to be widely used however the Catalytic convertor proves to be a major restriction. Others have shown that the total pressure drop in the system needs to be no more than about 14kpa (2 psi). To achieve this on our racer we had to remove the cat entirely, use a 80mm (3.25) main pipe & a straight thru (but still efficient) muffler. Originally, we had 2 small mufflers, but for space reasons we removed one. It made no measurable change to power, but it sounded more like a race car, so it had to be a good thing!!. There is no doubt that a well thought-out combination of hi-flow cat converter, low backpressure muffler & extractor manifold, can deliver small, but measurable benefits. However, on a stock engine, dont expect to see more than about 15hp (12kw). Until cam & computer changes are made, the maximum benefits wont occur.

Air filters & cold air intakes

Pod filters & cold air intakes seem to be mutually exclusive on most MRs, but it doesnt have to be that way. We have not been able to show any repeatable power increase on a dyno from just swapping to a pod filter. In many cases, the pod filters are so badly located

Copyright Terry OBeirne Road & Track 2006.

The factory TVIS system is designed to increase low to mid-range torque by maximising air velocity in the intake ports. Factory test data for both Gen 2 & 3 engines proves it works, even with significant changes to cam profiles where peak power & torque points are moved upwards. When the cams are changed, the operating point of the TVIS can be altered with the aftermarket computer but not so with a factory computer. The design of the TVIS on non-turbo Gen 3 engines does not offer any significant intake restriction & I cannot see any reason to remove it on road-going cars.

Page2

www.roadandtrack.net.au

Modifying the 3SG non-turbo engine by Terry OBeirne

On many other engines, increasing the throttle plate size, & reshaping of the housing has proven to release power, but we have not done enough experimentation on 3SGs to be definitive. The Gen 3 engine uses a slightly larger 60mm butterfly & perhaps we will one day fit this to an earlier engine & measure the change. For ultimate power engines, & when a programmable computer is used, 4 individual throttles can be fitted. These are hard to arrange on a MR2 due to the proximity of the rear bulkhead, but it can be done. The pictures show a slide plate throttle & conventional butterfly plate quad throttle for 3SGs. They have to be fitted to manifolds like the Gen 3 intake & mounted vertically to clear the bulkhead. the cam starts to open the valve (timing), opening the valve further (lift) & holding it open for a longer time (duration). The lift on any 3SG head is limited to 10.5mm by the springs, which will become coil bound. Flow studies on Gen 2 & 3 heads both indicate the intake flow drops off at about 13mm lift, & after that, the valve, port & head chambers all combine to limit the flow coming in. When we modify all these items, then such lift can be useful, but this requires the alloy head to be machined so that longer springs can be used. Longer springs have greater lift potential & more consistent spring rates. With factory cams, small alterations to only the cam (valve) opening points by moving the cam wheel, seems to have little nett benefit. Whilst some improvements may be made at one point, there is trade off in power elsewhere, & quite often, also with emissions. Once the cam design is altered however, then the cam timing point needs to be optimised. The stock cam gears have either 3 or 6 holes to allow this, but its a terrible job to do this on the car & thats where the need for a vernier gear comes in. Unless you have modified cams, vernier gears are mostly a gimmick. If you do buy them, only buy ones with hardened gears. Many well known Jap brands use unhardened gears and they dont last long. The duration of the cam governs how much air can be ingested for any given lift. The lumpiness of the cam is linked to duration, & to a lesser extent, the overlap. Stock duration on all Australian spec Gen 2 & Gen 3 cams is 244. Without complicating matters too much, it is safe to say that cams with advertised durations up to about 270 degrees will be acceptable with factory computers, & those with more duration, will not. Advertised duration by the way, is typically the degrees of crank rotation that the valve is actually on the move. It does not include that time when the cam is closing the tappet clearance. Valve overlap is that time when both intake & exhaust valves are open. If you have a Gen 2 engine, then radical cam changes are limited by the bucket & shim arrangement in the head. The Gen 2 engines have a 31mm cam bucket but only a 28mm shim for the cam to wipe on, which together limit the cam lift & acceleration. With radical cams, the shims can flick out & ruin everything. The Gen 3 however, has the same sized bucket but a wellsecured shim under the bucket (on top of the valve tip) & these cant ever flick out like the Gen 2 ones do. As the cam rides right across the 31mm, wilder cams can be used. Any cam swap however will require the tappet clearances to be re-set using the wide variety of shims readily available from Toyota & a few aftermarket sources. To quickly end this chapter, be aware that reground cams cause real problems in Gen 2 engines because the shims become too thick & fall out more easily. The Gen 3, with its shim under arrangement is more tolerant. In any case, cams ground from new billets are readily

