Beruflich Dokumente

Kultur Dokumente

Sample ITP Boiler

Hochgeladen von

intolscribOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sample ITP Boiler

Hochgeladen von

intolscribCopyright:

Verfügbare Formate

Descon PROJECT :

PROJECT :

DOCUMENT TITLE : INSPECTION AND TEST PLAN

ORIGINATOR:

Descon Engineering FZE

3/10/2012 DATE

0 REV.NO.

Issued for Client Review / Comments DESCRIPTION

RM

SK

SK APPROVED BY

PREPARED CHECKED BY BY

DOCUMENT NUMBER :

Des-XXXX-QA&QC-01

SHT.

OF

REV.

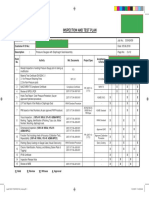

INSPECTION AND TEST PLAN (ITP)

PROJECT COMPANY MANUFACTURER CLIENT ITEM TAG COMPANY DOC No: LEGEND: H - HOLD, W - WITNESS, SW - SPOT WITNESS, R - REVIEW OF RECORD, RW-RANDOM WITNESS, A - APPROVAL , M - MONITORING DESCON ENGINEERING FZE PREPARED BY REVIEWED BY APPROVED BY RASHID MAHMOOD SAKET KUMAR SAKET KUMAR

Doc. No. : DES-QA&QC/FRM-05A Rev.: 01 Date: April 22, 2010

SIGNATURE

PO No.: DESCON PROJECT No.: DESCON DOC No.:

INSPECTION BY

DES-PROP-QA&QC-01

ITEM

QC ACTIVITY

PRIME RESPONSIBILTY

REFERENCE DOCUMENTS / ACCEPTANCE CRITERIA

VERIFYING DOCUMENT

DESCON QA/QC

ASME Authorized Inspector

NOBO (CE Marking)

JZ

End User

STATUS

SIGN

STATUS

SIGN

STATUS

SIGN

STATUS

SIGN

STATUS

SIGN

1

1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 1.10

DOCUMENTATION

Pre- Inspection Meeting Inspection and Test Plan Drawings and Design Calculations Welding Book Welders Qualification Record NDE Procedures Weld Repair Prcoedure Hydrostatic and Pneumatic test procedure Surface Preparation & Painting Procedure NDE Operator Qualification I/C QA&QC QC Engineer PIM Agenda ITP & Applicable Code Minutes of meeting DES-PROP-QA&QC-01 Approved drawings Welding Book DES-QA&QC/FRM-40 RT,MT,UT DPT Procedures Weld Repair Proceudre Hydro static and Pneumatic test procedure S.P & Painting Procedure Qualification Certificates H H H H H H H H H H

I/C Product Engineering ASME Sec.1 Welding Engineer Welding Engineer QC Engineer QC Engineer QC Engineer Coating Inspector NDE Engineer ASME IX, B31.1 , ASME IX ASME Sec.V ASME Sec.VIII Div.1 & Sec.I ASME Sec.VIII Div.1 & Sec.I ASTM / SSPC / Swedish Certificates / SNT-TC-1A

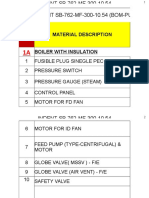

2

2.1

MATERIAL CONTROL

Material Inspection / Verification / Certificate review QC Material Inspector Drawings/ P.O/ ASME Sec.II Part A Material inspection report / MTC'S H

2.2

Controlling of Heat Number and stamp transfer for pressure parts and those which are directly weld with pressure parts / Traceability check

QC Material Inspector

Drawings/ P.O/ ASME Sec.II Part A

Material traceability report / MTC'S

3

3.1

DISH END FORMING

Inspection of Dish End QC Material Inspector ASME Sec.VIII Div.1+ DWG Inspection Report H

Do not duplicate. controlled copy if stamped in red. Descon Engineering FZE 2 of 6

INSPECTION BY

ITEM

QC ACTIVITY

PRIME RESPONSIBILTY

REFERENCE DOCUMENTS / ACCEPTANCE CRITERIA

VERIFYING DOCUMENT

DESCON QA/QC

ASME Authorized Inspector

NOBO (CE Marking)

