Beruflich Dokumente

Kultur Dokumente

ASTM C 1172 Laminated-Std PDF

Hochgeladen von

pandey0080 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

2K Ansichten1 SeiteASTM C 1172 laminated glass standard

Originaltitel

ASTM C 1172 laminated-std.pdf.pdf

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenASTM C 1172 laminated glass standard

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

2K Ansichten1 SeiteASTM C 1172 Laminated-Std PDF

Hochgeladen von

pandey008ASTM C 1172 laminated glass standard

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

7.

10 Visual Inspection-All visual inspections shall be

made with 20/20 vision (normal or corrected eye). The viewer

shall look at the sample at an angle of 90° (perpendicular) to

the surface using the following lighting unless otherwise

specifed: daylight (without direct sunlight) or other uniform

diffused background lighting that simulates daylight, with a

minimum luminance of 1700 lux (160 foot-candles) measured

at the surface of the glass facing the light source.

7.10.1 Laminated Vertical Glazing-Inspect glazing in the

vertical position at a distance of 1 m (39 in). If a blemish is

readily apparent under these viewing conditions, refer to Table

1 for acceptable criteria.

7.10.2 Laminated Overhead Glazing-Inspect glazing in

the vertical position at a distance of 3 m (10 ft). If a blemish is

readily apparent under these viewing conditions, refer to Table

2 for acceptable criteria.

7.11 Transmittance-Using Practice E 308, measure trans-

mittance by illuminating each laminated specimen at normal

incidence with light having the spectral composition of Inter-

national Commission on Illumination (CIE) illuminant C.

Measure the ratio of transmittance to incident luminous fux by

calculating from the spectral distribution of illuminant C as

defned by Practice E 308.

8. Fabrication Requirements

8.1 All dimensional fabrication, such as cutting to overall

dimensions, edgework, drilling, notching, grinding, sandblast-

ing and etching, on laminates incorporating heat-strengthened,

chemically strengthened, or fully tempered glass shall be

performed prior to strengthening or tempering. After the glass

has been strengthened or tempered, it shall not be modifed

except as recommended by the fabricator.

8.2 Edge-An edge shall be cut, sawed, ground, sanded to

remove sharp edges only, seamed, ground and polished,

beveled, or mitered as specifed.

8.3 Marking:

8.3.1 Each laminate, as supplied by the manufacturer, shall

bear the manufacturer`s name, or trademark, or both, unless

otherwise specifed.

8.3.2 Laminated glass intended for safety glazing applica-

tions specifed by building codes, shall be permanently marked

as required by the applicable safety glazing standard.

8.4 Thickness-For thickness tolerances consult the lamina-

tor. Nominal thickness tolerance computation guidelines are as

follows:

8.4.1 Minimum Thickness Tolerance-Minimum thickness

tolerance shall be the summation of the values for the mini-

mum thickness of each glass ply obtained from Specifcation

C 1036 and the minimum interlayer thickness obtained from

the laminator.

8.4.2 Maximum Thickness Tolerance:

8.4.2.1 Annealed Glasses-The summation of the values for

the maximum thickness of each glass ply obtained from

Specifcation C 1036 and the maximum interlayer thickness

obtained from the laminator.

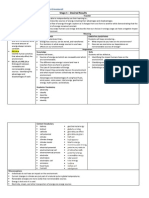

TABLE 2 Maximum AIIowabIe Laminating Process BIemishes for Overhead GIazing, in. (mm)

NOTE 1-Refer to Specifcation C 1036 for the quality specifcation for the individual glass lites.

NOTE 2- All imperfections noted should be separated by a minimum of 12 in. (300 mm).

NOTE 3-See 7.10 for method of inspection.

NOTE 4-Laminates with more than two lites of glass may contain proportionally more blemishes.

Blemish

up to 2.5 m (25 ft )

ft or greater 2.5 m or greater (25 ft or

greater)

Central Outer Central Outer

Boil (Bubbles) 2.4 mm ( ´ in.) 3.2 mm ( ´ in.) 4.8 mm ( ´ in.) 6.4 mm ( ´ in.)

