Beruflich Dokumente

Kultur Dokumente

M.K.Trading & M.K.Trading & M.K.Trading & M.K.Trading & Cont. Co.L.L.C Cont. Co.L.L.C Cont. Co.L.L.C Cont. Co.L.L.C

Hochgeladen von

cheligp1981Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

M.K.Trading & M.K.Trading & M.K.Trading & M.K.Trading & Cont. Co.L.L.C Cont. Co.L.L.C Cont. Co.L.L.C Cont. Co.L.L.C

Hochgeladen von

cheligp1981Copyright:

Verfügbare Formate

M.K.Trading & Cont. Co.L.L.

C

P.O.Box 2756, Ruwi, P.C. 112 Sultanate of Oman

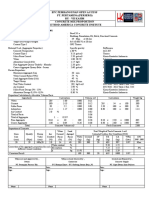

Project : Proposed Vehicle Facility Job No : BY : G.P.E

Date : Sheet No : Chk'd By :

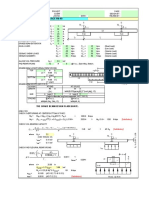

DESIGN OF PURLIN

INPUT DATA SPAN OF PURLIN = MAX. SPACING OF PURLIN = ROOF SLOPE = PURLIN SYSTEM 4.815 M (INTERMEDIATE SPANS) 1.5 M 2.86 DEG. ( 1 IN 20.02 ) Lap 360mm

LOADING = DEAD LOAD = LIVE LOAD = SERVICE LOAD = WIND LOAD = 0.13 0.75 0.1 1.19 KN KN KN KN / / / / SQ.M SQ.M SQ.M SQ.M 0.07 KN/M 2.86

1.38 KN/M LOAD ON PURLIN = DEAD LOAD = LIVE LOAD = SERVICE LOAD = WIND LOAD = 0.13 0.75 0.1 1.19 KN/ KN/ KN/ KN/ M M M M

1.380 KN/M

LOAD COMBINATION ( UNFACTORED ) = ( code : BS5950-5:1998, 9.2.1.a) DEAD + LIVE LOAD = DEAD+ WIND LOAD = 0.13 X 1.5 + 0.75 X 1.5 0.13 X 1.5 - 1.189 X 1.5 = = 1.379 KN/M -1.380 KN/M

CHOOSING PURLIN SECTION = YEILD STRESS (Ys) = MOMENT OF INERTIA = SECTION MODULUS = DEPTH OF NEUTRAL AXIS = WEIGHT / M RUN = SEC. MODULUS (WL/1800) = ( MIN. REQD )

20215 345 301.7 29.44 101 3.92 12.62

Z 20215

Z SECTION

Tiger Profile :

n/sq.mm CM^4 CM^3 MM KG/ M CM ^3

MOMENT CARRING CAPACITY OF A MEMBER SUBJECT TO BENDING IS GIVEN BY = Mc = Po x Zr BS 5950 PART 5 SECTION- 5.2, CL. 4.6 WHERE Po = LIMITING STRESS Design strength = Reduced sec. modulus = Depth of purlin = Thickness of purlin = Width of flange( top ) = Py = Zr = D = t = b1 = 345 n/sq.mm To be calculated 202 mm 1.5 mm 60 mm

M.K.Trading & Cont. Co.L.L.C

P.O.Box 2756, Ruwi, P.C. 112 Sultanate of Oman Width of flange( bot ) =

Project : Proposed Vehicle Facility Job No : BY : G.P.E b2 = 60 mm

Date : Sheet No : Chk'd By :

CALCULATION OF REDUCED EFFECTIVE COMPRESSIVE FLANGE WIDTH OF ZED SECTION =

MODIFIED WIDTH TO THICKNESS RATIO IS GIVEN BY = BS 5950 CL. 4.4 = (Ys / 70 k ) * ( b / t ) = SQRT. (291.86 / 70 x 4 ) x ( 60 / 1.5 ) = HENCE ( b eff. / b ) = 40.84 < 60 O. K. 0.924 b eff = = 0.924 x 60 55.44 MM ( compression flange ) 4 ( For stiffened member ) (REF. BS 5950, PART 5, TABLE-5 ) k=

