Beruflich Dokumente

Kultur Dokumente

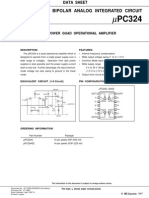

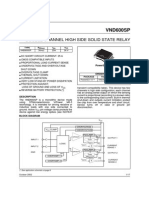

Data Sheet

Hochgeladen von

Juan Manuel Lopez GomezCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Data Sheet

Hochgeladen von

Juan Manuel Lopez GomezCopyright:

Verfügbare Formate

+

Bridge

Rectifier

LINE

INPUT

V

OUT

EMI Filter

UCC28019A

Rload

GND

ICOMP

ISENSE

GATE

VCC

VSENSE

VCOMP VINS

1

2

3

4

8

7

6

5

Auxilary

Supply

GND

ICOMP

ISENSE

GATE

VCC

VSENSE

VCOMP VINS

1

2

3

4

8

7

6

5

+

OVERVOLTAGE

5.25V

OVP

Input Brown-Out Protection

(IBOP)

+

+

VIN

ENABLE_th

1.5V

S Q

Q R

VIN

BROWNOUT_th

0.82V

5V

20k

IBOP

+

V

PCL

1.08V

Soft Over Current (SOC)

V

SOC

0.73V

Peak Current Limit (PCL)

SOC

40k 40k

+

-1x

300ns

Leading Edge

Blanking

UVLO

+

+

VCC

ON

10.5V S Q

Q R

VCC

OFF

9.5V

UVLO

R

SENSE

C

OUT

L

BST

R

ISENSEfilter

+

Bridge

Rectifier

C

ISENSEfilter

LINE

INPUT

D

BST

V

OUT

C

CV2

R

CV

C

CV1

+

gmv

Voltage Error

Amplifier

+

gmi C

ICOMP

S Q

Q R

PWM

Comparator

K

PC

(s)

SOC

M

2

M

1

EMI Filter

VCOMP

C

IN

5V

65kHz

Oscillator

R

LOAD

C

VCC

Auxiliary

Supply

Current

Amplifier

3

ISENSE

2

ICOMP

VINS

4

5

VCOMP

6

VSENSE

7

1

VCC

GND

8

GATE

GAIN

M

1

, K

1

+

UNDERVOLTAGE

4.75V

EDR

C

VINS

R

VINS1

R

VINS2

VCC

Gate Driver

UVLO

IBOP

OLP

S Q

Q R

Pre-Drive and

Clamp Circuit

R

FB1

R

FB2

Q

BST

10k

R

GATE

C

VSENSE

+

PWM

RAMP

M

2 Min Off Time

+

Fault

Logic

Fault

FAULT

PCL

Clock

FAULT

4V

OVP

0.6V +

ICOMP Protection

ISOP

ISOP

I

S

E

N

S

E

O

p

e

n

-

p

i

n

P

r

o

t

e

c

t

i

o

n

+

OLP/STANDBY

0.82V

OLP/STANDBY

100nA

+

END OF

SOFT-START

4.95V

END OF SS

S Q

Q R

EDR

END OF SS

FAULT

g

mv

Enhancement

UCC28019A Block Diagram

SS

V

PRECHARGE

Rapid Discharge

when

VCC < VCC

OFF

FAULT

UVLO

0 5 15

VCC - Bias Supply Voltage - V

0

0.5

1.5

2.5

3.0

4.0

10 20

1.0

2.0

3.5

SUPPLY CURRENT

vs

BIAS SUPPLY VOLTAGE

I

CC

Turn ON I

CC

Turn OFF

T

J

= 25C

VSENSE = VINS = 3V

No Gate Load

I

C

C

-

S

u

p

p

l

y

C

u

r

r

e

n

t

-

m

A

-60 -35 -10 65 115 140

T

J

- Temperature - C

8.0

9.0

11.0

12.0

15 40 90

10.0

V

C

C

(

o

n

)

/

V

C

C

(

o

f

f

)

-

U

V

L

O

T

h

r

e

s

h

o

l

d

-

V

UVLO THRESHOLDS

vs

TEMPERATURE

VCC Turn OFF

VCC Turn ON

T

J

- Temperature - C

0

2

4

6

8

10

1

3

5

7

9

I

C

C

-

S

u

p

p

l

y

C

u

r

r

e

n

t

-

m

A

SUPPLY CURRENT

vs

TEMPERATURE

Operating, GATE Load = 4.7 nF

VCC = 15V

Standby

-60 -35 -10 65 115 140 15 40 90

T

J

- Temperature - C

0

0.1

0.2

0.3

0.4

0.5

I

C

C

(

s

t

a

r

t

)

