Beruflich Dokumente

Kultur Dokumente

Split Meters

Hochgeladen von

rafathnisar100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

3K Ansichten2 SeitenELECTRICITY DISPENSER TYPE Single phase 2 wire Measurement and Control Unit (MCU) 3 x Single pole latch contactor disconnect (Amps) Programmable current trip USER INTERFACE Keypad Token type a large format custom LCD that supports numerics, a bar graph and icons, indicates low credit, token acceptance or rejection, the rate of consumption, remaining electricity credit, power on, and the status of the disconnect device.

Originalbeschreibung:

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenELECTRICITY DISPENSER TYPE Single phase 2 wire Measurement and Control Unit (MCU) 3 x Single pole latch contactor disconnect (Amps) Programmable current trip USER INTERFACE Keypad Token type a large format custom LCD that supports numerics, a bar graph and icons, indicates low credit, token acceptance or rejection, the rate of consumption, remaining electricity credit, power on, and the status of the disconnect device.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

3K Ansichten2 SeitenSplit Meters

Hochgeladen von

rafathnisarELECTRICITY DISPENSER TYPE Single phase 2 wire Measurement and Control Unit (MCU) 3 x Single pole latch contactor disconnect (Amps) Programmable current trip USER INTERFACE Keypad Token type a large format custom LCD that supports numerics, a bar graph and icons, indicates low credit, token acceptance or rejection, the rate of consumption, remaining electricity credit, power on, and the status of the disconnect device.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

MCU UIU

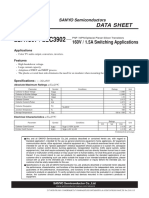

BEC 33/41/44/70p– technical specifications ELECTRICITY DISPENSER TYPE

Single phase 2 wire Measurement and Control Unit (MCU)

BEC 33

-

BEC 41 BEC 44 70P

-

electricity split meters

Three phase 4 wire Measurement and Control Unit (MCU) - - -

Single pole internal latch Contactor (Amps) 80 80 -

3 x Single pole latch contactor disconnect (Amps) 100 -

Programmable current trip

USER INTERFACE

N/A BEC 33/41/44/70P

Keypad Token type - - -

A large format custom LCD that supports numerics, a bar graph and - - -

icons, indicates low credit, token acceptance or rejection, the rate of

consumption, remaining electricity credit, power on, and the status

of the disconnect device

An LED indicating the rate of consumption 1000 pulses / kWh

SPECIFICATIONS / STANDARDS

SABS 1524 : 1994 x

SABS IEC 1036 : 1990 Alternating Current Static

Watt-Hour Meters for Active Energy

SABS ISO 9001 : 1994

NRS 009-4-2 : 1994 N/A

IEC68-2-27 Housing and electronics as per shock test

IEC68-2-6 Housing and electronics as per vibration test

ESKOM STS (Standard Transfer Specification) N/A

ESKOM MC 171

ESKOM MC 115 N/A

ESKOM MC 195 N/A

ESKOM TRMSCAAP rev 2 N/A

ESKOM DTS 1026 N/A

ENVIRONMENTAL

IP Rating 51 without suction

Humidity

Operating temperature range -10˚C to +55˚C

Storage temperature range -25˚C to +70˚C

SUPPLY VOLTAGE 70P

Rated voltage per phase 230 230 230 Max 25Vdc KEYPAD USER INTERFACE UNIT

Maximum continuous supply for normal operation 265 265 265 -

Minimum continuous supply for normal operation 180 180 180 -

Maximum continuous withstand voltage 400 400 400 -

LOAD CURRENT

Base current (Ib) in Amps 25 20 20 -

Accuracy range of 2.0% @ Rated voltage & unity power factor 2.5 – 100 2-60 2-60 -

