Beruflich Dokumente

Kultur Dokumente

JSA Tank Coating Work

Hochgeladen von

Perwez21Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

JSA Tank Coating Work

Hochgeladen von

Perwez21Copyright:

Verfügbare Formate

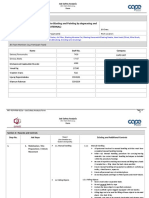

JOB SAFETY ANALYSIS (JSA) TANK MODIFICATION AND REPAIR WORK

JSANumber: Area: TaskDescription Step 1. Activity Sitepreparation

DESPRLK.KJSA001

KorangiandKeamariPRLTanks Hazard

Poorcommunicationbetween workparties. Inexperiencepersons/lackof safetyawareness Heatstress Noise VehiclesMovement

JSATitle: Activity: Uncontrolled Risk H M L

M

CoatingandRapingactivity

Coatingandrapingactivityinsideandoutsidetank Date 5/12/2012

Coatingandrapingactivityinsideandoutsidetank

ControlMeasures

DESCONemployeesshallhavemandatorytraining. Workpermitfromtheclient,withallconcurringpartiessignatures approvalmustbeobtainedpriortostartofworkanddisplayatsite Safetyrequirementsstatedontheworkpermitmustbeavailableonsite andstrictlyfollowed Toolboxtalkshallbeconductedtoallpersonnelonsite&documented beforestartofwork. AppropriatePPEshallbewornbyallpersonnelatsite. AssignedtraineddedicatedBanksmanforjobwithreflectivejacket. Nowaternoworkpolicyshallbefollowed. WorkScheduleaccordingtoheatIndex Earprotectionshallbewornwhererequired. Noisemeterwillbemadeavailableatsite. Maintenanceofequipmentonregularbasis. UseofApproved/Trainedlicensedrivers. Vehiclemovementsonsiteshallbecontrolledbybanksman Appropriatesignagetobeprovided.

ResidualRisk H M L L

2.

Confinedspace entry.

LakeofCommunication

Allpersonnelworkinginconfinedspacemusthave confinedspacetraining. PRLconfinedspaceprocedureshallbefollowed.

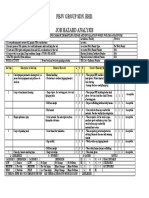

JOB SAFETY ANALYSIS (JSA) TANK MODIFICATION AND REPAIR WORK

JSANumber: Area: TaskDescription Step Activity

DESPRLK.KJSA001

KorangiandKeamariPRLTanks Hazard Ventilation. Damagematerial

JSATitle: Activity: Uncontrolled Risk H M L

CoatingandRapingactivity

Coatingandrapingactivityinsideandoutsidetank Date 5/12/2012

Coatingandrapingactivityinsideandoutsidetank

ResidualRisk M L

Oxygendeficiency accumulationoftoxic gases

Physicalhazards

ControlMeasures H Holewatcherisattentiveallthetimeduringconfined spaceactivity.LightingprovidedinCSEtobe24V. Easycommunicationbetweenholewatcherandsupervisor isestablishedallthetime. Ensurethatpassageandtransportroutisclearduring confinedspaceactivities.Properaccess/agreesshouldbe maintained. GastesttobedonebyAGTpriortoenteringintothe confinedspace. Atrainedandqualifiedindividualshouldoutsidethetank withtheresponsibilityofensuringthesafetyofauthorized entrants(Fabricator,Fitter,Weldere.tc)throughthe performancepreentrybriefing,checkingandinspecting PPE,equipmentandtoolsandperformingregular monitoringinensuringpersonworkinginsidepiperemains safeforentryandoccupation. Awrittenrescueplanthathasprovisionforconductinga timelyrescueofindividualsworkinginsidethepipe (ConfinedSpace)shouldbekeptonsite.Raisingthealarm intheeventofanemergencyusingtheradio/mobile

JOB SAFETY ANALYSIS (JSA) TANK MODIFICATION AND REPAIR WORK

JSANumber: Area: TaskDescription Step Activity

DESPRLK.KJSA001

KorangiandKeamariPRLTanks Hazard Lackofoxygen /oxygen/air deficiency Unauthorizedentrant Improperstackingof material