JZ

End User

STATUS 3.2 MT on Knuckle radius QC Material Inspector ASME Sec.VIII Div.1 + DWG MT Report H

SIGN

STATUS

SIGN

STATUS

SIGN

STATUS

SIGN

STATUS

SIGN

3.3

Thickness Check of Head

QC Material Inspector

ASME Sec.VIII Div.1 + DWG

Thickness Report

FABRICATION STEAM DRUM

4.1

Rolling Inspection ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications Physical verification / Signed ITP for record

4.2

Rolling / Re Rolling of Shell Course

QC Inspector

4.3

Fit up Inspection ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications Physical verification / Signed ITP for record Physical verification / Signed ITP for record Physical verification / Signed ITP for record Physical verification / Signed ITP for record Physical verification / Signed ITP for record Physical verification / Signed ITP for record Physical verification / Signed ITP for record

4.4

LS and CS Fit-up of shell course.

QC Inspector

4.5

Nozzles and Stubs Fit-up

QC Inspector

4.6

Marking of tube holes on the shell of Steam Drum

QC Inspector

4.7

Marking of tube holes on the shell of Mud Drum

QC Inspector

4.8

Holes drilling in Steam Drum and Mud Drum

QC Inspector

4.9

Insertion of Tubes in Tube Holes in the Shell of Steam Drum and Mud Drum

QC Inspector

4.10

Fit up of Tubes with Steam Drum Shell

QC Inspector

4.11

Fit up of Tubes with Mud Drum Shell

QC Inspector

ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications

Physical verification / Signed ITP for record

4.12

Expansion of tubes

QC Inspector

ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications

Tubes Expansion report

4.13

Fit up of Saddles

QC Inspector

ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications

Physical verification / Signed ITP for record

4.14

MUD DRUM

Rolling Inspection

4.15

4.16

Rolling / Re Rolling of Shell Course

QC Inspector

ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications

Physical verification / Signed ITP for record

4.17

Fit up Inspection Do not duplicate. controlled copy if stamped in red. Descon Engineering FZE 3 of 6

INSPECTION BY

ITEM

QC ACTIVITY

PRIME RESPONSIBILTY

REFERENCE DOCUMENTS / ACCEPTANCE CRITERIA

VERIFYING DOCUMENT

DESCON QA/QC

ASME Authorized Inspector

NOBO (CE Marking)

JZ

End User

STATUS ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications Physical verification / Signed ITP for record Physical verification / Signed ITP for record Physical verification / Signed ITP for record

SIGN

STATUS

SIGN

STATUS

SIGN

STATUS

SIGN

STATUS

SIGN

4.18

LS and CS Fit-up of shell course.

QC Inspector

4.19

Nozzles and Stubs Fit-up

QC Inspector

4.20

Marking of Tube holes on the shell of Steam Drum

QC Inspector

4.21

FLASH VESSEL

Rolling Inspection

4.22

4.23

Rolling / Re Rolling of Shell Course

QC Inspector

ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications

Physical verification / Signed ITP for record

4.24

Fit up Inspection ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications Physical verification / Signed ITP for record Physical verification / Signed ITP for record Physical verification / Signed ITP for record

4.25

LS and CS Fit-up of shell course.

QC Inspector

4.26

Nozzles and Stubs Fit-up

QC Inspector

4.27

Marking of Tube holes on the shell of Steam Drum

QC Inspector

4.28

SUPER HEATER HEADER

ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications, ASME Sec.V ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications Physical verification / Signed ITP for record Physical verification / Signed ITP for record Physical verification / Signed ITP for record Physical verification / Signed ITP for record

4.29

Final Visual and Dimensional inspection of Header

QC Inspector

4.30

Final Visual and Dimensional inspection of Coil

QC Inspector

4.31

NDE as per apporved drawing

QC Inspector

4.32

Hydrostatic test of Header as per approved drawing

QC Inspector

4.33

PIPING SPOOLS

Fit Up Inspection of Piping Spools QC Inspector ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications, ASME Sec.V Physical verification / Signed ITP for record Physical verification / Signed ITP for record H