Accuracy range of 2.5% @ Rated voltage & unity power factor 1.25 – 2.5 1-2 1-2 -

Accuracy of 2.5% @ Rated voltage & half power factor 2.5 – 5.0 2-4 2-4 -

Maximum current (Im) in Amps 100 80 80 -

Minimum registered load current (0.005Ib) in Amps 125 0,1 0,1 -

Maximum creep current (0.002Ib) in Amps 50 0,04 0,04 -

PROTECTION

Impulse withstand – 5KA/5KV N/A

POWER CONSUMED

Real power in W 3 <1 <1 N/A

Active power in VA 30 <10 <10 N/A

HOUSING

UIU is surface mounted with two hidden terminals for the - - -

communication wires

Maximum size of conductors 25mm 25mm 25mm

UIU Plastic material Bayblend FR90 (C-cream G-Grey) - - - C

IP rating 54 54 54 51

Proprietary Plastic seals - -

Wire seals - -

MCU housing conforms to BS5685 Footprint - -

Not polarity sensitive N/A N/A N/A

Maximum transmission range is 100m N/A N/A N/A

Protected against interference

SUPPORT

Conlog Hand Held Reader Rate LED verification - -

Hand Held Reader Optical data dump (F-Flag) x x x

Hand Held Reader probe as per MC171 -

BEC 44

Compatible with standard load (2.3 kW resistive) -

SINGLE PHASE

PACKAGING MEASUREMENT & CONTROL UNIT

Individual unit mass in Kg 2.5 0.4 0.25

Dimensions of meter in mm (height x width x depth) 275x150x140 140x40x90 135x135x45

GROWGRAPHICS 4709

Units per box 1 10 10

Dimensions of packaging in mm (height x width x depth) 280x220x180 360x220x180 260x220x180

Units per pallet 80 Units 1000 Units 1000 Units

Pallet Size in mm 1200x1000 1200x1000 1200x1000 1200x1000

Pallet mass in kg 252 472 312

Conlog reserves the right to alter without notice the specification, design, price or conditions of supply of any product or service.

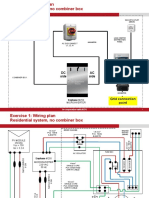

The Conlog E-Kard split meter has been designed

split electricity meters

for maximum security against fraud whilst still

retaining customer convenience. The E-Kard split

meter is available for both single and three phase

meter applications.

The split meter separates the User Interface Unit

(UIU) from the Measurement and Control Unit

(MCU). The MCU can be placed in the existing

meter box for retrofit installations or for ultimate

security, these units can even be placed in a secure

pole-mounted housing. The two units communicate

with each other over a pair of communication wires.

Measurement and Control Unit (MCU) FEATURES

The MCU contains the measurement and control

circuits. This includes; a power supply, a reset • UIU and MCU split for added security

circuit, latch driver, voltage and current sensing and convenience

circuits, a non volatile memory and either a single

80 Amp (BEC 41 and 44) or three single pole • BS Footprint or the world’s smallest

latched contactors rated at 100 Amps (BEC 33). housing which can be fitted onto a

BEC 41 and BEC 33 utilise the BS footprint making

BEC 41 standard DIN Rail

them ideal for retrofit whereas the BEC 44 offers

SINGLE PHASE MEASUREMENT & CONTROL UNIT

(BS FOOTPRINT) the world’s smallest MCU allowing the Utility to fit • Neat, durable units quick and simple

up to 10 individual units in a single box. The units

to mount

can be mounted onto a standard DIN rail for ease

of installation. Each user is allocated one MCU and • Custom designed LCD for maximum

one UIU, which are wired to each other. user friendliness

When replacing a conventional meter with an E-

Kard pre-payment split meter, there is no need for

• Factory sealed, no access to latching

the Utility to replace the wiring from the meter box contactor

to the home with secure wiring as the

• Electronics inaccessible unless units

measurement still occurs at the original meter box.

User Interface Unit (UIU)

are excessively vandalised

The User interface is installed in the consumer’s • Electronic circuits protected against

home for ease of token entry and communication

over-voltage

regarding available credit and indication of

consumption. The UIU forms the physical interface • Protected against low supply voltage

between the user and the remote meter MCU.

The UIU draws its power from the MCU via the

communication wires. All Conlog meters are

designed to ensure user friendliness thus

incorporating a large format custom designed LCD

display and a rate LED that gives a visual indication

of consumption. Credit is transferred by means of

a keypad (70P). Secure data transfer takes place

via an encryption algorithm included within the

BEC 33 Standard Transfer Specification* (STS). Reliability

THREE PHASE MEASUREMENT & CONTROL UNIT and durability are enhanced as the unit is

completely sealed and tamper resistant.