JSATitle: Activity: Uncontrolled Risk H M L

CoatingandRapingactivity

Coatingandrapingactivityinsideandoutsidetank Date 5/12/2012

Coatingandrapingactivityinsideandoutsidetank

ControlMeasures phonesprovidedtothem. Ensureeffectivecommunicationsystemsfortheentryare tested. Properlightshouldbeprovidedlessthan25v. Allmaterialstackproperandcategorywise. Rescuearrangementshallbemadewhileworkingmore thanfivemeterinsidelargeboresize. PRLSHE&SProcedureshallbefollowed. Closesupervisionrequiredwhileworkinginside. Executetheworkunderclosesupervisionandpresenceof holewatcher. Properairsupplytobeprovidedorairmoverwillbe provided. Properventilationshallbethere. Workingcrewshellbetrainedforconfinedspaceworking. CorrectPPEshouldbeworn MSDSshouldbekeptatsiteforPPEcompliances Appropriatemaskshouldbeworn ResidualRisk H M L

11. Coating Works

Healthhazards. RespirationHazards.

JOB SAFETY ANALYSIS (JSA) TANK MODIFICATION AND REPAIR WORK

JSANumber: Area: TaskDescription Step Activity

DESPRLK.KJSA001

KorangiandKeamariPRLTanks Hazard ManualHandling&storage paint. Environmentalpollution ChemicalSpillage Inhalationoftoxicfumes Orirritatingeyes. Splatterfrombrush. Slips,Trips,andFalls. Fire

JSATitle: Activity: Uncontrolled Risk H M L

CoatingandRapingactivity

Coatingandrapingactivityinsideandoutsidetank Date 5/12/2012

Coatingandrapingactivityinsideandoutsidetank

ControlMeasures Handsshouldbecleanedwithsoapsolutionbeforeeating StorageofpaintasperMSDS WastePainttinstoberemovedfromtheworksiteand disposetodesignatedarea(asperJGCProcedure) Providesecondarycontainment110%oflargestcane. Keeppropertypeoffireextinguisheratsite. Keepminimumstocklevelatsite. Spillstobereportedimmediately PortableEyewashbottleshallbeprovided Explaintheexpectedhazardsandremediestotheworking crewschemicalsthattheyaredealingwith.Hazardous materialtrainingtobedone. Caretobetakenbyallpersonshandlingchemicalsnotto spill,splashnorhavecontactwiththesubstances. Safetyharness/fallarrestortobewornforworkatheight 100%tieoffofsafetyharnessalltimesduring erection/dismantling ResidualRisk H M L

JOB SAFETY ANALYSIS (JSA) TANK MODIFICATION AND REPAIR WORK

JSANumber: Area: TaskDescription Step 13 Activity

DESPRLK.KJSA001

KorangiandKeamariPRLTanks Hazard

JSATitle: Activity: Uncontrolled Risk H M L M

CoatingandRapingactivity

Coatingandrapingactivityinsideandoutsidetank Date 5/12/2012

Coatingandrapingactivityinsideandoutsidetank

ControlMeasures Supervisortobeonsiteatalltimesduringworkactivity. AdequatelightingatworkareaandAccess/Egressarea. Emergencyroutetomusterpointtobeclearlyilluminated. Propercablemanagement Useclearsafetyglassfornightworkforgoodvisibility. WarningLightsandsignboards. TrainedFlagmanforequipmentmovementprovidedwith signaltorch. Closesupervisionrequiredwhileworkinginnightshift. EducatetheworkforceaboutEmergencyProcedure. Allsafetysignboardshallbedisplayedproperlyatsite. IncaseofanyEmergencyallworkwillbestopped,Shut downallrunningequipment&Machineriesandreportedto MusterPoint ProperAccess&Egressshallbeavailable. AllWorkforcesshallknowtheMusterPointlocation. PRLEmergencyProceduretobefollowed. ResidualRisk H M L L

Extended hour/nightWorks (Actualworkswill bethesameasday work)