CALCULATION OF REDUCED MODULUS OF SECTION.( Zr ) ( REF. BS 5950, PART 5 , CL. 3.5 ) MOMENT OF INERTIA ( M.I.) ABOUT ITS OWN NEUTRAL AXIS

M. I. about x.x axis = 16 Ixx = Iself + Ax^2 202

60

101 16 HERE, I self = MOMENT OF INERTIA ABOUT ITS OWN NEUTRAL AXIS A = AREA OF ELEMENT UNDER CONSIDERATION. X = DISTANCE BETWEEN NEUTRAL AXIS AND C.G. OF THE ELEMENT UNDER CONSIDERATION 60 Thickness = 1.5 mm

Min. mom. of inertia of lip = tB^3/375 MIN LIP REQD. = 19.0488 OK.

I xx = (1.5 x 16^ 3/12 + 16 X 1.5 x 93 ^ 2 ) +( 52.44 x 1.5 X 100.25^ 2 ) + (1.5 x 202^ 3 /12 +303 x 0^2) + ( 57 X 1.5 x 100.25^ 2) + (1.5 x 16 ^ 3 / 12 +16 X 1.5 x 93 ^ 2) = ( 208088 ) + ( 790537.92) + (1030301 ) + (859280.34 ) + ( 208088 ) 3096295.26 mm 4 REDUCED , Zr = I xx / x = 3096295.26 / 101 = = 30656 mm 3 30.66 cm 3

M.K.Trading & Cont. Co.L.L.C

P.O.Box 2756, Ruwi, P.C. 112 Sultanate of Oman

Project : Proposed Vehicle Facility Job No : BY : G.P.E

Date : Sheet No : Chk'd By :

THE COMPRESSIVE STRESS Po, IN A STIFFENED ELEMENT WHICH RESULTS FROM BENDING IN ITS PLANE, SHOULD NOT EXCEED THE LESSER OF FOLLOWING = Po = {(1.13 - 0.0019* (Ds / t ) *( Ys / 280)^0.5)}*py OR HENCE, Po = ( LESSER OF ) = HENCE , Po = Py 345 N/ SQ.MM REF. BS-5950 PART 5, cl. 5.2.2.2

291.86 OR 291.86 n/ sq.mm

HENCE MOMENT CARRING CAPACITY ( Mc ) = Po x Zr MOMENT CARRING CAPACITY = 8.59 KN-M =291.86 x 29.44 x (1000 / 1000000 )

ACTUAL BENDING MOMENT = MAX. BENDING MOMENT FOR PURLIN = MAX MOMENT DUE TO DL + LL = MAX MOMENT DUE TO DL + WL = 3.31 KN-M 3.31 KN-M < 8.59 KN-M = W * L^2 / 13.502

HENCE SAFE

CHECKING DEFLECTION = DEFLECTION = Lap 360mm 5 x W x L^4 384 x E x Ixx 0.2161 cm =L / 2228 < L/180 HERE W= L= E= I= , 0.98 4.815 2.05E+06 309.63 KN/M M KG/SQ.CM CM^4

HENCE SAFE PROVIDE PURLIN SIZE 20215

Das könnte Ihnen auch gefallen

- Reducing Business Jet Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemVon EverandReducing Business Jet Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemNoch keine Bewertungen

- 04E83326B1B9406B9D2130DE77817D12Dokument717 Seiten04E83326B1B9406B9D2130DE77817D12chemikas8389Noch keine Bewertungen

- LAB Design Procedure: 1. Decide The Type of Slab According To Aspect Ratio of Long and Short Side LengthsDokument20 SeitenLAB Design Procedure: 1. Decide The Type of Slab According To Aspect Ratio of Long and Short Side Lengthsmollikamin100% (1)

- Stability Requirements: EM 1110-2-2100 1 Dec 05Dokument20 SeitenStability Requirements: EM 1110-2-2100 1 Dec 05Edson HuertaNoch keine Bewertungen

- RCC72 Stairs & Landings - MultipleDokument3 SeitenRCC72 Stairs & Landings - MultipleMohammad Twaha JaumbocusNoch keine Bewertungen

- Frame - Portal and Gable Rigid Plane Frame AnalysisDokument6 SeitenFrame - Portal and Gable Rigid Plane Frame AnalysisCarlos Valverde PortillaNoch keine Bewertungen