Page3

Programmable computer

As far as we know, there is no readily available plug & play aftermarket computer for the non-turbo engines, but those made for the turbo, may be able to be adapted. The Motec M4 system is perfect for these engines & enables all the factory features to be retained. The real value of systems like these (whatever brand) only comes out when other changes are made. In fact, if youre planning performance increases much beyond about 10%, some sort of programmable computer is mandatory. We try to make up an adaptor harness , rather than chopping off the factory plug.

Internal mods

NA engines can only produce more useable power by some combination of 4 basic methods: 1. ingesting more air & fuel 2. combusting the mixture more efficiently 3. increasing the peak engine revs 4. reducing internal losses In essence, you have to venture into the internals of the engine if you want to significantly improve the power of an NA engine. This is a major leap for many owners who have grown up in an era where performance upgrades mean bolting on a bigger turbo or more simply, increasing the boost of the stock one.

Camshafts

Changes to the camshafts are the single greatest change that can be made to these engines. If you need to stick with the factory computer for budget reasons, then the performance changes will be not as great as they otherwise could be, but certainly noticeable. Basically, the changes you can make are changing the time when

Copyright Terry OBeirne Road & Track 2006.

www.roadandtrack.net.au

Modifying the 3SG non-turbo engine by Terry OBeirne

available here, so we always use these if building any serious performance engine. Regrinds are OK on simple street use cars, provided no more than an extra 1mm of lift is being used. Regrinds always require thicker shims than standard.

Cylinder head

3S compression ratio

Compression ratio (value :1) 11.0 10.0 9.0 8.0 86 Stock flat-top pistons Race NA engine 86.5 87 87.5 Bore (m m ) Stock dished pistons 10.3 9.6 8.9 10.4 9.7 8.9 10.5 9.8 9.0 10.6 9.9 9.1

All the MR2 Gen 2 & 3 heads are designed by Yamaha & generally flow very well for most applications. Despite that, changes can be beneficial. The usual order of actions is: 1. Modify the inlet port to lower restrictions to the absolute minimum. 2. Match the inlet port in the head to the manifold 3. Recut the valves & seats to optimise the flow (commonly called 3 angle valves seats) 4. Cut the head & valve guide to allow longer springs & more cam lift to be used 5. Enlarge the valve & seat diameters by 0.5 to 1.0mm & change to 1-piece stainless valves 6. Offset the exhaust manifold to hinder flow reversions 7. Substantially reshape the inlet port 8. Weld a divider into the combustion chamber to promote gas swirl If you want to run lumpy cams, with lift around 11mm & durations around 300, then you definitely have to factor in a conversion to shim-under buckets. Either use a Gen 3 head which has this arrangement or spend a packet to convert a Gen 2 head with Gen 3 parts or those equivalents made by aftermarket tuners. The number of these steps will basically depend on the intended use of the engine & your budget.

Dry sump

Dry sump systems are generally too exotic for road going cars. They involve housing about 8-10 litres of oil in an external container & pumping it thru the engine via a belt driven pump (see pic below). In racing, it all but eliminates oil surge under extreme cornering or acceleration forces. Internal friction losses are also reduced because a significant vacuum is created in the sump to suck out oil that would normally stick to parts like the crank & rods. Dyno testing usually shows a modest power gain. The pics show a TOMS system as used on an open-wheel Formula 3 race car. The slot in the bottom of the shallow sump (bottom pic) catches all the oil which is then sucked out through 2 holes at one end.

