Beruflich Dokumente

Kultur Dokumente

454 GD & HS Fuel Pump Timing & Calibrations

Hochgeladen von

slipsittinCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

454 GD & HS Fuel Pump Timing & Calibrations

Hochgeladen von

slipsittinCopyright:

Verfügbare Formate

Section 2000

BASIC ENGINE 0-155, D-179 3 D-206 1 0-239 3 D-246 9 D-268 9 D-310 9 0-358, DT-239, DT-358, DT402 Engines

J I Case

A Tenneco Company

co

Don 8-59030

Printed in England November. 1987

SPECIFICATIONS Static Timing (Degrees BTDC) *

D-155 423, E-423 383 500C/E 453 V/E 433, WE WE 433 Series II WE 533 Series II S.D. b33 5033 433 533/385

VA/VE/PS 10 10 12 10 53310 8/ 8/2.5 10/ 8/2.5 10 12 8/ 8/2.5 10/ 8/2.5

- 239 DT - 239

O 724, 734 824.744. S.U. 824. 834. 744 Crane TD 7E, 100 E P.S. TB 8 C. P.S.

0 246 VAlVE/PS 14 16 16 12 12 14 16 16 12 16 16/ 8/2.8 12 16/ 8/2.8 16 12 14 14 14 12 12 D-310 946 (2100 RPM) 946 (2200 RPM) 844 S 845 620 B 510 TD-8CA 884/885 270 A 0-268 824 834 844 784/785 84 Hydr. 2681T 2781T

VAJV E/ PS * 18 18 18 16/ 4/2.5 16 16 16

0-358 DT-358 1055, 955 1056. 956 1630 A. 1730 A, 1830 A 531. 541. (8--ill) Acer> 1 820 with AT - 540 1730B-1930B VANE 19

14/ 8/2.2 18 18 18 18 16 16 16 18 16 18 14 17 16 18 16 16 18 16 16 16 16 18

125 GD/P.S. H 30 B. Galion Cr. H-3OBNice, 321.431 Ingersoll-Rand 5000/5500 W.R. 1130/1 230 TOE

VA/VE/PS 8/ 8/2.5

Galion 102 Grader DU-2D H-60 Series 200 ATk. M.T. 1046 1521 S 725 SP H65B 866 -- HS (Austr.) 3964/3965

8/ 8/2.5 8 18 8 16/ 8/2.5 16

D-179 553 633/633 V 4500 B T.C. 454 G.D./454 ItS. 464 GD/U.S. 3654 S . U. 484. 248 IT 485 SU-644-LD 2454 GD/U.S. 240A SM/U.S/CC. 3400 A G.D./H.S. 2400 A GD/I -IS. Irrigation 506 Unit

VAlVE/PS 14

743, 745 S/833 574H.S. 574 G.D. 3654, 3654 S.U. 3500 A G.D./H.S. 674 G.D. 2500AG.D. 1258 u. TD-8B Ser. II S.U. 644 H.D. 4WD3400 B S.M. H.S./f.C. 684/685 2574G.D. 250 A. SM. 260 ATC SM./H.S.

E SlI

14/ 8/2.2 14 14 14 14 14/ 8/2.2 14 14 14 14 14 14 14

VA 16 10 14 10 12 16 12 16 18 16 10 8 14 14 14 12 16 10 8

3980 515 976, 986. 886 (U.S.) S-8A.SlO Ii-60B,520A It-65C 530A 943 953 923 933 1420/782 3990 650 3980 8/3984 B 630 280 PH 1246 1255 786 1400 Irrigation Unit 640(D-358) 640 )DT 358) 5208 8581 -

14/ 8/2.8

686 766 955

18 16/ 8/2.8 12 12 18 18 14 14 14 /8

431, 531 H SO B DU-2D 0 1500 C

16 16 18 --/10 16 16 20 18 20 16 /8 18 /12 16 16 20 /10

616/622 H.S. 711 S.P Header Harv. 165C 696 1 3820 A 9000 F. L.

- 206

VAlVE/PS 12 14 12 12

Irrigation Unit 2500 AH.S. 2574 H.S. 250A H.S./T.C. 856 XL 833 V + [

554. 654. 644 221 TD-7CG.D. 100 G.D. 733/733 V

F SIt

12/ 8/2.8 14 10 121 8/2.8 10 10 12 12

715 Comb. 782 Couon Picker 786 86 Ilydr.

474 G.D/H.S. 100 B Series II 584/585 TD-68 100 B. 624 25811 624 (Mexico)

VA = Machines with VA Injection Pump VIE = Machines with VIE Injection Pump PS = Plunger Stroke total stroke of injection plunger in mm with a tolerance of 0.02 mm (pumps without timing window only).

DT-402 3994, 650 HO 953 ItS. 953 GB 1455 53OASH

VIE 16 16

14

16

-13-

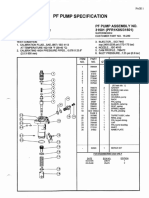

INJECTION PUMP EP/VA General:

This section consists of the following subsections: Checking Static Timing Removal Installing and Timing the Pump to the Engine Checking Timing with Dial Indicator For all other service instructions refer to service Manual "Fuel System. Injection Pump and Turbocharger".