Inadequatelightinginand aroundworkareas, causingshadowsorpoorly litworkareasthatcould resultinunsafeactsand injuriestakingplace

14

Emergency Procedure/ Response

PoorCommunication

ImproperAccess/Egress

JOB SAFETY ANALYSIS (JSA) TANK MODIFICATION AND REPAIR WORK

JSANumber: Area: TaskDescription Step Activity

DESPRLK.KJSA001

KorangiandKeamariPRLTanks Hazard

JSATitle: Activity: Uncontrolled Risk H M L

CoatingandRapingactivity

Coatingandrapingactivityinsideandoutsidetank Date 5/12/2012

Coatingandrapingactivityinsideandoutsidetank

ControlMeasures Emergency#00000000 PRLMedical#00000000 Allwastegeneratedshallbecontainedanddisposedoffin designatedwasteskips. Donotstorematerials/equipmentsinsidetheplantarea. UseProperPersonalprotectiveequipmentforhandlingof waste. Allmaterialsshallberemovedfromthesitetoasafe storagelocationimmediatelyafterthework. ResidualRisk H M L

15. Housekeeping

Tripsandfall

SharpObjects

Equipmentdamage

Approved_____________________________________________________________ SignaturePrintDate PerformingParty____________________________________________________________ SignaturePrintDate

JOB SAFETY ANALYSIS (JSA) TANK MODIFICATION AND REPAIR WORK

Das könnte Ihnen auch gefallen

- Appendix A-Job Safety Analysis FormDokument3 SeitenAppendix A-Job Safety Analysis Formjiks_i4uNoch keine Bewertungen

- 704 Area Vehicle Entry ProcedureDokument11 Seiten704 Area Vehicle Entry ProcedureObominuru Egwonor FestusNoch keine Bewertungen

- Ehv SWP Form Scaffolding RemovalDokument2 SeitenEhv SWP Form Scaffolding RemovalSn AhsanNoch keine Bewertungen

- JSA For New EmployeesDokument20 SeitenJSA For New EmployeesNilayNoch keine Bewertungen

- Workplace Hazards in ConstructionDokument2 SeitenWorkplace Hazards in ConstructionDWi Uwee DejHeNoch keine Bewertungen

- Petrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.013Dokument5 SeitenPetrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.013Yosua SitumorangNoch keine Bewertungen

- JSA-03 Shed DismantlingDokument3 SeitenJSA-03 Shed DismantlingSwaroop Cherry0% (1)

- 01 JSA CLEANING MgO Rev 05 017 BIDokument7 Seiten01 JSA CLEANING MgO Rev 05 017 BIMohd KhaidirNoch keine Bewertungen

- Job Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety PersonnelDokument2 SeitenJob Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety Personnelmahammed saleemNoch keine Bewertungen

- Asian Paints - Prem Gloss EnamelDokument1 SeiteAsian Paints - Prem Gloss EnamelwilliumstNoch keine Bewertungen

- How Chin Engineering: Job Safety AnalysisDokument5 SeitenHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNoch keine Bewertungen

- AEG - JSA - 107 - Oxygen Acetylene Torch PDFDokument2 SeitenAEG - JSA - 107 - Oxygen Acetylene Torch PDFanon_421433640Noch keine Bewertungen

- JSA NO 3-Pile CapDokument8 SeitenJSA NO 3-Pile Capknabpsho50% (2)

- Job Safety AnalysisDokument1 SeiteJob Safety AnalysisWati KaNoch keine Bewertungen

- Ev02 - Brief Program For New Work at Height CampaignDokument2 SeitenEv02 - Brief Program For New Work at Height CampaignFrancis Enriquez TanNoch keine Bewertungen

- HSE Department Graduate Associate Program and IJM Scholar Program Project MonitoringDokument16 SeitenHSE Department Graduate Associate Program and IJM Scholar Program Project MonitoringRoza AzaleaNoch keine Bewertungen

- Working at Height PresentationDokument11 SeitenWorking at Height PresentationAbdul Hameed OmarNoch keine Bewertungen

- Petrochina International Jabung LTD.: Job Safety AnalysisDokument4 SeitenPetrochina International Jabung LTD.: Job Safety AnalysisYosua SitumorangNoch keine Bewertungen