4.34

4.35

NDE as per approved Drawings

QC Inspector

4.36

LADDERS AND PLATFORMS

Final visual and dimensional Inspection of Ladders and Platforms Trial Assembly of Ladders and Platforms Do not duplicate. controlled copy if stamped in red. Descon Engineering FZE 4 of 6 QC Inspector ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications Physical verification / Signed ITP for record H

4.37

4.38

INSPECTION BY

ITEM

QC ACTIVITY

PRIME RESPONSIBILTY

REFERENCE DOCUMENTS / ACCEPTANCE CRITERIA

VERIFYING DOCUMENT

DESCON QA/QC

ASME Authorized Inspector

NOBO (CE Marking)

JZ

End User

STATUS

SIGN

STATUS

SIGN

STATUS

SIGN

STATUS

SIGN

STATUS

SIGN

4.39

NDE as per approved Drawings

QC Inspector

ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications

Physical verification / Signed ITP for record

5

6.4

WELDING INSPECTION

Welders Qualification Welding Inspector ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications Physical verification / Signed ITP for record H

6.6

Final weld visual Inspection

Welding Inspector

Weld visual Inspection report

6.7

Complete compliance of approved WPS

Welding Inspector

Physical verification / Signed ITP for record

PWHT

ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications

6.1

PWHT Specification

Welding Engineer

DES-QA&QC/FRM-56

6.2

PWHT Report and Graph (Chart)

Welding Engineer

DES-QA&QC/FRM-74

6.3

Hardness test of welds after PWHT

Welding Engineer

Hardness test report

7

7.1

NDE

BEFORE PWHT

RT as per approved Drawings NDE Inspector ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications, ASME Sec.V ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications , ASME Sec.V ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications, ASME Sec.V ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications, ASME Sec.V ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications, ASME Sec.V DES-QA&QC/FRM-60 + 62 H

7.2

7.3

MPT / DPT after grinding smooth temporary welds 100 % MT on Lifting Lugs 100% UT on Lifting Lugs (Full Penetration Joints) 10 % MT of LS & CS weld joints

NDE Inspector

DES-QA&QC/FRM-63 + 62

7.4

NDE Inspector

DES-QA&QC/FRM-62

7.5

NDE Inspector

DES-QA&QC/FRM- 62

7.6

10 % MT on Fillet Welds UT of Nozzle to Shell welds

NDE Inspector

DES-QA&QC/FRM-63 + 62

7.7

NDE Inspector

DES-QA&QC/FRM-61 + 62

7.8

AFTER PWHT

RT as per approved Drawings NDE Inspector ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications, ASME Sec.V ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications, ASME Sec.V ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications, ASME Sec.V ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications, ASME Sec.V DES-QA&QC/FRM-60 H

7.9

7.10

UT of Nozzle to Shell welds 10 % MT or PT on all nozzle welds and welded accessories 10 % MT of LS & CS weld joints

NDE Inspector

DES-QA&QC/FRM-61 + 62

7.11

NDE Inspector

DES-QA&QC/FRM-63 + 62

7.12

NDE Inspector

DES-QA&QC/FRM- 62

7.13

10 % MT on Fillet Welds

NDE Inspector

ASME Sec.VIII Div.1+Sec.I + DWG + DES-QA&QC/FRM-63 + 62 Project Specifications, ASME Sec.V Do not duplicate. controlled copy if stamped in red. Descon Engineering FZE

5 of 6

INSPECTION BY

ITEM

QC ACTIVITY

PRIME RESPONSIBILTY

REFERENCE DOCUMENTS / ACCEPTANCE CRITERIA

VERIFYING DOCUMENT

DESCON QA/QC

ASME Authorized Inspector

NOBO (CE Marking)

JZ

End User

STATUS 7.14 100 % MT on Lifting Lugs 100% UT on Lifting Lugs (Full Penetration Joints) NDE Inspector ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications, ASME Sec.V DES-QA&QC/FRM-62 H