VE

6. Slowly turn the crankshaft in direction of the rotation until the dial indicator shows 1.0 mm travel of the distributor plunger. 7. Read actual degrees of static timing on crankshaft pulley, see lIlust, 194 and 195, and compare with "Technical Data", 8. (Pumps without timing window only). Turn the engine to check the total plunger stroke and compare with timing specifications. If out by more than 0.02 mm repeat steps 4 - 8.

Checking Static Timing: B. Timing Window Method

It is good practice to check static timing of the injection pump before removing it from the engine. 1. Shut oft fuel supply, 2. Remove lower cover plate of the pump. Illust. 193 b. 3. Position the engine on the compression stroke number one cylinder (intake and exhaust valves are closed). 4. Turn the crankshaft in direction of rotation until the timing pointer (1) Illust. 194 is in line with the specified timing mark (2) on the graduation. For static degrees of the engine, see "Technical Data". 5. Read the graduation on the front pulley as outlined in lIlust. 195.

Note: The dial indicator method A) may be used with all injection pumps, whereas Method B) is restricted to pumps with timing window: Illust. 193b.

A. Dial Inidicator Method

1. Shut off fuel supply. 2. Position the engine on the compression stroke number one cylinder (intake and exhaust valves are closed). 1. Remove central plug from distributor head and mount dial indicator with extension (2), lIlust. 193 a. Rest stylus of the indicator on the face of the distributor plunger and pro-load approx. 3 mm.

Illust. 1 93b lIlust. 193 a. 1 - Dial indicator 2 Extension (special tool 1329 159C1) 3 - Packing ring 4. Slightly turn the crankshaft to and fro to find the bottom dead centre of the distributor plunger. 5. With the distributor plunger in BDC, zero the dial indicator, 1 - Pointer on roller ring 2 - Scribe line on face cam 6. With static timing correct, both pointers (Illust. 1 93b and 1 94) must be in line with their respective timing marks.

Note: On EP/VA pumps the face cam has a second scribe line marked with letter "L". Do not use this scribe line for adjustment.

-91-

INJECTION PUMP EP/VA VE

Removal

Thoroughly clean the left side of the engine to prevent dirt from entering the pump. Cap or plug all lines and ports as they are opened. Remove the injection pipes. Disconnect all lines from the pump.

Illust. 194 1 - Pointer 2 - Graduation on the front pulley

DC

10

2W

Must. 196

\2

Illust. 195 2

1 Drive shaft nut 2 - Hub 3 - Hub cap screws (three)

One graduation mark = 2 0 1 - TDC mark 100 BTDC 3 20 BTDC

-91a-

INJECTION PUMP EP/VA - VE

Remove rectangular cover plate from the crankcase front cover.

Installing and Timing the Pump to the Engine

The engine must be in static timing position (first cylinder on compression stroke and timing pointer lined up).

Remove nut (1) lllust. 196 and hub capscrews (3). Proceed as follows: 1. Remove cover plates of the injection pump (Illust. 1 93b) or mount dial indicator (lIlust. 1 93a). Remove cover plate of the front cover (lllust. 196).

Note:

Turn engine if necessary to place keyway in "up Position" (eleven oclock) to prevent the Woodruff-key from dropping into the oil pan, when the hub is removed.

/Engine front plate lllust. 197 Pulling hub from drive shaft Remove gear with hub from the shaft, lIlust. 197. Remove injection pump retainer nuts, using a special wrench extension for loosening the inner nut, see Illust. 198,

Note: When removing the injection pump be sure mating

C IW

Must. 199 2 - Gasket

2. Apply liquid sealer to both sides of new gasket (2)

Illust. 199. 3. Place woodruff-key into keyway of injection pump drive shaft. 4. Turn keyway in 11 oclock position and install the pump.

Note. The following step 5 A. does not apply for DT402 engines equipped with water channel version (1) Must. 200. On these engines position the pump as shown in Must. 201, step 5 B.

gears (pump drive gear - idler gear) are not disengaged to maintain the original timing.

,.

. $.

..

0

lllust. 198

0

Illust. 200 OT-402 engines 1 - Water channel, pump position according to step 5 B 2 - Water pump carrier, injection pump postition according to step 5 A

1 - Stud nuts (two) 2 - Washers (two) 3 - Wrench, with extension (special tool 3055 700RT)

INJECTION PUMP EP/VA - VE

SA. Positioning the pump so that washers (2) lIlust. 198 cover slotted holes of pump flange evenly, i. e. the pump is level. 5 B. On DT-402 engines with water channel (1) I Ilust. 200 take care to tilt the injection pump toward the engine all the way within the play of the flange slots (2) lIlust. 201 before tightening. If the engine is on number one compression at the specified static timing and the injection pump is installed with 1.0 mm plunger stroke the pump will be timed".

However, if the complete timing gear train has been removed, the timing of the gear train must be reset as shown in lIlust. 212.

