Beruflich Dokumente

Kultur Dokumente

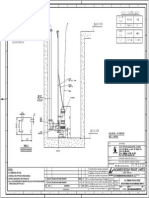

PIPing Layout For Coal Mill Rejection System

Hochgeladen von

Juhi SinghOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PIPing Layout For Coal Mill Rejection System

Hochgeladen von

Juhi SinghCopyright:

Verfügbare Formate

NOTES:-

1. ALL DIMENSIONS ARE IN MM & ELEVATIONS ARE IN METERS.

C

S.No. DESCRIPTION

REFERENCES

DRG. NO. DATE R.No. DESCRIPTION

REVISIONS

A

1

SUNIL SAINI

RKG

CHKD. BY APPD. APPROVED

NO. DT. DATE

RELEASE STATUS

PURPOSE

FOR APPROVAL

FOR TENDER ONLY

M

A

N

F

./

F

O

RMECH.

ELECT.

CIVIL/STR.

C

O

N

S

T

DATE SIGNATURE

DESIGNED

DRAWN

CHECKED

SCALE DRG. No.

MB/ C-1060/ 72777A 1 : 175

(FOR COAL MILL REJ ECT HANDLING SYSTEM)

PIPING LAYOUT

REV.

3

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

B

C

D

E

F

G

H

I

J

K

L

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Drawing Sheet - A1

A

B

C

D

E

F

G

H

I

J

K

L

Sheet 1 of 2

AP

SVS

11.10.2010

NEW DELHI

OWNER

ADANI POWER MAHARASHTRA LIMITED

TIR1-EPC-MRS-DM-D-010

EMPLOYER

POWERGEN INFRASTRUCTURE (L.L.C)

PROJ ECT

COAL MILL REJ ECTS HANDLING SYSTEM

T

R

U

E

N

O

R

T

H P

L

A

N

T

N

O

R

T

H

45

S174.900

W14.500

C

BOILER #1

C

O

F

B

O

I

L

E

R

L

W

/

E

0

E

5

0

S 150

S 125

S 175

E

7

5

E

2

5

S 150

S 125

S 175

W

/

E

0

E

5

0

E

7

5

E

2

5

1

0

0

0

0

1

0

0

0

0

1

0

0

0

0

1

0

0

0

0

13000

9200 3800

C

O

F

M

IL

L

L

C

O

F

M

IL

L

L

C

O

F

M

IL

L

L

5

0

0

0

5

0

0

0

5

0

0

0

5

0

0

0

5

0

0

0

5

0

0

0

5

0

0

0

5

0

0

0

C OF MILL

L

C OF MILL

L

C OF MILL L

C OF MILL L

5

0

0

0

5

0

0

0

5

0

0

0

5

0

0

0

5

0

0

0

5

0

0

0

5

0

0

0

5

0

0

0

1

0

0

0

0

1

0

0

0

0

1

0

0

0

0

1

0

0

0

0

1

0

0

0

0

1

0

0

0

0

C

O

F

M

IL

L

L

C

O

F

M

IL

L

L

C

O

F

M

IL

L

L

C OF MILL

L

C OF MILL

L

C OF MILL L

C OF MILL L

12000

12000

2500

CONV. AIR RECEIVER

(CAP.-10 Cu.M)

2500

1

7

5

0

L OF MANHOLE C

2

5

0

0

10000

INSTRUMENT AIR AT T.P. (BY CLIENT)

REulRE . 1.5 N/m|u @7 Kg/Cm

SERVICE WATER AT T.P. (BY CLIENT)

REulRE . 4N/h|. @2-2.5 Kg/Cm

TAPPING POINT

TAPPING POINT

C D D

F

F

LAYOUT BASE ON REF. DRAWING NO. 1

MILL FOUNDATION BASE ON REF. DRAWING NO 2

LAYOUT OF COAL MILL FOUNDATION 3

TO NEAREST DRAIN

DRAIN WATER HEADER

TO NEAREST DRAIN

DRAIN WATER HEADER

10000

COVER WITH SHED

G

G

G

G

3. THIS LAYOUT WILL BE SAME FOR ALL 5 UNITS

2. ELEVATION (+/-)0.000M CORRESPONDS TO FFL OF TG BUILDING WHICH

CORRESPONDS TO 328.75M ABOVE MSL.