Compression ratio

Increasing the compression ratio (CR) always increases the performance; however, there are limits before uncontrolled detonation of the fuel occurs (pinking). The following graph shows what you can expect with a 3SG engine using a stock composite head gasket (1.2mm compressed) and unmodified combustion chambers. Normal engine reconditioning changes the CR so slightly, it is not worth bothering about. If you are unfortunate enough to have one of the badly machined 3S blocks (common), then extensive machining of the block top may be required to correct it, and the CR will rise by about 0.25. Nowadays, with good 98 or 100 octane fuel, you should be able to handle about 10.5:1. Beyond that value, an aftermarket computer with careful mapping of the ignition, is required. Dont forget that these CR value are static only. High overlap cams will reduce the effective compression ratio. For example, race spec cams with 300 duration or thereabouts, will be able to handle more like 11.5:1 static CR.

Copyright Terry OBeirne Road & Track 2006.

www.roadandtrack.net.au

Page4

Modifying the 3SG non-turbo engine by Terry OBeirne

Introduction to part 2

In this second part I will concentrate on changes that will make a performance engine last longer and/or be smoother. None of these changes are really designed to make power in themselves, & in most cases, they changes can only be made when an engine is apart & being subjected to a n overhaul.

Crankshaft & rods

steel backings, and the mains have grooving to improve oiling. In some cases, the big end bearings can have extra eccentricity and/or clearance, and the choice will be up to the engine builder. For the small extra cost when rebuilding a performance engine, we generally recommend them. Special bolts like those supplied by ARP are marginally better than the stock parts & are good insurance if building an outright racer, but quite un-necessary in stock or lightly modified road car engines.

The factory rods are very good & will withstand anything a nonturbo engine can produce. If anything, they (& the factory pistons) are a bit heavy & that saps power driving them. Lightening the rods is possible, but various cheap aftermarket rods are a bit lighter & most come with quality ARP bolts. The cost of lightening, fitting ARP bolts, shot-peening & finally resizing stock rods, is about 60% of the cost of the cheapest aftermarket rods. Stock 3SG cranks of all versions are prone to cracking. We have developed a package of lightening & nitride hardening which seems to help them. If you are chasing max power, then the main bearing caps are modified to allow them to be stiffened with specially made blocks & bolts. The cap tunnels of the block are align honed (ie made perfectly round & in line).

Oil pumps & coolers

We use an old rule of thumb that every 1000rpm requires 10PSI oil pressure when at normal operating temperature. All (unworn) 3SG pumps can deliver this with a thin shim placed under the circlip of the pressure release valve. Adding more pressure than this just robs the engine of power. If you do this, make sure the circlip goes back the correct way, with the sharp edge outwards. The factory oil to water cooler arrangement under the filter is fine on stock road cars where fast warm up is essential, but otherwise useless. An alternative oil to air cooler is preferred for hard road or track use, but these are best with a thermostat in the oil cooler line. We place a 10 row cooler in behind the drivers side engine air intake & seal it so all the air goes thru it. Oil temps under 80C or over 110C are undesirable, even with very expensive oils & we generally put in a gauge to constantly check this. Oil grades of 5-40 or 10-50 suit most engines.

