Beruflich Dokumente

Kultur Dokumente

Quadrant Nylon Specs

Hochgeladen von

api-235905828Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Quadrant Nylon Specs

Hochgeladen von

api-235905828Copyright:

Verfügbare Formate

NYLON PRODUCTS

Sheaves on heavy-duty lifting equipment made from Nylatron GSM cast nylon increase wire rope life, reduce weight on the boom or mast, eliminate corrosion, and improve lift and over-the-road performance. (Prior materials: Steel, Cast iron)

CASE STUDY

Small/Screw Machine Nylon Parts (Extruded Type 6/6)

For general purpose wear and structural parts (FDA grades available)

Larger or Near Net Nylon Shapes (Cast Type 6 Nylons) MC 901 Nylon

Heat stabilized nylon offering long-term thermal stability to 260F. It is blue in color and used in a variety of bearing and structural applications such as wheels, gears, and custom parts.

Nylon 101

Of all the unmodified nylons, Nylon 101 is the strongest, most rigid and has one of the highest melting points. It is commonly specified for screw machined electrical insulators and food contact parts. It is stocked in both natural and black. Other colors are available on a custom basis. Nylon 101 natural is FDA, USDA, NSF, and 3A-Dairy compliant.

MC 907 Nylon

Unmodified type 6 nylon offering the highest strength and hardness of the nylon 6 grades. MC 907 natural is FDA, USDA and 3A-Dairy compliant. It is off-white in color and primarily used for food contact parts.

For improved load bearing capability

Nylatron GS Nylon

Molybdenum disulphide (MoS2) filled nylon offering improved strength and rigidity. With a lower coefficient of linear thermal expansion than Nylon 101, Nylatron GS parts maintain better fit and clearances, and have less tendency to seize as bearings. See Ertalyte TX, page 15

Nylatron GSM Nylon

Nylatron GSM contains finely divided particles of molybdenum disulphide (MoS2) to enhance its load bearing capabilities while maintaining the impact resistance inherent to nylon. It is the most commonly used grade for gears, sheaves, sprockets and custom parts. It is grey-black in color.

For best wear resistance and lowest coefficient of friction

Nylatron NSM Nylon

Best bearing and wear nylon product available today. Proprietary type 6 nylon formulation produced using Quadrants Monocast process. Solid lubricant additives impart self-lubricating, high pressure/velocity and superior wear resistance characteristics. Nylatron NSM was developed specifically for demanding applications where larger size parts are required. It is ideal for bearings, gears and wear pads. In wear applications, Nylatron NSM lasts up to 10 times longer than standard Type 6 nylon.

For improved load capacity or For improved frictional characteristics

30% Glass-reinforced Nylon 6/6

For applications requiring higher compressive strength and rigidity, 30% glass reinforced Nylon 6/6 is also available. It is stocked in diameters ranging from 10mm to 150mm (or .394 to 5.910 in meter lengths).

Nylatron GSM Blue Nylon

The first cast nylon to combine both molybdenum disulphide (MoS2) and oil for the load capability of Nylatron GSM nylon, plus improved frictional characteristics. It excels in higher pressures, and at low speedsup to 40 fpm. It offers 20% lower coefficient of friction, 50% greater limiting PV, and a lower k factor than Nylatron GSM, and the lowest slip-stick of any nylon product making it ideal for slide pads, thrust washers and trunion bearings. Nylatron GSM Blue should be considered for any oil-filled nylon application. It is dark blue in color.

