Beruflich Dokumente

Kultur Dokumente

MCC Bus Bar Sizing Calculation

Hochgeladen von

erkamlakar2234Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

MCC Bus Bar Sizing Calculation

Hochgeladen von

erkamlakar2234Copyright:

Verfügbare Formate

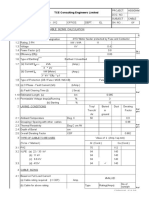

1000 A MCC BUSBAR SIZING CALCULATION

PROJECT CLIENT CONSULTANT EPC CONTRACTOR Document ID 5000 TCD SUGAR PLANT WITH 30 MW POWER PLANT M/s. K.P.R. SUGAR MILL LTD M/s AVANT GARDE ENGINEERS AND CONSULTANT (P) LTD. ISGEC HEAVY ENGINEERING LIMITED KR11-10302-CLC-001

Revision : 01

Date : 24-05-2012

No. of Sheet - 4

1 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 1.10

Input Data Type of Panel System Rated Voltage degree of Protection Panel Max. Current Rating in Amp (Design) Fault Current & Duration (KA RMS Symmetrical for 1 Sec.) Ambient Temperature (Deg. C.) Maximum Bus bar Temperature (Deg. C.) Maximum Enclosure Temperature (Deg. C.) Degree of Protection Bus bar Size for Phase Bus bar Size for Neutral No. of Runs : : : : : : : : : : : : : : : : : : Cubical Type 3PH ,3 Wire / 4 Wire 415V 50 Hz. 1000 50 50 85 70 IP: 52 & IP: 42 for ACB Incomer 1 x 1 x 125 x 10 MM 1 x 125 x 06 MM 1 1 125 10 750 1250 SMC support with ribbed construction

1.11

No. of times Interleaved Width of Bus Bar in mm Thickness of Bus Bar in mm Bus bar cross section for Neutral in Sq.mm Cross section of Bus bar Selected in Sq. mm Type of Insulator Basic Insulation Level: One Minute Power Frequency voltage Painting: a. Enclosure Interior & Exterior b. Bus bar Minimum Clearance: a. Phase to Phase b. Phase to Earth

1.12 1.13 1.14 1.15 a 1.16

2.5KV RMS

: : : : : : : :

Epoxy paint RAL-7032, Siemens Grey Heat Shrinkable Sleeved. 25 mm 20 mm IS: 8623 Construction IS : 5082 Bus bar IP: 54 for Indoor & IP: 55 for Outdoor 0.5mtr. (500mm)

1.17

1.18 1.19 1.20

Applicable Standard Degree of Protection Span Between 2 support

Page 1 of 12

1000 A MCC BUSBAR SIZING CALCULATION

PROJECT CLIENT CONSULTANT EPC CONTRACTOR Document ID 5000 TCD SUGAR PLANT WITH 30 MW POWER PLANT M/s. K.P.R. SUGAR MILL LTD M/s AVANT GARDE ENGINEERS AND CONSULTANT (P) LTD. ISGEC HEAVY ENGINEERING LIMITED KR11-10302-CLC-001

Revision : 01

Date : 24-05-2012

No. of Sheet - 4

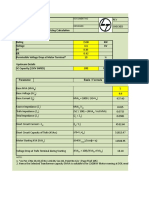

2 2.1

Bus duct Sizing Calculation for MCC Short Time Thermal Withstand Capability of Bus bar Minimum Cross Sectional Area of Busbar (A) In Sq. Inches Isc = Short Circuit Symmetrical Fault Current in KA T = Fault duration in Sec T1 = Initial Temperature of Busbar in Deg.C T2 = Final Temperature in Deg.C A = Cross sectional area of busbar in Sq.inches A in sq.mm = A x 645.16 = = = = = = ( Isc / T ) / {14 x 10 log [T1 +258)/(T2+258)] } 50 1 85 200 1.007851794 650.226 650.226 Sq.mm for pure aluminium. = 1250

2.2 2.2

Required cross sectional Area Actual Cross section of Bus bar Selected (As per Clause1.13) in Sq.mm Conclusion:

2.3 3 3.10

The required cross section 650.226 Sq.mm is less than actual cross section 1250 Sq.mm of the bus bar selected. Hence, the bus bar size chosen is safe for the envisaged system. Bus bar Selection for Continuous Current Rating : Bus bar Selected Open air rating of bus bar for 50 Deg. C rise over ambient in Amps. : : : : : : : : : : As per Clause1.11 1850 1 x 1850 1850 150 5500 x 800 x 2400 mm 800 x 400 mm 50 Deg. C 35 Deg. C MS Steel

3.11

No. of times Interleaved (As per Clause1.11) Overall Rating of Bus Bar in Amps. Phase spacing in mm. Enclosed Size in (W x D x H ) mm Bus bar Enclosed in (W x D ) mm Design Ambient Temperature Maximum allowable temp. rise Enclosure Material

3.12 3.13 3.14 3.15 3.16 3.17

Page 2 of 12

1000 A MCC BUSBAR SIZING CALCULATION

PROJECT CLIENT CONSULTANT EPC CONTRACTOR Document ID 5000 TCD SUGAR PLANT WITH 30 MW POWER PLANT M/s. K.P.R. SUGAR MILL LTD M/s AVANT GARDE ENGINEERS AND CONSULTANT (P) LTD. ISGEC HEAVY ENGINEERING LIMITED KR11-10302-CLC-001