Water cooling The stock MR2 system seems fine for non-turbo

About 1kg can be relatively easily machined from the 3S crank, & about 2kg if you are prepared to pay for machine time. This package of work allows the engine to rev more freely to 8000rpm & beyond. The TOMS billet crank shown in the adjacent pic totally solves the cracking problem, but is cost prohibitive for all but the most exotic engines. Toyota conrods are typically factory balanced to within 3 grammes (not brilliant by todays standards), but the crankshaft balance can be much worse. Any performance engine needs rebalancing. The crank, rods, pistons, front pulley, flywheel & clutch pressure plate are all balanced individually, followed by selected parts as an assembly. There are now race quality bearings made especially for these engines. Both big-ends and mains have hardened

Copyright Terry OBeirne Road & Track 2006.

performance upgrades. Operating temperatures below 80C or above 110C will cost power (you need a proper temp gauge to measure this). For race engines that spend most of their life with high revs, we slow the water pump by changing the pulley. Under no circumstances remove the thermostat, but if you have an engine with occasional or marginal overheating problems, then a higher flow rate thermostat may solve this.. The Gen 3 thermostat & housing are larger & allow about 25% more flow than the equivalent parts on earlier engines. Changing to a colder (low temp) thermostat rarely helps with chronic overheating problems. The switch in the radiator that controls when the fans switch on & off is prone to problems. If you have a Motec or similar computer, use it to drive the fans.

If you are working on a Gen 3 or later engine, you cannot use the earlier head gasket, or the aftermarket metal layer gaskets, otherwise you will have overheating problems. The water passages between the

Page5

www.roadandtrack.net.au

Modifying the 3SG non-turbo engine by Terry OBeirne

block & the head, & especially up towards the exhaust valves, are quite different on the later engines (the pic of Gen 3 head clearly shows the small hole leading up between the exhaust valves).

Flywheel & clutch

For ultimate engines, the final honing of the bores should be performed with a torque plate. This is thick plate of steel or cast iron, bolted to the block to replicate the presence of a cylinder head. Only a handful of shops around Australia would have one for a 3S.

Lightened flywheels/clutches allow the engine to accelerate faster, so it feels more powerful. The stock flywheel can be lightened by about 500grammes & some drivers may notice this amount, especially if the cams are changed & the engine needs to be driven harder to liberate the power increase. Very light flywheels with integral ring gears, (4kg or less) have to be specially made from steel, as the stock cast iron ones cant be easily or safely lighted very much. A twin plate 5.5 clutch & specially made flywheel for race use only, weighs just over 6kg. Be aware that there are 2 totally different stock flywheels for these engines, & they dont interchange. Use NEW crank to flywheel bolts. Stock Toyota ones are perfectly OK.

Pistons

Cambelts etc If you have modified the cams, or intend to use the engine for competition, then an up-rated cam belt is good insurance. These are readily available for Gen 2, but require other mods to fit them onto Gen 3 because its belt is normally 1 tooth longer). Whatever you do, dont buy a cheap cam belt. Independent tests have proven many cheap belts on the market have inferior construction. Stock Toyota belts are fine, but dont buy just on brand name. Ask for construction details & if its a stock replacement, make sure you get one made with HSN (highly saturated nitrile). The hydraulic belt tensioner can be swapped for a custom made adjustable one which makes changing or removing the belt in the car so much easier. Both tensioner & idler rollers should be changed with the belt, & beware, some aftermarket supplies sell lower spec idler rollers as the tensioner roller, & while they look OK, they wont last as long as they otherwise should.

Stock pistons are OK for all but full-house engines where we use a forged piston with higher compression ratio. Forged pistons have the added benefit of being marginally lighter & of course, dont have the annoying habit of cracking thru the rings lands like stock ones. The shape on the top of the piston can be optimised for ultra-performance engines. Any of the well-known brands are perfectly OK. For outright race use, special coatings can be applied to the piston. Engine blocks 3S blocks (of all forms) are generally poorly machined ex-factory. The bores are often not square to the top deck, which is also often not parallel to the crank centre line. These problems can only be rectified by a machine shop & in conjunction with a rebuild. Fixing the poor machining can liberate power by reducing internal friction. Experience shows that #3 cylinder has the worst water flow around it so it in engines with more than about 150,000km on them, its bore may be unacceptably worn.

Metal treatments For maximum longevity & reliability, several parts can be re-treated metallurgically. We use cryogenic toughening on items like valve springs, valve collets, & flywheels. The crankshaft can be nitrided & the conrods shot-peened. Oil shedding agents are a good idea for crankshafts.