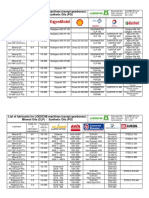

Table 2 Wear Rate, Coefficient of Friction and Limiting PV Data

Comparative Wear Rate Wear Factor to Nylatron Nylon Nylatron NSM Nylatron GSM Blue Nylatron GSM Standard Type 6 (a) Nylon 6/6

(1)

Measured on 1/2 I.D. journal at 5000 PV (118 fpm & 42.2 psi) K = h/PVT + 1010 (cu.in.min./ft.lb.hr.) where h =radial wear (in) P =normal pressure, (psi) V =sliding speed, (fm) T =test duration, (hrs) Measured on thrust washer bearing under a normal load of 50 lbs. Gradually increasing torque was applied until the bearing completed at 90 rotation in about one second. Measured on thrust washer testing machine, unlubricated @ 20 fpm & 250 psi. Limiting PV (Test valueunlubricated @ 100 fpm (lb.ft/in.2 min.) Equivalent to Quadrants MC 901.

Coefficient of Friction Static (2) .17.25 .17.23 .21.25 .21.24 .16.20 Dynamic (3) .17.23 .17.21 .19.23 .21.23 .27.31

Limiting PV (4) 15,000 3,400 2,500 1,875 2,700

(3) (4) (a) (2)

k (1) 12 86 91 92 72

NSM 1.0 7.2 7.6 7.7 6.0

Quadrant Engineering Plastic Products

12

global leader in engineering plastics for machining

Quadrant Engineering Plastic Products

global leader in engineering plastics for machining

Products And Applications Guide

Global Leader in Engineering Plastics for Machining.

Quadrant Engineering Plastic Products (Quadrant EPP) is the worlds leading manufacturer of plastic machining stock. In 1946, we invented and then patented the first process for extruding nylon stock shapes for machining. The industry we created gives designers more flexibility and design possibilities by producing shapes that can easily be machined into parts. Quadrant assists engineers in selecting the optimum material for their application.

GLOBAL PRODUCT QUALITY STANDARDS Consistent quality standards have been established for the major shapes products coming from Quadrant Engineering Plastic Products primary production sites worldwide. This assures our customers the same high level of performance and machinability lot to lot, regardless of where the product is manufactured.

GLOBAL PRODUCTION AND LOGISTICS Quadrant Engineering Plastic Products is unique in its ability to serve all major regional markets in the world. Our unmatched - and ongoing - investment in production and logistics sites around the globe solidifies our commitment to world-class service, quality and market development for engineering plastics for machining. Our range of process technology includes casting, extrusion and compression molding to deliver the widest range of engineering plastics shapes materials in the market.

GLOBAL TECHNICAL SERVICE AND APPLICATION DEVELOPMENT SUPPORT Our teams of technical service and application development engineers are based in all major Quadrant Engineering Plastic Products locations. Their sole mission is to help equipment manufacturers and machinists get the full performance benefits and cost efficiency from our materials. Quadrant Engineering Plastic Products has also invested in complete test facilities and the best technical data both in print and on the worldwide web to support our customers on material selection.

GLOBAL PRODUCT LINE BRANDS Quadrant Engineering Plastic Products branding program integrates our products under a unified set of tradenames regionally and globally. This provides a clear and consistent identification of all products, and makes them available through all distributor and fabricator partners worldwide.

Quadrant Engineering Plastic Products

2

global leader in engineering plastics for machining

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Design Calculation of Spherical MSM Fixed Bearing - 319 MTDokument7 SeitenDesign Calculation of Spherical MSM Fixed Bearing - 319 MTChandan VatsNoch keine Bewertungen

- CHP 7 8 Energy Energy Transfer Potential EnergyDokument66 SeitenCHP 7 8 Energy Energy Transfer Potential EnergyNur Hafizah Md DisaNoch keine Bewertungen

- E105 - FrictionDokument11 SeitenE105 - FrictionvinceNoch keine Bewertungen

- Quick Quizes & MiniExDokument9 SeitenQuick Quizes & MiniExsadaf nasirNoch keine Bewertungen

- AF Catalogo de Balatas MalacatesDokument28 SeitenAF Catalogo de Balatas MalacatesEduardoCastilloNoch keine Bewertungen

- Determination of Thermal Material Properties For The Numerical Simulation of Cutting ProcessesDokument32 SeitenDetermination of Thermal Material Properties For The Numerical Simulation of Cutting Processeskibaiben0Noch keine Bewertungen