IN

1 Illust. 203 1 - Hub 2 - Hub retainer bolts, with washers 3 - Keyway (in 11 oclock position) 7. Install hub (1) Illust. 203, use quality bolts (six lines Illust. 204) and steel washers. Tighten bolts (2) I [lust. 203 slightly.

-z -

Must. 201 VE-Injection pump position on DT-402 with (1) Illust. 200 1 Stud 2 - Slot 3 - Engine 4 - Injection pump, VE

F6 F-6

6. Tighten stud nuts (1) Illust. 198 to specified torque.

-

lllust. 204

1

lIlust. 202 1 - Injection pump drive gear 2 - Timing marks

2 1

Must. 205 1 - Hub 2 - Hub retainer nut, with lock washer 3 - Bolts, hub to gear -93-

Note: Since the idler gear is a walking gear, proper timing

alignment (2) Illust. 202 will not always be noted.

INJECTION PUMP EP/VA - VE

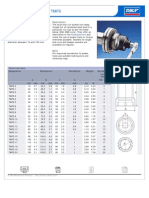

8. Install lock washer and nut (2) Illust. 205 Block the engine and tighten nut (2), observe the different special torques for the respective nut size: M - 12 = (19 mm spanner) 6 - 7 daNm M 14 = (22 mm spanner) 8.5-10 daNm 9. Loosen bolts (3).

Checking Injection Pump Timing with Dial Indicator (pumps with timing window)

)

Illust. 208 1 - Graduation marks, pulley 2 - Pointer shows degrees of timing as specified 3 - Pointer on roller ring 4 - Scribe line on face cam 5 - Extension (special tool) 6 - Dial indicator, shows 1.0 mm plunger stroke If the position of timing pointer (1) lIlust. 207 is in doubt or if scribe mark on face cam cannot be clearly seen check pump timing with dial indicator, following method A. See also Illust. 1 93a

Illust. 206 Adjusting the injection pump 10. Turn the injection pump drive shaft until the pointer on the roller ring is in line with the scribe mark on the face cam lIlust. 207 or the dial indicator shows 1.0 mm plunger stroke, lIlust. 1 93a. At this point tighten the retainer bolts to specified torque. See "Special Bolt and Nut Torque Data". Finally turn the engine through a complete cycle and check to make sure that the timing of the front pulley at compression stroke coincides with that of the face cam lIlust. 207 or with the 1.0 mm plunger stroke shown on the indicator lIlust. 1 93a.

lIlust. 207 1 - Pointer on roller ring 2 - Scribe line on face cam

94 -

INJECTION PUMP EP/VA - VE

Note: (VE-pumps only). When connecting the fuel lines, make sure to use the fuel return valve (5) lllust. 211 on the pump return port. The feed pumps is a diaphragm-type pump driven by the engine camshaft. It can also be operated manually on hand lever (6) lIlust. 209 to fill the fuel system or for venting purposes.

Fuel Feed Pump

A filter screen is installed in the feed pump to primarily filter the fuel from the fuel tank. When servicing the engine it is good practice to remove the filter screen. Use a soft brush and carefully clean in Diesel fuel, On reassembly make sure all parts seat properly to avoid leakage. Install a new feed pump if the diaphragm is damaged or the operating mechanism is defective. 4 10 Install plug (11) using liquid sealer.

13

Note: The fuel feed pump is attached to the crankcase side cover by means of an additional flange with two studs. To prevent dropping the flange into the crankcase on removal or installation, stud nuts should be cautiously removed and installed respectively.

14 lIlust. 209

_95-

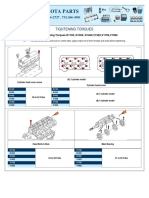

INJECTION NOZZLE HOLDER Installation

A. Flange Mounted Holder Place the sealing 0-ring approx. 6 mm (24 in.) above the nozzle holder nut, them install the nozzle holder. Make sure the 0-ring is not twisted Tighten stud nuts or necked-down bolts in two steps to specified torque.

<" 4j 5\

) /2

lllust. 211

.1

1 - Nozzle holder 2 - Crab 3 Bolt

4 - Fuel return line 5 - Return valve 6 Return line

Make sure hollow screws, show to the valve cover, Must. 211. Place the nozzle crabs into position and install the dished washers and crab bolts. Illust. 210 Tighten the bolts (3) to specified torque. 1 - Nozzle holder seat capped up 2 - Nozzle holder Connect the fuel supply pipes and the fuel return line to the nozzle holders. B. Crab Mounted Holder Clean sleeves in cylinder head and install nozzle holders using new 0-rings. Tighten pipe union nuts and fuel return hollow screws to specified torque, refer to "Special Nut and Bolt Torque Data".

1111"I

TIMING GEAR TRAIN Adjustment

78

A - B AA

lllust 212 1 - Crankshaft pinion 2 Idler gear Injection pump drive gear 3 Camshaft drive gear 4 End play of idler gear = 5 0.20 0.33 mm (.0078 -.0130 in.) 6 End play of camshaft = 0.09-0.44mm(.0035.fl173in.) 7 - Scribe mark on pump flange (displaced) 8 Front plate 9 Injection pump hub 10 Idler gear carrier

BB

IlIust. 212 shows the gear train of a 6-cyl.-engine with piston number one on compression bC.