10000

12000

7500

125 NB MAT. CONV. PIPELINE 125 NB MAT. CONV. PIPELINE

17.11.10 1 REVISED AS PER CLIENT'S COMMENT'S AP SN SVS

5000

9

0

0

0

7000

DRAIN TRENCH

1

0

0

1

0

0

DRAIN TRENCH

1

2

0

0

1

2

0

0

DET.'A'

EMERGENCY EMPTY PIPE

DET.'C'

S174.900

E 94.500

H H

J J

2

4

0

0

E

E

1

1

1

1

1

1

1

MB/ C-1060/ 72497D

PLEASE REF.DRG. NO.

REF. SH.2

REF. SH.2

20NB INST. AIR PIPE 40NB COOLING WATER PIPE 100NB CONV. AIR PIPE

CONV. AIR RECEIVER

(CAP.-10 Cu.M)

C

O

N

V

E

Y

IN

G

A

IR

C

O

M

P

R

E

S

S

O

R

M

A

K

E

: A

T

L

A

S

C

O

P

C

O

M

O

D

E

L

: G

A

-5

5

(A

IR

C

O

O

L

E

D

)

Q

T

Y

. - 2

N

O

S

.-(1

W

+

1

S

)

C

A

P

A

C

IT

Y

: 8

.5

N

M

3/M

in

.

w

0

R

K

lh

P

R

E

S

S

u

R

E

. 5

.O

K

g

/C

m

(g

)

L

0

A

lh

P

R

E

S

S

u

R

E

. 4

.5

K

g

/C

m

(g

)

u

h

L

0

A

lh

P

R

E

S

S

u

R

E

. 5

.5

K

g

/C

m

(g

)

11.01.11 2 REVISED AS PER CLIENT'S COMMENT'S AP SN SVS

S158.200

W17.500

2

M

M

DET. 'D'

2

REVISED AS PER CLIENT'S COMMENT'S AP SN SVS 24.01.11 3

3

Category-A1

Shrikant Garje

Digitally signed by Shrikant Garje

DN: cn=Shrikant Garje, o=B&V,

ou=Enerjy, email=garjes@bv.com,

c=IN

Date: 2011.02.04 14:25:18 +05'30'

Category - A1

DN: cn=VIKAS, o=AIIL, ou=CEG,

email=vikas.kodan@adani.in, c=IN

Date: 2011.02.19 11:27:20 +05'30'

NOTES:-

S.No. DESCRIPTION

REFERENCES

DRG. NO. DATE R.No. DESCRIPTION

REVISIONS

A

1

SUNIL SAINI

RKG

CHKD. BY APPD. APPROVED

NO. DT. DATE

RELEASE STATUS

PURPOSE

FOR APPROVAL

FOR TENDER ONLY

M

A

N

F

./

F

O

RMECH.

ELECT.

CIVIL/STR.

C

O

N

S

T

DATE SIGNATURE

DESIGNED

DRAWN

CHECKED

SCALE DRG. No.

MB/ C-1060/ 72777A 1 : 50

(FOR COAL MILL REJ ECT HANDLING SYSTEM)

PIPING LAYOUT

REV.