Revision : 01

Date : 24-05-2012

No. of Sheet - 4

3.18

De-rating / Up rating: a Ambient correction factor for 35 Deg. Rise b Enclosure correction factor corresponding to bus bar c Enclosure Correction factor Material (MS) d Proximity Effect Factor e Bus bar Configuration Factor g Combined Correction Factor De-rated Current rating of bus bar after applying Correction factor in Amps. = = = = = = = 0.9 0.87 0.9 0.95 1 0.67 1850 x 0.67

3.19

3.20 3.21 4 4.10 a b c

= 1238.51025 Rating of Panel required (As per Clause 1.5) = 1000 Conclusion : The de-rated Current rating 1238.51 amp of Panel selected is more than the required current rating 1000 amp of Bus duct Bus bar. Hence, the bus bar size chosen is safe for the envisaged system. Support Insulator Span Calculation During Short Circuit Fm = Peak Electromagnetic force along the centre = K x 16 x Isc x 10 / S line of busbar without enclosure Isc = Short Circuit Symmetrical Fault Current in KA S = Phase spacing in Meter K = Multiplying factor (s-a)/(a+b) corresponding to a that is 60 Fm (Nm / cm ) Fm ( Kg / cm ) = (Fm x 0.1019716) F = Force acting on top of the insulator Where, H = Cantilever Height of insulator in mm h = Distance between surface of insulator to centre of Bus bar in mm F Average span to be addopted in mm = = = = = = = = = = = = 50 0.250 0.904 0.4 (Reffering to curve K is 0.9) 14400.000 1468.391 Fm (H+h)/4H 38 75 1091.632813 Cantilever Strength of insulator / safety factor x F Sk / (SF x F ) 1600 2.5 586.278 OK

4.12 a b

4.13

a b

SK = Cantilever strength of insulator(Kg/cm) SF = Safety factor Length of Span of insulator in mm Adopted Span is Conclusion:

= = =

4.4

Average span of 586.278 mm is required but span adopted is 500 mm, hence it is safe for the system envisaged.

Page 3 of 12

1000 A MCC BUSBAR SIZING CALCULATION

PROJECT CLIENT CONSULTANT EPC CONTRACTOR Document ID 5000 TCD SUGAR PLANT WITH 30 MW POWER PLANT M/s. K.P.R. SUGAR MILL LTD M/s AVANT GARDE ENGINEERS AND CONSULTANT (P) LTD. ISGEC HEAVY ENGINEERING LIMITED KR11-10302-CLC-001

Revision : 01

Date : 24-05-2012

No. of Sheet - 4

5 5.1 5.2 5.3 5.4

Temperature Rise Calculation Where, I1=Calculated Rating in Amps (After deration) As per Clause 3.19 I2 = Specified Rating in Amps as per clause 1.5 T1 = Max. Temp. Rise (in Deg.C) Specified T2 = Temp. Rise in Deg. C to be calculated as T2 = = = = = = Calculated Temperature is Conclusion : = 1238.51025 1000 35 ( I1 / I2 ) = ( T1 / T2 T1 / (I1 / I2 ) 24.64 OK

1.64 )0.61

5.5

The Calculated Temperature rise of bus bar is 24.64 Deg. C, which is within the design Specified Temp. 35 Deg. C and it is safe for the System envisaged.

Prepared By: Ganpat C

Checked By : Kamlakar D.

Approved By : A.B.H

Page 4 of 12

630 A MCC BUSBAR SIZING CALCULATION

PROJECT CLIENT CONSULTANT EPC CONTRACTOR Document ID 5000 TCD SUGAR PLANT WITH 30 MW POWER PLANT M/s. K.P.R. SUGAR MILL LTD M/s AVANT GARDE ENGINEERS AND CONSULTANT (P) LTD. ISGEC HEAVY ENGINEERING LIMITED KR11-10302-CLC-001

Revision : 01

Date : 24-05-2012

No. of Sheet - 4

1 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 1.10

Input Data Type of Panel System Rated Voltage degree of Protection Panel Max. Current Rating in Amp (Design) Fault Current & Duration (KA RMS Symmetrical for 1 Sec.) Ambient Temperature (Deg. C.) Maximum Bus bar Temperature (Deg. C.) Maximum Enclosure Temperature (Deg. C.) Degree of Protection Bus bar Size for Phase Bus bar Size for Neutral No. of Runs : : : : : : : : : : : : : : : : : : Cubical Type 3PH ,3 Wire / 4 Wire 415V 50 Hz. 630 50 50 85 70 IP: 52 & IP: 42 for ACB Incomer 1 x 1 x 75 x 12 MM 1 x 75 x 06 MM 1 1 75 12 450 900 SMC support with ribbed construction

1.11

No. of times Interleaved Width of Bus Bar in mm Thickness of Bus Bar in mm Bus bar cross section for Neutral in Sq.mm Cross section of Bus bar Selected in Sq. mm Type of Insulator Basic Insulation Level: One Minute Power Frequency voltage Painting: a. Enclosure Interior & Exterior b. Bus bar Minimum Clearance: a. Phase to Phase b. Phase to Earth