-

S

u

p

p

l

y

C

u

r

r

e

n

t

-

m

A

SUPPLY CURRENT

vs

TEMPERATURE

Pre-Start

VCC = UVLO - 0.1 V

-60 -35 -10 65 115 140 15 40 90

T

J

- Temperature - C

55

59

63

67

71

75

f

S

W

-

S

w

i

t

c

h

i

n

g

F

r

e

q

u

e

n

c

y

-

k

H

z

OSCILLATOR FREQUENCY

vs

TEMPERATURE

Switching Frequency

57

61

65

69

73 VCC = 15V

-60 -35 -10 65 115 140 15 40 90 10 16

VCC - Bias Supply Voltage - V

55

59

63

67

71

75

f

S

W

-

S

w

i

t

c

h

i

n

g

F

r

e

q

u

e

n

c

y

-

k

H

z

OSCILLATOR FREQUENCY

vs

BIAS SUPPLY VOLTAGE

57

61

65

69

73

Switching Frequency

T

J

= 25C

20 18 14 12

T

J

- Temperature - C

0

0.4

0.8

1.2

1.6

2.0

g

m

i

-

G

a

i

n

-

m

A

/

V

CURRENT AVERAGING

AMPLIFIER TRANSCONDUCTANCE

vs

TEMPERATURE

Gain

0.2

0.6

1.0

1.4

1.8 VCC = 15V

-60 -35 -10 65 115 140 15 40 90

T

J

- Temperature - C

30

34

38

42

46

50

g

m

v

-

G

a

i

n

-

A

/

V

VOLTAGE ERROR AMPLIFIER

TRANSCONDUCTANCE

vs

TEMPERATURE

32

36

40

44

48

Gain, No EDR

VCC = 15V

-60 -35 -10 65 115 140 15 40 90

T

J

- Temperature - C

V

S

O

C

-

I

S

E

N

S

E

T

h

r

e

s

h

o

l

d

-

V

ISENSE THRESHOLD

vs

TEMPERATURE

Soft Over-Current Protection (SOC)

-60 -35 -10 65 115 140 15 40 90

VCC = 15V

0

-0.2

-0.4

-0.6

-0.8

-1.0

-0.1

-0.3

-0.5

-0.7

-0.9

T

J

- Temperature - C

4.50

4.75

5.00

5.25

5.50

V

R

E

F

-

R

e

f

e

r

e

n

c

e

V

o

l

t

a

g

e

-

V

REFERENCE VOLTAGE

vs

TEMPERATURE

Reference Voltage

VCC = 15V

-60 -35 -10 65 115 140 15 40 90

T

J

- Temperature - C

4.50

5.25

5.50

V

O

V

P

/

V

U

V

D

-

V

S

E

N

S

E

T

h

r

e

s

h

o

l

d

-

V

VSENSE THRESHOLD

vs

TEMPERATURE

4.75

5.00

Under-Voltage Protection (V

UVD

)

Over-Voltage Protection (V

OVP

)

-60 -35 -10 65 115 140 15 40 90

VCC = 15V

T

J

- Temperature - C

0

0.4

0.8

1.2

1.6

2.0

V

O

L

P

V

S

E

N

S

E

T

h

r

e

s

h

o

l

d

-

V

VSENSE THRESHOLD

vs

TEMPERATURE

0.2

0.6

1.0

1.4

1.8

-60 -35 -10 65 115 140 15 40 90

Open Loop Protection

VCC = 15V

T

J

- Temperature - C

0

0.4

0.8

1.2

1.6

2.0

V

I

N

S

E

N

A

B

L

E

_

T

H

/

V

I

N

S

B

R

O

U

W

N

O

U

T

_

T

H

V

I

N

S

T

h

r

e

s

h

o

l

d

-

V

VINS THRESHOLD

vs

TEMPERATURE

0.2

0.6

1.0

1.4

1.8

-60 -35 -10 65 115 140 15 40 90

VINS Enable (VINS

ENABLE_TH

)

VCC = 15V

Input Brown-Out Protection (VINS

BROWNOUT_TH

)

T

J

- Temperature - C

100

200

300

400

500

600

t

-

T

i

m

e

-

n

s

MINIMUM OFF TIME

vs

TEMPERATURE

t

OFF(min)

VSENSE = 3 V

ICOMP = 1 V

105

250

350

450

550

-60 -35 -10 65 115 140 15 40 90

T

J

- Temperature - C

0

10

20

30

40

50

t

-

T

i

m

e

-

n

s

GATE DRIVE SWITCHING

vs

TEMPERATURE

Fall Time

VCC = 15V

C

GATE

= 4.7 nF

V

GATE

= 2V-8V

Rise Time

5

15

25

35

45

-60 -35 -10 65 115 140 15 40 90 10 12 16 20

VCC - Bias Supply Voltage - V

0

10

20

30

40

50

18

t

-

T

i

m

e

-

n

s

GATE DRIVE SWITCHING

vs

BIAS SUPPLY VOLTAGE

Fall Time

T

J

= 25C,

C

GATE

= 4.7 nF

V

GATE

= 2V-8V

Rise Time

5

15

25

35

45

14

T

J

- Temperature - C

0

0.4

0.8

1.2

1.6

2.0

V

G

A

T

E

G

a

t

e

L

o

w

V

o

l

t

a

g

e

-

V

GATE LOW VOLTAGE

WITH DEVICE OFF

vs

TEMPERATURE

0.2

0.6

1.0

1.4

1.8

-60 -35 -10 65 115 140 15 40 90

V

GATE

VCC = 5V

I

CC

= 20mA

VCC

VCC

(ON)

10.5V

VCC

(OFF)

9.5V

I

CC

I

CC(start)

<200A

I

CC(stby)

<2.9mA

I

CC(ON)

UVLO Soft-Start UVLO Run Run Fault/Standby

Controller

State

PWM

State

OFF Ramp Regulated OFF Regulated OFF

Soft-

Start

Ramp

5V

VSENSE

VCOMP

VCOMP

FAULT

Soft-Start

gmv

I

SS

= -30uA

for VSENSE < 4.25V

during Soft-Start

+

+

V

PRECHARGE

source for

rapid pre-charge

of VCOMP prior

to Soft-Start

FAULT

END OF SS

(LATCHED)