Road and Track is a small engineering shop specialising in performance enhancement work. We supply a large range of stock & performance oriented parts for MR2s Our race experiences with various Toyotas over many years mean we get a large number of these in to be modified, or simply serviced. We design and make many parts, testing them on our own vehicles before releasing them to the public. More info can be found at www.roadandtrack.net.au.

Copyright Terry OBeirne Road & Track 2006.

www.roadandtrack.net.au

Page6

Das könnte Ihnen auch gefallen

- 1993 Toyota Corolla ABSDokument22 Seiten1993 Toyota Corolla ABSAsepPopyHermawan100% (1)

- 4AGE To 7AGE ConversionDokument7 Seiten4AGE To 7AGE Conversionmellymoyo100% (1)

- Engine Control: System OutlineDokument14 SeitenEngine Control: System OutlineHernanCalderonDíaz100% (1)

- Adjustable Fuel Pressure RegulatorDokument5 SeitenAdjustable Fuel Pressure RegulatorAchintya MehrotraNoch keine Bewertungen

- Toyota Yaris 2007Dokument10 SeitenToyota Yaris 2007romeo_mecNoch keine Bewertungen

- Starlet GTDokument38 SeitenStarlet GTjavier.abraham100% (13)

- Toyota Yaris IIIDokument2 SeitenToyota Yaris IIIIoniță Sorin CristianNoch keine Bewertungen

- Accord 1993Dokument1 SeiteAccord 1993Dam Nguyen100% (1)

- RB 25 HeadDokument9 SeitenRB 25 HeadAlexander Dominguez0% (1)

- Mitsubishi Galant Owners Manual 2001: Read/DownloadDokument2 SeitenMitsubishi Galant Owners Manual 2001: Read/DownloadShannanAdams33% (3)

- Archive For The Glanza CategoryDokument6 SeitenArchive For The Glanza CategoryCristian Rosales MorenoNoch keine Bewertungen

- Throttle Body Dan TPS Corolla 88-97Dokument4 SeitenThrottle Body Dan TPS Corolla 88-97Fitri Wibowo100% (1)

- 031 - Engine - Igniter Circuit Malfunction (No. 1)Dokument6 Seiten031 - Engine - Igniter Circuit Malfunction (No. 1)Ayun AhmNoch keine Bewertungen

- System Wiring Diagrams Cooling Fan Circuit, A/TDokument1 SeiteSystem Wiring Diagrams Cooling Fan Circuit, A/TcjtrybiecNoch keine Bewertungen

- T1 Cam Trigger Instructions 1Dokument10 SeitenT1 Cam Trigger Instructions 1Initial_BG100% (1)

- 1 ZzfeDokument8 Seiten1 ZzfeScuderia Redin100% (1)

- Toyota CorollaDokument166 SeitenToyota CorollaGjhgyhbgNoch keine Bewertungen

- DTC 61 No. 2 Speed Sensor Circuit MalfunctionDokument3 SeitenDTC 61 No. 2 Speed Sensor Circuit Malfunctioncelestino tuliaoNoch keine Bewertungen

- 4age VacuumDokument6 Seiten4age VacuumSharul Hakimi100% (5)

- Zspeedracing Master Catalogue 2008Dokument13 SeitenZspeedracing Master Catalogue 2008api-3863246100% (1)

- Honda CRV 2015 Wiring Diagrams Service ManualDokument1 SeiteHonda CRV 2015 Wiring Diagrams Service Manualamandeep kaur0% (1)

- Vafc SettingDokument11 SeitenVafc SettingMohd KhairulNoch keine Bewertungen

- 4afe O2sensor TestDokument3 Seiten4afe O2sensor Testkkg4782Noch keine Bewertungen

- HYUNDAI SANTA FE 2002 - Schemat ElektrycznyDokument60 SeitenHYUNDAI SANTA FE 2002 - Schemat Elektrycznylukasz.mietlowskiNoch keine Bewertungen