SIGN

STATUS

SIGN

STATUS

SIGN

STATUS

SIGN

STATUS

SIGN

8

8.1

FINAL INSPECTION

Final visual and dimensional Inspection QC Inspector ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications ASME Sec.VIII Div.1 / Sec.I Dimensional inspection report Physical verification / Signed ITP for record Dimensional inspection report H

8.2

Internal Inspection before Hydrostatic test

QC Inspector

8.3

Visual Inspection after PWHT

QC Inspector

8.4

NDT Verifications

QC Inspector QC Inspector / QA Engineer QC Inspector

NDE Summary sheet

8.5

Verification of Close out of NCR's (if any) Leak test on RF Pads

NDE Summary sheet

8.6

DES-QA&QC/FRM-52

8.7

Hydrostatic testing

QC Inspector

ASME Sec.VIII Div.1 / Sec.I ASME Sec.VIII Div.1+Sec.I + DWG + Project Specifications

DES-QA&QC/FRM-52 Physical verification / Signed ITP for record

8.8

Draining & Drying after Hydrostatic test

QC Inspector

9

9.1

NAME PLATE

Stamping & Attachment of name plate QC Inspector ASME Sec.VIII Div.1 / Sec.I Name plate copy H

9.2

Signing of Manufacturer Data Report

QC Inspector

ASME Sec.VIII Div.1 / Sec.I

MDR

10

10.1

SURFACE PREPARATION AND PAINTING

Final Coat DFT and Final Colour Check Coating Inspector SSPC / Swedish Painting inspection report H

11

11.1

PRE-SHIPMENT INSPECTION AND DOCUMENTATION

Inspection of packing of shipment QC Inspector Packing and Shipping Instructions Packing List Physical verification / Signed ITP for record IRC H

11.2

Flange Protection inspection

QC Inspector

Packing and Shipping Instructions

11.3

Issuance of inspection release note

QC Inspector

Release Note

11.4

Manufacturer data record book

QC Inspector

Final Data Book

Final Data Book

Do not duplicate. controlled copy if stamped in red. Descon Engineering FZE 6 of 6

Das könnte Ihnen auch gefallen

- ITP Installation of Boiler - R1Dokument14 SeitenITP Installation of Boiler - R1crys100% (4)

- Inspection and Test Plan For New Pressure VesselDokument2 SeitenInspection and Test Plan For New Pressure VesselCak Nhass0% (1)

- ctc-189 Answerbook PDFDokument136 Seitenctc-189 Answerbook PDFmenosoft100% (1)

- Artificial Intelligence Questions&Ans Uninformed SearchDokument5 SeitenArtificial Intelligence Questions&Ans Uninformed Searchjaijohnk83% (6)

- Inspection and Test Plan (Itp) For Fabrication Pressure VesselDokument1 SeiteInspection and Test Plan (Itp) For Fabrication Pressure VesselNikki RobertsNoch keine Bewertungen

- ITP For Boiler ErectionDokument6 SeitenITP For Boiler ErectionUmair Awan100% (2)

- Inspection and Test Plan For Shell and Tube Heat ExchangerDokument6 SeitenInspection and Test Plan For Shell and Tube Heat ExchangertomychalilNoch keine Bewertungen

- LTHEDokument5 SeitenLTHEMohit Goswami100% (1)

- Electrode Test Record E6010Dokument9 SeitenElectrode Test Record E6010Veeraraghavan GuruNoch keine Bewertungen

- Tank Erection Itp & Org ChartDokument34 SeitenTank Erection Itp & Org Charthasan_676489616100% (2)

- ASTM C158-02 (2012) Strength of Glass by Flexure (Determination of Modulus of Rupture)Dokument9 SeitenASTM C158-02 (2012) Strength of Glass by Flexure (Determination of Modulus of Rupture)Cristian Perez100% (1)

- Lab 2.1Dokument2 SeitenLab 2.1Manjari Srivastava100% (3)

- ITP Heat ExchangerDokument3 SeitenITP Heat ExchangerĐỗ Thị Huyền100% (3)

- Vessel ItpDokument3 SeitenVessel ItpVineet KhanduriNoch keine Bewertungen

- Ayari Maher: Qualified Welder I.D.CardDokument10 SeitenAyari Maher: Qualified Welder I.D.CardZouhair BenmabroukNoch keine Bewertungen