- SHOT BLASTING SAFETYDokument3 SeitenSHOT BLASTING SAFETYAkhilesh KumarNoch keine Bewertungen

- JSA Pipe Installation 2012Dokument2 SeitenJSA Pipe Installation 2012Deshbandhu Aman Pandey100% (2)

- Health and Safety Induction ChecklistDokument2 SeitenHealth and Safety Induction ChecklistYathawan Nair ThamutharamNoch keine Bewertungen

- SWP 02 - Use of Mobile ScaffoldDokument4 SeitenSWP 02 - Use of Mobile ScaffoldGerald Wong NttNoch keine Bewertungen

- Jsa Welding Diesel PipelineDokument3 SeitenJsa Welding Diesel PipelineHow Chin Engineering Sdn BhdNoch keine Bewertungen

- Abrasive Blasting Inspection Checklist - Rev 00Dokument1 SeiteAbrasive Blasting Inspection Checklist - Rev 00okba labdiNoch keine Bewertungen

- Rumaila Working at Height PermitDokument2 SeitenRumaila Working at Height PermitMohammed KadhimNoch keine Bewertungen

- SWP Grinder Bench AS520Dokument1 SeiteSWP Grinder Bench AS520Tosif AliNoch keine Bewertungen

- Ocp BatchingDokument1 SeiteOcp BatchingAarya Mishra TiwariNoch keine Bewertungen

- Project: Install Generator For Back Up Power Supply For Building 3056 For ShedgumDokument11 SeitenProject: Install Generator For Back Up Power Supply For Building 3056 For ShedgumAnonymous voA5Tb0Noch keine Bewertungen

- Employee Incident Report Form 1 1Dokument3 SeitenEmployee Incident Report Form 1 1api-459048769100% (1)

- WELDING AND CUTTING SAFETYDokument14 SeitenWELDING AND CUTTING SAFETYinfos2magi856Noch keine Bewertungen

- Caretaker Risk Assessment - Working at HeightDokument8 SeitenCaretaker Risk Assessment - Working at HeightLina MarcelaNoch keine Bewertungen

- PTO PaintingDokument2 SeitenPTO Paintinggrant100% (1)

- Lifting Support Risk AssessmentDokument10 SeitenLifting Support Risk AssessmentcitraNoch keine Bewertungen

- Hira - Excavation, PCC, RCCDokument6 SeitenHira - Excavation, PCC, RCCPrithika AnbuNoch keine Bewertungen

- JSA of Charging UnitDokument3 SeitenJSA of Charging UnitMuhammad AliNoch keine Bewertungen

- JHA For Installation 2 Inch Nozzle..Dokument6 SeitenJHA For Installation 2 Inch Nozzle..arnolhari100% (1)

- JSA - Blasting - EXTERNALDokument13 SeitenJSA - Blasting - EXTERNALAzad pravesh khanNoch keine Bewertungen

- SOP For Use of Grinder Machines in WorkshopDokument8 SeitenSOP For Use of Grinder Machines in WorkshopFaisal RajaNoch keine Bewertungen

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Dokument6 SeitenThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Nitesh KumarNoch keine Bewertungen

- Dry Bulk Product Safety SOPDokument14 SeitenDry Bulk Product Safety SOPWan Sek ChoonNoch keine Bewertungen

- Scaffold Inspection Report 1Dokument2 SeitenScaffold Inspection Report 1ronachaif3191Noch keine Bewertungen

- Building De-Dusting JSADokument3 SeitenBuilding De-Dusting JSAJayesh J PillaiNoch keine Bewertungen

- JsaDokument10 SeitenJsaTanzeel LiaqatNoch keine Bewertungen

- JSA For Coating and Raping Activity in TankDokument7 SeitenJSA For Coating and Raping Activity in TankEslam lotfy- Eslam elsadatNoch keine Bewertungen

- Concrete Mixer Safety ChecklistDokument1 SeiteConcrete Mixer Safety ChecklistSafety Man Shop100% (1)

- Excavation Permit FormDokument2 SeitenExcavation Permit FormKarim KachourNoch keine Bewertungen