3

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

B

C

D

E

F

G

H

I

J

K

L

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Drawing Sheet - A1

A

B

C

D

E

F

G

H

I

J

K

L

Sheet 2 of 2

AP

SVS

11.10.2010

NEW DELHI

OWNER

ADANI POWER MAHARASHTRA LIMITED

TIR1-EPC-MRS-DM-D-010

EMPLOYER

POWERGEN INFRASTRUCTURE (L.L.C)

PROJ ECT

COAL MILL REJ ECTS HANDLING SYSTEM

T

R

U

E

N

O

R

T

H P

L

A

N

T

N

O

R

T

H

45

1. ALL DIMENSIONS ARE IN MM & ELEVATIONS ARE IN METERS.

LAYOUT BASE ON REF. DRAWING NO. 1

MILL FOUNDATION BASE ON REF. DRAWING NO 2

LAYOUT OF COAL MILL FOUNDATION 3

2. ELEVATION (+/-)0.000M CORRESPONDS TO FFL OF TG BUILDING WHICH

CORRESPONDS TO 328.75M ABOVE MSL.

3. THIS LAYOUT WILL BE SAME FOR ALL 5 UNITS

REVISED AS PER CLIENT'S COMMENT'S AP SN SVS 17.11.10 1

DETAIL-A

EXISTING COLUMN

VIEW C-C

3 NOS. 125 NB

MAT. CON. PIPE LINE

(B.O.P.)

EL(+)12.500M

700

3

0

0

3

0

0

EL(+)12.200M

(B.O.P.)

EL(+)11.900M

(B.O.P.)

(B.O.P.)

EL(+)3.500M

170

125 140

100NB CONV. AIR PIPE

20NB INTRUMENT AIR PIPE

40NB COOLING WATER PIPE

200

50NB DRAIN WATER HEADER

TO NEAREST DRAIN

TAPER WASHER (TYP.)

200x280x12 Thk.

1 No. (TYP)

HEX. BOLT M12x40 LONG

WITH NUTS 2 Nos. &

STIFFENING PLATE

125 NB MATL. CON.

PIPE LINE

1

2

2

0

0

VIEW B-B

10

014 h0LES lh ChAhhEL'S T0P lLAhE

& SL0TTE h0LES 014/8O L0h

M12x40 LONG HEX. SCREW.

IN PLATE ONLY, SHALL BE DONE FOR

(TYPICAL VERTICAL PIPE SUPPORT DETAIL)

700

6

2

9

B

B

ENLARGE DETAIL-B

125 NB CON.

PIPE LINE

EXISTING COLUMN

EL(+)3.500M

(C.L. OF PIE SUPPORT)

C OF MILL REJECT OUTLET C OF MILL REJECT OUTLET L

1600 1300

1

5

N

B

IN

S

T

. A

IR

EMERGENCY EMPTY PIPE

EL(+)11.600M

(B.O.P.)

EL(+)11.900M

(B.O.P.)

EL(+)12.200M

(B.O.P.)

EL(+)0.100M

EL(-)2.370M

C OF EXISTING COLUMN

L

EL()O.OOON

EL(-)2.170M

VIEW D-D

EXISTING COLUMN

3 NOS. 125 NB

MAT. CON. PIPE LINE

(B.O.P.)

EL(+)12.500M

700

3

0

0

3

0

0

EL(+)12.200M

(B.O.P.)

EL(+)11.900M

(B.O.P.)

(B.O.P.)

EL(+)3.500M

170

125 140 100NB CONV. AIR PIPE

20NB INTRUMENT AIR PIPE

40NB COOLING WATER PIPE

200

50NB DRAIN WATER HEADER

TO NEAREST DRAIN

(B.O.P.)

EL(+)12.500M

(B.O.P.)

EL(+)12.200M

(B.O.P.)

EL(+)11.900M

(B.O.P.)

EL(+)11.600M

900

250

3

0

0

3

0

0

3

0

0

4 NOS. 125 NB

MAT. CON. PIPE LINE

TO SILO

VIEW F-F

15NB INSTRUMENT AIR

TO SILO

450

(B.O.P.)

EL(+)12.500M

(B.O.P.)

EL(+)12.200M

(B.O.P.)