- Itp For Ball ValveDokument9 SeitenItp For Ball ValveHamid Taghipour ArmakiNoch keine Bewertungen

- NDT Map Itp Pressure VesselDokument4 SeitenNDT Map Itp Pressure VesselSYED FADZIL SYED MOHAMEDNoch keine Bewertungen

- List of Itp新 for HrsgDokument16 SeitenList of Itp新 for HrsgzhangNoch keine Bewertungen

- GTL WPSDokument6 SeitenGTL WPSYoucef ChorfaNoch keine Bewertungen

- Itp TankageDokument7 SeitenItp TankageIr FankovicNoch keine Bewertungen

- Hydrotest ProcedureDokument12 SeitenHydrotest Procedurealex_feryando42100% (1)

- Inspecton ProcedureDokument3 SeitenInspecton ProcedureSanthosh ReddyNoch keine Bewertungen

- Visit Report - 325 Dated 25.09.18Dokument3 SeitenVisit Report - 325 Dated 25.09.18Vinay YadavNoch keine Bewertungen

- MD1-0-T-030-05-00370-A - ITP For CFBC Boiler InstallationDokument30 SeitenMD1-0-T-030-05-00370-A - ITP For CFBC Boiler InstallationTran KhuynhNoch keine Bewertungen

- ITP-format For VesselsDokument5 SeitenITP-format For VesselsHanuman RaoNoch keine Bewertungen

- Inspection Test Plan Fuel Gas Conditioning SkidDokument19 SeitenInspection Test Plan Fuel Gas Conditioning SkidDin AizuNoch keine Bewertungen

- Sec-Visual Inspection Report For Boiler Pressure Parts Lower Panels (Unit - #6)Dokument5 SeitenSec-Visual Inspection Report For Boiler Pressure Parts Lower Panels (Unit - #6)حمودي معز100% (2)

- En 13445 WPS PQR WPQDokument5 SeitenEn 13445 WPS PQR WPQmuhammad hadiNoch keine Bewertungen

- Welder Qualifications and The ASME CodeDokument2 SeitenWelder Qualifications and The ASME CodeWaqas WaqasNoch keine Bewertungen

- ITP's and ITR's A Necessary - Monster - PDFDokument5 SeitenITP's and ITR's A Necessary - Monster - PDFshastri85Noch keine Bewertungen

- Inspection Report - ValvesDokument2 SeitenInspection Report - ValvesJaspal KaurNoch keine Bewertungen

- Metrode Welding Duplex & Superduplex Stainless SteelsDokument18 SeitenMetrode Welding Duplex & Superduplex Stainless SteelsClaudia Mms50% (2)

- QC Dossier 1Dokument1 SeiteQC Dossier 1VishnuGKNoch keine Bewertungen

- Third Party Inspection For Power CableDokument6 SeitenThird Party Inspection For Power CableBeareaterNoch keine Bewertungen

- Floating Head Heat Exchanger Hydrotest ProcedureDokument15 SeitenFloating Head Heat Exchanger Hydrotest ProcedureDoğuhan DenizgezNoch keine Bewertungen

- TANK 06 Test PackDokument12 SeitenTANK 06 Test PackGomathyselvi100% (2)

- ITPDokument1 SeiteITPVenkatesh PethurajNoch keine Bewertungen

- NDE Manual R01Dokument210 SeitenNDE Manual R01Arun Mathan100% (1)

- Qap HPCLDokument13 SeitenQap HPCLdarshan100% (1)

- AGP-GPS-ANOGP-Z21-0010 - C02 Advance Copy - Piping Material Specification PDFDokument157 SeitenAGP-GPS-ANOGP-Z21-0010 - C02 Advance Copy - Piping Material Specification PDFRubénNoch keine Bewertungen

- Hydro Vs PneumaticDokument4 SeitenHydro Vs PneumaticAnonymous rYZyQQot55Noch keine Bewertungen

- Pressure Vessel SpecificationDokument15 SeitenPressure Vessel Specificationmichael chiwuezeNoch keine Bewertungen

- SB 762 IndentDokument200 SeitenSB 762 Indentanon_687665429Noch keine Bewertungen