- Ae101 3sgte SetupDokument1 SeiteAe101 3sgte SetupjaiusopNoch keine Bewertungen

- Hyper Rev Magazine StarletDokument172 SeitenHyper Rev Magazine StarletJavier Gomez100% (8)

- Toyota 3f PDFDokument5 SeitenToyota 3f PDFJOSE,ENoch keine Bewertungen

- AE86 Levin-TruenoDokument1 SeiteAE86 Levin-TruenoToshiba PortegeNoch keine Bewertungen

- 4AG TuneDokument9 Seiten4AG TuneMohd Hatta100% (1)

- Apex'i Super ITC English ManualDokument37 SeitenApex'i Super ITC English ManualAkemi SeagalNoch keine Bewertungen

- AE101 4AGE 20 Valve Pins 2019Dokument5 SeitenAE101 4AGE 20 Valve Pins 2019jorgeNoch keine Bewertungen

- Apexi Installation Instruction Manual: S-AFC 2Dokument64 SeitenApexi Installation Instruction Manual: S-AFC 2THMotorsports.netNoch keine Bewertungen

- Nissan Ga16de Engine Service ManualDokument3 SeitenNissan Ga16de Engine Service ManualLorenzo Burnley33% (3)

- Camry Gasket Kit-UnlockedDokument28 SeitenCamry Gasket Kit-UnlockeddfbdfzNoch keine Bewertungen

- Transmission Toyota C - Toyota C Transmission - Abcdef - Wiki 3Dokument1 SeiteTransmission Toyota C - Toyota C Transmission - Abcdef - Wiki 3AbdulNoch keine Bewertungen

- Ignition System: 1988 Toyota CelicaDokument7 SeitenIgnition System: 1988 Toyota CelicaToua Yaj100% (1)

- Toyota Altezza Ecu Side Terminal (TP5-7Base) Refer The Following For Special Setting When Modifying The Wiring, EtcDokument9 SeitenToyota Altezza Ecu Side Terminal (TP5-7Base) Refer The Following For Special Setting When Modifying The Wiring, EtcAlifNoch keine Bewertungen

- Speeduino Manual PDFDokument121 SeitenSpeeduino Manual PDFXander StoneNoch keine Bewertungen

- Apex'i AFC2 WiringDokument64 SeitenApex'i AFC2 WiringDave_B0% (1)

- R32.engine - Manual Ca18i, Rb20e, Rb20de, Rb20det, Rb25de & Rb26dettDokument580 SeitenR32.engine - Manual Ca18i, Rb20e, Rb20de, Rb20det, Rb25de & Rb26dettNick Viccajee100% (1)

- Pinout Toyota Jza70Dokument1 SeitePinout Toyota Jza70Anonymous 6Gi5uqJNoch keine Bewertungen

- Yaris: It Can Run. But It Can't HideDokument14 SeitenYaris: It Can Run. But It Can't HideabyzenNoch keine Bewertungen

- Kia Picanto PDFDokument3 SeitenKia Picanto PDFManuales De Maquinaria Jersoncat100% (1)

- Celica Wiring Diagram FullDokument66 SeitenCelica Wiring Diagram Fullda_tru_nigga8122100% (3)

- Safc WiringDokument33 SeitenSafc WiringMarlon CaldoNoch keine Bewertungen

- Apexi RSMDokument52 SeitenApexi RSMAde Rachmat Pandapotan50% (2)

- Nissan Skyline R33 GTS-T Tuning GuideDokument4 SeitenNissan Skyline R33 GTS-T Tuning GuidePhilip BroodrykNoch keine Bewertungen

- Instructions For Pro Climb and Pro Cross 800 Turbo Kits Stage 2Dokument21 SeitenInstructions For Pro Climb and Pro Cross 800 Turbo Kits Stage 2cpcracingNoch keine Bewertungen

- R33 GTST Tuning Stages 1 & 2Dokument4 SeitenR33 GTST Tuning Stages 1 & 2Lijah AzrinNoch keine Bewertungen