- Job Safety Analysis WorksheetDokument14 SeitenJob Safety Analysis WorksheetCherry Betonio100% (2)

- Housekeeping Hazards Tool Box TalkDokument1 SeiteHousekeeping Hazards Tool Box TalkAli Alqaisy100% (1)

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDokument5 SeitenThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh KumarNoch keine Bewertungen

- JSA NO 2 Piling WorkDokument6 SeitenJSA NO 2 Piling WorkfadliNoch keine Bewertungen

- JHA - (Power Brush & Touch-Up Painting Activities 1)Dokument1 SeiteJHA - (Power Brush & Touch-Up Painting Activities 1)shaiful annuarNoch keine Bewertungen

- Bending MachineDokument52 SeitenBending MachineFarrukh AhmedNoch keine Bewertungen

- Blinding and De-Blinding SWSDokument11 SeitenBlinding and De-Blinding SWSThái Đạo Phạm Lê100% (1)

- Part 3 ObservationsDokument7 SeitenPart 3 ObservationsAmjadNoch keine Bewertungen

- AL AIN MALL WORK PERMITDokument1 SeiteAL AIN MALL WORK PERMITVeterano 1968Noch keine Bewertungen

- JHA Arc WeldingDokument2 SeitenJHA Arc WeldingechaNoch keine Bewertungen

- Name Signature Date Name Signature Date Name Signature DateDokument1 SeiteName Signature Date Name Signature Date Name Signature DateMithlesh SinghNoch keine Bewertungen

- Nebosh Igc 3 Report-1-1 - 1Dokument17 SeitenNebosh Igc 3 Report-1-1 - 1Muhammad ShahzaibNoch keine Bewertungen

- TANK MODIFICATION REPAIRDokument18 SeitenTANK MODIFICATION REPAIRPerwez21100% (2)

- Why Implement a Safety and Health Program to Reduce Costs and Improve BusinessDokument1 SeiteWhy Implement a Safety and Health Program to Reduce Costs and Improve BusinessPerwez21Noch keine Bewertungen

- Guide Emp RecognitionDokument8 SeitenGuide Emp RecognitionPerwez21Noch keine Bewertungen

- Common Materials That May Contain AsbestosDokument14 SeitenCommon Materials That May Contain AsbestosPerwez21Noch keine Bewertungen

- Asbestos Information and TrainingDokument7 SeitenAsbestos Information and TrainingPerwez21Noch keine Bewertungen

- Health and Safety Induction - ChecklistDokument3 SeitenHealth and Safety Induction - ChecklistPerwez21100% (1)

- Const PK Qa&Qc Ms C PCL 14 Method Statementfor CF Silo Concrete WorksDokument7 SeitenConst PK Qa&Qc Ms C PCL 14 Method Statementfor CF Silo Concrete WorksPerwez21Noch keine Bewertungen

- Management LeadershipDokument1 SeiteManagement LeadershipPerwez21Noch keine Bewertungen

- Construction Safety Budget BreakdownDokument3 SeitenConstruction Safety Budget BreakdownPerwez2150% (2)

- Workplace Vehicle Safety Tips Under 40 CharactersDokument2 SeitenWorkplace Vehicle Safety Tips Under 40 CharactersPerwez21Noch keine Bewertungen

- Adults Can Make New Brain Cells Even in Their 70s: NewsweekDokument5 SeitenAdults Can Make New Brain Cells Even in Their 70s: NewsweekPerwez21Noch keine Bewertungen

- Guide to Selecting and Purchasing Hammer CrushersDokument24 SeitenGuide to Selecting and Purchasing Hammer CrushersPerwez21100% (1)

- Construction Dust Control Measures GuideDokument3 SeitenConstruction Dust Control Measures GuidePerwez210% (1)

- BbsDokument23 SeitenBbsPerwez21Noch keine Bewertungen

- Const PK Qa&Qc Ms C PCL 02 Concrete WorkDokument8 SeitenConst PK Qa&Qc Ms C PCL 02 Concrete WorkPerwez21Noch keine Bewertungen