- Single Legged Staircase DesignDokument12 SeitenSingle Legged Staircase DesignrahulNoch keine Bewertungen

- RampDokument2 SeitenRampJose EllisNoch keine Bewertungen

- Steel JoistDokument2 SeitenSteel JoistWilliam Greco100% (1)

- Jobaid3 Inspection Checklist For Masonry ConstructionDokument3 SeitenJobaid3 Inspection Checklist For Masonry Constructionrmm99rmm99Noch keine Bewertungen

- BMREINF9Dokument3 SeitenBMREINF9Rajed MaglinteNoch keine Bewertungen

- "Rectbeam" - Rectangular Concrete Beam Analysis/Design: Program DescriptionDokument22 Seiten"Rectbeam" - Rectangular Concrete Beam Analysis/Design: Program DescriptionLee Man HonNoch keine Bewertungen

- Daniel T. Li: Grade Beam Design Based On ACI 318-99Dokument2 SeitenDaniel T. Li: Grade Beam Design Based On ACI 318-99RamadanNoch keine Bewertungen

- Base Plate Anchor Bolt DesignDokument8 SeitenBase Plate Anchor Bolt DesignnoneofyourbusineesNoch keine Bewertungen

- Ec - 1110 2 6066Dokument540 SeitenEc - 1110 2 6066path967Noch keine Bewertungen

- Cold-Formed Steel Joist Design (AISI)Dokument1 SeiteCold-Formed Steel Joist Design (AISI)Mallesh NenkatNoch keine Bewertungen

- US Stair oDokument3 SeitenUS Stair oRenvil PedernalNoch keine Bewertungen

- Rectbeam (318-05)Dokument16 SeitenRectbeam (318-05)Tayyab ZafarNoch keine Bewertungen

- Geometry of Staircase: (Limit State Method As Per IS 456-2000) Design of Stair-CaseDokument2 SeitenGeometry of Staircase: (Limit State Method As Per IS 456-2000) Design of Stair-CaseSujan SinghNoch keine Bewertungen

- RCD-DeSIGN Engr. Mark ChristianDokument9 SeitenRCD-DeSIGN Engr. Mark ChristianTaki TachibanaNoch keine Bewertungen

- "Deckslab" - Slab On Metal Deck Analysis / Design: Program DescriptionDokument26 Seiten"Deckslab" - Slab On Metal Deck Analysis / Design: Program DescriptionXXgabocivXXNoch keine Bewertungen

- 9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 2Dokument2 Seiten9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 2Ahmad Badsha QuadriNoch keine Bewertungen

- "Weldgrp" - Weld Group Analysis ProgramDokument20 Seiten"Weldgrp" - Weld Group Analysis Programbharathanin0% (1)

- Is.11134.1984 Code of Practice Fof Setting Out BuildingsDokument16 SeitenIs.11134.1984 Code of Practice Fof Setting Out BuildingsVVRAONoch keine Bewertungen

- Epc Pembangunan Open Access Pt. Pertamina (Persero) Ru - Vii Kasim Concrete Mix Proportion Method America Concrete InsituteDokument4 SeitenEpc Pembangunan Open Access Pt. Pertamina (Persero) Ru - Vii Kasim Concrete Mix Proportion Method America Concrete InsituteBengkulu BetonNoch keine Bewertungen

- "Weldgrp" - Weld Group Analysis ProgramDokument16 Seiten"Weldgrp" - Weld Group Analysis ProgramMario BertiNoch keine Bewertungen

- ColumnDokument3 SeitenColumnprashanth palaniNoch keine Bewertungen

- Deep Footing Design Based On ACI 318-08: Input DataDokument4 SeitenDeep Footing Design Based On ACI 318-08: Input DataMiguel MoralesNoch keine Bewertungen

- Reinforcing Bar Development and Splice Lengths Per ACI 318-05Dokument8 SeitenReinforcing Bar Development and Splice Lengths Per ACI 318-05cengizNoch keine Bewertungen

- SSE Retaining - Wall - ACI Sheet v1.02Dokument1 SeiteSSE Retaining - Wall - ACI Sheet v1.02SES DESIGNNoch keine Bewertungen

- ECP201-2008 Earthquake Lateral Forces - Protected-09!06!2012Dokument23 SeitenECP201-2008 Earthquake Lateral Forces - Protected-09!06!2012magdyamdbNoch keine Bewertungen