UVLO

+

+

VCC

ON

10.5V

S Q

Q R

C

DECOUPLE

VCC

Auxilary Supply

GND

VCC

OFF

9.5V

UVLO

Input Brown-Out Protection (IBOP)

+

+

VINENABLE_th 1.5V

S Q

Q R

VIN

BROWNOUT_th

0.8V

C

VINS

Rectified AC Line

R

VINS1

R

VINS2

VINS

5V

20k

IBOP C

IN

2 1

2

ENABLE _th

VINS VINS

ACturnon ENABLE _th

VINS

R R

V VINS

=

-

2

1 2

IN( RMS )

VINS

VINS VINS

V

P

R R

=

+

2

2

1 2

0 9

dischrg

VINS

BROWNOUT _th

VINS

VINS

ACmin

VINS VINS

t

C

VINS

R ln

R

. V

R R

-

=

+

1

2

dischrg

LINE

t N

f

=

+

Over and Under Voltage Protection

Open Loop Protection / Standby

Soft-Start Complete

OPEN LOOP

PROTECTION/STANDBY

R

FB1

Output Voltage

Standby

OLP/STANDBY

R

FB2

+

OVERVOLTAGE

OVP

VSENSE

Optional

+ UNDERVOLTAGE UVD 4.75V

5.25V

0.82V

+

SOFT-START COMPLETE 4.95V END OF SS

Feedback

Voltage

OVP 105%VREF

OLP

Soft-Start

(No EDR

to 99%VREF)

OLP

OVP

(No Gate Output)

Run

UVD

(EDR on)

Protection

State

100% VREF

OLP/SS 16%VREF

Run

EDR 95%VREF

PCL

+

VPCL

1.08V

ISENSE

Soft Over Current (SOC)

R

ISENSE

R

ISENSEfilter

+

CISENSEfilter

(Optional)

LINE

INPUT

V

OUT

VSOC

0.73V

Peak Current Limit (PCL)

SOC

+

-1x

300 ns

Leading Edge

Blanking

+

VISOP

0.1V ISOP

+

I

ISOP

1.5A

ISENSE Open-Pin

Protection (ISOP)

1 1

SOC(min)

ISENSE

L_ PEAK(max)

V

R

. I

2

RISENSE IN _ RMS(max) ISENSE

P ( I ) R =

PCL

PCL

ISENSE

V

I

R

=

VCC

VCC

GATE

C

OUT

L

BOOST D

BOOST

V

OUT

Rectified

AC

GND

Gate Driver

R

GATE

UVLO

IBOP

OLP

From

PWM

Latch

10k S Q

Q R

PCL

OVP

CLOCK

Pre-Drive and

Clamp Circuit

Q

BOOST

Fault

Logic

FAULT

PWMcycle

PWM

V

RAMP

=

F(V

VCOMP

)

V

ICOMP

t

ON

t

OFF

t

Cutoutin

groundplane

Signal

GND

Power

GND

GND

ICOMP

ISENSE

VINS VCOMP

VSENSE

VCC

GATE

+

+

OUT(max)

OUT(max)

OUT

P

I

V

=

350

0 9

390

OUT(max)

W

I . A

V

= @

OUT(max)

IN _ RMS(max)

IN(min)

P

I

V PF h

=

350

4 52

0 92 85 0 99

IN _ RMS(max)

W

I . A

. V .

= =

2

IN _ PEAK(max) IN _ RMS(max)

I I =

2 4 52 6 39

IN _ PEAK(max)

I . A . A = =

2

IN _ PEAK(max)

IN _ AVG(max)

I

I

p

=

2 6 39

4 07

IN _ AVG(max)

. A

I . A

p

= =

2

BRIDGE F _ BRIDGE IN _ AVG(max)

P V I =

2 0 95 4 07 7 73

BRIDGE

P . V . A . W = =

RIPPLE RIPPLE IN _ PEAK(max)

I I I = D

0 2

RIPPLE

I . D =

0 2 6 39 1 28

RIPPLE

I . . A . A = =

IN _ RIPPLE(max) RIPPLE _ IN IN _ RECTIFIED(min)

V V V = D

0 06

RIPPLE _ IN

V . D =

2

IN _ RECTIFIED IN

V V =

2 85 120 2

IN _ RECTIFIED(min)

V V . V = =

0 06 120 2 7 21

IN _ RIPPLE(max)

V . . V . V = =

8

RIPPLE

IN

SW IN _ RIPPLE(max)

I

C

f V

=

1 28

0 341

8 65 7 21

IN

. A

C . F

kHz . V

m = =

2

RIPPLE

L_ PEAK(max) IN _ PEAK(max)

I

I I = +

1 28

6 39 7 03

2

L_ PEAK(max)

. A

I . A . A = + =

1

OUT

BST(min)

SW( typ ) RIPPLE

V D( D)

L

f I

-

390 0 5 1 0 5

1 17

65 1 28

BST(min)

V . ( . )

L . mH

kHz . A

-

OUT IN _ RECTIFIED(min)

(max)

OUT

V V

DUTY

V

-

=

2 85 120

IN _ RECTIFIED(min)

V V V = =

390 120

0 692

390

(max)

V V

DUTY .