- Engine Tuning Stage 1: ExhaustDokument8 SeitenEngine Tuning Stage 1: ExhaustJuan PerezNoch keine Bewertungen

- Stage 1 Instructions For Pro Climb and Pro Cross 800 Turbo KitsDokument18 SeitenStage 1 Instructions For Pro Climb and Pro Cross 800 Turbo KitscpcracingNoch keine Bewertungen

- 2011 CPC Turbo M8 Handbook With Garrett Automotive TurboDokument19 Seiten2011 CPC Turbo M8 Handbook With Garrett Automotive TurbocpcracingNoch keine Bewertungen

- Tuning AdviceDokument9 SeitenTuning Advicejameel babooramNoch keine Bewertungen

- 2011 CPC Turbo Pump Gas M8 Handbook With Garrett Automotive TurboDokument15 Seiten2011 CPC Turbo Pump Gas M8 Handbook With Garrett Automotive TurbocpcracingNoch keine Bewertungen

- Mike Kojima SE-RDokument33 SeitenMike Kojima SE-Rpinoypride172001Noch keine Bewertungen

- Starlet FaqDokument12 SeitenStarlet Faqjavier.abraham100% (2)

- TD 5 EngineDokument6 SeitenTD 5 Enginenormy112Noch keine Bewertungen

- VFR400 Engine Mods-R OliverDokument5 SeitenVFR400 Engine Mods-R OliverAndrés Nuñez0% (1)

- Salary Survey 2013Dokument440 SeitenSalary Survey 2013antontansilNoch keine Bewertungen

- 20 KG Dumbbell ProgramDokument2 Seiten20 KG Dumbbell ProgramBadshah PeerNoch keine Bewertungen

- Challenger 150 Exercise ProgramDokument22 SeitenChallenger 150 Exercise ProgramBadshah Peer25% (4)

- Modifying The Toyota 3SGEDokument6 SeitenModifying The Toyota 3SGEBadshah Peer50% (2)

- Sun Tzu Art WarDokument398 SeitenSun Tzu Art Wartranngan100% (11)

- Sun Tzu Art WarDokument398 SeitenSun Tzu Art Wartranngan100% (11)

- Car BaseDokument91 SeitenCar BaseSpeedoshop RobertoNoch keine Bewertungen

- ILD Parts Manual: INTERLIFT, INC. A Member of MBBDokument24 SeitenILD Parts Manual: INTERLIFT, INC. A Member of MBBRafał DworakNoch keine Bewertungen

- Applications Manual: Section 2 Pressure and Speed Limits For Hydrostatic UnitsDokument14 SeitenApplications Manual: Section 2 Pressure and Speed Limits For Hydrostatic UnitsPatrick QuirionNoch keine Bewertungen

- Tiger 800 Service ManualDokument508 SeitenTiger 800 Service ManualMarcos Samsoniuk83% (6)

- Lennox - Mini Split - 16 SEER - T - 24KDokument3 SeitenLennox - Mini Split - 16 SEER - T - 24KruyNoch keine Bewertungen

- Manual Grimme GT300Dokument10 SeitenManual Grimme GT300Fabiano100% (1)

- Specialist Suppliers To The Oil, Gas, Waterwell and Mining IndustriesDokument12 SeitenSpecialist Suppliers To The Oil, Gas, Waterwell and Mining IndustriesGhinet Teodor-ioanNoch keine Bewertungen

- Configuration Diagrams: Group 80Dokument28 SeitenConfiguration Diagrams: Group 80Stasio PiwowarskiNoch keine Bewertungen

- Turbocharger Division: Specification: Hs 5800 A1F 91 Ms 156 Serial N°: 527 000Dokument17 SeitenTurbocharger Division: Specification: Hs 5800 A1F 91 Ms 156 Serial N°: 527 000ronny ArdiansyahNoch keine Bewertungen