EL(+)11.900M

(B.O.P.)

EL(+)11.600M

900

250

3

0

0

3

0

0

3

0

0

4 NOS. 125 NB

MAT. CON. PIPE LINE

TO SILO

VIEW E-E

15NB INSTRUMENT AIR

TO SILO

450

EXISTING COLUMN

(B.O.P.)

EL(+)3.500M

170

100NB CONV. AIR PIPE

20NB INTRUMENT AIR PIPE

40NB COOLING WATER PIPE

175 100

VIEW G-G

K

K

VIEW K-K

DRAIN SUMP PUMP

1

7

5

0

9

0

0

1600

3800

13000

EMERGENCY EMPTY PIPE

12000

4000

2 1

OPERATING FLOOR

T.O.S EL(+)4.500M

MILL REJECT BUNKER

CAP.= 71T

5

1

5

3

3

4

5

3

0

8

2

8

0

0

EL(+)11.442M

TOP OF BUNKER

4

7

0

0

1

1

6

4

2

04OO

500

G

1

.7

VENT FILTER

MODLE V18/15

HAND RAILING

AROUND THE BUNKER

BOX ASSY.

125NB TERMINAL

CANVAS CHUTE

125NB MATL. CONV. PIPE

TRUCK (BY CLIENT)

04OOO (l..) 10 THK.

FR

E

E

B

O

A

R

D

1000

7

5

3

1

2

5

8

HAND RAILING

EL(+)12.500M

(B.O.P.)

12000

EL(+)2.500M

(B.O.P.)

EL(+)6.500M

(B.O.P.)

EL(+)10.500M

(B.O.P.)

EL(+)3.500M

(B.O.P.)

100NB CONV. AIR PIPE

20NB INTRUMENT AIR PIPE

40NB COOLING WATER PIPE

125NB MATL.CONV. PIPE

2

6

0

01

9

2

9

50NB DRAIN PIPE

TO NEAREST DRAIN

3800

C OF EXISTING COLUMN

L

C OF EXISTING COLUMN

L

C OF EXISTING COLUMN

L

C OF EXISTING COLUMN

L

C OF EXISTING COLUMN

L

C OF EXISTING COLUMN

L

DETAIL-C

1600

50NB DRAIN WATER HEADER

TO NEAREST DRAIN

8800

VIEW H-H

EXISTING COLUMN

700

3

0

0

EL(+)12.500M

(B.O.P.)

EL(+)12.200M

(B.O.P.)

(B.O.P.)

EL(+)3.500M

170

125 140

100NB CONV. AIR PIPE

20NB INTRUMENT AIR PIPE

40NB COOLING WATER PIPE

200

50NB DRAIN WATER HEADER

TO NEAREST DRAIN

C OF EXISTING COLUMN

L

VIEW J -J

EXISTING COLUMN

700

EL(+)12.500M

(B.O.P.)

(B.O.P.)

EL(+)3.500M

170

125 140

100NB CONV. AIR PIPE

20NB INTRUMENT AIR PIPE

40NB COOLING WATER PIPE

200

50NB DRAIN WATER HEADER

TO NEAREST DRAIN

C OF EXISTING COLUMN

L

1

1

1 1

1

1

1

1

2

1

REVISED AS PER CLIENT'S COMMENT'S AP SN SVS 11.01.2011 2

1

5

0

0

DETAIL-D

20NB INST. AIR PIPE

AT T.P. (BY CLIENT)

TAPPING POINT SERVICE WATER

REulRE . 4N/h|. @ 2-2.5 Kg/Cm

INSTRUMENT AIR AT T.P. (BY CLIENT)

REulRE . 1.5 N/m|u @ 7 Kg/Cm

TAPPING POINT

(B.O.P.)

EL(+)3.500M

100NB CONV. AIR PIPE

C OF AIR RECEIVER SHED

L

VIEW M-M

1500

EL(-)0.200M

F.F.L.