V

-

= =

125

0 5

DIODE F _ C OUT(max) SW( typ ) OUT RR

P V I . f V Q = +

125

1 5

F _ C

V . V =

0

RR

Q nC =

1 5 0 897 0 5 65 390 0 1 35

DIODE

P . V . A . kHz V nC . W = + =

2

125 COND DS _ RMS DSon( C )

P I R =

125

0 35

DSon( C )

R . = W

16

2

3

OUT(max) IN _ RECTIFIED(min)

DS _ RMS

IN _ RECTIFIED(min) OUT

P V

I

V V p

= -

350 16 120

2 3 54

120 3 390

DS _ RMS

W V

I . A

V V p

= - =

2

3 54 0 35 4 38

COND

P . A . . W = W =

5 0 4 5 = =

r f

t . ns ,t . ns

780

OSS

C pF =

( )

2

0 5 0 5

-

= + +

SW SW ( typ ) OUT IN PEAK (max) r f OSS OUT

P f ( . V I t t . C V )

( )

2

65 0 5 390 6 39 5 4 5 0 5 780 390 4 626 = + + =

SW

P kHz( . V . A n . ns . pF V ) . W

4 38 4 626 9 007 + = + =

COND SW

P P . W . W . W

1 25

SOC

SENSE

L_ PEAK(max)

V

R

I .

=

0 66

0 075

7 03 1 25

SENSE

. V

R .

. A .

= = W

0 067

SENSE

R . = W

SENSE RMS IN Rsense

R I P

2

(max) _

=

2

4 52 0 067 1 37 = W =

Rsense

P ( . A) . . W

PCL

PCL

SENSE

V

I

R

=

1 15

17 16

0 067

PCL

. V

I . A

.

= =

W

2 2

2

OUT HOLDUP

OUT(min)

OUT OUT _ HOLDUP(min)

P t

C

V V

2 2

2 350 21 28

240

390 300

OUT(min)

W . ms

C F

V V

m

-

0 05

OUT _ RIPPLE( pp ) OUT

V . V <

0 05 390 19 5

OUT _ RIPPLE( pp ) PP

V . V . V < <

2

OUT

OUT _ RIPPLE( pp )

LINE(min) OUT

I

V

( f )C p

=

0 9

11 26

2 47 270

OUT _ RIPPLE( pp )

. A

V . V

( Hz ) F p m

= =

2

2

OUT(max)

Cout _ fline

I

I =

2

0 9

0 635

2

Cout _ fline

. A

I . A = =

16

1 5

3

OUT

Cout _ HF OUT(max)

IN _ RECTIFIED(min)

V

I I .

V p

= -

16 390

0 9 1 5 1 8

3 120

Cout _ HF

V

I . A . . A

V p

= - =

2 2

2 Cout _ RMS( total ) Cout _ fline Cout _ HF

I I I = +

2 2

0 635 1 8 1 9

Cout _ RMS( total )

I . A . A . A = + =

1

2

REF FB

FB

OUT REF

V R

R

V V

=

-

2

5 1

13 04

390 5

FB

V M

R . k

V V

W

= = W

-

1 2

2

FB FB

OUT( OVP ) OVP

FB

R R

V VSENSE

R

+

=

1 13

5 25 410 7

13

OUT( OVP )

M k

V . V . V

k

W + W

= =

W

1 2

2

FB FB

OUT( UVD ) UVD

FB

R R

V VSENSE

R

+

=

1 13

4 75 371 6

13

OUT ( UVD )

M k

V . V . V

k

W + W

= =

W

2

0 01

=

VSENSE

FB

. ms

C

R

0 01

769

13

= =

W

VSENSE

. ms

C pF

k

2

1

1 2 2 2

OUT(max) OUT SENSE

IN _ RMS FQ

I V R K

M M

V K h

=

1

FQ

SW( typ )

K

f

=

1

15 385

65

FQ

K . s

kHz

m = =

1

7 K =

2

1 2 2 2

0 9 391 0 067 7

0 374

0 92 115 15 385m m

W

= =

. A V . V

M M .

. V . s s

VCOMP - V

0

0.4

0.8

1.2

1.6

2.0

M

1

M

2

M

1

M

2

vs

VCOMP

0.2

0.6

1.0

1.4

1.8

0 1 2 5 7 3 4 6

1

0 064 = then : M .

1

0 139 0 214 = - then : M . VCOMP .

1

0 279 0 632 = - then : M . VCOMP .

1

0 903 = then : M .

1

4

0 279 4 0 632 0 484

VCOMP

M . . .

=

= - =

2

0

m

=

V

then : M

s

2

2

0 1223 1 5

m

= -

V

then : M . (VCOMP . )

s

2

2 056

m

=

V

then : M .

s

2

2

4

0 1223 4 1 5 0 764

VCOMP

V V

M . ( . ) .

s s m m

=

= - =

1 2

0 484 0 764 0 37

V V

M M . . .

s s m m

= =

1 2

0 37 0 372

V V

. M M .

s s m m

@ =

2

3

0 0510 0 1543 0 1167 = - - then : M . VCOMP . VCOMP .

2

3

0 1026 0 3596 0 3085 = - + then : M . VCOMP . VCOMP .

2

3

4

0 1026 4 0 3596 4 0 3085 0 512

VCOMP

M . . . .