- Boletin Técnico Cta PDF Julio 2001Dokument8 SeitenBoletin Técnico Cta PDF Julio 2001Fabian Carrasco NaulaNoch keine Bewertungen

- RGPH Specification Sheets PDFDokument0 SeitenRGPH Specification Sheets PDFITLHAPNNoch keine Bewertungen

- Coldwork Puller Tooling Manual: For WCI-1700, WCI-1800 and WCI-1900 Puller Guns and AccessoriesDokument21 SeitenColdwork Puller Tooling Manual: For WCI-1700, WCI-1800 and WCI-1900 Puller Guns and AccessoriesWattsonDiazRuizNoch keine Bewertungen

- Adblue Delete: List of Cars Currently Covered by Adblue RemovalDokument3 SeitenAdblue Delete: List of Cars Currently Covered by Adblue RemovalELHADDOUNI PROGNoch keine Bewertungen

- Heliαseries Parts List-65Dokument2 SeitenHeliαseries Parts List-65MatheusNoch keine Bewertungen

- 2018 Subaru OutbackDokument13 Seiten2018 Subaru OutbackValentin BakaievNoch keine Bewertungen

- Broquet Pump - EnglishDokument8 SeitenBroquet Pump - Englisharinda fsNoch keine Bewertungen

- CP66 Series: The Most Robust Pneumatic Nutrunner in Its ClassDokument4 SeitenCP66 Series: The Most Robust Pneumatic Nutrunner in Its ClassJMNoch keine Bewertungen

- TQ340-35 Power Casing Tong Operation & Maintenance ManualDokument18 SeitenTQ340-35 Power Casing Tong Operation & Maintenance ManualAbo FatmaNoch keine Bewertungen

- Hướng Dẫn Bảo Trì Sửa Chữa Xe Tải Hyundai HD120 (Full)Dokument680 SeitenHướng Dẫn Bảo Trì Sửa Chữa Xe Tải Hyundai HD120 (Full)ThủyBìnhNoch keine Bewertungen

- Flight Control QsDokument5 SeitenFlight Control Qssachin jainNoch keine Bewertungen

- MY Pajero Sport VGT Service Plan & PriceDokument1 SeiteMY Pajero Sport VGT Service Plan & PriceNugroho FamNoch keine Bewertungen

- The Vintage Power Wagons 2016 Parts Catalog - Group 01 EngineDokument6 SeitenThe Vintage Power Wagons 2016 Parts Catalog - Group 01 EnginekaiNoch keine Bewertungen

- Rig Inspection ModuSpecDokument514 SeitenRig Inspection ModuSpecAbrarhassan100% (7)

- HP750-E48 XP825-E47 WCU MAR12 CPN46559964 GB PDFDokument114 SeitenHP750-E48 XP825-E47 WCU MAR12 CPN46559964 GB PDFrobert fitzpatrickNoch keine Bewertungen

- Kaizen Super - ManualDokument59 SeitenKaizen Super - Manualvser19100% (1)

- N2 Triplex Pump-MaintenanceDokument14 SeitenN2 Triplex Pump-MaintenanceIbrahim AhmedNoch keine Bewertungen

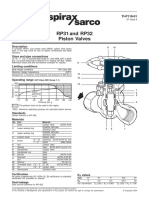

- Spirax Sarco Piston Valve RP31Dokument2 SeitenSpirax Sarco Piston Valve RP31PaulNoch keine Bewertungen

- Tracking Mantra Solutions Pvt. LTD.: Track Any Where Any TimeDokument6 SeitenTracking Mantra Solutions Pvt. LTD.: Track Any Where Any TimeDeepanshu SharmaNoch keine Bewertungen

- DTC C1554/23 Power Supply Relay Failure DTC C1555/25 Motor Relay Welding FailureDokument3 SeitenDTC C1554/23 Power Supply Relay Failure DTC C1555/25 Motor Relay Welding FailureOswaldo Sierra100% (1)

- Elme 817 1 1615 PDFDokument32 SeitenElme 817 1 1615 PDFmarioNoch keine Bewertungen