Conlog (Pty) Ltd

P.O. Box 2332 Durban 4000 RSA

270 Brickfield Road Overport 4001

South Africa

*S.T.S. developed by Conlog in conjunction with Eskom as the industry standard. Telephone: +27-31-268-1111

Facsimile: +27-31-268-1500

e-mail: corporate@conlog.co.za

Internet: www.conlog.co.za

Das könnte Ihnen auch gefallen

- Danh Sach Khach Hang VIP Diamond PlazaDokument9 SeitenDanh Sach Khach Hang VIP Diamond PlazaHiệu chuẩn Hiệu chuẩnNoch keine Bewertungen

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Von EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Bewertung: 4.5 von 5 Sternen4.5/5 (3)

- HandbookDokument194 SeitenHandbookSofia AgonalNoch keine Bewertungen

- SQL Datetime Conversion - String Date Convert Formats - SQLUSA PDFDokument13 SeitenSQL Datetime Conversion - String Date Convert Formats - SQLUSA PDFRaul E CardozoNoch keine Bewertungen

- Dynamics of Interest Rate and Equity VolatilityDokument9 SeitenDynamics of Interest Rate and Equity VolatilityZhenhuan SongNoch keine Bewertungen

- 12kV Air Insulated Metal Clad Switchgear PanelDokument2 Seiten12kV Air Insulated Metal Clad Switchgear PanelHarmanPreetNoch keine Bewertungen

- Flow Chart For SiFUS Strata Title ApplicationDokument5 SeitenFlow Chart For SiFUS Strata Title ApplicationPhang Han XiangNoch keine Bewertungen

- EC2 406006 001 EFE 0121 - Controgen Generator Excitation System Description - Rev - ADokument29 SeitenEC2 406006 001 EFE 0121 - Controgen Generator Excitation System Description - Rev - AAnonymous bSpP1m8j0n50% (2)

- Paul Milgran - A Taxonomy of Mixed Reality Visual DisplaysDokument11 SeitenPaul Milgran - A Taxonomy of Mixed Reality Visual DisplaysPresencaVirtual100% (1)

- Managerial Accounting-Fundamental Concepts and Costing Systems For Cost Analysis Module 1Dokument40 SeitenManagerial Accounting-Fundamental Concepts and Costing Systems For Cost Analysis Module 1Uzma Khan100% (1)

- 4004R (Simplex Panel)Dokument8 Seiten4004R (Simplex Panel)oki121Noch keine Bewertungen

- مشخصات فنی برق گیرDokument26 Seitenمشخصات فنی برق گیرiman MHNavehNoch keine Bewertungen

- 2SB698/2SD734: 1W AF Output, Electronic Governor, DC-DC Converter ApplicationsDokument4 Seiten2SB698/2SD734: 1W AF Output, Electronic Governor, DC-DC Converter ApplicationsMauricio MaldonadoNoch keine Bewertungen

- 2N3904 / MMBT3904 / PZT3904 NPN General Purpose Amplifier: FeaturesDokument7 Seiten2N3904 / MMBT3904 / PZT3904 NPN General Purpose Amplifier: FeaturesBenjamin VillegasNoch keine Bewertungen

- An5649 How To Evaluate and Improve Triacs Immunity To Eft Bursts StmicroelectronicsDokument19 SeitenAn5649 How To Evaluate and Improve Triacs Immunity To Eft Bursts StmicroelectronicsSérgio SilvaneresNoch keine Bewertungen

- B1449 SanyoDokument5 SeitenB1449 SanyogilvanNoch keine Bewertungen

- 2SA1507 / 2SC3902: Data SheetDokument5 Seiten2SA1507 / 2SC3902: Data SheetJamgNoch keine Bewertungen

- 2SA1469 / 2SC3746: Data SheetDokument4 Seiten2SA1469 / 2SC3746: Data SheetJavier Mendoza CastroNoch keine Bewertungen

- 2N3906 / MMBT3906 / PZT3906 PNP General Purpose Amplifier: FeaturesDokument6 Seiten2N3906 / MMBT3906 / PZT3906 PNP General Purpose Amplifier: FeaturesBenjamin VillegasNoch keine Bewertungen