1.12 1.13 1.14 1.15 a 1.16

2.5KV RMS

: : : : : : : :

Epoxy paint RAL-7032, Siemens Grey Heat Shrinkable Sleeved. 25 mm 20 mm IS: 8623 Construction IS : 5082 Bus bar IP: 54 for Indoor & IP: 55 for Outdoor 0.5mtr. (500mm)

1.17

1.18 1.19 1.20

Applicable Standard Degree of Protection Span Between 2 support

Page 5 of 12

630 A MCC BUSBAR SIZING CALCULATION

PROJECT CLIENT CONSULTANT EPC CONTRACTOR Document ID 5000 TCD SUGAR PLANT WITH 30 MW POWER PLANT M/s. K.P.R. SUGAR MILL LTD M/s AVANT GARDE ENGINEERS AND CONSULTANT (P) LTD. ISGEC HEAVY ENGINEERING LIMITED KR11-10302-CLC-001

Revision : 01

Date : 24-05-2012

No. of Sheet - 4

2 2.1

Bus duct Sizing Calculation for MCC Short Time Thermal Withstand Capability of Bus bar Minimum Cross Sectional Area of Busbar (A) In Sq. Inches Isc = Short Circuit Symmetrical Fault Current in KA T = Fault duration in Sec T1 = Initial Temperature of Busbar in Deg.C T2 = Final Temperature in Deg.C A = Cross sectional area of busbar in Sq.inches A in sq.mm = A x 645.16 = = = = = = ( Isc / T ) / {14 x 10 log [T1 +258)/(T2+258)] } 50 1 85 200 1.007851794 650.226 650.226 Sq.mm for pure aluminium. = 900

2.2 2.2

Required cross sectional Area Actual Cross section of Bus bar Selected (As per Clause1.13) in Sq.mm Conclusion:

2.3 3 3.10

The required cross section 650.226 Sq.mm is less than actual cross section 900 Sq.mm of the bus bar selected. Hence, the bus bar size chosen is safe for the envisaged system. Bus bar Selection for Continuous Current Rating : Bus bar Selected Open air rating of bus bar for 50 Deg. C rise over ambient in Amps. : : : : : : : : : : As per Clause1.11 1350 1 x 1350 1350 150 7800 x 800 x 2400 mm 800 x 400 mm 50 Deg. C 35 Deg. C MS Steel

3.11

No. of times Interleaved (As per Clause1.11) Overall Rating of Bus Bar in Amps. Phase spacing in mm. Enclosed Size in (W x D x H ) mm Bus bar Enclosed in (W x D ) mm Design Ambient Temperature Maximum allowable temp. rise Enclosure Material

3.12 3.13 3.14 3.15 3.16 3.17

Page 6 of 12

630 A MCC BUSBAR SIZING CALCULATION

PROJECT CLIENT CONSULTANT EPC CONTRACTOR Document ID 5000 TCD SUGAR PLANT WITH 30 MW POWER PLANT M/s. K.P.R. SUGAR MILL LTD M/s AVANT GARDE ENGINEERS AND CONSULTANT (P) LTD. ISGEC HEAVY ENGINEERING LIMITED KR11-10302-CLC-001

Revision : 01

Date : 24-05-2012

No. of Sheet - 4

3.18

De-rating / Up rating: a Ambient correction factor for 35 Deg. Rise b Enclosure correction factor corresponding to bus bar c Enclosure Correction factor Material (MS) d Proximity Effect Factor e Bus bar Configuration Factor g Combined Correction Factor De-rated Current rating of bus bar after applying Correction factor in Amps. = = = = = = = 0.9 0.87 0.9 0.95 1 0.67 1350 x 0.67

3.19

3.20 3.21 4 4.10 a b c

= 903.77775 Rating of Panel required (As per Clause 1.5) = 630 Conclusion : The de-rated Current rating 903.78 amp of Panel selected is more than the required current rating 630 amp of Bus duct Bus bar. Hence, the bus bar size chosen is safe for the envisaged system. Support Insulator Span Calculation During Short Circuit Fm = Peak Electromagnetic force along the centre = K x 16 x Isc x 10 / S line of busbar without enclosure Isc = Short Circuit Symmetrical Fault Current in KA S = Phase spacing in Meter K = Multiplying factor (s-a)/(a+b) corresponding to a that is 60 Fm (Nm / cm ) Fm ( Kg / cm ) = (Fm x 0.1019716) F = Force acting on top of the insulator Where, H = Cantilever Height of insulator in mm h = Distance between surface of insulator to centre of Bus bar in mm F Average span to be addopted in mm = = = = = = = = = = = = 50 0.250 0.904 0.4 (Reffering to curve K is 0.9) 14400.000 1468.391 Fm (H+h)/4H 38 75 1091.632813 Cantilever Strength of insulator / safety factor x F Sk / (SF x F ) 1600 2.5 586.278 OK

4.12 a b

4.13

a b

SK = Cantilever strength of insulator(Kg/cm) SF = Safety factor Length of Span of insulator in mm Adopted Span is Conclusion:

= = =

4.4

Average span of 586.278 mm is required but span adopted is 500 mm, hence it is safe for the system envisaged.