Blow-in; edge boil CE 6.4 ( ´ in.)

EE 2.4 mm ( ´ in)

CE 8.0 mm ( ´

in.) EE 3.2 mm

( ´ in)

Fuse 1.6 mm ( ´ in.) 1.6 mm ( ´ in.) 2.4 mm ( ´ in.) 4.0 mm ( ´ in.)

Hair, lint (single strand) medium intensity medium intensity medium intensity medium intensity

Ìnside dirt (dirt spot) 2.4 mm ( ´ in.) 2.4 mm ( ´ in.) 4.0 mm ( ´ in.) 4.8 in ( ´ in.)

Lint-areas of concentrated lint medium intensity medium intensity medium intensity medium intensity

Separation, discoloration none none none none

Short interlayer; un-laminated area,

chip;

CE 6.4 mm ( ´ in)

EE 2.4 mm ( ´ in.)

CE 6.4 mm ( ´ in)

EE 3.2 mm ( ´

in.)

Scuff; streak medium intensity medium intensity medium intensity medium intensity

The central area is an area formed by an oval or circle whose axes or diameters, when centered, do not exceed 80 % of the overall dimension. The outer area is the

area outside of the central area.

Not applicable.

CE = covered edge of glass edge bite and

EE = exposed edge. (Ìf CE or EE is unknown use EE tolerance.)

Medium Intensity-Noticeable at 1 m (39 in.) but not at 3 m (10 ft).

TABLE 3 Length and Width ToIerances for RectanguIar Shapes

of SymmetricaIIy Laminated GIass IncIuding Mismatch

Tolerances, mm (in.)

Laminate Thickness

Designation, t

Transparent

Glass

Patterned and

Wired Glass

Heat Strengthened

and Tempered Glass

t 6.4 +4.0, -1.6 +7.9, -3.2 +5.6, -2.4

(t 1/4) (+ ´ , - ´ ) (+ ´ - ´ ) (+ ´ - ´ )

6.4 , t 12.7 + 6.4, -1.6 + 7.9, -3.2 + 6.4, -3.2

( ´ < t ´ ) (+ ´ , - ´ ) (+ ´ , - ´ ) (+ ´ , - ´

12.7 < t 25.4 + 6.4, -3.2 + 7.9, -3.2 + 7.9, -3.2

( ´ < t 1) (+ ´ , - ´ ) (+ ´ , - ´ ) (+ ´ , - ´ )

For nonsymmetrical laminated glass contact the laminator for size tolerances.

Size includes cutting and fabrication tolerances and mismatch (see 8.5.1)

For exposed edge applications, consult the supplier to determine their

capabilities.

C 1172 - 09

4

Copyright ASTM Ìnternational

Provided by ÌHS under license with ASTM Sold to:GUARDÌAN ÌND CORP, 01761496

Not for Resale,2009/7/10 15:58:9 GMT No reproduction or networking permitted without license from ÌHS

Das könnte Ihnen auch gefallen

- Astmc864 05Dokument11 SeitenAstmc864 05pandey0080% (1)

- A156.4 - 2008 Door Control-Closers Hardware HighlightsDokument1 SeiteA156.4 - 2008 Door Control-Closers Hardware HighlightsteramodNoch keine Bewertungen

- C 1503 - 08 (2013)Dokument6 SeitenC 1503 - 08 (2013)NhutChauNoch keine Bewertungen

- Terracotta Rainscreen CladdingDokument9 SeitenTerracotta Rainscreen CladdingAbdul Hafeez100% (1)

- FL - Aluminum Widows - Arcadia IncDokument25 SeitenFL - Aluminum Widows - Arcadia IncDeepakDeepuNoch keine Bewertungen

- Previews-ANSI Z97!1!2009 PreDokument12 SeitenPreviews-ANSI Z97!1!2009 PreMetzy Nieto SanchezNoch keine Bewertungen