=

= - + =

1

1

2p

=

mi

ICOMP

IAVG

g M

C

K f

0 95 0 484

1100

7 2 9 5

ICOMP

. mS .

C pF

. kHz p

= =

1

1

2p

=

mi

IAVG

ICOMP

g M

f

K C

0 95 0 484

8 7

7 2 1200 p

= =

IAVG

. mS .

f . kHz

pF

1

2

1 1 2

1

1

=

+

SENSE OUT

CL

ICOMP FQ BST

mi

K R V

G ( f )

s( f ) K C K M M L

s( f )

g M

( )

20

CLdB CL

G ( f ) log G ( f ) =

1*10

4

q

G

C

L

(

f

)

f - Hz

-100

-60

-20

20

60

100

G

C

L

d

B

(

f

)

CURRENT AVERAGING CIRCUIT

-80

-40

0

40

80

10 100 1*10

3

1*10

6

1*10

5

-180

-160

-140

-120

-100

-80

Gain

Phase

2

1 2

FB

FB

FB FB

R

G

R R

=

+

13

0 013

1 13

FB

k

G .

M k

W

= =

W+ W

3

1

2

1 2

1

2

PWM _ PS

SENSE OUT OUT

FQ IN( typ )

f

K R V C

K M M V

p

=

3

2

1

1 581

7 0 067 391 270

2

15 385 0 484 0 764 115

m

p

m

m

= =

W

PWM _ PS

f . Hz

. V F

V

. s . . V

s

3

1 2

1

1

2

OUT

PWM _ PS

PWM _ PS

M V

M M s

G ( f )

s( f )

f

m

p

=

+

VL FB PWM _ PS

G ( f ) G G ( f ) =

( )

20

VLdB VL

G ( f ) log G ( f ) =

1*10

4

q

G

V

L

(

f

)

f - Hz

-60

20

G

V

L

d

B

(

f

)

OPEN LOOP VOLTAGE TRANSFER

FUNCTION

-40

-20

0

10 100 1*10

3

-100

-80

-60

-40

-20

0

1 0.1 0.01

Gain

Phase

1

2

ZERO

VCOMP VCOMP

f

R C p

=

1

2

POLE

VCOMP VCOMP VCOMP_ P

VCOMP VCOMP_ P

f

R C C

C C

p

=

+

( )

1

1

VCOMP VCOMP

EA

VCOMP VCOMP VCOMP_ P

VCOMP VCOMP_ P

VCOMP VCOMP_ P

s( f )R C

G ( f ) gmv

R C C

C C s( f ) s( f )

C C

+

=

+ +

+

10

V

f Hz =

20

10 2

G ( f )

VLdB

V

PWM _ PS

VCOMP

V

f

gmv

f

C

f p

=

0 667

20

10

42

1 581

3 92

10 2 10

m

m

p

= =

. dB VCOMP

Hz

S

. Hz

C . F

Hz

1

2

VCOMP

ZERO VCOMP

R

f C p

=

1

30 51

2 1 581 3 3 p m

= = W

VCOMP

R . k

. Hz . F

2 1

VCOMP

VCOMP_ P

POLE VCOMP VCOMP

C

C

f R C p

=

-

3 3

0 258

2 20 33 2 3 3 1

m

m

p m

= =

W -

VCOMP _ P

. F

C . F

Hz . k . F

VL_total FB PWM _ PS EA

G ( f ) G ( f )G ( f )G ( f ) =

( )

20

VL_totaldB VL_total

G ( f ) log G ( f ) =

1*10

4

f - Hz

-150

100

G

V

L

_

t

o

t

a

l

d

B

(

f

)

CLOSED LOOP VOLTAGE TRANSFER

FUNCTION

-50

0

50

10 100 1*10

3

0

20

40

60

80

100

1 0.1 0.01

-100

q

G

V

L

_

t

o

t

a

l

(

f

)

Gain

Phase

0

150

VINS VINS _ V

I I =

150 0 1 15 m m = =

VINS

I . A A

75

AC( on )

V V =

65

AC( off )

V V =

1

2

AC( on ) F _ BRIDGE ENABLE _th(max)

VINS

VINS

V V VINS

R

I

- -

=

1

2 75 0 95 1 6

6 9

15

VINS

V . V . V

R . M

A m

- -

= = W

1

2

2

ENABLE _th(max) VINS

VINS

AC( on ) ENABLE _th(max) F _ BRIDGE

VINS R

R

V VINS V

=

- -

2

1 6 6 5

100

2 75 1 6 0 95

VINS

. V . M

R k

V . V . V

W

= = W

- -

2

HALF _ CYCLES

CVINS _ dischrg

LINE(min)

N

t

f

=

2 5

25 6

2 47

CVINS _ dischrg

.

t . ms

Hz

= =

2

2

1 2

0 9

CVINS _dischrg

VINS

BROWNOUT _th(min)

VINS

VINS

IN _ RMS(min)

VINS VINS

t

C

VINS

R ln

R

. V

R R

-

=

25 6

0 63

0 76

100

100

0 9 85

6 5 100

VINS

. ms

C . F

. V

k ln

k

. V

. M k

m

-

= =

W

W

W + W

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

(2)

Lead/Ball Finish MSL Peak Temp

(3)

UCC28019AD ACTIVE SOIC D 8 75 Green (RoHS &

no Sb/Br)

