Beruflich Dokumente

Kultur Dokumente

Boilers Chimney Draft and Breeching Calculation

Hochgeladen von

joabjim8392Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Boilers Chimney Draft and Breeching Calculation

Hochgeladen von

joabjim8392Copyright:

Verfügbare Formate

169278644.xlsx.

ms_office

1 of 15

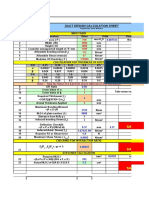

SUMMARY SHEET FOR STACK ADEQUACY

1 Overfire draft: (Given by manufacturer) Boiler draft loss: (Given by manufacturer) Total friction loss due to straight run of ducts: (Pages: 4,5,6) Total friction loss due to bends: (Pages: 7,8) Total pressure drops or gains due to area changes: (Pages: 9) Other friction losses: Item Dampers: Entry Port: Stack Draft Effect: (Pages: 3)

Pressure

0.5000 in. w.c.

0.3000 in. w.c.

0.0029 in. w.c.

0.2029 in. w.c.

0.0000 in. w.c.

Qty.: friction loss (in w.g.) 1 1 0.1

0.0088 in. w.c. 0.1000 in. w.c. 0.2823 in. w.c.

TOTAL GAINS ( Sum of positive pressure differentials) TOTAL LOSSES ( Sum of negative pressure differentials) FACTOR OF SAFETY (note: e.g. 10% is to be entered as 1.1) 8 Net available draft: (TOTAL GAINS) - (TOTAL LOSSES) x (FACTOR OF SAFETY): If line 8 is positive the stack is adequate. If line 8 is negative and an I.D. fan is to be used to convert net loss to equivalent loss at 70 deg. F and size I.D. fan accordingly; 9 Conclusion: The Stack is adequate

0.7823 in. w.c. 0.6146 in. w.c. 1.1

0.1062 in. w.c.

Stack Adequacy

9/3/2013

169278644.xlsx.ms_office

2 of 15

Volume flow rate of flue gases Calculation (Method 1)

Assuming that one(1) cubic feet of 60 F flue gas is produced for every 95 Btu of gross input (Reference: Flow of flue gases, page 155, North American Combustion Handbook, 1965) ( assumed that the flue gas and air density are the same ) Boiler Horsepower 265 BHP Total Btu of gross input: 8,857 MBH at 60 F or (data from vendor) 8,857,000 Btu/hr per one(1) boiler

520 R

Formula Constant 1 Assumed flue gas temp. where breeching joins chimney (Tbc): Assumed flue gas temp. at top of stack (Ts): Average stack flue gas temperature (Te): Flue gas volume rate (1) Boiler:

177,500,000 430 F 370 F 400 F 43 cfs 2,575 cfm 4 (4) Boilers 172 cfs 10,299 cfm

Number of Boilers Total Flue gas volume rate

Volume flow rate of flue gases Calculation (Method 2)

Using equation from page (ii) GK calculation notes) Excess air Average stack flue gas temperature (Te): (From Calculation Method 1) Oil Fired Rate per (1) Boiler, light oil, EASCO Model 199 Number of Boilers: After applying Formula in 3.a, Page (ii), Gary Krishnan Hand out copy, we found : Flue gas volume rate, per one(1) boiler Flue gas volume rate, per two(4) boilers 3,083 cfm 12,332.40 cfm 30 % 400 F

60 GPH 4

Volume flow rate of flue gases Calculation (Method 3)

Based on GPH and CFM rule of thumb (1) GPH is equivalent to: Flue gas volume rate, per one(1) boiler Flue gas volume rate, per two(4) boilers Flue Gas 53 cfm 3,180 cfm 12,720 cfm

USE:

3,250 cfm 13,000 cfm

1 boiler 4 boilers

Flue CFM

9/3/2013

169278644.xlsx.ms_office

3 of 15

Flue CFM

9/3/2013

169278644.xlsx.ms_office

4 of 15

Chimney Height

Refer to dwg. Elevations, Original Design, A-8, Sheet 8, Nov. 6,1956 Elev. (ft) Finished Cellar Fl Bottom of Steel Breeching Finished First Fl Finished Second Fl Finished Third Fl Finished Fourth Fl Top of Roof Slab Tof of Penthouse Roof Slab Top of Brick Chimney Chimney total height 44' - 0" 60'-0" 66' - 0"

121'-4" 124' - 4"