125NB MAT. CONV. PIPE

TO NEAREST DRAIN

DRAIN WATER HEADER

100NB CONV. AIR PIPE

40NB COOLIMG WATER PIPE

L L

100NB CONV. AIR PIPE

50NB DRAIN WATER HEADER

TO NEAREST DRAIN

40NB COOLING WATER PIPE

20NB INTRUMENT AIR PIPE

VIEW L-L

170 200

125

140

C OF EXISTING COLUMN

L

2

2

3

COLUMN

5

0

0

0

5

0

0

0

1

0

0

0

0

1

2

0

0

3800

1000 900

1900

1600 1300

2

2

0

4

5

1

1

9

2

9

1

9

0

0

2

6

0

0

2

6

2

1

450 1600

2050

DETAIL-B

EL(-)2.370M

SUBMERSIBLE PUMP

NON CLOG

5

7

5

3

2

5

EL(-)2.170M

EL()O.OOON

EMERGENCY EMPTY PIPE

C OFMILL

L

MILL-A,B,C,

C

O

F

M

I

L

L

L

8800

1454 2350 2350 1446 1600

C OF MAT. L

DISCHARGE

RUNG LADDER

TO EL(-)2.170M

EL()O.OOON

13000

HAND RAILING

25THK. SHALITEX

150mm WALL

EL()O.OOON

2

EXISTING MILL FOUNDATION

REMOVABLE TYPE

GRATING. 25 mm

(BY MBPL) EL(+)0.100M

65NB CONV. AIR PIPE

20NB COOLING WATER PIPE

15NB INST. AIR PIPE PIPE TREANCH

EL(-)0.800M

EL(-)2.170M

INSERT PLATE FOR

PIPE SUPPORT

(10THK x 125 x 150)

125NB MAT. COV. PIPE

571 429

VIEW A-A

900

2

2

1

2

2

2

2

2

25THK. SHALITEX

150mm WALL

1454 2350 2350 1446 1600

8800

1000 900

1

9

0

0

450 1600

3

3

REVISED AS PER CLIENT'S COMMENT'S AP SN SVS 24.01.2011 3

3

3

2 NOS. 125 NB

MAT. CON. PIPE LINE

125NB MAT. CON. PIPE LINE

Distance between

two supports shall

not be morte than

6m. BSBK to

provide support at

this location.

CATEGORY - A2

DN: cn=VIKAS, o=AIIL, ou=CEG,

email=vikas.kodan@adani.in,

c=IN

Date: 2011.02.19 11:27:59

+05'30'

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The lEE Regulations, BS 7671 and This Guide PDFDokument259 SeitenThe lEE Regulations, BS 7671 and This Guide PDFatramanathanNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Gen2 Otis PDFDokument6 SeitenGen2 Otis PDFEng M ElseaidyNoch keine Bewertungen

- Green HydrogenDokument20 SeitenGreen HydrogenBhavana CNoch keine Bewertungen

- Cannot Be Located Taxpayers Master List 12152016 PDFDokument78 SeitenCannot Be Located Taxpayers Master List 12152016 PDFHanabishi Rekka100% (1)

- Practix - Convenio Philips Mobile X-RayDokument243 SeitenPractix - Convenio Philips Mobile X-RayNilufer Medical95% (19)

- CapacitorDokument96 SeitenCapacitorHipolito MBNoch keine Bewertungen

- Monthly Equ. Report (21-05-11 To 20-06-11) 1Dokument103 SeitenMonthly Equ. Report (21-05-11 To 20-06-11) 1sivathegrateNoch keine Bewertungen

- Kiln Emergency Conditions OkDokument30 SeitenKiln Emergency Conditions OkmustafNoch keine Bewertungen

- Diploma Trainee-2013: Registration Slip SR HQ, HyderabadDokument1 SeiteDiploma Trainee-2013: Registration Slip SR HQ, HyderabadJuhi SinghNoch keine Bewertungen