- 084413-Glazed Aluminum Curtain Walls (VersaWall SM 2500)Dokument12 Seiten084413-Glazed Aluminum Curtain Walls (VersaWall SM 2500)Md Jahangir AlamNoch keine Bewertungen

- Eta-120114 Spax ScrewsDokument84 SeitenEta-120114 Spax ScrewsSunnyWongNoch keine Bewertungen

- Glass in Building Ð Coated Glass Ð: Part 1: Definitions and ClassificationDokument14 SeitenGlass in Building Ð Coated Glass Ð: Part 1: Definitions and Classificationraybo1Noch keine Bewertungen

- Etag 002-1Dokument75 SeitenEtag 002-1DerRennerNoch keine Bewertungen

- 16 CFR Part 1201 - 2002 ADokument19 Seiten16 CFR Part 1201 - 2002 Abatteekh100% (1)

- WK4-Salhia Shading CoeffficientDokument17 SeitenWK4-Salhia Shading CoeffficienttriplbingaziNoch keine Bewertungen

- SJ Mepla Manual Short Eng 50ee8Dokument14 SeitenSJ Mepla Manual Short Eng 50ee8Aqil GhaffarNoch keine Bewertungen

- Certification & Testing For Insulating Glass Units ASTM E 2190Dokument2 SeitenCertification & Testing For Insulating Glass Units ASTM E 2190Mohammad ALTAKINoch keine Bewertungen

- Structural Sealant Glazing: Standard Guide ForDokument52 SeitenStructural Sealant Glazing: Standard Guide ForĐường Nguyễn ThừaNoch keine Bewertungen

- The Pearl Rating System For Estidama - Community Rating SystemDokument182 SeitenThe Pearl Rating System For Estidama - Community Rating SystemY TingNoch keine Bewertungen

- SMD Technical Manual-2011Dokument20 SeitenSMD Technical Manual-2011karfire1982Noch keine Bewertungen

- 9 Painting WorksDokument5 Seiten9 Painting WorksNorazmiMohdNorNoch keine Bewertungen

- Glass Standards PDFDokument4 SeitenGlass Standards PDFCristian TofanNoch keine Bewertungen

- Measuring The Forced Entry Resistance of Window Assemblies, Excluding Glazing ImpactDokument8 SeitenMeasuring The Forced Entry Resistance of Window Assemblies, Excluding Glazing ImpactOscar Gutiérrez-JuncoNoch keine Bewertungen

- Preliminary Structural Calculation (66 1 - RV1) XIII MILANDokument486 SeitenPreliminary Structural Calculation (66 1 - RV1) XIII MILANNenad JevdosicNoch keine Bewertungen

- BS en 1279-4-2002Dokument32 SeitenBS en 1279-4-2002donalexx100% (1)

- Factors That Caused Glass Curtain Wall Visual DistortionDokument4 SeitenFactors That Caused Glass Curtain Wall Visual DistortionHAN HAN100% (1)

- SJ Mepla Version 40 f88f9Dokument4 SeitenSJ Mepla Version 40 f88f9wal1547Noch keine Bewertungen

- Glass Inspection CriteriaDokument4 SeitenGlass Inspection CriteriabatteekhNoch keine Bewertungen

- CDC - Glass Railing System Handouts PDFDokument14 SeitenCDC - Glass Railing System Handouts PDFMina AdlyNoch keine Bewertungen

- Astm C1036-06Dokument55 SeitenAstm C1036-06Mauricio RiquelmeNoch keine Bewertungen

- SJ MEPLA Calculation Protocol:: Basic Form: QuadrangleDokument5 SeitenSJ MEPLA Calculation Protocol:: Basic Form: Quadranglewaweng22Noch keine Bewertungen

- Code of Practice For Use of Glass in BuildingsDokument110 SeitenCode of Practice For Use of Glass in BuildingsNaveen KarkiNoch keine Bewertungen