58.33 assumed 64.33

Theoretical Chimney Draft Effect

Using equations from page (iii) GK calculation notes) Formula Constant (C1) Formula Constant (C2) Formula Constant (C3) Formula Constant (C4) Formula Constant (C5) 2.96 0.000388 0.00126 0.031 0.029

Height of Chimney (H) Barometric pressure (Bo) Weight of air at 0F and sea level pressure (Wo) Weight of stack gases at 0F and sea level pressure (Wc) Absolute temperature of outside air in worst condition (To) Average stack flue gas temperature (Tc): Weight of gases generated by boiler (W) Coefficient of friction (F) Stack Inside diameter (D) Cross sectional dimensions of stack (W x H) Width: Height:

64.33 29.92 0.0863 0.09 555 860

ft in. Hg lbs/cf lbs/cf R R

9.528 lbs/sec 0.016

60 in 60 in

5.00 5.00

Rectangular Stack Draft Effect (Dr)

0.282 in. w.c.

Stack Effct Calc

9/3/2013

169278644.xlsx.ms_office

5 of 15

ft ft

Stack Effct Calc

9/3/2013

169278644.xlsx.ms_office

6 of 15

Breeching Straight Runs Friction Losses

Straight Run location: Type of duct: Breeching equivalent diameter: Straight Duct Length Exhaust gas flow Flue velocity Straight Run Friction Losses: Friction Loss Correction for temperature Correction for roughness Corrected Friction loss Friction Loss: 0.015 in. w.c. /100ft 0.74 at 400 deg F 0.97 medium smooth 0.011 in. w.c. /100ft 0.0007 in. w.c. from Fig.C-9, Calculation notes, GK from Fig.C-5, Calculation notes, GK from Fig.C-3C, Calculation notes, GK B-D Rectangular 30 in 30 in Width Height

32.79 in 6.50 ft 3250 cfm 520 fpm

Duct Design, Chapter 14, Table 14-2, SMACNA

One boiler

Straight Run location: Type of duct: Breeching equivalent diameter: Straight Duct Length Exhaust gas flow Flue velocity Straight Run Friction Losses: Friction Loss Correction for temperature Correction for roughness Corrected Friction loss Friction Loss:

C Rectangular 30 in 30 in Width Height

32.79 ft 5.42 ft 3250 cfm 520 fpm

Duct Design, Chapter 14, Table 14-2, SMACNA

One boiler

0.015 in. w.c. /100ft 0.74 at 400 deg F 0.98 medium smooth 0.011 in. w.c. /100ft 0.0006 in. w.c.

from Fig.C-9, Calculation notes, GK from Fig.C-5, Calculation notes, GK from Fig.C-3C, Calculation notes, GK

Straight Run Losses

9/3/2013

169278644.xlsx.ms_office

7 of 15

Straight Run location: Type of duct: Breeching equivalent diameter: Straight Duct Length Exhaust gas flow Flue velocity Straight Run Friction Losses: Friction Loss Correction for temperature Correction for roughness Corrected Friction loss Friction Loss:

E Rectangular 26 in 34 in Width Height

32.43 in 6.50 ft 3250 cfm 529 fpm

Duct Design, Chapter 14, Table 14-2, SMACNA

One boiler

0.017 in. w.c. /100ft 0.7 at 400 deg F 0.98 medium smooth 0.012 in. w.c. /100ft 0.001 in. w.c.

from Fig.C-9, Calculation notes, GK from Fig.C-5, Calculation notes, GK from Fig.C-3C, Calculation notes, GK

Straight Run location: Type of duct: Breeching equivalent diameter: Straight Duct Length Exhaust gas flow Flue velocity Straight Run Friction Losses: Friction Loss Correction for temperature Correction for roughness Corrected Friction loss Friction Loss:

G Rectangular 32 in 32 in Width Height

34.98 in 10.00 ft 3250 cfm 457 fpm

Duct Duct Design, Chapter 14, Table 14-2, SMACNA

One boiler

0.01 in. w.c. /100ft 0.7 at 400 deg F 0.98 medium smooth 0.007 in. w.c. /100ft 0.0007 in. w.c.

from Fig.C-9, Calculation notes, GK from Fig.C-5, Calculation notes, GK from Fig.C-3C, Calculation notes, GK

Straight Run Losses

9/3/2013

169278644.xlsx.ms_office

8 of 15

Straight Run location: Type of duct: Breeching equivalent diameter: Straight Duct Length Exhaust gas flow Equivalent diameter Flue velocity