Note: Marks on injection drive gear are for easy assembly. It is not essential that the timing marks of injection pump drive gear be aligned for proper timing. If the engine is on number one compression at the specified static timing and the injection pump is installed with the injection plunger at 1.0 mm stroke. the pump will be timed. However, the following timing instructions should be used to facilitate gear installation.

On all engines the timing marks of gears (1) and (4) must be in line with the timing marks of the idler gear (2).

The injection pump drive gear (3) is marked with num bers 1 up to 6.

TIMING GEAR TRAIN

Timing Instructions for Injection Pump Gear (3) IlIust. 212 (Part Numbers 3055 066 R3, 3056 885 R3, 3218 450 Ri)

Illust. 212 a.

3 - Cylinder Engines Engines with water channel A, use timing, mark 1. Engines with water pump carrier B, use timing mark 3. Cylinder Engines Engines with water channel A. use timing mark 2. Engines with water pump carrier B, use timing mark 4. 6 - Cylinder Engines Engines with water channel A, use timing mark 5. Engines with water pump carrier B, use timing mark 6.

Fuel Rator Test Specifications

Engine: D 179

Application: 2400 A G. D., 2454 G. D., 4500 A, 454 G. 0., 3400 A G. 0., (Britain), 240A S.M./G.D. (Britain), 484 (xxx), 248 (xxx)

Injection Pump "Bosch" EP/VA31100H 1100 CR-62 (3 144 402 R91)

Pump speed ....................................................1/2 engine speed Low idle speed - engine ............................................750 High idle speed - engine ............................................ max. 2455 Rated load speed - engine ..........................................2200 Minimum overload speed - engine .....................................1600 Max. torque daNm (ft.lbs) at 1600 engine rpm .............................18.3 Rated kW (HP) at engine rated load speed ................................38

Timing Advance

Static timing - engine, degrees BTDC ...................................14 Total advance - engine, degrees BTDC ..................................25.9 Start to advance - engine rpm ........................................380 Pump advance at minimum overload engine speed (travel of advance piston) mm (inch) ....................................4.7 (.19) Full pump advance (travel of advance piston) mm (inch).......................5.4 (.21)

Charging Pump Pressure, at:

Low idle, MPa (PSI) ...............................................0.29 (43) Minimum overload speed, MPa (PSI) ....................................0.50 (73) Rated load speed, MPa (PSI) .........................................0.57 (85) Max. permissible vacuum at inlet side of pump kPa (PSI) ......................20 (-2.9)

Fuel Ra tar Specifications

Maximum fuel at rated load speed kg/h (Ibs/hr) ............................ Minimum time sec/1000 ccm (sec/qt) * Fuel at 2100 rpm engine speed kg/h (lbs/hr)............................... Minimum time sec/1 000 ccm (sec/qt) * Fuel at minimum overload speed kg/h (lbslhr) ............................. Minimum time sec/1000 ccm (sec/qt) Fuel temperature at overflow line OC )0F) 8.98 337 8.57 352 6.26 483 47 ( 19.8) (319 ( 18.9) (333 ( 13.8) (457 (116.5)

US qt

(NEZG 2836) Engine power, fuel consumption and charging pump pressure + 3 %

5-19

Flow Bench Test Specifications

Engine: Rated Speed: 2200 RPM D 179 Application: 2400 A G.D., 2454 G.D., 4500 A, 454 G.D., 3400 A G.D. (Britain), 240 A S.M./G.D. (Britain), 484 (xxx), 248 (xxx)

Injection Pump I H CNo. 3 144 402 R91 BoschNo. EP/VA3/100H 1100 CR-62

Correction of Control Specifications acc. to "Bosch" Test Instruction VDTWPP 161/4 or Pre-Adjusting Dimensions see "Bosch" Repair Manual VDTWIP 161/4 Plunger Lift to Port Closure 0.3 ( 0.02 mm ( 0.04 mm) Static Timing Alignment of the Pointer at 1 mm Plunger Stroke (ref. to Outlet A) Delivery Difference 1. Control Specifications RPM cu.cm./1000 Strokes 1.1 Injection Advance 600 3-4 mm 1.2 Charging Pump Pressure 600 0.4-0.45 MPa cu.cm. 1.3 Full Load Delivery 2.5 800 65.5-66.5 1.4 Idler-Governor Run-Out 375 16 22 1.5 Start 95 100 mm. 1.6 End-Governor Run-Out 1170 31 39 2. Check Data and in Brackets (Re-check Data) RPM 2.1 Injection Advance 160-300 (120-330) mm Begin 2.2 Charging Pump Pressure RPM 200 MPa 0.16-0.21 (0.14-0.23)

" " -

3 Opening P. 20 MPa

600 (2,7-4.3) 600 (0.38-0.47)

820.970 (790-1000) End (5.2-5.9) 1100 0.61-0.66 (0.59-0.68)

2.3 Feed Quantity Speed Lever End-Position

Feed Lever Full

RPM 1190-1240 1170 1080 800 500

cu.cm ./1000 Strokes 10 0 (30-40) 66-69 (66.5-69.5) (65-67) 68 - 72(67 - 73)

Overflow Quantity cu.cm./10 sec.