CU NIPDAU Level-1-260C-UNLIM

UCC28019ADR ACTIVE SOIC D 8 2500 Green (RoHS &

no Sb/Br)

CU NIPDAU Level-1-260C-UNLIM

UCC28019AP ACTIVE PDIP P 8 50 Pb-Free

(RoHS)

CU NIPDAU N / A for Pkg Type

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and

package, or 2) lead-based die adhesive used between the die and leadframe. The component is otherwise considered Pb-Free (RoHS

compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

PACKAGE OPTION ADDENDUM

www.ti.com 23-Jun-2009

Addendum-Page 1

TAPE AND REEL INFORMATION

*All dimensions are nominal

Device Package

Type

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0 (mm) B0 (mm) K0 (mm) P1

(mm)

W

(mm)

Pin1

Quadrant

UCC28019ADR SOIC D 8 2500 330.0 12.4 6.4 5.2 2.1 8.0 12.0 Q1

PACKAGE MATERIALS INFORMATION

www.ti.com 12-May-2009

Pack Materials-Page 1

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

UCC28019ADR SOIC D 8 2500 340.5 338.1 20.6

PACKAGE MATERIALS INFORMATION

www.ti.com 12-May-2009

Pack Materials-Page 2

MECHANICAL DATA

MPDI001A JANUARY 1995 REVISED JUNE 1999

POST OFFICE BOX 655303 DALLAS, TEXAS 75265

P (R-PDIP-T8) PLASTIC DUAL-IN-LINE

8

4

0.015 (0,38)

Gage Plane

0.325 (8,26)

0.300 (7,62)

0.010 (0,25) NOM

MAX

0.430 (10,92)

4040082/D 05/98

0.200 (5,08) MAX

0.125 (3,18) MIN

5

0.355 (9,02)

0.020 (0,51) MIN

0.070 (1,78) MAX

0.240 (6,10)

0.260 (6,60)

0.400 (10,60)

1

0.015 (0,38)

0.021 (0,53)

Seating Plane

M 0.010 (0,25)

0.100 (2,54)

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Falls within JEDEC MS-001

For the latest package information, go to http://www.ti.com/sc/docs/package/pkg_info.htm

Das könnte Ihnen auch gefallen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen

- 110 Waveform Generator Projects for the Home ConstructorVon Everand110 Waveform Generator Projects for the Home ConstructorBewertung: 4 von 5 Sternen4/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Bewertung: 2.5 von 5 Sternen2.5/5 (3)

- Balancing of Reciprocating MassesDokument74 SeitenBalancing of Reciprocating MassesBharaniSai100% (1)

- Stability Analysis of Steel Storage Rack Structures PDFDokument7 SeitenStability Analysis of Steel Storage Rack Structures PDFFabian Flemin BahamondeNoch keine Bewertungen

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Von EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Bewertung: 4.5 von 5 Sternen4.5/5 (3)

- User's Manual HEIDENHAIN Conversational Format ITNC 530Dokument747 SeitenUser's Manual HEIDENHAIN Conversational Format ITNC 530Mohamed Essam Mohamed100% (2)

- Solution Manual For Introductory Statistics 9th Edition by Mann Chapters 1 13 PDFDokument10 SeitenSolution Manual For Introductory Statistics 9th Edition by Mann Chapters 1 13 PDFa40095824643% (14)

- NATCO Presentation - Desalters PDFDokument12 SeitenNATCO Presentation - Desalters PDFshahmkamalNoch keine Bewertungen

- Low Power Dual Operational Amplifiers: Order CodesDokument13 SeitenLow Power Dual Operational Amplifiers: Order CodesGyeTaeBaeNoch keine Bewertungen

- OpAmp - LF147 LF247 LF347 - STDokument11 SeitenOpAmp - LF147 LF247 LF347 - STLudwig SchmidtNoch keine Bewertungen

- A358FDokument4 SeitenA358FMy USERNAMENoch keine Bewertungen

- Double Channel High Side Solid State RelayDokument18 SeitenDouble Channel High Side Solid State RelayDan EsentherNoch keine Bewertungen

- LM358Dokument12 SeitenLM358riskiauliaNoch keine Bewertungen

- LM124 LM224Dokument16 SeitenLM124 LM224sb_jaiNoch keine Bewertungen

- Amplificador Operacional Jfet-LF153, LF253, LF353Dokument10 SeitenAmplificador Operacional Jfet-LF153, LF253, LF353Erick Dos SantosNoch keine Bewertungen

- Datasheet lf351Dokument9 SeitenDatasheet lf351medo_mausi03Noch keine Bewertungen

- PM20CSJ060: Mitsubishi Intelligent Power ModulesDokument6 SeitenPM20CSJ060: Mitsubishi Intelligent Power ModulesJefferson GiovaniNoch keine Bewertungen

- lm833 Rev2Dokument8 Seitenlm833 Rev2Jefri ErlanggaNoch keine Bewertungen

- Low Power Quad Voltage Comparators: LM139, A LM239, A - LM339, ADokument11 SeitenLow Power Quad Voltage Comparators: LM139, A LM239, A - LM339, Alinguyen1Noch keine Bewertungen

- TL062CPDokument12 SeitenTL062CPCleison FerreiraNoch keine Bewertungen

- MC34262-D-Power Factor Controller-ON-SEMI PDFDokument19 SeitenMC34262-D-Power Factor Controller-ON-SEMI PDFnightreader99Noch keine Bewertungen