G-H Rectangular 50 in 28 in Width Height

40.48 in 2.50 ft 13000 cfm 40.48 in 1455 fpm

Duct Duct Design, Chapter 14, Table 14-2, SMACNA

Two boilers 3.37 ft

Straight Run Friction Losses: Friction Loss Correction for temperature Correction for roughness Corrected Friction loss Friction Loss: 0.01 in. w.c. /100ft 0.7 at 400 deg F 0.98 medium smooth 0.007 in. w.c. /100ft 0.0002 in. w.c. from Fig.C-9, Calculation notes, GK from Fig.C-5, Calculation notes, GK from Fig.C-3C, Calculation notes, GK

Total Straight Run Friction Losses:

0.0029 in. w.c.

Straight Run Losses

9/3/2013

169278644.xlsx.ms_office

9 of 15

Bend Losses in Breeching

Bend location: Type of bend: Breeching equivalent diameter: B Rectangular W= 30 in H= 30 in

32.79 in R (ft) W (ft) 2.50 H (ft) 2.50 R/W 0.000 H/W 1 L/W L (ft)

Rectangular breeching: Exhaust gas flow Equivalent diameter Flue velocity Bend Loss: Elbow Loss Coefficent Velocity Pressure Pressure Loss: Bend location: Type of bend: Breeching equivalent diameter: C Rectangular 0.1

3250 cfm 33 in 554 fpm

One Boiler 2.73 ft

from Table 3, Calculation notes, GK

0.019 in. w.c. 0.002 in. w.c.

W=

34 in

H=

26 in

32.43 in R (ft) W (ft) 2.83 H (ft) 2.17 R/W H/W L/W 0.000 0.764706 0.176471 L (ft) 0.5

Rectangular breeching: Exhaust gas flow Equivalent diameter Flue velocity Bend Loss: Elbow Loss Coefficent Velocity Pressure Pressure Loss: 1.104

3200 cfm 32.43 in 558 fpm

One Boiler 2.70 ft

from Table CR3-8, Pag 200, Duct Fitting Loss Coefficient Tables, ASHRAE

0.019 in. w.c. 0.021 in. w.c.

Bend Losses

9/3/2013

169278644.xlsx.ms_office

10 of 15

Bend location: Type of bend: Breeching equivalent diameter:

F-G Rectangular W= 50 in H= 28 in

40.48 in R (ft) 5.41 W (ft) 4.17 H (ft) 2.33 H/W (ft) 0.6 R/W (ft) 1.30

Rectangular breeching: Exhaust gas flow Equivalent diameter Flue velocity Bend Loss: Elbow Loss Coefficent Velocity Pressure Pressure Loss:

13000 cfm 40.48 in 1455 fpm

Two Boilers 3.37 ft

0.13 0.132 in. w.c. 0.017 in. w.c.

from Table 3, Calculation notes, GK (Rectangular section)

Bend location: Type of bend: Breeching equivalent diameter:

H Rectangular W= 50 in H= 28 in

40.48 in R (ft) 5.41 W (ft) 4.17 H (ft) 2.33 H/W (ft) 0.6 R/W (ft) 1.30

Rectangular breeching: Exhaust gas flow Equivalent diameter Flue velocity Bend Loss: Elbow Loss Coefficent Velocity Pressure Pressure Loss:

13000 cfm 40.48 in 1455 fpm

Two Boilers 3.37 ft

1.23 0.132 in. w.c. 0.162 in. w.c.

from Table CR3-6, Pag 198, Duct Fitting Loss Coefficient Tables, ASHRAE

Total Bend Losses:

0.203 in. w.c.

Bend Losses

9/3/2013

169278644.xlsx.ms_office

11 of 15

Transition and Area change Losses in Breeching

Fitting location: Type : A-B Transition Wo = W1 = L= 34.23 in 33.85 in R (ft) Wo (ft) 3.83 3250 cfm 509 fpm 520 fpm 46 in 30 in 48 in 2.85 ft 2.82 ft Ho (ft) W1-Wo (ft) 1.67 1.333 One Boiler L(ft) 4 Deg. 18.4 Ho = H1 = 20 in 30 in

Equivalent diameter Do: Equivalent diameter D1: Rectangular Transition:

Exhaust gas flow Flue velocity at Do Flue velocity at D1 Transition Friction Losses: Loss Coefficent Velocity Pressure (at D1) Pressure Loss:

0 0.017 in. w.c.

from Table 4, Calculation notes, GK (Gradual Contraction)

0.000 in. w.c.