- HSE Flyer On Falling Objects April 2018Dokument4 SeitenHSE Flyer On Falling Objects April 2018Perwez21Noch keine Bewertungen

- HSE Flyer On Falling ObjectsDokument1 SeiteHSE Flyer On Falling ObjectsPerwez21Noch keine Bewertungen

- The Surahs Prophet (S.a.w) Used To ReciteDokument16 SeitenThe Surahs Prophet (S.a.w) Used To RecitePerwez21Noch keine Bewertungen

- Health and Safety Induction - ChecklistDokument3 SeitenHealth and Safety Induction - ChecklistPerwez210% (1)

- HSE-SOP-14 Transportation Logistics Safety ManagementDokument29 SeitenHSE-SOP-14 Transportation Logistics Safety ManagementPerwez2190% (10)

- Power of DoaDokument76 SeitenPower of DoaAbu MusaNoch keine Bewertungen

- Virtues and Laws Pertaining To BismillahDokument18 SeitenVirtues and Laws Pertaining To BismillahPerwez21Noch keine Bewertungen

- Hilti 1-9-16 SDS Max Rotary Hammer DrillDokument10 SeitenHilti 1-9-16 SDS Max Rotary Hammer DrillPerwez21Noch keine Bewertungen

- The Surahs Prophet (S.a.w) Used To ReciteDokument16 SeitenThe Surahs Prophet (S.a.w) Used To RecitePerwez21Noch keine Bewertungen

- Guide Emp RecognitionDokument8 SeitenGuide Emp RecognitionPerwez21Noch keine Bewertungen

- Management LeadershipDokument1 SeiteManagement LeadershipPerwez21Noch keine Bewertungen

- Standard SOP Recruitment ProcedureDokument3 SeitenStandard SOP Recruitment ProcedurePerwez21Noch keine Bewertungen

- Pioneer Cement Project Color Coding: Color Code For Rigging GearsDokument1 SeitePioneer Cement Project Color Coding: Color Code For Rigging GearsPerwez21Noch keine Bewertungen

- JSA-For Hot Jobs NRL (E-64)Dokument3 SeitenJSA-For Hot Jobs NRL (E-64)Perwez21Noch keine Bewertungen

- Managment Walk DownDokument2 SeitenManagment Walk DownPerwez21Noch keine Bewertungen

- Electrical Inspection Color CodeDokument3 SeitenElectrical Inspection Color CodePerwez21Noch keine Bewertungen

- Disaster Management, Electrical Safety Procedures and Accident PreventionDokument261 SeitenDisaster Management, Electrical Safety Procedures and Accident PreventionGunadevan ChandrasekaranNoch keine Bewertungen

- CISSP Cheat Sheet Domain 1-2 PDFDokument1 SeiteCISSP Cheat Sheet Domain 1-2 PDFnjNoch keine Bewertungen

- Health Safety Committee Meeting MinutesDokument3 SeitenHealth Safety Committee Meeting MinutesMuhammad Iqbal NiyaziNoch keine Bewertungen

- PELs TLV 2018 PORTUGUÊS OSHA ACGIH NIOSH PDFDokument64 SeitenPELs TLV 2018 PORTUGUÊS OSHA ACGIH NIOSH PDFMedlei CurzelNoch keine Bewertungen

- A Study On Job Safety Analysis of Sewing Operation in Textile IndustriesDokument6 SeitenA Study On Job Safety Analysis of Sewing Operation in Textile Industriesruchika prasadNoch keine Bewertungen

- HS 065 Objectives and ProgrammesDokument14 SeitenHS 065 Objectives and ProgrammesgrantNoch keine Bewertungen

- (PAPER) Trbojevic, V. M. (2009) Another Look at Risk and Structural Reliability Criteria.Dokument6 Seiten(PAPER) Trbojevic, V. M. (2009) Another Look at Risk and Structural Reliability Criteria.O SNoch keine Bewertungen

- Portable Electrical Equipment Prompt SheetDokument2 SeitenPortable Electrical Equipment Prompt Sheetmyo zaw100% (1)