55-100(40-110)

Idling Position

Stop Full

1100 460-510 (4 40- 530) 375 100 220(200) 340 (360)

0 0 (14-24) mm. 95 min. 95 max. 60 2 mm 24.6 mm

Start

Opening Pressure 20MPa

Shim thickness under advance piston spring Pre-load length of governor spring

(NEZG 2775)

5-20

PERFORMANCE DATA Engine: D-179 Application: 454 HS, 464 HS/GD, 240A HS/TC, 2400A HS, 2454 HS, 3400A HS/GD (U.S.), 4500B TC, 506

Injection Pump: EP/VA31100H 1200 CR 61 (3 144 403 R91)

Pump speed .......................................................... Engine speed: low idle ..................................................... 1 /min 1 /min 1 /min 1 /min kW

1/2 engine speed

700-800 2710 2400 1600 39 18.5

high idle .....................................................

rated load .................................................... minimum overload ..............................................

Rated power at rated load speed

.........................................

Max. torque at minimum overload speed .................................. Torquerise

daNm

........................................................

%

14 650 27.9 3.1 6.3

Static timing - engine ......................................... Start to advance - engine speed

degrees BTDC 1/min

.......................................

Total advance - engine ........................................ Pump advance at minimum overload speed

degrees BTDC

.................................. mm

Full pump advance at rated load speed ..................................... mm Charging pump pressure at: low idle .......................................................kPa

248 448 675 - 20

minimum overload speed ............................................kPa rated load speed ..................................................kPa Max. permissible vacuum at inlet side of pump ................................kPa

Fuel rator specifications: Fuel consumption at: rated load speed ................................................. kg/h 9.7 314 9.3 328 6.9 440

time......................................................... s/I 1 00/min below rated speed .......................................... kg/h

time......................................................... s/I minimum overload speed ........................................... kg/h

time......................................................... s/I Turbocharger, boost pressure at rated speed .................................. kPa

Engine power, fuel consumption and charging pump pressure + 3 % (NEZG 2835)

5-21

Flow Bench Test Specifications

Engine: Application:

Injection Pump

Rated Speed: 24001rn/n D-179 454 H.S., 464 H.S./G.D., 240A H.S./T.C., 2400A H.S., 2454 H.S., 3400A H.S./G.D. (U.S.), 4500B, T.C., 506

IHCNo. 3 144 403 R91 BoschNo. EP/VA3/100H1200CR61

Correction of Control Specifications acc. to "Bosch" Test Instruction VDTWPP 161/4 or Pie-Adjusting Dimensions see "Bosch" Repair Manual VDTWIP 161/4 Plunger Lift to Port Closure 0.3 0.02 ( 0.04) mm Alignment of the Pointer at 1 mm Plunger Stroke (ref. to Outlet A) Static Timing Delivery Difference 1 . Control Specifications 1/mm. cm-_/_1000_Strokes 3.9 - 4.9 mm 800 1.1 Injection Advance 480 - 530 kPa 1.2 Charging Pump Pressure 800 cm3 68 -69 2.5 800 1.3 Full Load Delivery 1000 Strokes 400 12 - 18 " 3 1.4 Idler-Governor Run-Out " Opening P. 20 MPa mm. 95 100 1.5 Start 34 -42 1250 1.6 End-Governor Run-Out 2. Check Data and in Brackets (R e-chec k Data ) 800 200-350 (170-380) 980-1130(950-1160) 2.1 Injection Advance 11mm. Begin mm (3.6-5.2) End (6.0-6.7) 200 800 1200 2.2 Charging Pump Pressure 1/mm. kPa (460-550) 630-680 (610-700) 160-210 (140-230) 2.3 Feed Quantity . Delivery Overflow Quantity Feed Lever Speed Lever mm. cm 3 / 1000 Strokes cm3 / 10 sec. Full End-Position 1290-1340 10.0 0. (1275-1355) 1250 (33.0-43.0) 1150 69.0-72.0 (68.5-72.5) (67.5-69.5) 800 55-100 (40-110) 500 67.0-71.0 (66.0-72.0)

Idling Position

Stop Full

Start

1200 490-540 ( 470 - 560) 400 100 220 (200) 340 (360)

0 0 (10.0-20.0) mm. 95 mm. 95 less than 60

Opening Pressure 20 MPa

1: Shim thickness under advance piston spring 2: Pre-load length of governor spring

1.6 mm 24.6 mm

(NEZG 2776)

5-22

Das könnte Ihnen auch gefallen

- CVT Manual - CVT Manual PDFDokument56 SeitenCVT Manual - CVT Manual PDFZakaria Kalomar89% (9)

- Contrails ! Bosch VE Inection PumpDokument17 SeitenContrails ! Bosch VE Inection Pumpesyjam100% (2)

- Meritor Air Brake Workbook PDFDokument31 SeitenMeritor Air Brake Workbook PDFslipsittin100% (2)

- Diesel Pump and TimingDokument60 SeitenDiesel Pump and TimingMickye Mickyedj100% (3)