- PDS STAAD Foundation Advanced LTR EN LR PDFDokument2 SeitenPDS STAAD Foundation Advanced LTR EN LR PDFAndres Felipe Forero GacharnáNoch keine Bewertungen

- ACI 318M-11 Slab Punching StressDokument9 SeitenACI 318M-11 Slab Punching StressIsprotec IngenieriaNoch keine Bewertungen

- Joist DesignDokument1 SeiteJoist Designalexkirokos0% (1)

- Super Structure: Verticle Sei. Coeff. (Only For Stru. Built in Zone 4 & 5)Dokument3 SeitenSuper Structure: Verticle Sei. Coeff. (Only For Stru. Built in Zone 4 & 5)Omar RubioNoch keine Bewertungen

- Guidelines Design Example 1Dokument7 SeitenGuidelines Design Example 1pigpig6Noch keine Bewertungen

- From Vice President: MessageDokument36 SeitenFrom Vice President: MessageThaung Myint OoNoch keine Bewertungen

- 05 Erection ChecklistDokument8 Seiten05 Erection ChecklistAnonymous cG5MyHMNoch keine Bewertungen

- Aisc - Chapter JDokument13 SeitenAisc - Chapter JDinesh KumarNoch keine Bewertungen

- Concrete Column Design Based On ACI 318-11: Input Data & Design SummaryDokument3 SeitenConcrete Column Design Based On ACI 318-11: Input Data & Design Summaryjaimeleoxxx0% (1)

- Precast Driven Pile Section Analysis: Input DataDokument1 SeitePrecast Driven Pile Section Analysis: Input DatacivixxNoch keine Bewertungen

- Seismic Load Calc: Equivalent Lateral Force Analysis: InputDokument5 SeitenSeismic Load Calc: Equivalent Lateral Force Analysis: InputMohammed Saleem Syed KhaderNoch keine Bewertungen

- "Rectbeam" - Rectangular Concrete Beam Analysis/Design: Program DescriptionDokument24 Seiten"Rectbeam" - Rectangular Concrete Beam Analysis/Design: Program DescriptionWaqas AnjumNoch keine Bewertungen

- Cell K11 1 Cell K11 0.5 For F 0, For F 0Dokument9 SeitenCell K11 1 Cell K11 0.5 For F 0, For F 0HaymanAHMEDNoch keine Bewertungen

- Timber Truss Design: ProjectDokument8 SeitenTimber Truss Design: ProjectEvello MercanoNoch keine Bewertungen

- Add An Extra DL and Revise - 0.15 PSFDokument1 SeiteAdd An Extra DL and Revise - 0.15 PSFsharif uddinNoch keine Bewertungen

- Guia de Encofrados para Concreto Aci 347r-14Dokument63 SeitenGuia de Encofrados para Concreto Aci 347r-14Yessica Paola MAMANI MAMANINoch keine Bewertungen

- T ShapeCapacityDokument1 SeiteT ShapeCapacityAmey GudigarNoch keine Bewertungen

- Short Column: P F ' F A, and The Total Cross Section Area of The Steel RebarDokument2 SeitenShort Column: P F ' F A, and The Total Cross Section Area of The Steel Rebaraditya2053Noch keine Bewertungen

- Deck SlabDokument22 SeitenDeck SlabFarid TataNoch keine Bewertungen

- The Design Is Adequate.: Channel Steel Member Capacity Based On AISC 360-10Dokument1 SeiteThe Design Is Adequate.: Channel Steel Member Capacity Based On AISC 360-10Somi KhanNoch keine Bewertungen

- TM 5 809 12 Slab On GradeDokument54 SeitenTM 5 809 12 Slab On GradeGreg RabulanNoch keine Bewertungen

- 26 Design of Singly Reinforced Continous RCC Beam As Per Is456-2000 23052014Dokument1 Seite26 Design of Singly Reinforced Continous RCC Beam As Per Is456-2000 23052014Ahmad Badsha QuadriNoch keine Bewertungen

- Bridge Formwork Without AnchorsDokument10 SeitenBridge Formwork Without AnchorsAbdelrahman ElkhollyNoch keine Bewertungen