- Dual Intelligent Power Low Side Switch: DescriptionDokument10 SeitenDual Intelligent Power Low Side Switch: DescriptionDan EsentherNoch keine Bewertungen

- tl082 DatasheetDokument11 Seitentl082 DatasheetJoseph BaltazarNoch keine Bewertungen

- AN4558 (AN6552), AN4558S (AN6552S) : Dual Operational AmplifiersDokument4 SeitenAN4558 (AN6552), AN4558S (AN6552S) : Dual Operational AmplifiersRicardo SoniNoch keine Bewertungen

- DC Power Switch 1473lfDokument16 SeitenDC Power Switch 1473lfshabaz_yousaf2734Noch keine Bewertungen

- LM-339 Data SheetDokument11 SeitenLM-339 Data SheetThorik AchsanNoch keine Bewertungen

- tl074cn MXRXRVQ PDFDokument11 Seitentl074cn MXRXRVQ PDFOsman KoçakNoch keine Bewertungen

- Low Power J-Fet Dual Operational Amplifiers: TL062 TL062A - TL062BDokument11 SeitenLow Power J-Fet Dual Operational Amplifiers: TL062 TL062A - TL062BJohn PachecoNoch keine Bewertungen

- TD 62308Dokument8 SeitenTD 62308cubareNoch keine Bewertungen

- MC33030PDokument17 SeitenMC33030PGisela ValdezNoch keine Bewertungen

- Datasheet 2Dokument10 SeitenDatasheet 2miguel angel jaramilloNoch keine Bewertungen

- Description Features: CMOS Low-Power Monostable/Astable MultivibratorDokument15 SeitenDescription Features: CMOS Low-Power Monostable/Astable Multivibratorதினேஷ் குமார்Noch keine Bewertungen

- 04 Spec Sheet PWM Controller ChipDokument16 Seiten04 Spec Sheet PWM Controller Chipxuanhiendk2Noch keine Bewertungen

- 78 S 40Dokument9 Seiten78 S 40Luis AlbertoNoch keine Bewertungen

- P45N02LD Niko-Sem: N-Channel Logic Level Enhancement Mode Field Effect TransistorDokument3 SeitenP45N02LD Niko-Sem: N-Channel Logic Level Enhancement Mode Field Effect TransistorAnonymous qrSsYuxyoYNoch keine Bewertungen

- 20 N 60 C 3Dokument13 Seiten20 N 60 C 3rashidmirzaNoch keine Bewertungen

- TL 071pdf PDFDokument9 SeitenTL 071pdf PDFGustavo MathiasNoch keine Bewertungen

- Datasheet Mc33178pDokument17 SeitenDatasheet Mc33178pNegro Danny AyosaNoch keine Bewertungen

- 2sj 598 Power Mos Dell 2407wfpbDokument8 Seiten2sj 598 Power Mos Dell 2407wfpbkarkeraNoch keine Bewertungen

- Datasheet JFETDokument16 SeitenDatasheet JFETaldontetNoch keine Bewertungen

- LM339N PDFDokument10 SeitenLM339N PDFebertecnicoNoch keine Bewertungen

- Switching Regulator Applications: Absolute Maximum RatingsDokument6 SeitenSwitching Regulator Applications: Absolute Maximum RatingsSyed Azhar HussainNoch keine Bewertungen

- Ta8229 Sip Ic DatasheetDokument9 SeitenTa8229 Sip Ic DatasheetNoliCatangoganSalcedoNoch keine Bewertungen

- Amplificador Tlo82Dokument11 SeitenAmplificador Tlo82Miguel CombarizaNoch keine Bewertungen

- General Purpose J-Fet Single Operational Amplifiers: TL081 TL081A - TL081BDokument11 SeitenGeneral Purpose J-Fet Single Operational Amplifiers: TL081 TL081A - TL081BLaura Itzel MoralesNoch keine Bewertungen

- C324G Low Power Quad OpAmpDokument12 SeitenC324G Low Power Quad OpAmpwhynot05Noch keine Bewertungen

- Datasheet 3Dokument8 SeitenDatasheet 3haranahalliNoch keine Bewertungen

- TL081Dokument9 SeitenTL081Lazar MaruivaNoch keine Bewertungen

- Datasheet 2SK3797 Mosfet Fuente Proyector Viewsonic PJD5123Dokument6 SeitenDatasheet 2SK3797 Mosfet Fuente Proyector Viewsonic PJD5123Rubén Nicanor Sandoval BascuñanNoch keine Bewertungen

- Double Channel High Side Solid State Relay: VND600SPDokument17 SeitenDouble Channel High Side Solid State Relay: VND600SPDan EsentherNoch keine Bewertungen

- G 4 BC 20 KDDokument11 SeitenG 4 BC 20 KDJuan Carlos Terrones NuñezNoch keine Bewertungen

- LM 339Dokument11 SeitenLM 339Adi PamungkasNoch keine Bewertungen

- mc1776 - Datasheet PDFDokument12 Seitenmc1776 - Datasheet PDFLg GnilNoch keine Bewertungen

- Power Transistor: SPW20N60S5 Cool MOS™Dokument12 SeitenPower Transistor: SPW20N60S5 Cool MOS™Bogdan OlaruNoch keine Bewertungen