- General Purpose Transistor: Semiconductor 2N3904UDokument7 SeitenGeneral Purpose Transistor: Semiconductor 2N3904UChristian DiazNoch keine Bewertungen

- Electrical Devices List: Samberah EPF ProjectDokument4 SeitenElectrical Devices List: Samberah EPF ProjectJeffrie Nagara NasutionNoch keine Bewertungen

- 2SB892 / 2SD1207: Data SheetDokument5 Seiten2SB892 / 2SD1207: Data SheetSamuel RodrigoNoch keine Bewertungen

- MK17 EngDokument2 SeitenMK17 EnghejimenezNoch keine Bewertungen

- 2SB892/2SD1207: Large-Current Switching ApplicationsDokument4 Seiten2SB892/2SD1207: Large-Current Switching ApplicationsFrancisco BandresNoch keine Bewertungen

- 2SB892/2SD1207: Large-Current Switching ApplicationsDokument4 Seiten2SB892/2SD1207: Large-Current Switching ApplicationsIrwantoirwanNoch keine Bewertungen

- JiangsuMJE2955 C78883Dokument3 SeitenJiangsuMJE2955 C78883gabriel taberneroNoch keine Bewertungen

- Nec'S High Isolation Voltage Single Transistor Type Multi Photocoupler SeriesDokument6 SeitenNec'S High Isolation Voltage Single Transistor Type Multi Photocoupler SeriesDee RajaNoch keine Bewertungen

- Ac-Msb 02-01-2023Dokument12 SeitenAc-Msb 02-01-2023John MunyilNoch keine Bewertungen

- TO-92 Plastic-Encapsulate Transistors: Transistor (NPN)Dokument2 SeitenTO-92 Plastic-Encapsulate Transistors: Transistor (NPN)cgmannerheimNoch keine Bewertungen

- DS Surge Trap PCB Socket ENDokument2 SeitenDS Surge Trap PCB Socket ENessen999Noch keine Bewertungen

- Data Sheet: High-Voltage Switching ApplicationsDokument4 SeitenData Sheet: High-Voltage Switching ApplicationsAnyun SangPemburuNoch keine Bewertungen

- MPS2222A: Elektronische Bauelemente NPN SiliconDokument6 SeitenMPS2222A: Elektronische Bauelemente NPN SiliconJose CordovaNoch keine Bewertungen

- kmz10b 3Dokument8 Seitenkmz10b 3Naur AvilaNoch keine Bewertungen

- 2SB892/2SD1207: Large-Current Switching ApplicationsDokument5 Seiten2SB892/2SD1207: Large-Current Switching ApplicationsSandyNoch keine Bewertungen

- ABB Price List 2017-2018Dokument218 SeitenABB Price List 2017-2018Rafid A. Jassem Alashor100% (1)

- 2SB892/2SD1207: Large-Current Switching ApplicationsDokument4 Seiten2SB892/2SD1207: Large-Current Switching ApplicationsAbdul WahidNoch keine Bewertungen

- MC33390Dokument16 SeitenMC33390bettinemed2023Noch keine Bewertungen

- Grid-Connect Wiring DiagramsDokument4 SeitenGrid-Connect Wiring Diagramstop GeeNoch keine Bewertungen

- 2N5038 ZalecanyDokument2 Seiten2N5038 ZalecanyEdzNoch keine Bewertungen

- Secos 2N3904Dokument3 SeitenSecos 2N3904Internet Cero0Noch keine Bewertungen

- Regulators: Integrated Circuits GroupDokument1 SeiteRegulators: Integrated Circuits GroupKSNoch keine Bewertungen

- DatasheetDokument4 SeitenDatasheetIsmdark DarkNoch keine Bewertungen

- B764-Sanyo Semicon Device PDFDokument4 SeitenB764-Sanyo Semicon Device PDFDiego LombeidaNoch keine Bewertungen

- 2 N3904 NDKDokument6 Seiten2 N3904 NDKJeffree Alexander RamirezNoch keine Bewertungen

- Annexure ADokument1 SeiteAnnexure Arahul patraNoch keine Bewertungen

- MJE15034 NPN, MJE15035 PNP Complementary Silicon Plastic Power TransistorsDokument6 SeitenMJE15034 NPN, MJE15035 PNP Complementary Silicon Plastic Power TransistorsMehmet ÇatçatNoch keine Bewertungen