- Welding Procedure Specification For Storage Tank & Piping SystemDokument3 SeitenWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNoch keine Bewertungen

- MTC For SCN-574 PDFDokument154 SeitenMTC For SCN-574 PDFthomasNoch keine Bewertungen

- 005-WPS For Carbon Steel (1.6-4.6MM) PDFDokument7 Seiten005-WPS For Carbon Steel (1.6-4.6MM) PDFKöksal Patan0% (1)

- Itp For ValvesDokument2 SeitenItp For ValvesSuraj ShettyNoch keine Bewertungen

- Pressure Vessel ITP Rev 0Dokument21 SeitenPressure Vessel ITP Rev 0Ahmad HasnanNoch keine Bewertungen

- Pressure Vessel Dimension Inspection PDFDokument17 SeitenPressure Vessel Dimension Inspection PDFEqubal KhanNoch keine Bewertungen

- Asme Sec Ix (Welder Qualification)Dokument39 SeitenAsme Sec Ix (Welder Qualification)VinodNoch keine Bewertungen

- Inspection and Test Plan - StructureDokument10 SeitenInspection and Test Plan - StructureFerdie OSNoch keine Bewertungen

- As For Boiler PackagesDokument17 SeitenAs For Boiler PackagesjkNoch keine Bewertungen

- Itp Electrical SwitchgearDokument4 SeitenItp Electrical SwitchgearpertmasterNoch keine Bewertungen

- Method Statement OF Air Blowing / Water Flushing of PipesDokument19 SeitenMethod Statement OF Air Blowing / Water Flushing of Pipesarun kumar100% (1)

- Material Traceability Inspection ReportDokument32 SeitenMaterial Traceability Inspection ReportBalmiki SinghNoch keine Bewertungen

- PWHTDokument103 SeitenPWHTChetan B KapadiaNoch keine Bewertungen

- IRN - 18.07.2019 - Harshad Panchal - Revision-0 - Furnace Fabrica - JNK - PORVAIR - RIL PDFDokument3 SeitenIRN - 18.07.2019 - Harshad Panchal - Revision-0 - Furnace Fabrica - JNK - PORVAIR - RIL PDFsaptarshi jashNoch keine Bewertungen

- Inspection Test Plan (Itp) at Site: Natural Gas Transportation Development Project - Siak RiauDokument6 SeitenInspection Test Plan (Itp) at Site: Natural Gas Transportation Development Project - Siak Riauanang_pri100% (1)

- 038-Itp For Coldboxes PDFDokument25 Seiten038-Itp For Coldboxes PDFKöksal PatanNoch keine Bewertungen

- Boiler Inspection and Test PlanDokument13 SeitenBoiler Inspection and Test Plandoley_pranab100% (3)

- Hydro Testing + Post Weld Heat TreatmentDokument20 SeitenHydro Testing + Post Weld Heat TreatmentRafia ZafarNoch keine Bewertungen

- Pages From 9.0 Itp Cn. Pipe FittingsDokument1 SeitePages From 9.0 Itp Cn. Pipe FittingskamilNoch keine Bewertungen

- Sample Itp For VesselDokument10 SeitenSample Itp For VesselWijayanto BekasiNoch keine Bewertungen

- QIPDokument9 SeitenQIPzahid_497Noch keine Bewertungen

- First-Man-Up User ManualDokument24 SeitenFirst-Man-Up User ManualJoshuaNoch keine Bewertungen

- Parts Catalog: Paper Feed Unit Type 3800C (G568)Dokument23 SeitenParts Catalog: Paper Feed Unit Type 3800C (G568)poldisagtNoch keine Bewertungen

- A Study On The Design Optimization of An AUV by Using Computational Fluid Dynamic AnalysisDokument7 SeitenA Study On The Design Optimization of An AUV by Using Computational Fluid Dynamic AnalysisSalma SherbazNoch keine Bewertungen

- Persuasive Speech Outline Spring 2016Dokument2 SeitenPersuasive Speech Outline Spring 2016api-311467409Noch keine Bewertungen