- Laboratory Measurement of Impact Sound Transmission Through Floor-Ceiling Assemblies Using The Tapping MachineDokument9 SeitenLaboratory Measurement of Impact Sound Transmission Through Floor-Ceiling Assemblies Using The Tapping MachineDiego GarcésNoch keine Bewertungen

- Aci 211-1-91 - Standard Practice For Selecting Proportions For ConcreteDokument8 SeitenAci 211-1-91 - Standard Practice For Selecting Proportions For ConcretedrfkamalodeenNoch keine Bewertungen

- TDS - Sadovac SP (F8102102)Dokument2 SeitenTDS - Sadovac SP (F8102102)Krishna Vacha67% (3)

- Performance Testing of FacadeDokument26 SeitenPerformance Testing of FacadeVivek G. AbhyankarNoch keine Bewertungen

- Ansi NFRC 100-2017 E0a1rlDokument123 SeitenAnsi NFRC 100-2017 E0a1rlDespoina PostantziNoch keine Bewertungen

- Glass Standards (Draft) PDFDokument5 SeitenGlass Standards (Draft) PDFCristian TofanNoch keine Bewertungen

- 2808-084413 - Glazed Aluminum Curtain WallsDokument52 Seiten2808-084413 - Glazed Aluminum Curtain WallsAmro Ahmad AliNoch keine Bewertungen

- Astm c1048 Specification For Heat Treated Flat GlassDokument7 SeitenAstm c1048 Specification For Heat Treated Flat GlassWayce C. GabrilloNoch keine Bewertungen

- Sandtrap Louver DetailedDokument10 SeitenSandtrap Louver Detailedzahee007Noch keine Bewertungen

- As Standard ListDokument6 SeitenAs Standard ListNguyen Duc DungNoch keine Bewertungen

- Astm C1036-16Dokument10 SeitenAstm C1036-16josemanuel0525100% (3)

- Section 09260 Gypsum Board AssembliesDokument10 SeitenSection 09260 Gypsum Board AssembliesMØhãmmed ØwięsNoch keine Bewertungen

- Full List of Glass Related StandardsDokument3 SeitenFull List of Glass Related StandardsCephanie MuthamiNoch keine Bewertungen

- ASTM C 1523 Standard Test Method For Determining Modulus, Tear and Adhesion Properties of ... (PDFDrive)Dokument161 SeitenASTM C 1523 Standard Test Method For Determining Modulus, Tear and Adhesion Properties of ... (PDFDrive)Han Win AungNoch keine Bewertungen

- AS 1288/amdt 2/2011-11-11Dokument11 SeitenAS 1288/amdt 2/2011-11-11shrikant_pesitNoch keine Bewertungen

- ANSI Z97.1 SummaryDokument4 SeitenANSI Z97.1 SummaryAli YalazNoch keine Bewertungen

- En 1999 1 5 2007 PDFDokument67 SeitenEn 1999 1 5 2007 PDFNiko NeznanovicNoch keine Bewertungen

- Astm c1048Dokument10 SeitenAstm c1048Michael LimNoch keine Bewertungen

- Molded Glass Fiber Reinforced Gypsum Parts: Standard Specification ForDokument2 SeitenMolded Glass Fiber Reinforced Gypsum Parts: Standard Specification ForJesús Luis Arce Guillermo100% (1)

- Astm C 1201-09Dokument4 SeitenAstm C 1201-09kishor150688Noch keine Bewertungen

- Branz Advisory Trower PartitionsDokument6 SeitenBranz Advisory Trower PartitionsMatt Stubbins100% (1)

- Iso 3537-1999Dokument6 SeitenIso 3537-1999Anovar_ebooks0% (1)

- MEPLADokument4 SeitenMEPLAinitbashNoch keine Bewertungen

- Gutmann Curtain Wall Systems f50 Plus f60 Plus enDokument1 SeiteGutmann Curtain Wall Systems f50 Plus f60 Plus enNacer IzriNoch keine Bewertungen

- Sealant PrimerDokument10 SeitenSealant PrimerAlex BeldnerNoch keine Bewertungen

