Beruflich Dokumente

Kultur Dokumente

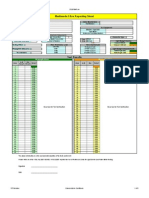

Alcoa Fujikura Ltd. Routine Inspection and Test Plan For Stainless Steel in Pipe Optical Ground Wire

Hochgeladen von

Fernando Patiño GuevaraOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Alcoa Fujikura Ltd. Routine Inspection and Test Plan For Stainless Steel in Pipe Optical Ground Wire

Hochgeladen von

Fernando Patiño GuevaraCopyright:

Verfügbare Formate

Process Item Test References Sampling Accuracy Responsibility

Receive raw materials Fiber None Check for damage and quantity 100 % N/A Receiving

Receive raw materials Stainless steel None Check for damage, dimensions,

condition and quality

100 % N/A Receiving

SST

Fiber Prep

Fiber color

&striping

Color and stripes

Fiber ID

Level wind

Length (OTDR)

SPC-2-10-212

OPT-3-10-051

100%

100%

N/A

0.01dB/km

Fiber Prep

and SST

SST

Stainless steel

loose tube unit

Attenuation (OTDR)

SS Tube Diameter

Gel fill

Fiber overlength

Weld quality

OPT-3-10-051

OPT-3-10-053

OPT-3-10-387

Eddy current

100 %

OSE AND ISE

OSE

OSE

100%

0.01 dB/km

0.01 mm

+/- 5%

+/-0.05%

N/A

SST

*SST IN PIPE

*(This section pertains to SST in a

Pipe Only)

Stainless steel

tube in pipe

Pipe integrity

Pipe weld projection

Pipe inner diameter

Pipe outer diameter

Fiber overlength

Attenuation (OTDR)

Eddy current

OPT-3-10-080

OPT-3-10-080

OPT-3-10-080

OPT-3-10-387

OPT-3-10-051

100 %

OSE and ISE

OSE and ISE

OSE and ISE

OSE

100% of pipes going to

offsite strander

N/A

0.01 mm

0.01 mm

0.01 mm

+/- 0.5%

0.01dB/km

Pipe

SST

Pipe/ Fiinal

QC

Final Inspection

Finished Product Attenuation (OTDR)

Dimensional checks :

Cable core

Wire preform

Check in-process data

OPT-3-10-051

Pipe Resistance per

OPT-3-10-289

Visual inspection

Verify that all inspections have

been performed and meet

specifications.

100 % bi-directional

OSE and ISE

OSE and ISE

100%

0.01 dB/km

Final QC

Document Number:OPT-2-10-439 Revision: 1 Originator: Tim Hartpence Effective:10/31/2001

Alcoa Fujikura Ltd.

Telecommunications Division

Routine Inspection and Test Plan for Stainless Steel In Pipe Optical Ground Wire

a

Das könnte Ihnen auch gefallen

- Dno 6282 OpgwDokument2 SeitenDno 6282 OpgwJuanNoch keine Bewertungen

- Optical Con Field Assembly - Technical Info v1.0Dokument14 SeitenOptical Con Field Assembly - Technical Info v1.0Mariano AcostaNoch keine Bewertungen

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- Testing and Commissioning of MVHV CablesDokument7 SeitenTesting and Commissioning of MVHV CablesFernando Patiño GuevaraNoch keine Bewertungen

- Electrical Resistance (ER) Probes: Features and Advantages Other EquipmentDokument4 SeitenElectrical Resistance (ER) Probes: Features and Advantages Other EquipmentHạo Nam-Born To WinNoch keine Bewertungen

- UT ReportDokument5 SeitenUT ReportMohamed SiddiqueNoch keine Bewertungen

- Technical - Specification - Group D - Tubing - 2023 07 05 13 16 29Dokument2 SeitenTechnical - Specification - Group D - Tubing - 2023 07 05 13 16 29Chinnaraj SNoch keine Bewertungen

- Technical Data - 28071401EDokument1 SeiteTechnical Data - 28071401EManoj AgarwalNoch keine Bewertungen

- Senzo Rip Rox ImitateDokument4 SeitenSenzo Rip Rox ImitatevalentincaciorNoch keine Bewertungen

- Technical Data SheetDokument10 SeitenTechnical Data SheetaqazamNoch keine Bewertungen

- JSPL Line-2 Erection BOMDokument11 SeitenJSPL Line-2 Erection BOMRakesh Karan SinghNoch keine Bewertungen