- Aster Private Limited Ibo Division - Secunderabad: Foundation Design For Tower Type Da Foundation Type-1Dokument9 SeitenAster Private Limited Ibo Division - Secunderabad: Foundation Design For Tower Type Da Foundation Type-1svrao4uNoch keine Bewertungen

- Insert Plate DesignDokument8 SeitenInsert Plate Designvrajan1988Noch keine Bewertungen

- Two Way Slab DesignDokument9 SeitenTwo Way Slab DesignChan Kin Cheung100% (1)

- 6 X 8.1M ShadeDokument7 Seiten6 X 8.1M ShadeehikmatNoch keine Bewertungen

- 5054 TW D 35 PDFDokument43 Seiten5054 TW D 35 PDFbalaramNoch keine Bewertungen

- Flat Slab Design by FemDokument7 SeitenFlat Slab Design by FemBathrudeen IshakNoch keine Bewertungen

- F01B2Dokument9 SeitenF01B2cheligp1981Noch keine Bewertungen

- Percentage Strength of Concrete at Various AgesDokument2 SeitenPercentage Strength of Concrete at Various Agescheligp1981Noch keine Bewertungen

- Structural Design For Proposed Swimming Pool To Be Constructed For Madam Rawad Mohammed Said Al Sakakiny at Al Quram, MuscatDokument1 SeiteStructural Design For Proposed Swimming Pool To Be Constructed For Madam Rawad Mohammed Said Al Sakakiny at Al Quram, Muscatcheligp1981Noch keine Bewertungen

- Class Activity Live LoadDokument2 SeitenClass Activity Live Loadcheligp1981Noch keine Bewertungen

- Part 1 Frame DetailsDokument10 SeitenPart 1 Frame Detailscheligp1981Noch keine Bewertungen

- Rawad Villa ScheduleDokument1 SeiteRawad Villa Schedulecheligp1981Noch keine Bewertungen

- S235jr Carbon SteelDokument2 SeitenS235jr Carbon Steelcheligp1981Noch keine Bewertungen

- Sohar Aluminium Smelter: Amphitheater Structural Steel Details Roof Framing Plan ADokument3 SeitenSohar Aluminium Smelter: Amphitheater Structural Steel Details Roof Framing Plan Acheligp1981Noch keine Bewertungen

- 19-Dec-15 25-Dec-2015 17:37 FR03DB1.std: Job No Sheet No RevDokument3 Seiten19-Dec-15 25-Dec-2015 17:37 FR03DB1.std: Job No Sheet No Revcheligp1981Noch keine Bewertungen

- UK & IrelandDokument13 SeitenUK & Irelandcheligp1981Noch keine Bewertungen

- Site PlanDokument1 SeiteSite Plancheligp1981Noch keine Bewertungen

- PDF - New Facility BuildingDokument17 SeitenPDF - New Facility Buildingcheligp1981Noch keine Bewertungen

- National Hotels Co.: Sheraton Hotel RefurbishmentDokument1 SeiteNational Hotels Co.: Sheraton Hotel Refurbishmentcheligp1981Noch keine Bewertungen

- Item Queries Description Action by Remarks 01 Collateral Load, Service Load & False Ceiling Load To Be Rechecked and To Reduce To The Actual RequiredDokument2 SeitenItem Queries Description Action by Remarks 01 Collateral Load, Service Load & False Ceiling Load To Be Rechecked and To Reduce To The Actual Requiredcheligp1981Noch keine Bewertungen

- Software Activation Key LetterDokument1 SeiteSoftware Activation Key Lettercheligp1981Noch keine Bewertungen

- Sai Kalyanaram Teegala +968 - 92832143: ObectiveDokument2 SeitenSai Kalyanaram Teegala +968 - 92832143: Obectivecheligp1981Noch keine Bewertungen

- 3.2 Access Driveways-Width and LocationDokument1 Seite3.2 Access Driveways-Width and Locationcheligp1981Noch keine Bewertungen

- Panoramic Lift HS Forces Detail 20 Oct 15Dokument1 SeitePanoramic Lift HS Forces Detail 20 Oct 15cheligp1981Noch keine Bewertungen

- GAMS TutorialDokument28 SeitenGAMS TutorialWendy Tie Kai SingNoch keine Bewertungen