- Amplificador Operacional TL081 (THOMSON)Dokument10 SeitenAmplificador Operacional TL081 (THOMSON)lah.fisicaNoch keine Bewertungen

- KIA4558SDokument5 SeitenKIA4558SEnzo CeballosNoch keine Bewertungen

- 70+70W STEREO Power Amplifier: Bash® Licence RequiredDokument16 Seiten70+70W STEREO Power Amplifier: Bash® Licence RequiredlemahuNoch keine Bewertungen

- Features Descriptio: Lt1632/Lt1633 45Mhz, 45V/ S, Dual/Quad Rail-To-Rail Input and Output Precision Op AmpsDokument16 SeitenFeatures Descriptio: Lt1632/Lt1633 45Mhz, 45V/ S, Dual/Quad Rail-To-Rail Input and Output Precision Op Ampssoft4gsmNoch keine Bewertungen

- Volt RegDokument59 SeitenVolt RegAyesha AmbaniNoch keine Bewertungen

- MC33030 MotorolaDokument16 SeitenMC33030 MotorolaLuiz EduardoNoch keine Bewertungen

- (Vishay Siliconix) 2N4393Dokument6 Seiten(Vishay Siliconix) 2N4393SevenUp2014Noch keine Bewertungen

- Famous MathematicianDokument116 SeitenFamous MathematicianAngelyn MontibolaNoch keine Bewertungen

- 2018 AniketDokument60 Seiten2018 Aniketaniket chakiNoch keine Bewertungen

- Specializations MTech Software SystemsDokument5 SeitenSpecializations MTech Software SystemsAkanksha SinghNoch keine Bewertungen

- Cópia de Teste Excel - Intermediário (5166) .XLS: BIM Technology For EngineersDokument6 SeitenCópia de Teste Excel - Intermediário (5166) .XLS: BIM Technology For EngineersFernanda AzevedoNoch keine Bewertungen

- MoazzamMaqsood Transcript PDFDokument3 SeitenMoazzamMaqsood Transcript PDFmoazzam maqsoodNoch keine Bewertungen

- PS1Dokument2 SeitenPS1Nitesh Kumar DubeyNoch keine Bewertungen

- RRB JE CBT-2 Electronics Tech Paper With Key 31-8-2019 1st ShiftDokument55 SeitenRRB JE CBT-2 Electronics Tech Paper With Key 31-8-2019 1st ShiftKuldeep SinghNoch keine Bewertungen

- 10 2Dokument26 Seiten10 2cristinatubleNoch keine Bewertungen

- Unit-3 BPDokument48 SeitenUnit-3 BPShreyas ShreyuNoch keine Bewertungen

- University of Cambridge International Examinations General Certificate of Education Advanced LevelDokument4 SeitenUniversity of Cambridge International Examinations General Certificate of Education Advanced LevelHubbak KhanNoch keine Bewertungen

- P 130881757895329843Dokument44 SeitenP 130881757895329843Vijay MohanNoch keine Bewertungen

- ElutriatorDokument9 SeitenElutriatoratiyorockfan9017Noch keine Bewertungen

- F3 Chapter 1 (SOALAN) - RespirationDokument2 SeitenF3 Chapter 1 (SOALAN) - Respirationleong cheng liyNoch keine Bewertungen

- Pressure Sensor Air PST Datasheet 51 en 2780071435Dokument3 SeitenPressure Sensor Air PST Datasheet 51 en 2780071435Luis GuevaraNoch keine Bewertungen

- Parts Catalog: Parts - Sales - Service - RestorationsDokument32 SeitenParts Catalog: Parts - Sales - Service - RestorationsJean BelzilNoch keine Bewertungen

- A Spectrum Analyser For The Radio AmateurDokument24 SeitenA Spectrum Analyser For The Radio AmateurRavindra MogheNoch keine Bewertungen

- Acuvim II Profibus Modules Users Manual v1.10Dokument36 SeitenAcuvim II Profibus Modules Users Manual v1.10kamran719Noch keine Bewertungen

- X500Dokument3 SeitenX500yu3zaNoch keine Bewertungen

- Slip Rings: SRI085 V100 - XX - XX - Xxx1XxDokument3 SeitenSlip Rings: SRI085 V100 - XX - XX - Xxx1XxMatheus Henrique MattiaNoch keine Bewertungen

- Serie W11 PDFDokument2 SeitenSerie W11 PDFOrlandoNoch keine Bewertungen

- Shaping Plastic Forming1Dokument24 SeitenShaping Plastic Forming1Himan JitNoch keine Bewertungen

- College of Technology & Engineering: Practical Training at Hindustan Zinc Limited Zinc Smelter, Debari UdaipurDokument24 SeitenCollege of Technology & Engineering: Practical Training at Hindustan Zinc Limited Zinc Smelter, Debari UdaipurPooja SahuNoch keine Bewertungen

- Solved - Which $1,000 Bond Has The Higher Yield To Maturity, A T...Dokument4 SeitenSolved - Which $1,000 Bond Has The Higher Yield To Maturity, A T...Sanjna ChimnaniNoch keine Bewertungen

- North Sails Brochure 2007 enDokument24 SeitenNorth Sails Brochure 2007 ennorthsailsNoch keine Bewertungen

- Carel MxproDokument64 SeitenCarel MxproPreot Andreana CatalinNoch keine Bewertungen