Total Transition Losses:

0.0000 in. w.c.

Trans. Loss Calc

9/3/2013

Dampers Losses in Breeching

Fitting location: Type : Exhaust gas flow Flue velocity at Duct Damper Friction Loss Using ASHRAE Duct Fitting Loss Coefficient Table CR9-4, for Damper, Opposed Blades (Brown 1957) assuming: (N) Number of Damper Blades: (W) Duct dimension parallel to blades axis, in. (H) Duct Height, in. L Sum of Damper Blade length, in. (N x W) R Perimeter of Duct, in (2 x (H + W) L/R: Blades Angle: Loss Coefficent Velocity Pressure Pressure Loss: 1.5 0 Degree 0.52 0.017 in. w.c. 0.009 in. w.c. from Table CR9-4 6 30 30 Rect Duct 3250 cfm 520 fpm C Wo = 30 in One Boiler Ho = 30

Total Damper Losses:

0.0088 in. w.c.

in

Das könnte Ihnen auch gefallen

- Combustion and Mass Transfer: A Textbook with Multiple-Choice Exercises for Engineering StudentsVon EverandCombustion and Mass Transfer: A Textbook with Multiple-Choice Exercises for Engineering StudentsBewertung: 3 von 5 Sternen3/5 (1)

- Exhaust Gas Pressure Drop in DuctDokument6 SeitenExhaust Gas Pressure Drop in DuctMyungkwan HaNoch keine Bewertungen

- Design of A Deaerator Presentation OneDokument12 SeitenDesign of A Deaerator Presentation OnegeorgeNoch keine Bewertungen

- Heat Exchanger Design CalculationsDokument6 SeitenHeat Exchanger Design CalculationsryanarthurNoch keine Bewertungen

- Boiler and Boiler CalculationsDokument7 SeitenBoiler and Boiler CalculationsChaya Stia ClaluiNoch keine Bewertungen

- Chimney Design Guide LinesDokument9 SeitenChimney Design Guide LinesluckynaveenrajNoch keine Bewertungen

- Shellmax Boiler Design CalculationDokument2 SeitenShellmax Boiler Design Calculationrahult19Noch keine Bewertungen

- Boiler FormulasDokument5 SeitenBoiler FormulasAnonymous 6Mb7PZjNoch keine Bewertungen

- Waste Heat Boiler Part 1Dokument56 SeitenWaste Heat Boiler Part 1mulldoctor1100% (2)

- Cooling Tower-CalculatorDokument7 SeitenCooling Tower-CalculatorparykoochakNoch keine Bewertungen

- Heat Transfer Water Tube BoilerDokument8 SeitenHeat Transfer Water Tube BoilerilyaskureshiNoch keine Bewertungen

- Design of A Waste Heat BoilerDokument43 SeitenDesign of A Waste Heat BoilerPius100% (3)

- Film Temp Calculation For Thermic Fluid ApplicationDokument2 SeitenFilm Temp Calculation For Thermic Fluid ApplicationmayurjannuNoch keine Bewertungen

- Wet Cooling Towers: Rule-of-Thumb Design and SimulationDokument32 SeitenWet Cooling Towers: Rule-of-Thumb Design and SimulationMohammed Alnefayei100% (10)

- Chimney Calculation SheetDokument12 SeitenChimney Calculation SheetVinoth Rajendra40% (5)

- Longitudinal Deflection Calculation SheetDokument8 SeitenLongitudinal Deflection Calculation SheetXplore Engg100% (1)

- Air Cooled Condensors: General DescriptionDokument7 SeitenAir Cooled Condensors: General DescriptionRajeev MaheshwariNoch keine Bewertungen

- Assessment of Heat ExchangersDokument14 SeitenAssessment of Heat ExchangersranveerNoch keine Bewertungen

- Chimney CalculationsDokument2 SeitenChimney CalculationsRamesh Kuppili75% (4)

- Pneumatic Conveying CalculationDokument3 SeitenPneumatic Conveying CalculationJeyaraj LawerenceNoch keine Bewertungen

- Sizing Stack HeightDokument1 SeiteSizing Stack Heightashwini_kumar19840% (1)