- BOQ For PRMS Instrumentation, Electrical & Automation Job B.O.Q Project: PRMS Job, Visakhapatnam Steel PlantDokument31 SeitenBOQ For PRMS Instrumentation, Electrical & Automation Job B.O.Q Project: PRMS Job, Visakhapatnam Steel Plantkoushik42000Noch keine Bewertungen

- LRPC StrandDokument3 SeitenLRPC Strandanon_655956777100% (1)

- Conductivity sensor-SC4Dokument12 SeitenConductivity sensor-SC4Ziyaur RahmanNoch keine Bewertungen

- Technical Data - 2019EBDokument4 SeitenTechnical Data - 2019EBManoj AgarwalNoch keine Bewertungen

- ACSR - InformationDokument15 SeitenACSR - Informationvishnu ojhaNoch keine Bewertungen

- General Specifications: Conductivity Sensors and Fittings For 2-Electrode Systems Model SC4A and PR4ADokument8 SeitenGeneral Specifications: Conductivity Sensors and Fittings For 2-Electrode Systems Model SC4A and PR4AHolicsNoch keine Bewertungen

- 511 Pressure TransmitterDokument5 Seiten511 Pressure TransmitterDhp CiaNoch keine Bewertungen

- Opti Flux 4000 Spec SheetDokument8 SeitenOpti Flux 4000 Spec SheetAhmad Adel El TantawyNoch keine Bewertungen

- Sl2000-Detector de HumoDokument2 SeitenSl2000-Detector de Humocarlos.castillo.ing.1Noch keine Bewertungen

- ZTT Spec SheetDokument8 SeitenZTT Spec SheetEnzo del PradoNoch keine Bewertungen

- Frequency Calculation For ECT Tube InspectionDokument12 SeitenFrequency Calculation For ECT Tube InspectionDhanasekaran RNoch keine Bewertungen

- Ultrasonic Inspection-Test BlocksDokument0 SeitenUltrasonic Inspection-Test BlocksSreeji ChittamveeduNoch keine Bewertungen

- TelecomunicacionesDokument32 SeitenTelecomunicacionesMarco OlazabalNoch keine Bewertungen

- STP - Test PlugsDokument1 SeiteSTP - Test PlugssalesNoch keine Bewertungen

- Pin Description Features: P-Channel Enhancement Mode MOSFETDokument0 SeitenPin Description Features: P-Channel Enhancement Mode MOSFETShaher Bano KazmiNoch keine Bewertungen

- FFB CableDokument3 SeitenFFB CableNaveed IrshadNoch keine Bewertungen

- Testing Format For FibreDokument5 SeitenTesting Format For FibrePaul KwongNoch keine Bewertungen

- RTR Question and Answer For OWS and Utility LinesDokument18 SeitenRTR Question and Answer For OWS and Utility Linesjana.alqimmaNoch keine Bewertungen

- Factory Test Procedure For AccessoriesDokument7 SeitenFactory Test Procedure For Accessoriesrenjithas2005Noch keine Bewertungen

- Technical Data - CABLE 2P X 1 SQMMDokument1 SeiteTechnical Data - CABLE 2P X 1 SQMMManoj AgarwalNoch keine Bewertungen

- 6 Pro DP1001 C DSDokument4 Seiten6 Pro DP1001 C DSnino16041973Noch keine Bewertungen

- STT Lincoln Electric Miskei ZoltanDokument30 SeitenSTT Lincoln Electric Miskei ZoltanHrvoje JakoplićNoch keine Bewertungen

- 0.9. OPGW - Tech - Discription For OPGWDokument12 Seiten0.9. OPGW - Tech - Discription For OPGWgiorgis072Noch keine Bewertungen

- Ts Remarks: of Raw Materials Item Manufacture System / Requiremen Thicknes S (Min. MM) Resin % Glass % Testing FrequencyDokument1 SeiteTs Remarks: of Raw Materials Item Manufacture System / Requiremen Thicknes S (Min. MM) Resin % Glass % Testing FrequencySaud PathiranaNoch keine Bewertungen

- El 2271 PDFDokument2 SeitenEl 2271 PDFJavierbritosNoch keine Bewertungen

- Conductivity SensorDokument3 SeitenConductivity SensorDanish AkhtarNoch keine Bewertungen

- BAW M18ME-UAC50B-BP03 Ordering Code: BAW0022: Cable, 3m, PUR PNP / AnalogDokument2 SeitenBAW M18ME-UAC50B-BP03 Ordering Code: BAW0022: Cable, 3m, PUR PNP / AnalogFrancisco Salas GalvanNoch keine Bewertungen