- Hazardous Waste Management Questions and AnswersDokument3 SeitenHazardous Waste Management Questions and Answersmary joy v, chiquilloNoch keine Bewertungen

- Safety Data Sheet: 1 Identification of The Substance/mixture and of The Company/undertakingDokument7 SeitenSafety Data Sheet: 1 Identification of The Substance/mixture and of The Company/undertakingBradyNoch keine Bewertungen

- Isobutane (0.001% - 1.30%), Oxygen (19.5% - 23.5%) in Balance NitrogenDokument9 SeitenIsobutane (0.001% - 1.30%), Oxygen (19.5% - 23.5%) in Balance NitrogentruongNoch keine Bewertungen

- Questionnaire: Personal Information: A. Name of Respondent: B. Designation: C. Department: D. Marital StatusDokument10 SeitenQuestionnaire: Personal Information: A. Name of Respondent: B. Designation: C. Department: D. Marital Statusanon_567413438Noch keine Bewertungen

- SHM HSE 001 Health Safety Environment ManualDokument53 SeitenSHM HSE 001 Health Safety Environment ManualAnonymous 7XSrezBVm100% (1)

- Laboratory Biosecurity: A Survey of The U.S. Bioscience CommunityDokument6 SeitenLaboratory Biosecurity: A Survey of The U.S. Bioscience CommunityAle Peña GalarzaNoch keine Bewertungen

- Process Hazard AnalysisDokument103 SeitenProcess Hazard AnalysisSabrinaQurrotaayun50% (2)

- Shell Corena S4 R 68 MSDSDokument7 SeitenShell Corena S4 R 68 MSDSNg Thiam YongNoch keine Bewertungen

- MSDS 1-Bromooctane (Sigma Aldrich)Dokument8 SeitenMSDS 1-Bromooctane (Sigma Aldrich)David SonyNoch keine Bewertungen

- Noise HazardsDokument27 SeitenNoise HazardsZainorin Ali0% (1)

- 3.05B - Mock Drill Report - DISH 10.03.14Dokument4 Seiten3.05B - Mock Drill Report - DISH 10.03.14Vaibhav Vithoba Naik88% (8)

- Construction Project Emergency Response PlanDokument24 SeitenConstruction Project Emergency Response PlanALADINHENoch keine Bewertungen

- Pre-Task Planning, Risk AnalysisDokument39 SeitenPre-Task Planning, Risk Analysismyfelb100% (1)

- Fire Safety Checklist - 31st July 2018Dokument2 SeitenFire Safety Checklist - 31st July 2018VK RathoreNoch keine Bewertungen

- Identification of The Substance / Preparation and Company: Product - COTTWET Rev. Date - 01.08.2016Dokument5 SeitenIdentification of The Substance / Preparation and Company: Product - COTTWET Rev. Date - 01.08.2016raju_hosssenNoch keine Bewertungen

- HSE risk assessment for deluge foam systemDokument7 SeitenHSE risk assessment for deluge foam systemnathisonsNoch keine Bewertungen

- NEBOSH International General Certificate in Occupational Safety and HealthDokument5 SeitenNEBOSH International General Certificate in Occupational Safety and Healthوأكثرهم كارهونNoch keine Bewertungen

- Beware of Signal Leakage: TEMPEST and Common Criteria StandardsDokument4 SeitenBeware of Signal Leakage: TEMPEST and Common Criteria StandardsViorel AldeaNoch keine Bewertungen

- BS 476-7:1997 Classification of Spread of FlameDokument1 SeiteBS 476-7:1997 Classification of Spread of Flamejuli_radNoch keine Bewertungen

- Supreme 5W-30: Safety Data SheetDokument10 SeitenSupreme 5W-30: Safety Data SheetZuhailiNoch keine Bewertungen

- CPF-JSA-018 Drilling and Pipes Support Erection ZONE CLASS0Dokument5 SeitenCPF-JSA-018 Drilling and Pipes Support Erection ZONE CLASS0MajdiSahnounNoch keine Bewertungen

- COSHH Assessment - MasterGlenium Sky 8711Dokument2 SeitenCOSHH Assessment - MasterGlenium Sky 8711Clifford100% (1)