- Mack Truck t200 To t300 UpgradeDokument36 SeitenMack Truck t200 To t300 UpgradeslipsittinNoch keine Bewertungen

- In Service Certification (Wof and Cof)Dokument1.080 SeitenIn Service Certification (Wof and Cof)slipsittinNoch keine Bewertungen

- Pump Test Specifications: InjectionDokument3 SeitenPump Test Specifications: InjectionJaqueline S. S. Maicá100% (1)

- Mazda T3000 T3500 T4000 Workshop Repair ManualDokument905 SeitenMazda T3000 T3500 T4000 Workshop Repair ManualBestManuals4u87% (15)

- ZF-16S151 Rebuild PDFDokument66 SeitenZF-16S151 Rebuild PDFslipsittin100% (4)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceVon EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNoch keine Bewertungen

- Full Inyection NEW HollandDokument66 SeitenFull Inyection NEW HollandERMINSUL VICUÑA SALAS100% (1)

- Pe and Tics Type Injection Pump Connector Part Numbers For North AmericaDokument9 SeitenPe and Tics Type Injection Pump Connector Part Numbers For North AmericaSubhojit Samonta100% (1)

- Ki T S & Component S Ki T S & Component SDokument52 SeitenKi T S & Component S Ki T S & Component SEdinson Ariel Chavarro QuinteroNoch keine Bewertungen

- EDokument34 SeitenEEdinson Ariel Chavarro Quintero100% (1)

- Amarok (2H) : Volkswagen 2.0 Bitdi CdbaDokument14 SeitenAmarok (2H) : Volkswagen 2.0 Bitdi CdbaMarco Antonio Tomaylla Huamani100% (2)

- SKF Nut Sockets PDFDokument1 SeiteSKF Nut Sockets PDFslipsittinNoch keine Bewertungen

- Worshop Manual DPS Fuel Injection Pum PDFDokument139 SeitenWorshop Manual DPS Fuel Injection Pum PDFDaniel Falcones100% (1)

- Airbus A320 Powerplant Training ManualDokument51 SeitenAirbus A320 Powerplant Training Manualm21m29100% (1)

- Diesel e in Spritz UngDokument82 SeitenDiesel e in Spritz Ungrectificacionesvera100% (1)

- Two-Spring Nozzle Holder Calibration Data: For IsuzuDokument61 SeitenTwo-Spring Nozzle Holder Calibration Data: For IsuzuLuis MirandaNoch keine Bewertungen

- KKK K14 K16Dokument6 SeitenKKK K14 K16Cesar Riquelme100% (1)

- LM6000 Package Familiarization & Operations PDFDokument787 SeitenLM6000 Package Familiarization & Operations PDFJadid Abdullah100% (19)

- 1/11 Engine Model: 4He1-X: Ass'y No.: 107492-1112Dokument11 Seiten1/11 Engine Model: 4He1-X: Ass'y No.: 107492-1112Marco100% (3)

- B&J Fuel InjectionDokument24 SeitenB&J Fuel InjectionZeeshan Ahmad100% (1)

- Brinkman 4435 Owners ManualDokument36 SeitenBrinkman 4435 Owners ManualslipsittinNoch keine Bewertungen

- CAT 3204 Pin Time EngineDokument3 SeitenCAT 3204 Pin Time Engineslipsittin60% (5)

- Manual Partes Motog. ONAN MDKAL - 981-0261CDokument91 SeitenManual Partes Motog. ONAN MDKAL - 981-0261Ccarlos moralesNoch keine Bewertungen

- Intro To AutomotiveDokument49 SeitenIntro To AutomotiverezoltNoch keine Bewertungen

- Deteqstandart PDFDokument4 SeitenDeteqstandart PDFMoaed KanbarNoch keine Bewertungen

- Katalog 1Dokument103 SeitenKatalog 1INoch keine Bewertungen

- Cat Classic PartsDokument382 SeitenCat Classic PartsDaniel Prado Pino100% (1)

- Perkins 400 Series: Workshop ManualDokument6 SeitenPerkins 400 Series: Workshop ManualDella AstariNoch keine Bewertungen

- Single Aisle Technical Training Manual T2 (IAE V2500) (LVL 2&3) Power Plant Iae V2500Dokument212 SeitenSingle Aisle Technical Training Manual T2 (IAE V2500) (LVL 2&3) Power Plant Iae V2500Mahmoud Krayem0% (1)

- Grs 900rDokument11 SeitenGrs 900rslipsittin92% (13)

- Dongtai Catalog2022.4.29Dokument335 SeitenDongtai Catalog2022.4.29Flores Brayan100% (1)

- Data Kalibrasi Injection Pump Forklift MitsubishiDokument3 SeitenData Kalibrasi Injection Pump Forklift Mitsubishinarama100% (1)

- Test PlanDokument4 SeitenTest PlanOFFICE DANACNoch keine Bewertungen

- 110 PDFDokument41 Seiten110 PDFSoeAye100% (1)

- Injector Specification: Assembly No: 36710Dokument1 SeiteInjector Specification: Assembly No: 36710johnny sabinNoch keine Bewertungen