Page 7 of 12

630 A MCC BUSBAR SIZING CALCULATION

PROJECT CLIENT CONSULTANT EPC CONTRACTOR Document ID 5000 TCD SUGAR PLANT WITH 30 MW POWER PLANT M/s. K.P.R. SUGAR MILL LTD M/s AVANT GARDE ENGINEERS AND CONSULTANT (P) LTD. ISGEC HEAVY ENGINEERING LIMITED KR11-10302-CLC-001

Revision : 01

Date : 24-05-2012

No. of Sheet - 4

5 5.1 5.2 5.3 5.4

Temperature Rise Calculation Where, I1=Calculated Rating in Amps (After deration) As per Clause 3.19 I2 = Specified Rating in Amps as per clause 1.5 T1 = Max. Temp. Rise (in Deg.C) Specified T2 = Temp. Rise in Deg. C to be calculated as T2 = = = = = = Calculated Temperature is Conclusion : = 903.77775 630 35 ( I1 / I2 ) = ( T1 / T2 T1 / (I1 / I2 ) 19.37 OK

1.64 )0.61

5.5

The Calculated Temperature rise of bus bar is 19.37 Deg. C, which is within the design Specified Temp. 35 Deg. C and it is safe for the System envisaged.

Prepared By: Ganpat C

Checked By : Kamlakar D.

Approved By : A.B.H

Page 8 of 12

800 A MCC BUSBAR SIZING CALCULATION

PROJECT CLIENT CONSULTANT EPC CONTRACTOR Document ID 5000 TCD SUGAR PLANT WITH 30 MW POWER PLANT M/s. K.P.R. SUGAR MILL LTD M/s AVANT GARDE ENGINEERS AND CONSULTANT (P) LTD. ISGEC HEAVY ENGINEERING LIMITED KR11-10302-CLC-001

Revision : 01

Date : 24-05-2012

No. of Sheet - 4

1 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 1.10

Input Data Type of Panel System Rated Voltage degree of Protection Panel Max. Current Rating in Amp (Design) Fault Current & Duration (KA RMS Symmetrical for 1 Sec.) Ambient Temperature (Deg. C.) Maximum Bus bar Temperature (Deg. C.) Maximum Enclosure Temperature (Deg. C.) Degree of Protection Bus bar Size for Phase Bus bar Size for Neutral No. of Runs : : : : : : : : : : : : : : : : : : Cubical Type 3PH ,3 Wire / 4 Wire 415V 50 Hz. 800 50 50 85 70 IP: 52 & IP: 42 for ACB Incomer 1 x 1 x 100 x 10 MM 1 x 100 x 06 MM 1 1 100 10 600 1000 SMC support with ribbed construction

1.11

No. of times Interleaved Width of Bus Bar in mm Thickness of Bus Bar in mm Bus bar cross section for Neutral in Sq.mm Cross section of Bus bar Selected in Sq. mm Type of Insulator Basic Insulation Level: One Minute Power Frequency voltage Painting: a. Enclosure Interior & Exterior b. Bus bar Minimum Clearance: a. Phase to Phase b. Phase to Earth

1.12 1.13 1.14 1.15 a 1.16

2.5KV RMS

: : : : : : : :

Epoxy paint RAL-7032, Siemens Grey Heat Shrinkable Sleeved. 25 mm 20 mm IS: 8623 Construction IS : 5082 Bus bar IP: 54 for Indoor & IP: 55 for Outdoor 0.5mtr. (500mm)

1.17

1.18 1.19 1.20

Applicable Standard Degree of Protection Span Between 2 support

Page 9 of 12

800 A MCC BUSBAR SIZING CALCULATION

PROJECT CLIENT CONSULTANT EPC CONTRACTOR Document ID 5000 TCD SUGAR PLANT WITH 30 MW POWER PLANT M/s. K.P.R. SUGAR MILL LTD M/s AVANT GARDE ENGINEERS AND CONSULTANT (P) LTD. ISGEC HEAVY ENGINEERING LIMITED KR11-10302-CLC-001

Revision : 01

Date : 24-05-2012

No. of Sheet - 4

2 2.1

Bus duct Sizing Calculation for MCC Short Time Thermal Withstand Capability of Bus bar Minimum Cross Sectional Area of Busbar (A) In Sq. Inches Isc = Short Circuit Symmetrical Fault Current in KA T = Fault duration in Sec T1 = Initial Temperature of Busbar in Deg.C T2 = Final Temperature in Deg.C A = Cross sectional area of busbar in Sq.inches A in sq.mm = A x 645.16 = = = = = = ( Isc / T ) / {14 x 10 log [T1 +258)/(T2+258)] } 50 1 85 200 1.007851794 650.226 650.226 Sq.mm for pure aluminium. = 1000

2.2 2.2

Required cross sectional Area Actual Cross section of Bus bar Selected (As per Clause1.13) in Sq.mm Conclusion:

2.3 3 3.10

The required cross section 650.226 Sq.mm is less than actual cross section 1000 Sq.mm of the bus bar selected. Hence, the bus bar size chosen is safe for the envisaged system. Bus bar Selection for Continuous Current Rating : Bus bar Selected Open air rating of bus bar for 50 Deg. C rise over ambient in Amps. : : : : : : : : : : As per Clause1.11 1500 1 x 1500 1500 150 4400 x 800 x 2400 mm 800 x 400 mm 50 Deg. C 35 Deg. C MS Steel