- EC9-1,3 - Design of Aluminium Structures - Structures Susceptible To Fatigue PDFDokument100 SeitenEC9-1,3 - Design of Aluminium Structures - Structures Susceptible To Fatigue PDFnebojsadj6411Noch keine Bewertungen

- Fire-Rated Glass Document38Dokument5 SeitenFire-Rated Glass Document38jefftemple0% (1)

- StorefrontDokument5 SeitenStorefrontMary Mae JeremiasNoch keine Bewertungen

- AWMAC NAAWS CSC Section 06 41 00 - Architectural Wood Casework - May2018Dokument11 SeitenAWMAC NAAWS CSC Section 06 41 00 - Architectural Wood Casework - May2018Gilang PratamaNoch keine Bewertungen

- Testing Application Standard 202 94Dokument6 SeitenTesting Application Standard 202 94maikelc1Noch keine Bewertungen

- Advances in Ceramic Armor XIVon EverandAdvances in Ceramic Armor XIJerry C. LaSalviaNoch keine Bewertungen

- 498ADokument8 Seiten498Apandey008Noch keine Bewertungen

- Durability of Building and Construction Sealants and Adhesives Volume 2 Andreas T WolfDokument132 SeitenDurability of Building and Construction Sealants and Adhesives Volume 2 Andreas T Wolfpandey008100% (2)

- FOSG Quality StandardsDokument1 SeiteFOSG Quality Standardspandey008Noch keine Bewertungen

- SFE RULEBOOK Issue 01 Board Approved 6 Nov 08Dokument9 SeitenSFE RULEBOOK Issue 01 Board Approved 6 Nov 08pandey008Noch keine Bewertungen

- HST HiltiDokument4 SeitenHST HiltimariuspiNoch keine Bewertungen

- TurkeyDokument1 SeiteTurkeypandey008Noch keine Bewertungen

- Job Description SHH502 Housing Repairs - Carpenter - Multi Trade OperativeDokument5 SeitenJob Description SHH502 Housing Repairs - Carpenter - Multi Trade Operativepandey008Noch keine Bewertungen

- Project SpecificationDokument1 SeiteProject Specificationpandey008Noch keine Bewertungen

- ACP SpecDokument1 SeiteACP Specpandey008Noch keine Bewertungen

- SkyScape Design Installation Guide 2014Dokument17 SeitenSkyScape Design Installation Guide 2014pandey008Noch keine Bewertungen

- Fire Lite: Glass Technique Queries and AnswersDokument5 SeitenFire Lite: Glass Technique Queries and Answerspandey008Noch keine Bewertungen

- Midterm Exam Fall 2012Dokument5 SeitenMidterm Exam Fall 2012Asanka RodrigoNoch keine Bewertungen

- Theravada and Henri Bergson On TimeDokument7 SeitenTheravada and Henri Bergson On TimeDren HotiNoch keine Bewertungen

- Maths Grade 9 Ujian SekoahDokument10 SeitenMaths Grade 9 Ujian SekoahKopi LuwakNoch keine Bewertungen

- Question Bank EC802CDokument7 SeitenQuestion Bank EC802CSatyaki PalNoch keine Bewertungen

- Burns & Mayne (S&F 2002) PiezoDissipationDokument7 SeitenBurns & Mayne (S&F 2002) PiezoDissipationJesus GonzalezNoch keine Bewertungen

- Formation of ElementsDokument17 SeitenFormation of ElementsWinde SerranoNoch keine Bewertungen

- SHS LAS Gen - Physics1 MELC12 Q2 Week-1Dokument14 SeitenSHS LAS Gen - Physics1 MELC12 Q2 Week-1ChricellFNoch keine Bewertungen

- Australia Shell Spirax S6 AXME 80W-140 TDSDokument2 SeitenAustralia Shell Spirax S6 AXME 80W-140 TDSfdpc1987Noch keine Bewertungen