- Computer Organization: - by Rama Krishna Thelagathoti (M.Tech CSE From IIT Madras)Dokument118 SeitenComputer Organization: - by Rama Krishna Thelagathoti (M.Tech CSE From IIT Madras)iamy2ramsNoch keine Bewertungen

- ProjectDokument34 SeitenProjectSarvajeet Kshirsagar100% (1)

- Master Antenna Television System and Satellite SystemDokument6 SeitenMaster Antenna Television System and Satellite SystemMHEP_DANIELNoch keine Bewertungen

- Parts Catalog: Paper Feed Unit Type 3800C (G568)Dokument23 SeitenParts Catalog: Paper Feed Unit Type 3800C (G568)poldisagtNoch keine Bewertungen

- Debug 1214Dokument3 SeitenDebug 1214Anonymous B4WiRjNoch keine Bewertungen

- Allen BradleyDokument36 SeitenAllen BradleyotrepaloNoch keine Bewertungen

- NCERT Class 7 Geography WaterDokument9 SeitenNCERT Class 7 Geography Waterbalamurali_aNoch keine Bewertungen

- 9.16. Prepare A Plot of Work Per Pound Mole Versus The Pressue Ratio PDokument6 Seiten9.16. Prepare A Plot of Work Per Pound Mole Versus The Pressue Ratio PttussenoNoch keine Bewertungen

- Tools of BiotechnologyDokument10 SeitenTools of Biotechnologyiamforu1Noch keine Bewertungen

- One Pipe Steam DesignDokument44 SeitenOne Pipe Steam Designreyes hernandezNoch keine Bewertungen

- Manual Aspire 5551Dokument210 SeitenManual Aspire 5551Arnaud NetoNoch keine Bewertungen

- Water Technology 2015 2016 1Dokument86 SeitenWater Technology 2015 2016 1Srinivas AkHilNoch keine Bewertungen

- SFF 8448Dokument8 SeitenSFF 8448eleptonNoch keine Bewertungen

- T.C. Electronic M3000 User ManualDokument78 SeitenT.C. Electronic M3000 User ManualStanleyNoch keine Bewertungen

- Da10 Air Cooled Engine (Appn Code D3.2007 & D3Dokument26 SeitenDa10 Air Cooled Engine (Appn Code D3.2007 & D3Sandeep NikhilNoch keine Bewertungen

- VocationalDokument2 SeitenVocationalMegha RoyNoch keine Bewertungen

- Manual Deus II UkDokument52 SeitenManual Deus II UkMariusNoch keine Bewertungen

- OML Section CDokument3 SeitenOML Section Cمهند ستارNoch keine Bewertungen

- 4 Contamination Control 2Dokument61 Seiten4 Contamination Control 2Vijay RajaindranNoch keine Bewertungen

- Practical Considerations For The Use of A Howland Current SourceDokument4 SeitenPractical Considerations For The Use of A Howland Current SourceRamiShaabannnnNoch keine Bewertungen

- CT Terminology LexiconDokument12 SeitenCT Terminology LexiconjtbushbergNoch keine Bewertungen

- Customizing The ADFS Sign-In PagesDokument4 SeitenCustomizing The ADFS Sign-In Pagesmicu0% (1)

- Chapter 2 Review of Related LiteratureDokument16 SeitenChapter 2 Review of Related LiteratureRodel D Dosano50% (6)

- Mole Reactions and Stoichiometry MultipleDokument25 SeitenMole Reactions and Stoichiometry MultiplelinaNoch keine Bewertungen

- Thermophysical Properties of Containerless Liquid Iron Up To 2500 KDokument10 SeitenThermophysical Properties of Containerless Liquid Iron Up To 2500 KJose Velasquez TeranNoch keine Bewertungen

- Business Dynamics in The 21st CenturyDokument270 SeitenBusiness Dynamics in The 21st CenturyskilmagNoch keine Bewertungen

- MS275 10 Inch Compound Miter Saw MB4B2ADokument4 SeitenMS275 10 Inch Compound Miter Saw MB4B2ArightoutacontrolNoch keine Bewertungen

- ctc-189 Answerbook PDFDokument136 Seitenctc-189 Answerbook PDFmenosoft100% (1)

- DPR Guidelines Oil and Gas 2019 PDFDokument114 SeitenDPR Guidelines Oil and Gas 2019 PDFRubénNoch keine Bewertungen