- Control Write Up A388Dokument57 SeitenControl Write Up A388Juhi SinghNoch keine Bewertungen

- CV FormateDokument2 SeitenCV FormateJuhi SinghNoch keine Bewertungen

- JKKKLLDokument1 SeiteJKKKLLJuhi SinghNoch keine Bewertungen

- AbdulDokument1 SeiteAbdulJuhi SinghNoch keine Bewertungen

- IRCTC LTD, Booked Ticket PrintingDokument2 SeitenIRCTC LTD, Booked Ticket PrintingJuhi SinghNoch keine Bewertungen

- FormulaDokument4 SeitenFormulaJuhi SinghNoch keine Bewertungen

- FormulaDokument4 SeitenFormulaJuhi SinghNoch keine Bewertungen

- Cover Sheet - Pneumatic Circuit (Bunkar Discharge Gate)Dokument2 SeitenCover Sheet - Pneumatic Circuit (Bunkar Discharge Gate)Juhi SinghNoch keine Bewertungen

- BE-A-402-020234-0-R-0 ModelDokument1 SeiteBE-A-402-020234-0-R-0 ModelJuhi SinghNoch keine Bewertungen

- ResumeDokument4 SeitenResumeJuhi SinghNoch keine Bewertungen

- Ga-Sale10000278 10-Submersible Pump Set R2-ModelDokument1 SeiteGa-Sale10000278 10-Submersible Pump Set R2-ModelJuhi SinghNoch keine Bewertungen

- G.A Drawing of TankDokument1 SeiteG.A Drawing of TankJuhi SinghNoch keine Bewertungen

- NANDAN 1 1 (1) ADokument2 SeitenNANDAN 1 1 (1) AJuhi SinghNoch keine Bewertungen

- TGC 120 543809arpit KhannaDokument4 SeitenTGC 120 543809arpit KhannaJuhi SinghNoch keine Bewertungen

- Cover Sheet - Pneumatic Circuit (Denseveyor)Dokument3 SeitenCover Sheet - Pneumatic Circuit (Denseveyor)Juhi SinghNoch keine Bewertungen

- 01 & 02.Str - Ga of Mill Reject Bunker-1 ApprovedDokument1 Seite01 & 02.Str - Ga of Mill Reject Bunker-1 ApprovedJuhi SinghNoch keine Bewertungen

- C-1060-77890D-1-R-1 ModelDokument1 SeiteC-1060-77890D-1-R-1 ModelJuhi SinghNoch keine Bewertungen

- Tir2 Epc Mrs DM D 008 Sh2 r6Dokument1 SeiteTir2 Epc Mrs DM D 008 Sh2 r6Juhi SinghNoch keine Bewertungen

- BE-A-402-020294-0-R-0 ModelDokument1 SeiteBE-A-402-020294-0-R-0 ModelJuhi SinghNoch keine Bewertungen

- C-1060-77890D-2-R-1 ModelDokument1 SeiteC-1060-77890D-2-R-1 ModelJuhi SinghNoch keine Bewertungen

- Tir1-Epc-Mrs-Dm-D-008-Sh-1, R-6Dokument1 SeiteTir1-Epc-Mrs-Dm-D-008-Sh-1, R-6Juhi SinghNoch keine Bewertungen

- BE-A-402-020295-0-R-0 ModelDokument1 SeiteBE-A-402-020295-0-R-0 ModelJuhi SinghNoch keine Bewertungen

- BE-A-402-020213-0-R-1 ModelDokument1 SeiteBE-A-402-020213-0-R-1 ModelJuhi SinghNoch keine Bewertungen

- Be-A-402-020039 - Detail of Clear Water Tank Roof (r1)Dokument1 SeiteBe-A-402-020039 - Detail of Clear Water Tank Roof (r1)Juhi SinghNoch keine Bewertungen