- Is 14164 2008Dokument45 SeitenIs 14164 2008Pukhraj DagaNoch keine Bewertungen

- Ibr CalDokument11 SeitenIbr Calmailtosamraj100% (4)

- Heat Exchanger Specification Sheet: MM M? M? Performance of One UnitDokument9 SeitenHeat Exchanger Specification Sheet: MM M? M? Performance of One UnitGladys ZiSing LeeNoch keine Bewertungen

- Heat Exchanger DesignDokument48 SeitenHeat Exchanger DesignJose SotoNoch keine Bewertungen

- Evaporator heat transfer and surface area calculationDokument4 SeitenEvaporator heat transfer and surface area calculationDaniyal HashmiNoch keine Bewertungen

- Steam Drum LevelsDokument11 SeitenSteam Drum LevelsAnith kumar Reddy100% (1)

- DraughtDokument33 SeitenDraughtNipun SabharwalNoch keine Bewertungen

- HCL Scrubber DesignDokument5 SeitenHCL Scrubber DesignManish0301198375% (4)

- Waste Heat BoilerDokument2 SeitenWaste Heat BoilerSharon LambertNoch keine Bewertungen

- Scrubber Wet Stack Design GuideDokument211 SeitenScrubber Wet Stack Design Guideruzicastoprase100% (5)

- Condenser DesignDokument2 SeitenCondenser DesignRahul ParmarNoch keine Bewertungen

- SCR Heat Exchanger Design 2018 For NO PHASE CHANGEDokument37 SeitenSCR Heat Exchanger Design 2018 For NO PHASE CHANGEAnonymous 1uUqRkc9p8100% (1)

- Design of Cooling TowerDokument17 SeitenDesign of Cooling TowerMohan VarkeyNoch keine Bewertungen

- Fan Capacity CalculationDokument6 SeitenFan Capacity CalculationAu Tagolimot70% (10)

- Reactors Dimensions - 1Dokument10 SeitenReactors Dimensions - 1Abhijit MoreNoch keine Bewertungen

- 2 Design CalculationDokument22 Seiten2 Design CalculationLynn HuiNoch keine Bewertungen

- YOSHIMINE WASTE HEAT RECOVERY BOILERSDokument12 SeitenYOSHIMINE WASTE HEAT RECOVERY BOILERSardiansyahhandikaNoch keine Bewertungen

- Boiler CalculationsDokument24 SeitenBoiler Calculationsgkdora574100% (1)

- Cost 3 TPH 12kg Fo Fired Boiler p0Dokument3 SeitenCost 3 TPH 12kg Fo Fired Boiler p09913489806Noch keine Bewertungen

- Comparative Analysis of Alternative Means for Removing Noncondensable Gases from Flashed-Steam Geothermal Power PlantsDokument354 SeitenComparative Analysis of Alternative Means for Removing Noncondensable Gases from Flashed-Steam Geothermal Power Plantsjlcheefei925850% (2)

- Chimney Sizing Calculation-R1Dokument3 SeitenChimney Sizing Calculation-R1Arun Kumar67% (3)

- Steam Ejector DesignDokument4 SeitenSteam Ejector DesignHaider Tyebally TyeballyNoch keine Bewertungen

- Boiler Draft CalculationDokument25 SeitenBoiler Draft Calculationsehono100% (1)

- Sizing Calculation of General Service PumpsDokument193 SeitenSizing Calculation of General Service Pumpsmkha87Noch keine Bewertungen

- Turbine Heat Rate and EfficiecyDokument48 SeitenTurbine Heat Rate and EfficiecyPralay Raut100% (6)

- Thumb Rules For Chemical EngineerDokument44 SeitenThumb Rules For Chemical EngineerNallathambiNoch keine Bewertungen

- Thumb Rules Xls For Chemical EngineerDokument44 SeitenThumb Rules Xls For Chemical EngineershashibagewadiNoch keine Bewertungen

- Line Sizing and Pressure Drop Calculations for Sanstar Bio-Polymers Ltd Steam LinesDokument11 SeitenLine Sizing and Pressure Drop Calculations for Sanstar Bio-Polymers Ltd Steam Linessantosh_raju0% (1)

- 1) Flow: 239869283.xls - Ms - Office Piping Pressure Drop and Pump Design Calculation SheetDokument4 Seiten1) Flow: 239869283.xls - Ms - Office Piping Pressure Drop and Pump Design Calculation SheetHemantk8731100% (1)