3.11

No. of times Interleaved (As per Clause1.11) Overall Rating of Bus Bar in Amps. Phase spacing in mm. Enclosed Size in (W x D x H ) mm Bus bar Enclosed in (W x D ) mm Design Ambient Temperature Maximum allowable temp. rise Enclosure Material

3.12 3.13 3.14 3.15 3.16 3.17

Page 10 of 12

800 A MCC BUSBAR SIZING CALCULATION

PROJECT CLIENT CONSULTANT EPC CONTRACTOR Document ID 5000 TCD SUGAR PLANT WITH 30 MW POWER PLANT M/s. K.P.R. SUGAR MILL LTD M/s AVANT GARDE ENGINEERS AND CONSULTANT (P) LTD. ISGEC HEAVY ENGINEERING LIMITED KR11-10302-CLC-001

Revision : 01

Date : 24-05-2012

No. of Sheet - 4

3.18

De-rating / Up rating: a Ambient correction factor for 35 Deg. Rise b Enclosure correction factor corresponding to bus bar c Enclosure Correction factor Material (MS) d Proximity Effect Factor e Bus bar Configuration Factor g Combined Correction Factor De-rated Current rating of bus bar after applying Correction factor in Amps. = = = = = = = 0.9 0.87 0.9 0.95 1 0.67 1500 x 0.67

3.19

3.20 3.21 4 4.10 a b c

= 1004.1975 Rating of Panel required (As per Clause 1.5) = 800 Conclusion : The de-rated Current rating 1004.19 amp of Panel selected is more than the required current rating 800 amp of Bus duct Bus bar. Hence, the bus bar size chosen is safe for the envisaged system. Support Insulator Span Calculation During Short Circuit Fm = Peak Electromagnetic force along the centre = K x 16 x Isc x 10 / S line of busbar without enclosure Isc = Short Circuit Symmetrical Fault Current in KA S = Phase spacing in Meter K = Multiplying factor (s-a)/(a+b) corresponding to a that is 60 Fm (Nm / cm ) Fm ( Kg / cm ) = (Fm x 0.1019716) F = Force acting on top of the insulator Where, H = Cantilever Height of insulator in mm h = Distance between surface of insulator to centre of Bus bar in mm F Average span to be addopted in mm = = = = = = = = = = = = 50 0.250 0.904 0.4 (Reffering to curve K is 0.9) 14400.000 1468.391 Fm (H+h)/4H 38 75 1091.632813 Cantilever Strength of insulator / safety factor x F Sk / (SF x F ) 1600 2.5 586.278 OK

4.12 a b

4.13

a b

SK = Cantilever strength of insulator(Kg/cm) SF = Safety factor Length of Span of insulator in mm Adopted Span is Conclusion:

= = =

4.4

Average span of 586.278 mm is required but span adopted is 500 mm, hence it is safe for the system envisaged.

Page 11 of 12

800 A MCC BUSBAR SIZING CALCULATION

PROJECT CLIENT CONSULTANT EPC CONTRACTOR Document ID 5000 TCD SUGAR PLANT WITH 30 MW POWER PLANT M/s. K.P.R. SUGAR MILL LTD M/s AVANT GARDE ENGINEERS AND CONSULTANT (P) LTD. ISGEC HEAVY ENGINEERING LIMITED KR11-10302-CLC-001

Revision : 01

Date : 24-05-2012

No. of Sheet - 4

5 5.1 5.2 5.3 5.4

Temperature Rise Calculation Where, I1=Calculated Rating in Amps (After deration) As per Clause 3.19 I2 = Specified Rating in Amps as per clause 1.5 T1 = Max. Temp. Rise (in Deg.C) Specified T2 = Temp. Rise in Deg. C to be calculated as T2 = = = = = = Calculated Temperature is Conclusion : = 1004.1975 800 35 ( I1 / I2 ) = ( T1 / T2 T1 / (I1 / I2 ) 24.11 OK

1.64 )0.61

5.5

The Calculated Temperature rise of bus bar is 24.11 Deg. C, which is within the design Specified Temp. 35 Deg. C and it is safe for the System envisaged.

Prepared By: Ganpat C

Checked By : Kamlakar D.

Approved By : A.B.H

Page 12 of 12

Das könnte Ihnen auch gefallen

- Panel Busbar Sizing Calculations - Thomas and RataDokument4 SeitenPanel Busbar Sizing Calculations - Thomas and Ratakapil100% (12)

- BusBar Short Circuit CalculationDokument3 SeitenBusBar Short Circuit Calculationbhaskarinvu80% (20)

- 3200A Busduct Busbar Calculation PDFDokument4 Seiten3200A Busduct Busbar Calculation PDFPramod B.Wankhade100% (8)

- Bus Bar Calculation - RequirementDokument20 SeitenBus Bar Calculation - Requirementsrigirisetty208100% (2)

- Calculation of Short-Circuit CurrentsDokument35 SeitenCalculation of Short-Circuit CurrentsdaodoquangNoch keine Bewertungen

- Short Circuit CalculationDokument3 SeitenShort Circuit CalculationA Hem Navas Navas100% (2)

- Short Circuit Current CalculationDokument5 SeitenShort Circuit Current CalculationDheeraj YadavNoch keine Bewertungen