- Nozzles and Spare Parts For: Denso Common Rail InjectorsDokument6 SeitenNozzles and Spare Parts For: Denso Common Rail InjectorsBalariniRetífica100% (1)

- Seven Nozzles 2017Dokument128 SeitenSeven Nozzles 2017DenisEcheverri0% (1)

- Dpico: Inj. Pump Calibration DataDokument4 SeitenDpico: Inj. Pump Calibration DataGiovaniBalzaniNoch keine Bewertungen

- 16s151 Ahelical TeethaDokument11 Seiten16s151 Ahelical TeethaslipsittinNoch keine Bewertungen

- Dpico: Inj. Pump Calibration DataDokument3 SeitenDpico: Inj. Pump Calibration DataMiguel Rojas100% (1)

- Fuel Injection Pump Housing and Governor (New Scroll Fuel System Effective in Production With 10X5411-UP, 45V36536-UP)Dokument9 SeitenFuel Injection Pump Housing and Governor (New Scroll Fuel System Effective in Production With 10X5411-UP, 45V36536-UP)Hammam al HammamNoch keine Bewertungen

- 2 Cylinder PDFDokument106 Seiten2 Cylinder PDFRicardo AguirreNoch keine Bewertungen

- Makalah Wirausahawan SuksesDokument6 SeitenMakalah Wirausahawan SuksesSurya IrawanNoch keine Bewertungen

- Eaton: Medium Duty Piston PumpDokument20 SeitenEaton: Medium Duty Piston PumpFernando SabinoNoch keine Bewertungen

- Grs 900r PDFDokument11 SeitenGrs 900r PDFslipsittinNoch keine Bewertungen

- Diesel Fuel Injection Pump Disassemble Retainer Tools For SaleDokument3 SeitenDiesel Fuel Injection Pump Disassemble Retainer Tools For SaleChrisNoch keine Bewertungen

- Spicer AXIP 0085Dokument52 SeitenSpicer AXIP 0085slipsittinNoch keine Bewertungen

- F4RDokument42 SeitenF4Rδαιβελ εςριησςα75% (4)

- GT3-Cup 2007 PA07 0002 Technical Manual PDFDokument80 SeitenGT3-Cup 2007 PA07 0002 Technical Manual PDFjoop12311770% (1)

- Oem Components For VRZ Type Injection PumpsDokument3 SeitenOem Components For VRZ Type Injection PumpsMoaed KanbarNoch keine Bewertungen

- GE 109: Introduction To Engineering Product: Week 1Dokument22 SeitenGE 109: Introduction To Engineering Product: Week 1Hemant MeenaNoch keine Bewertungen

- TICS Pump Electrical Part Resistance For HINODokument35 SeitenTICS Pump Electrical Part Resistance For HINOBala Equal BalanceNoch keine Bewertungen

- Catálogo de Productos MurphyDokument28 SeitenCatálogo de Productos MurphyRené GPNoch keine Bewertungen

- Nozzles - Catalogue - 2013-03 - Updates PDFDokument96 SeitenNozzles - Catalogue - 2013-03 - Updates PDFanshel100% (1)

- 2011-03-13 134535 New Opendocument TextDokument5 Seiten2011-03-13 134535 New Opendocument TextUriel MFNoch keine Bewertungen

- Manual de Utilizare Honda JazzDokument457 SeitenManual de Utilizare Honda Jazzjuancarlosk2000Noch keine Bewertungen

- DE08 Engine ManualDokument80 SeitenDE08 Engine ManualRonaldi motter100% (6)

- Yeson 28S ManualDokument5 SeitenYeson 28S Manuala100% (1)

- Simms Cav Cat.26id.126Dokument3 SeitenSimms Cav Cat.26id.126David LincolnNoch keine Bewertungen

- VS1131Dokument2 SeitenVS1131Stroia Constantin MariusNoch keine Bewertungen

- 454 GD HS Fuel Pump Timing Calibrations PDFDokument15 Seiten454 GD HS Fuel Pump Timing Calibrations PDFlan1-x1Noch keine Bewertungen

- PF Pump Specification: Stmdyne"Dokument2 SeitenPF Pump Specification: Stmdyne"Miguel RojasNoch keine Bewertungen

- VP44 InstallDokument6 SeitenVP44 InstallDeybbi Olmos OlayaNoch keine Bewertungen

- Nantai Catalog NewDokument30 SeitenNantai Catalog Newspalomos100% (1)

- EPS100Dokument4 SeitenEPS100basilio obregon lopezNoch keine Bewertungen

- Catalogue 2016 EngDokument256 SeitenCatalogue 2016 Engdiagnopro100% (2)

- Parts Bulletin: Technical Support Group Product Support DepartmentDokument7 SeitenParts Bulletin: Technical Support Group Product Support DepartmentUserfabian215Noch keine Bewertungen

- Fuel Injection SystemDokument22 SeitenFuel Injection SystemAlkaf Quraishi100% (2)

- lt1000d6 PDFDokument3 Seitenlt1000d6 PDFJo Ferry0% (1)