- Contoh Dan Jawaban Soal Metode Elemen HinggaDokument16 SeitenContoh Dan Jawaban Soal Metode Elemen HinggadhiafahheraNoch keine Bewertungen

- Astro Solar Information-EDokument1 SeiteAstro Solar Information-EMutoha ArkanuddinNoch keine Bewertungen

- Longitudinal and Lateral Trim of A HelicopterDokument1 SeiteLongitudinal and Lateral Trim of A HelicopterP_leeNoch keine Bewertungen

- Gree Change 18-24 Technical Manual EngDokument101 SeitenGree Change 18-24 Technical Manual Engstr.maintenance.reNoch keine Bewertungen

- Duraturf Product Group Harver Magnetic Induction: Harver Induction InfoDokument8 SeitenDuraturf Product Group Harver Magnetic Induction: Harver Induction Infoadrianajones4Noch keine Bewertungen

- Arlon Microwave MaterialsDokument18 SeitenArlon Microwave MaterialsFelipe RabeloNoch keine Bewertungen

- UBD Physics Unit 2 - Energy and The EnviornmentDokument5 SeitenUBD Physics Unit 2 - Energy and The EnviornmentAlfred Melvin SolivaNoch keine Bewertungen

- Wolfson Eup3 Ch18 Test BankDokument18 SeitenWolfson Eup3 Ch18 Test BankifghelpdeskNoch keine Bewertungen

- A Lens Is Defined As A Portion of A Refracting Medium Bordered by Two Curved Surfaces Which Have A Common AxisDokument12 SeitenA Lens Is Defined As A Portion of A Refracting Medium Bordered by Two Curved Surfaces Which Have A Common AxisSaif HassanNoch keine Bewertungen

- Digital Signal Processing: Instructor: Jen-Hui Chuang Instructor: Jen-Hui ChuangDokument31 SeitenDigital Signal Processing: Instructor: Jen-Hui Chuang Instructor: Jen-Hui ChuangRakesh InaniNoch keine Bewertungen

- A7 - 20-SEP-2016 - RM001 - POCE5 - Module-4-Energy Balance-NumericalsDokument17 SeitenA7 - 20-SEP-2016 - RM001 - POCE5 - Module-4-Energy Balance-NumericalssantoshNoch keine Bewertungen

- Cse169 01Dokument49 SeitenCse169 01hhedfiNoch keine Bewertungen

- Stats&Prob - WEEK 1Dokument3 SeitenStats&Prob - WEEK 1Ji PaoNoch keine Bewertungen

- Study Guide Velocity and AccelerationDokument2 SeitenStudy Guide Velocity and Accelerationapi-259781257100% (1)

- QTMS Brochure Rev2Dokument8 SeitenQTMS Brochure Rev2ManibalanNoch keine Bewertungen

- Derrick Scott Van Heerden - Mathemagical Music Scales, 2013Dokument54 SeitenDerrick Scott Van Heerden - Mathemagical Music Scales, 2013Tiago Ramos100% (1)

- BN-S-UC001B Checklist For The Mechanical Completion, Incl. Pre-Commissioning ActivitiesDokument13 SeitenBN-S-UC001B Checklist For The Mechanical Completion, Incl. Pre-Commissioning ActivitiesGiftObionochieNoch keine Bewertungen

- 2008 10 08 Product Show Mixing SpeakersDokument18 Seiten2008 10 08 Product Show Mixing SpeakersyhjhzzjNoch keine Bewertungen

- BS 300Dokument121 SeitenBS 300Anonymous GhWU5YK8Noch keine Bewertungen

- BC 559 CDokument7 SeitenBC 559 CAndy SanchezNoch keine Bewertungen

- 5STR 03T2040Dokument8 Seiten5STR 03T2040Vikas PatelNoch keine Bewertungen

- Shear Wave Velocity: Comparison Between Centrifuge and Triaxial Based MeasurementsDokument6 SeitenShear Wave Velocity: Comparison Between Centrifuge and Triaxial Based MeasurementsLuciano JuniorNoch keine Bewertungen