- Power Cable SizingDokument8 SeitenPower Cable SizingPagdi Srini100% (1)

- MCC SizingDokument1 SeiteMCC Sizingmanirup_tce0% (1)

- Calculation of Cable Tray Sizes by ZahoorDokument3 SeitenCalculation of Cable Tray Sizes by ZahoorZahoor Abbas67% (3)

- Earthing Design CalculationsDokument7 SeitenEarthing Design CalculationsVamsiNoch keine Bewertungen

- Bus Bar Design Calculations For Busduct MarsDokument8 SeitenBus Bar Design Calculations For Busduct MarsKamesh1977Noch keine Bewertungen

- CCI Feasibility Study For 500 KV AC Underground CablesDokument310 SeitenCCI Feasibility Study For 500 KV AC Underground Cableserkamlakar2234100% (1)

- Osho On Ten Bulls of Zen PDFDokument2 SeitenOsho On Ten Bulls of Zen PDFerkamlakar2234Noch keine Bewertungen

- Jetronic Opel MantaDokument41 SeitenJetronic Opel MantamhahtoNoch keine Bewertungen

- GL - Sizing of Grounding TransformerDokument11 SeitenGL - Sizing of Grounding TransformerVeera BramhamNoch keine Bewertungen

- 3 Bus Bar Sizing CalculationDokument42 Seiten3 Bus Bar Sizing CalculationAnonymous OKkHA0NzNoch keine Bewertungen

- Aluminium Busbar Sizing Software OutputDokument3 SeitenAluminium Busbar Sizing Software Outputkapil100% (4)

- Busbar Sizing CalculationDokument13 SeitenBusbar Sizing CalculationPower Solution100% (2)

- Busbar Calulation For 2000a Copper BusbarsDokument3 SeitenBusbar Calulation For 2000a Copper Busbarsbalaallied100% (5)

- Arar-33kV Cable Sizing Calc 30.10Dokument13 SeitenArar-33kV Cable Sizing Calc 30.10srigirisetty208Noch keine Bewertungen

- Bus Bar SizingDokument16 SeitenBus Bar Sizingusamaanfield100% (1)

- Parameters: Calculation For Al Bus Bar Suitable For 50ka Fault LevelDokument1 SeiteParameters: Calculation For Al Bus Bar Suitable For 50ka Fault Levelanand_girgaonkarNoch keine Bewertungen

- Selection and Sizing of APFC PanelDokument21 SeitenSelection and Sizing of APFC PanelpvpavanNoch keine Bewertungen

- Motor Feeder Cable Voltage DropDokument13 SeitenMotor Feeder Cable Voltage Dropapi-384435467% (9)

- LT & HT Cable SizingDokument5 SeitenLT & HT Cable Sizingguptaakhil99Noch keine Bewertungen

- HT Cable SizingDokument12 SeitenHT Cable SizingGanesh SantoshNoch keine Bewertungen

- Electrical - Bus Bar SizingDokument9 SeitenElectrical - Bus Bar SizingsbpathiNoch keine Bewertungen

- Calculation of Cable SizingDokument10 SeitenCalculation of Cable SizingRusdianto MuhammadNoch keine Bewertungen

- Busbar CalculationDokument8 SeitenBusbar Calculationdsilvasaucedo100% (4)

- Busbar Sizing CalculationDokument4 SeitenBusbar Sizing CalculationRahul Bhattacharyya100% (1)

- Ac Ups Battery Rack SizesDokument12 SeitenAc Ups Battery Rack Sizescherif yahyaoui100% (1)

- HV Cable Sizing Calculation (MOL) - FahahilDokument5 SeitenHV Cable Sizing Calculation (MOL) - Fahahilkarikal_valavan100% (3)

- Al Hassan Switchgear MFG - Co.Llc Busbar Calculation: FactorsDokument2 SeitenAl Hassan Switchgear MFG - Co.Llc Busbar Calculation: FactorsSAI0% (1)

- MCCB & Cable Size CalculationsDokument6 SeitenMCCB & Cable Size Calculationsnicrajesh90% (10)

- Bus Bar CalculationDokument1 SeiteBus Bar Calculationelectrical_1012000Noch keine Bewertungen

- Ieee 80 Tiuch and Step Volt - Full CalcDokument22 SeitenIeee 80 Tiuch and Step Volt - Full CalcVasu Iyer100% (1)

- Short Circuit HayabusaDokument3 SeitenShort Circuit Hayabusameeng2014Noch keine Bewertungen

- Cable Sizing CalculationDokument72 SeitenCable Sizing CalculationHARI my songs100% (1)

- 33kV-11kV CT-VT Size 16.10.06 (R2) - MANDokument88 Seiten33kV-11kV CT-VT Size 16.10.06 (R2) - MANjm.mankavil6230100% (3)

- MV Capacitor SizingDokument3 SeitenMV Capacitor SizingRaja ShannmugamNoch keine Bewertungen

- 7.Lt Cable Sizing CalculationDokument7 Seiten7.Lt Cable Sizing CalculationPrabhash Verma67% (3)

- Transformer Sizing CalculationDokument2 SeitenTransformer Sizing CalculationAvishek Chowdhury100% (3)

- Cable Sizing For Main Cable - DBDokument8 SeitenCable Sizing For Main Cable - DBDharmenderSinghChoudharyNoch keine Bewertungen