- Advanced NDTEquipmentsDokument4 SeitenAdvanced NDTEquipmentsshamsNoch keine Bewertungen

- OS1LTSTA12UBKDokument2 SeitenOS1LTSTA12UBKShimahNoch keine Bewertungen

- Presentasi Welding Prosedur Specification (WPS) Pre QualifiedDokument8 SeitenPresentasi Welding Prosedur Specification (WPS) Pre QualifiedDeri Agung WicaksonoNoch keine Bewertungen

- Oglaend Cable Tray SPB 0911Dokument20 SeitenOglaend Cable Tray SPB 0911gregb_169101Noch keine Bewertungen

- A 228 - A 228M - 00 Qtiyoc9bmji4ts1sruq - PDFDokument7 SeitenA 228 - A 228M - 00 Qtiyoc9bmji4ts1sruq - PDFTiến Lượng NguyễnNoch keine Bewertungen

- Pipe Inspection, Testing & MarkingDokument12 SeitenPipe Inspection, Testing & MarkingRamalingam PrabhakaranNoch keine Bewertungen

- Specs of The Tehsino Opgw Fiber CableDokument12 SeitenSpecs of The Tehsino Opgw Fiber CableCarlos Aviles CutiñoNoch keine Bewertungen

- WELDING ESAB Welding Handbook XA00106720 - Pipeline Catalogue (Ebook, 66 Pages)Dokument66 SeitenWELDING ESAB Welding Handbook XA00106720 - Pipeline Catalogue (Ebook, 66 Pages)Denny SyamsuddinNoch keine Bewertungen

- Especificaciones Tecnicas OPGWDokument11 SeitenEspecificaciones Tecnicas OPGWSebastián AlmagroNoch keine Bewertungen

- Et 01Dokument2 SeitenEt 01simpangrayaNoch keine Bewertungen

- Armatura OkDokument10 SeitenArmatura OkDragos PetrovicNoch keine Bewertungen

- Traductor de Temperatura TS 100: Drucktransmitter Mit Piezoresitivem Messelement. Caracteristici AplicatiiDokument4 SeitenTraductor de Temperatura TS 100: Drucktransmitter Mit Piezoresitivem Messelement. Caracteristici AplicatiiJoseph TaylorNoch keine Bewertungen

- General: Part Number: Status: Overview: DescriptionDokument4 SeitenGeneral: Part Number: Status: Overview: DescriptionselocaNoch keine Bewertungen

- Komparasi New MTO Vs Kontrak (Scope Instrument)Dokument20 SeitenKomparasi New MTO Vs Kontrak (Scope Instrument)henryNoch keine Bewertungen

- A-2Y2YB2Y Nx1x0,9 I Nx1x1,4Dokument2 SeitenA-2Y2YB2Y Nx1x0,9 I Nx1x1,4Daliborka Stojcinovic RisticNoch keine Bewertungen

- The New RF-Probes Catalog: Bild Fehlt!Dokument6 SeitenThe New RF-Probes Catalog: Bild Fehlt!வினோத் குமார் சேகர்Noch keine Bewertungen

- Improving Small Diameter Pipe Weld Inspections With Phased Arrays NDT For ManagersDokument34 SeitenImproving Small Diameter Pipe Weld Inspections With Phased Arrays NDT For Managerssriraj.kadabaNoch keine Bewertungen

- Revise Insp Report - 1 PDFDokument4 SeitenRevise Insp Report - 1 PDFShankar RajNoch keine Bewertungen

- Conduit-PVC Coated T&B Catalog Number: UPC Number: Status: DescriptionDokument10 SeitenConduit-PVC Coated T&B Catalog Number: UPC Number: Status: DescriptionXinoko MosqueiraNoch keine Bewertungen

- A790 PDFDokument2 SeitenA790 PDFrizairawan09Noch keine Bewertungen

- Operational Amplifier Noise: Techniques and Tips for Analyzing and Reducing NoiseVon EverandOperational Amplifier Noise: Techniques and Tips for Analyzing and Reducing NoiseBewertung: 5 von 5 Sternen5/5 (1)

- Testing and Commissioning of MetalClad SwitchgearDokument3 SeitenTesting and Commissioning of MetalClad SwitchgearFernando Patiño GuevaraNoch keine Bewertungen

- RI 6000226-1001 001 - PrysmianDokument4 SeitenRI 6000226-1001 001 - PrysmianFernando Patiño GuevaraNoch keine Bewertungen

- TestPlan ASTM 123Dokument9 SeitenTestPlan ASTM 123Fernando Patiño Guevara100% (1)