- 3149 LET-60-500-VTC Step and Touch Measurement DatasheetDokument2 Seiten3149 LET-60-500-VTC Step and Touch Measurement DatasheetkashifNoch keine Bewertungen

- Entes Elektronik - 2009Dokument52 SeitenEntes Elektronik - 2009Stancu BranNoch keine Bewertungen

- PNP Silicon Elektronische Bauelemente: High Voltage PNP TransistorDokument3 SeitenPNP Silicon Elektronische Bauelemente: High Voltage PNP TransistorNestor MartinNoch keine Bewertungen

- Optical Instrument Transformers For EHV SubstationsS 0910Dokument28 SeitenOptical Instrument Transformers For EHV SubstationsS 0910vijaykrishnatennetiNoch keine Bewertungen

- 2SA1469/2SC3746: 60V/5A High-Speed Switching ApplicationsDokument3 Seiten2SA1469/2SC3746: 60V/5A High-Speed Switching ApplicationsJavier Mendoza CastroNoch keine Bewertungen

- Laptek Breaker MCCDokument2 SeitenLaptek Breaker MCCenergiprimer.sintangNoch keine Bewertungen

- 2 Sa 673Dokument7 Seiten2 Sa 673pyithu26Noch keine Bewertungen

- Semiconductor Technical Data: Maximum RatingsDokument6 SeitenSemiconductor Technical Data: Maximum Ratingsjames gonzalezNoch keine Bewertungen

- Emx1 / Umx1N / Imx1: General Purpose Transistor (Dual Transistors)Dokument9 SeitenEmx1 / Umx1N / Imx1: General Purpose Transistor (Dual Transistors)dumberNoch keine Bewertungen

- Emx1 / Umx1N / Imx1: General Purpose Transistor (Dual Transistors)Dokument9 SeitenEmx1 / Umx1N / Imx1: General Purpose Transistor (Dual Transistors)Juan CarlosNoch keine Bewertungen

- Emx1t2r e PDFDokument9 SeitenEmx1t2r e PDFyeison parraNoch keine Bewertungen

- Emx1t2r e PDFDokument9 SeitenEmx1t2r e PDFEfrenGarciaContrerasNoch keine Bewertungen

- 2N5088 2N5089 MMBT5088 MMBT5089: NPN General Purpose AmplifierDokument8 Seiten2N5088 2N5089 MMBT5088 MMBT5089: NPN General Purpose AmplifierGioVoTamNoch keine Bewertungen

- 2N5088 2N5089 MMBT5088 MMBT5089: NPN General Purpose AmplifierDokument7 Seiten2N5088 2N5089 MMBT5088 MMBT5089: NPN General Purpose AmplifierJano GrungeNoch keine Bewertungen

- 2N5088 2N5089 MMBT5088 MMBT5089: NPN General Purpose AmplifierDokument8 Seiten2N5088 2N5089 MMBT5088 MMBT5089: NPN General Purpose AmplifierjakeNoch keine Bewertungen

- AT89C2051-based Countdown TimerDokument3 SeitenAT89C2051-based Countdown TimerKumawat ArunNoch keine Bewertungen

- 2N5088 2N5089 MMBT5088 MMBT5089: NPN General Purpose AmplifierDokument15 Seiten2N5088 2N5089 MMBT5088 MMBT5089: NPN General Purpose AmplifierBenjamin VillegasNoch keine Bewertungen

- 2n3390 91,,92 93 PDFDokument3 Seiten2n3390 91,,92 93 PDFAndrei Blas AzañaNoch keine Bewertungen

- Dtc143tcat116 eDokument7 SeitenDtc143tcat116 edejang84Noch keine Bewertungen

- DC-MSB 02-01-2023Dokument10 SeitenDC-MSB 02-01-2023John MunyilNoch keine Bewertungen

- RM ST40Dokument2 SeitenRM ST40LUIS SLEITER NAPÁN HUAMANÍNoch keine Bewertungen

- Analog Electronic E-MI-AC Drivers: DIN 43650 Plug-In Format, For Proportional Valves Without TransducerDokument4 SeitenAnalog Electronic E-MI-AC Drivers: DIN 43650 Plug-In Format, For Proportional Valves Without Transducerfrancis_15inNoch keine Bewertungen