- Short Circuit Current On Secondary Side in KADokument2 SeitenShort Circuit Current On Secondary Side in KANaresh MudaniNoch keine Bewertungen

- Transformer & DG SizingDokument10 SeitenTransformer & DG Sizingvinaynagvanshi5100% (1)

- Transformer Sizing CalculationDokument6 SeitenTransformer Sizing CalculationAvijnan Mitra100% (3)

- Transformer Sizing CalculationDokument7 SeitenTransformer Sizing CalculationArunava BasakNoch keine Bewertungen

- Cable Tray Calculation 15% (FAME)Dokument43 SeitenCable Tray Calculation 15% (FAME)Mohamed MostafaNoch keine Bewertungen

- Busbar Selection ChartDokument4 SeitenBusbar Selection ChartArvind KumawatNoch keine Bewertungen

- Bus Duct-DesignDokument4 SeitenBus Duct-DesignjaktomsNoch keine Bewertungen

- LT Cable Sizing Calculatioin (29.06.2011)Dokument5 SeitenLT Cable Sizing Calculatioin (29.06.2011)SARAVANANoch keine Bewertungen

- Design Calculation: Larsen & Toubro Limited ECC Division - EDRCDokument16 SeitenDesign Calculation: Larsen & Toubro Limited ECC Division - EDRCamit100% (1)

- MCC Bus Bar Sizing CalculationDokument12 SeitenMCC Bus Bar Sizing CalculationdanishNoch keine Bewertungen

- Cable Sizing CWPH PDFDokument21 SeitenCable Sizing CWPH PDFsouheil boussaidNoch keine Bewertungen

- GA DrgsDokument17 SeitenGA Drgskbl11794100% (3)

- Technical Data Sheet Rev03 Chandwa IpbDokument7 SeitenTechnical Data Sheet Rev03 Chandwa Ipbsuleman247Noch keine Bewertungen

- MCC Bus Bar Sizing CalculationDokument42 SeitenMCC Bus Bar Sizing Calculationmohan babuNoch keine Bewertungen

- Cathodic Protection System Calculation: I.P.D.C ProjectDokument10 SeitenCathodic Protection System Calculation: I.P.D.C ProjectnourfarmajidNoch keine Bewertungen

- FTPower Cable Size (1089 - 21)Dokument3 SeitenFTPower Cable Size (1089 - 21)Nishu JainNoch keine Bewertungen

- R1 VE-J061-D-E201 REV-1 Earthing Design Calculation 271010Dokument10 SeitenR1 VE-J061-D-E201 REV-1 Earthing Design Calculation 271010S Manohar100% (1)

- DS - 6.6kV HT SWGRDokument22 SeitenDS - 6.6kV HT SWGRcherif yahyaoui0% (1)

- HT Cable Sizing Cal - For HT SWBD, Dist. Trafo. & HT Motor 27.07.10Dokument12 SeitenHT Cable Sizing Cal - For HT SWBD, Dist. Trafo. & HT Motor 27.07.10mahesh_sali2003Noch keine Bewertungen

- Earthing System Design Criteria and Calculation: ProjectDokument9 SeitenEarthing System Design Criteria and Calculation: Projectcherif yahyaouiNoch keine Bewertungen

- Design of Conical Storage TankDokument17 SeitenDesign of Conical Storage TankvijaypatelnewtonNoch keine Bewertungen

- Reference TG - Cable ScheduleDokument21 SeitenReference TG - Cable Scheduleerkamlakar2234Noch keine Bewertungen

- NerationDokument531 SeitenNerationMUSTAKUL ALAM BARLASKARNoch keine Bewertungen

- Difference Between RS485 & Modbus ProtocolDokument1 SeiteDifference Between RS485 & Modbus Protocolerkamlakar2234Noch keine Bewertungen

- Bus Bar Protection Scheme 2003Dokument34 SeitenBus Bar Protection Scheme 2003srinu247Noch keine Bewertungen

- Abb Disconnector Gw54 1yva000105 Reva enDokument8 SeitenAbb Disconnector Gw54 1yva000105 Reva enerkamlakar2234Noch keine Bewertungen

- Glands: Comet Weatherproof Type Double Compression Cable GlandDokument2 SeitenGlands: Comet Weatherproof Type Double Compression Cable Glanderkamlakar2234Noch keine Bewertungen

- Minimum Clearance in SubstationDokument7 SeitenMinimum Clearance in Substationerkamlakar2234100% (1)

- Frequently Asked Questions: Your Solar PV and Electronic MeterDokument4 SeitenFrequently Asked Questions: Your Solar PV and Electronic Metererkamlakar2234Noch keine Bewertungen

- HT Cable ClampsDokument1 SeiteHT Cable Clampserkamlakar2234Noch keine Bewertungen

- A Guide To Solar PV SystemsDokument24 SeitenA Guide To Solar PV Systemserkamlakar2234100% (1)

- 440v, 50hz, 75-100ka Sirius Load Feeder En-UsDokument7 Seiten440v, 50hz, 75-100ka Sirius Load Feeder En-Userkamlakar2234Noch keine Bewertungen

- IDMT Relay Calculation (12.10.12)Dokument8 SeitenIDMT Relay Calculation (12.10.12)Achmad Zaenuri Rajasa100% (1)