- PSV Sizing (Steam)Dokument2 SeitenPSV Sizing (Steam)Saeid Rahimi Mofrad100% (1)

- Chapter 5 - Equipment Sizing and CostingDokument21 SeitenChapter 5 - Equipment Sizing and CostingHaiqal AzizNoch keine Bewertungen

- Vertical Mill CalculationsDokument12 SeitenVertical Mill CalculationsAbhijeet Jhankal100% (1)

- Technical Dairy: 1-Boiler and Auxillaries Main BoilerDokument59 SeitenTechnical Dairy: 1-Boiler and Auxillaries Main Boilersuleman247Noch keine Bewertungen

- Vertical Mill CalculationsDokument11 SeitenVertical Mill CalculationsSai Sricharan Reddy84% (19)

- Chapter 1,2Dokument25 SeitenChapter 1,2Илья СергеевNoch keine Bewertungen

- Boiler DataDokument28 SeitenBoiler DataMonique ThomasNoch keine Bewertungen

- DP - TXT (2021-01-18 4:12:14 PM)Dokument4 SeitenDP - TXT (2021-01-18 4:12:14 PM)Rufus D SNoch keine Bewertungen

- BoilerDokument13 SeitenBoilerEDUARDONoch keine Bewertungen

- Properties of WaterDokument23 SeitenProperties of WaterNiken Rumani100% (1)

- AutofileDokument889 SeitenAutofileJeff RogersNoch keine Bewertungen

- Dampers - All Types and Actuators-Johnson PUBL-7211Dokument2 SeitenDampers - All Types and Actuators-Johnson PUBL-7211joabjim8392Noch keine Bewertungen

- Articles From NYT PS NewDokument73 SeitenArticles From NYT PS Newjoabjim8392Noch keine Bewertungen

- Construction-Costs in NYC USADokument55 SeitenConstruction-Costs in NYC USAjoabjim8392Noch keine Bewertungen

- Model Airplane PropellersDokument24 SeitenModel Airplane PropellersNenad_BraNoch keine Bewertungen

- HP 35s Quick Start Guide EnglishDokument60 SeitenHP 35s Quick Start Guide Englishjoabjim8392Noch keine Bewertungen

- Estimating Procedures TrainingDokument21 SeitenEstimating Procedures Trainingjoabjim8392Noch keine Bewertungen

- Commercial Kitchen Exhaust System - Fire Dept 2015Dokument39 SeitenCommercial Kitchen Exhaust System - Fire Dept 2015joabjim8392Noch keine Bewertungen

- AutoCAD Release History TimelineDokument4 SeitenAutoCAD Release History Timelinejoabjim8392Noch keine Bewertungen

- Piping System FundamentalsDokument173 SeitenPiping System Fundamentalsjoabjim8392100% (3)

- The StalkerDokument8 SeitenThe Stalkerjoabjim8392Noch keine Bewertungen

- Fan CalcDokument1 SeiteFan CalcGregory Nick Toledo VelizNoch keine Bewertungen

- Lift Station Pump CalculationDokument7 SeitenLift Station Pump Calculationjoabjim8392100% (1)

- Vary Duct Width and Height to Graph Friction LossDokument8 SeitenVary Duct Width and Height to Graph Friction Lossjoabjim8392Noch keine Bewertungen

- Varieties of SpanishDokument2 SeitenVarieties of Spanishjoabjim8392Noch keine Bewertungen

- Boiler FormulasDokument4 SeitenBoiler Formulasjoabjim8392100% (1)

- Leadership Character: The Role of Courage: in This SeriesDokument8 SeitenLeadership Character: The Role of Courage: in This Seriesjoabjim8392Noch keine Bewertungen

- Group 2 Financial Brick Case StudyDokument9 SeitenGroup 2 Financial Brick Case StudyMDNoch keine Bewertungen

- Brazil Chapter 12: Agriculture, Minerals, Industries & TradeDokument8 SeitenBrazil Chapter 12: Agriculture, Minerals, Industries & TradeHaseebullahNoch keine Bewertungen

- Kings Motorbikes 80cc Bicycle Engine Kit Installation ManualDokument11 SeitenKings Motorbikes 80cc Bicycle Engine Kit Installation ManualnwobastardsNoch keine Bewertungen

- NewsStand - 24 of October 2021Dokument16 SeitenNewsStand - 24 of October 2021Ahmed MansourNoch keine Bewertungen