- 09c01 Fuel Injection Pump (Rotor)Dokument6 Seiten09c01 Fuel Injection Pump (Rotor)hbpate3Noch keine Bewertungen

- 1960000-5272 2Dokument5 Seiten1960000-5272 2Edinson Ariel Chavarro QuinteroNoch keine Bewertungen

- Ford Ranger BrochureDokument8 SeitenFord Ranger BrochureGabriel Andrew EstrellaNoch keine Bewertungen

- Bosch Inline Piezo Injector Delivery PlanDokument9 SeitenBosch Inline Piezo Injector Delivery PlandieseldvNoch keine Bewertungen

- Fuel Supply Pump Inner Parts PDFDokument2 SeitenFuel Supply Pump Inner Parts PDFMilorad ZelenovicNoch keine Bewertungen

- EE4760Dokument2 SeitenEE4760OFFICE DANACNoch keine Bewertungen

- China Factory Dlla149p1515 Nozzle Fit For Common Rail Volvo Fuel Injector 0445110259Dokument4 SeitenChina Factory Dlla149p1515 Nozzle Fit For Common Rail Volvo Fuel Injector 0445110259Alen HuangNoch keine Bewertungen

- 532 Referencias de GyjuDokument448 Seiten532 Referencias de Gyjuوالله حبيتكNoch keine Bewertungen

- ESI2.0 - Prices & Order FormDokument5 SeitenESI2.0 - Prices & Order FormAmr MohamedNoch keine Bewertungen

- CR Nozzle Brochure ApplicationDokument2 SeitenCR Nozzle Brochure ApplicationTamer Moustafa100% (1)

- 9161Dokument5 Seiten9161BaytolgaNoch keine Bewertungen

- PF Pump Specification: Stanadyne"Dokument2 SeitenPF Pump Specification: Stanadyne"Miguel RojasNoch keine Bewertungen

- Pump Repair ManualDokument17 SeitenPump Repair ManualSergiSerrano100% (1)

- Two Stroke RotaryDokument8 SeitenTwo Stroke RotaryslipsittinNoch keine Bewertungen

- Elan 5 SPDDokument6 SeitenElan 5 SPDslipsittinNoch keine Bewertungen

- Axsm 0038Dokument48 SeitenAxsm 0038slipsittinNoch keine Bewertungen

- SKF Nut SocketsDokument1 SeiteSKF Nut SocketsslipsittinNoch keine Bewertungen

- 2020 Honda crf150r RB 74971Dokument163 Seiten2020 Honda crf150r RB 74971Fredrik LingNoch keine Bewertungen

- TCD 2015m Marine enDokument2 SeitenTCD 2015m Marine enNguyễn Tấn TrưởngNoch keine Bewertungen

- Original Mak Injector Nozzle Elements Are World-Class High-Tech ProductsDokument1 SeiteOriginal Mak Injector Nozzle Elements Are World-Class High-Tech ProductsHải Lưu MinhNoch keine Bewertungen

- Turbocharging in Switzerland - A HistoryDokument14 SeitenTurbocharging in Switzerland - A HistoryDiego KuschauskyNoch keine Bewertungen

- Supercharging and Turbocharging: High Performance Aircraft EnginesDokument42 SeitenSupercharging and Turbocharging: High Performance Aircraft EnginesBalachander RkNoch keine Bewertungen

- EVAP - OBD II Motocraft Service Manual Theory PDFDokument1 SeiteEVAP - OBD II Motocraft Service Manual Theory PDFRachel RykesNoch keine Bewertungen

- DBGFC 633 - 5DB: ModelDokument2 SeitenDBGFC 633 - 5DB: Modeljohnny sabinNoch keine Bewertungen

- Kubota Parts: Tightening TorquesDokument3 SeitenKubota Parts: Tightening TorquesAlaina SousaNoch keine Bewertungen

- Infopack 2016 enDokument44 SeitenInfopack 2016 enAlbertoNoch keine Bewertungen

- Me 010 505 Internal Combustion Engines and CombustionDokument2 SeitenMe 010 505 Internal Combustion Engines and CombustionAswith R ShenoyNoch keine Bewertungen

- Mechanical (L3 With TelDokument36 SeitenMechanical (L3 With TelYordano PerezNoch keine Bewertungen

- Toyota GlanzaDokument1 SeiteToyota GlanzaQa LabNoch keine Bewertungen

- Torque de Bancada DD15Dokument6 SeitenTorque de Bancada DD15Jhovanny TorresNoch keine Bewertungen

- Ravenol Vmo Sae 5W-40Dokument2 SeitenRavenol Vmo Sae 5W-40costin rusuNoch keine Bewertungen

- p11 5S-FE+ENGINE+REPAIR+MANUALDokument5 Seitenp11 5S-FE+ENGINE+REPAIR+MANUALkavindaNoch keine Bewertungen

- Data and Dimensions: Phaser/1000 SeriesDokument1 SeiteData and Dimensions: Phaser/1000 SeriesNikNoch keine Bewertungen

- PerkinsDokument3 SeitenPerkinsJacques Van NiekerkNoch keine Bewertungen

- HW1Dokument3 SeitenHW1Paul RubleNoch keine Bewertungen