- Expenses LogDokument12 SeitenExpenses Logerkamlakar2234Noch keine Bewertungen

- NSL - Technical Specification For Electrical PackageDokument175 SeitenNSL - Technical Specification For Electrical Packageerkamlakar22340% (1)

- List of Feeders For ACDB PanelDokument1 SeiteList of Feeders For ACDB Panelerkamlakar2234Noch keine Bewertungen

- 14Q2269565 RET650 IKE Rev 01Dokument4 Seiten14Q2269565 RET650 IKE Rev 01erkamlakar2234Noch keine Bewertungen

- DuckTales LyricsDokument1 SeiteDuckTales Lyricserkamlakar2234Noch keine Bewertungen

- AlstomDokument34 SeitenAlstomHitesh MehtaNoch keine Bewertungen

- Acdb SpecificationsDokument51 SeitenAcdb Specificationspratik100% (1)

- Craft Appreciation For Engineers (Cafe) ProtectionDokument28 SeitenCraft Appreciation For Engineers (Cafe) Protectionsherif ahmed moussaNoch keine Bewertungen

- NT3919ADokument266 SeitenNT3919AcarevolutionNoch keine Bewertungen

- Siemens Power Engineering Guide 7E 432Dokument1 SeiteSiemens Power Engineering Guide 7E 432mydearteacherNoch keine Bewertungen

- Coordination and Selection of Expulsion and Current-Limiting Fuses (Pad-Mounted Transformer Primary Protection)Dokument6 SeitenCoordination and Selection of Expulsion and Current-Limiting Fuses (Pad-Mounted Transformer Primary Protection)Aerwin BautistaNoch keine Bewertungen

- Personal Protective Grounding Vol5-1-PpgDokument86 SeitenPersonal Protective Grounding Vol5-1-PpgYasir HamidNoch keine Bewertungen

- Transformer Short Circuit PerformanceDokument39 SeitenTransformer Short Circuit PerformanceKamran Daud Panhwar100% (1)

- Insulation Resistance Testing Guide ENGDokument28 SeitenInsulation Resistance Testing Guide ENGRahul More100% (1)

- ANSI Standards For Protection Devices - CsanyiGroupDokument13 SeitenANSI Standards For Protection Devices - CsanyiGroupKakumanu SubhashNoch keine Bewertungen

- Overcurrent and Earth Fault Protection Systems Assessment: Hossein - Askarian@eng - Monash.edu - AuDokument0 SeitenOvercurrent and Earth Fault Protection Systems Assessment: Hossein - Askarian@eng - Monash.edu - AuAnonymous 9VcxlFErfNoch keine Bewertungen

- Energex Distribution Earthing ManualDokument42 SeitenEnergex Distribution Earthing ManualdmcalderoncNoch keine Bewertungen

- What Is Power System ProtectionDokument36 SeitenWhat Is Power System ProtectionAmberMeerabNoch keine Bewertungen

- SPLN 9d 1978Dokument76 SeitenSPLN 9d 1978emaNoch keine Bewertungen

- Earthing CalculationDokument19 SeitenEarthing CalculationNoli OtebaNoch keine Bewertungen

- Cable Fault DetectionDokument15 SeitenCable Fault DetectionVarun Thakur100% (1)

- Edition 7 Arcing Faults in Medium and Low Voltage Switchgear PDFDokument12 SeitenEdition 7 Arcing Faults in Medium and Low Voltage Switchgear PDFE.ANANDANNoch keine Bewertungen

- 3m Locator&MarkingDokument16 Seiten3m Locator&Markingzein mubarakNoch keine Bewertungen

- 2012 Catalog Index SiemensDokument45 Seiten2012 Catalog Index SiemensSnehashis SharmaNoch keine Bewertungen

- Panorama: Medium Voltage ProductsDokument6 SeitenPanorama: Medium Voltage Productsdilo001Noch keine Bewertungen

- Eaton Working With Arc Flash SolutionsDokument50 SeitenEaton Working With Arc Flash SolutionsRogelio RevettiNoch keine Bewertungen

- Symmetrical Faults Part I PDFDokument39 SeitenSymmetrical Faults Part I PDFGunjan lalakiya100% (2)

- Sync OlnDokument4 SeitenSync OlnhomaNoch keine Bewertungen

- Schneider RelaysDokument12 SeitenSchneider Relaysrajpre1213Noch keine Bewertungen

- 100% Stator Ground Fault Protection of Alternators by Low Frequency Injection and Using Real Power SignalDokument6 Seiten100% Stator Ground Fault Protection of Alternators by Low Frequency Injection and Using Real Power SignalWrya SaeedNoch keine Bewertungen

- Introduction To Substation AutomationDokument36 SeitenIntroduction To Substation AutomationIlaiyaa RajaNoch keine Bewertungen

- 05 04 7SJ602 enDokument24 Seiten05 04 7SJ602 enAbu Yussif AlaboodiNoch keine Bewertungen

- Performance Standard of Electricity Supply Services of TNB - 2016Dokument10 SeitenPerformance Standard of Electricity Supply Services of TNB - 2016anon_937316317Noch keine Bewertungen

- Fault LevelDokument23 SeitenFault Levelsuleman247100% (1)