- Allen BradleyDokument36 SeitenAllen BradleyotrepaloNoch keine Bewertungen

- Vem BrochureDokument8 SeitenVem BrochureVamshi Krishnam Raju NadimpalliNoch keine Bewertungen

- 19 Element YagiDokument4 Seiten19 Element YagiVanessa BileNoch keine Bewertungen

- ASTM D287-92 (Metodo de Prueba Estandar para Gravedad API de Petroleo Crudo y Productos Del Petroleo Metodo Del Hidrómetro)Dokument3 SeitenASTM D287-92 (Metodo de Prueba Estandar para Gravedad API de Petroleo Crudo y Productos Del Petroleo Metodo Del Hidrómetro)Juan MonjeNoch keine Bewertungen

- CHCE 3004 CHEG 333 Chemical Reaction Engineering I QP 2020 SUPPLIMENTRY - AM PDFDokument2 SeitenCHCE 3004 CHEG 333 Chemical Reaction Engineering I QP 2020 SUPPLIMENTRY - AM PDFLGK KlanNoch keine Bewertungen

- EOT CRANE - Rev 2Dokument6 SeitenEOT CRANE - Rev 2Koushik BhaumikNoch keine Bewertungen

- Tpa3110D2-Q1 15-W Filter-Free Stereo Class-D Audio Power Amplifier With Speakerguard™Dokument37 SeitenTpa3110D2-Q1 15-W Filter-Free Stereo Class-D Audio Power Amplifier With Speakerguard™tran anh tuanNoch keine Bewertungen

- Production ManagementDokument81 SeitenProduction ManagementrrathoreNoch keine Bewertungen

- Astm A769 PDFDokument5 SeitenAstm A769 PDFCristian OtivoNoch keine Bewertungen

- DFH00191 - RAUTHERM SPEED HKV P - TI - EN - LayoutDokument4 SeitenDFH00191 - RAUTHERM SPEED HKV P - TI - EN - LayoutRENSO BirouClujNoch keine Bewertungen

- Use of Multimeter TextDokument76 SeitenUse of Multimeter Textprueba1100% (2)

- RAB PE20Tx1set Amo, 60HP (1) Cetakan 50kg (400 Balok 16 Can) + Ice Storage 50TDokument3 SeitenRAB PE20Tx1set Amo, 60HP (1) Cetakan 50kg (400 Balok 16 Can) + Ice Storage 50THidayat SyamsiNoch keine Bewertungen

- Using A GMR Effect Sensor To Measure The Current in A Wire by Means of Its Magnetic FieldDokument6 SeitenUsing A GMR Effect Sensor To Measure The Current in A Wire by Means of Its Magnetic FieldManeesha WijesingheNoch keine Bewertungen

- Nickel-Titanium Alloys: A Systematic Review: Original ArticleDokument12 SeitenNickel-Titanium Alloys: A Systematic Review: Original ArticleMudavath BaburamNoch keine Bewertungen

- 80010360Dokument2 Seiten80010360mdisicNoch keine Bewertungen

- Customizing The ADFS Sign-In PagesDokument4 SeitenCustomizing The ADFS Sign-In Pagesmicu0% (1)

- Electrochemical Measurement of Diffusible Hydrogen in Steels (Barnacle Electrode)Dokument6 SeitenElectrochemical Measurement of Diffusible Hydrogen in Steels (Barnacle Electrode)Faiber AndrésNoch keine Bewertungen

- Hero Forge: 3D Printed Miniature Care and Painting GuideDokument4 SeitenHero Forge: 3D Printed Miniature Care and Painting GuideDanilo FirminoNoch keine Bewertungen

- Ncomputing VSpace Server Management Console User ManualDokument34 SeitenNcomputing VSpace Server Management Console User ManualJeff IvanNoch keine Bewertungen

- Polymers For Transdermal Drug Delivery SystemsDokument9 SeitenPolymers For Transdermal Drug Delivery SystemsAmjadRazaNoch keine Bewertungen

- CSG CMT CalculationsDokument5 SeitenCSG CMT Calculationsfrancisryan4519Noch keine Bewertungen

- September 2015Dokument2 SeitenSeptember 2015Patriziah Marie SeldaNoch keine Bewertungen