- Lubrication and Circuit Breakers PDFDokument4 SeitenLubrication and Circuit Breakers PDFSRINIVASA RAO DUVVADANoch keine Bewertungen

- Rtu PDFDokument13 SeitenRtu PDFKhushnoodNoch keine Bewertungen

- Chapter 3 Problems: Article 3/3 Problems Introductory ProblemsDokument55 SeitenChapter 3 Problems: Article 3/3 Problems Introductory ProblemsM100% (1)

- 15 FCI Examen SpanishDokument18 Seiten15 FCI Examen SpanishCésar DiazNoch keine Bewertungen

- Mini Kin Design Book 4 The DitionDokument36 SeitenMini Kin Design Book 4 The Ditionhalder_kalyan9216Noch keine Bewertungen

- 01 - Basic Module - Fundamentals of Lubrication - FilterDokument34 Seiten01 - Basic Module - Fundamentals of Lubrication - FilterJack PranNoch keine Bewertungen

- 04 Work Energy and PowerDokument6 Seiten04 Work Energy and PowerJerico LlovidoNoch keine Bewertungen

- Exam PaperDokument11 SeitenExam PaperSi JampangNoch keine Bewertungen

- In-Class Activities: Today's Objectives:: Wedges and Frictional Forces On Flat BeltsDokument21 SeitenIn-Class Activities: Today's Objectives:: Wedges and Frictional Forces On Flat BeltsAtef NazNoch keine Bewertungen

- H-14 MicroformingDokument29 SeitenH-14 MicroformingVishwajeet GuptaNoch keine Bewertungen

- ch06 Force and Motion 2Dokument24 Seitench06 Force and Motion 2nailaNoch keine Bewertungen

- Distributed By:: 5285 Port Royal Road, Springfield Va. 22151Dokument43 SeitenDistributed By:: 5285 Port Royal Road, Springfield Va. 22151IanNoch keine Bewertungen

- EagleBurgmann - DMS - TSE - E5 - Brochure Mechnical Seal Technology and Selection - EN - 16.05.2017 PDFDokument58 SeitenEagleBurgmann - DMS - TSE - E5 - Brochure Mechnical Seal Technology and Selection - EN - 16.05.2017 PDFImmanuel AutomatonNoch keine Bewertungen

- Unit 5 Learning Guide Name: InstructionsDokument17 SeitenUnit 5 Learning Guide Name: Instructionsnatalie manNoch keine Bewertungen

- AiatsDokument92 SeitenAiatsMohammad ZaidNoch keine Bewertungen

- List of Lubricants For LOESCHE-machines (Except Gearboxes) : Mineral Oils (CLP) / Synthetic Oils (PG)Dokument8 SeitenList of Lubricants For LOESCHE-machines (Except Gearboxes) : Mineral Oils (CLP) / Synthetic Oils (PG)MossaabSelaimiaNoch keine Bewertungen

- Types of Friction PowerpointDokument15 SeitenTypes of Friction PowerpointNOORAEGN BAUTISTANoch keine Bewertungen

- Astm D6773-08Dokument28 SeitenAstm D6773-08Black GokuNoch keine Bewertungen

- Brake Design AnalysisDokument16 SeitenBrake Design AnalysisBalkrishna ChaudharyNoch keine Bewertungen

- Hydraulics FestoDokument232 SeitenHydraulics FestoCHRISTOPHER100% (10)

- Science Chapter - (Friction) Class 8Dokument6 SeitenScience Chapter - (Friction) Class 8Khushi Kumari class 9 adm 664Noch keine Bewertungen

- 2019 Fundamentals in Adhesive Bonding Design For PDFDokument10 Seiten2019 Fundamentals in Adhesive Bonding Design For PDFHamza HussainNoch keine Bewertungen

- Managing Torque and DragDokument34 SeitenManaging Torque and DragMilad Ebrahimi DastgerdiNoch keine Bewertungen