- Item Description RCVD Unit Price Gross Amt Disc % Ta Amount DeptDokument1 SeiteItem Description RCVD Unit Price Gross Amt Disc % Ta Amount DeptGustu LiranNoch keine Bewertungen

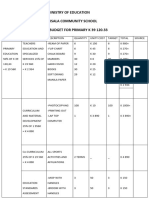

- Ministry of Education Musala SCHDokument5 SeitenMinistry of Education Musala SCHlaonimosesNoch keine Bewertungen

- Unit 5 Andhra Pradesh.Dokument18 SeitenUnit 5 Andhra Pradesh.Charu ModiNoch keine Bewertungen

- LT1256X1 - Revg - FB1300, FB1400 Series - EnglishDokument58 SeitenLT1256X1 - Revg - FB1300, FB1400 Series - EnglishRahma NaharinNoch keine Bewertungen

- TP1743 - Kertas 1 Dan 2 Peperiksaan Percubaan SPM Sains 2023-20243Dokument12 SeitenTP1743 - Kertas 1 Dan 2 Peperiksaan Percubaan SPM Sains 2023-20243Felix ChewNoch keine Bewertungen

- (ENG) Visual Logic Robot ProgrammingDokument261 Seiten(ENG) Visual Logic Robot ProgrammingAbel Chaiña Gonzales100% (1)

- Small Signal Analysis Section 5 6Dokument104 SeitenSmall Signal Analysis Section 5 6fayazNoch keine Bewertungen

- Oxygen BarrierDokument20 SeitenOxygen BarrierKarina ArdizziNoch keine Bewertungen

- Fundamental RightsDokument55 SeitenFundamental RightsDivanshuSharmaNoch keine Bewertungen

- Bba Colleges in IndiaDokument7 SeitenBba Colleges in IndiaSumit GuptaNoch keine Bewertungen

- Floor Paln ModelDokument15 SeitenFloor Paln ModelSaurav RanjanNoch keine Bewertungen

- 6 AsianregionalismDokument32 Seiten6 AsianregionalismChandria Ford100% (1)

- Manuscript - Batallantes &Lalong-Isip (2021) Research (Chapter 1 To Chapter 3)Dokument46 SeitenManuscript - Batallantes &Lalong-Isip (2021) Research (Chapter 1 To Chapter 3)Franzis Jayke BatallantesNoch keine Bewertungen

- Design & Construction of New River Bridge On Mula RiverDokument133 SeitenDesign & Construction of New River Bridge On Mula RiverJalal TamboliNoch keine Bewertungen

- Assessment 21GES1475Dokument4 SeitenAssessment 21GES1475kavindupunsara02Noch keine Bewertungen

- A Comparison of Pharmaceutical Promotional Tactics Between HK & ChinaDokument10 SeitenA Comparison of Pharmaceutical Promotional Tactics Between HK & ChinaAlfred LeungNoch keine Bewertungen

- UBITX V6 MainDokument15 SeitenUBITX V6 MainEngaf ProcurementNoch keine Bewertungen

- Agoura Hills DIVISION - 6. - NOISE - REGULATIONSDokument4 SeitenAgoura Hills DIVISION - 6. - NOISE - REGULATIONSKyle KimNoch keine Bewertungen

- Algorithm - WikipediaDokument34 SeitenAlgorithm - WikipediaGilbertNoch keine Bewertungen

- U.S. Pat. 9,514,727, Pickup With Integrated Contols, John Liptac, (Dialtone) Issued 2016.Dokument39 SeitenU.S. Pat. 9,514,727, Pickup With Integrated Contols, John Liptac, (Dialtone) Issued 2016.Duane BlakeNoch keine Bewertungen

- Lec # 26 NustDokument18 SeitenLec # 26 NustFor CheggNoch keine Bewertungen

- PE Range Moulded Case Current Transformers: Energy DivisionDokument7 SeitenPE Range Moulded Case Current Transformers: Energy DivisionUlfran MedinaNoch keine Bewertungen