- Lecture 30 - Enamine and Iminium OrganocatalysisDokument22 SeitenLecture 30 - Enamine and Iminium OrganocatalysisDênisPiresdeLimaNoch keine Bewertungen

- Reference List AW Offshore Installation SYS 2007-08-16Dokument10 SeitenReference List AW Offshore Installation SYS 2007-08-16Sugeng WahyudiNoch keine Bewertungen

- Encore 22 lb. Capacity Front Load DryerDokument2 SeitenEncore 22 lb. Capacity Front Load Dryermairimsp2003Noch keine Bewertungen

- Straight Differential Expansion - DMXDokument4 SeitenStraight Differential Expansion - DMXJurun_BidanshiNoch keine Bewertungen

- CAT079 SwitchDokument232 SeitenCAT079 SwitchDan688100% (1)

- PPR Techincal Data SheetDokument0 SeitenPPR Techincal Data SheetKrish ChennaiNoch keine Bewertungen

- PRAI-M0-YT01-LA-7500 - As-Built - Data Sheet For Feed Water PumpDokument3 SeitenPRAI-M0-YT01-LA-7500 - As-Built - Data Sheet For Feed Water PumpSuman GhoshNoch keine Bewertungen

- PC400 400LC-8R PDFDokument8 SeitenPC400 400LC-8R PDFAsmar FixNoch keine Bewertungen

- Dynamis MaxxDokument14 SeitenDynamis MaxxJas SumNoch keine Bewertungen

- Nerc Sra 2022Dokument46 SeitenNerc Sra 2022The Western Journal100% (1)

- High Voltage Engineering Ref ManualDokument147 SeitenHigh Voltage Engineering Ref Manualzeus009100% (1)

- To Access The Fuel Oil Management Plan Sample TemplateDokument35 SeitenTo Access The Fuel Oil Management Plan Sample TemplateΦοίβος ΖούκηςNoch keine Bewertungen

- IAEA-SM-346/113 Regional Safeguards Arrangements: The Argentina-Brazil ExperienceDokument13 SeitenIAEA-SM-346/113 Regional Safeguards Arrangements: The Argentina-Brazil ExperiencePeter AngeloNoch keine Bewertungen

- 1104C Torque Specs PERKINS-1104-11-15-2018-657Dokument11 Seiten1104C Torque Specs PERKINS-1104-11-15-2018-657Jose Ricardo Gomez CardenasNoch keine Bewertungen

- General Science: 1. Introduction and Role of ScienceDokument2 SeitenGeneral Science: 1. Introduction and Role of ScienceCh Shakeel Ahmed MayoNoch keine Bewertungen

- RLA Test FormatDokument11 SeitenRLA Test Formatmayur dhandeNoch keine Bewertungen

- Examiners' Report June 2013 GCE Physics 6PH05 01Dokument46 SeitenExaminers' Report June 2013 GCE Physics 6PH05 01dhulanjalieeh josephNoch keine Bewertungen

- En 16252-2012Dokument42 SeitenEn 16252-2012Fabio Manente100% (1)

- Conservation of Energy Worksheet #1 Answers - 1Dokument3 SeitenConservation of Energy Worksheet #1 Answers - 1Fitz Baniqued67% (3)

- PAES 233: Multicrop Washer-Peeler StandardDokument16 SeitenPAES 233: Multicrop Washer-Peeler StandardFaroukNoch keine Bewertungen

- Carter Auto Water Pump Components 072420Dokument2 SeitenCarter Auto Water Pump Components 072420geniusNoch keine Bewertungen

- Fuel ImbalanceDokument7 SeitenFuel Imbalancedarryl_baguioNoch keine Bewertungen

- Overview of The Kuraymat Solar Power Plant enDokument4 SeitenOverview of The Kuraymat Solar Power Plant enKhaled TahaNoch keine Bewertungen

- Q3 Module 2A - Nature of Solids and Phase Changes 1Dokument34 SeitenQ3 Module 2A - Nature of Solids and Phase Changes 1Rance BobadillaNoch keine Bewertungen

- Aluminum Extrusions in Solar Power ApplicationsDokument4 SeitenAluminum Extrusions in Solar Power ApplicationsСтанислав ПодольскийNoch keine Bewertungen

- Climate Change The Facts (Annotated)Dokument3 SeitenClimate Change The Facts (Annotated)api-276929919Noch keine Bewertungen