- BE-A-402-020234-0-R-0 ModelDokument1 SeiteBE-A-402-020234-0-R-0 ModelJuhi SinghNoch keine Bewertungen

- BE-A-402-020219-0-R-1 ModelDokument1 SeiteBE-A-402-020219-0-R-1 ModelJuhi SinghNoch keine Bewertungen

- BE-A-402-020213-0-R-1 ModelDokument1 SeiteBE-A-402-020213-0-R-1 ModelJuhi SinghNoch keine Bewertungen

- BE-A-402-020095-1-R-2 ModelDokument1 SeiteBE-A-402-020095-1-R-2 ModelJuhi SinghNoch keine Bewertungen

- Classical Physics Prof. V. Balakrishnan Department of Physics Indian Institute of Technology, Madras Lecture No. # 38Dokument27 SeitenClassical Physics Prof. V. Balakrishnan Department of Physics Indian Institute of Technology, Madras Lecture No. # 38Anonymous 8f2veZfNoch keine Bewertungen

- FRQ Post Nuclear PowerDokument2 SeitenFRQ Post Nuclear Powerdenise solerNoch keine Bewertungen

- SuperTuff R Tuff R SellSheetDokument2 SeitenSuperTuff R Tuff R SellSheetZainuddinNoch keine Bewertungen

- 1-Tabela Iluctron 08-2020 - Revenda - 45%Dokument19 Seiten1-Tabela Iluctron 08-2020 - Revenda - 45%Uiter GuedesNoch keine Bewertungen

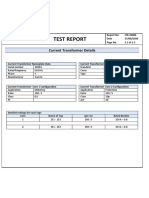

- Test Report: Current Transformer DetailsDokument3 SeitenTest Report: Current Transformer DetailsJRC TestingNoch keine Bewertungen

- Phys 1111 SygsuDokument4 SeitenPhys 1111 SygsuLeporeNoch keine Bewertungen

- BLDC 1500 2018 BC Building Code-Part 9 Single Family Dwelling BuildingsDokument12 SeitenBLDC 1500 2018 BC Building Code-Part 9 Single Family Dwelling BuildingsHamza TikkaNoch keine Bewertungen

- 3 Mass Balance Agro1 PDFDokument28 Seiten3 Mass Balance Agro1 PDFLiam LagartoNoch keine Bewertungen

- User Manual: Where Sun Shined Power Always OnDokument20 SeitenUser Manual: Where Sun Shined Power Always OnАнатолий ЯновскийNoch keine Bewertungen

- Dangerous Goods Panel (DGP) : Working PaperDokument50 SeitenDangerous Goods Panel (DGP) : Working PaperexpairtiseNoch keine Bewertungen

- Diesel Fuel MSDS 2019Dokument12 SeitenDiesel Fuel MSDS 2019bobNoch keine Bewertungen

- Human Activity and The Environment: 2. Liquid WasteDokument3 SeitenHuman Activity and The Environment: 2. Liquid WasteDanellNoch keine Bewertungen

- #5 With Answer RecoverDokument9 Seiten#5 With Answer Recoverkan limNoch keine Bewertungen

- Energy Management System Using Particle Swarm Optimization For MicrogridDokument2 SeitenEnergy Management System Using Particle Swarm Optimization For MicrogridNellis BlancoNoch keine Bewertungen

- The Dominant Planets of Kim JongDokument12 SeitenThe Dominant Planets of Kim JongCelia SteimanNoch keine Bewertungen

- ECE Bubble Power PDFDokument15 SeitenECE Bubble Power PDFsachinsdurgadNoch keine Bewertungen

- Relay Catalogue Feb 2015Dokument20 SeitenRelay Catalogue Feb 2015Mahesh KumbharNoch keine Bewertungen

- IS 2165 Part2-1965 Ins Coord - Phase To Phase PDFDokument14 SeitenIS 2165 Part2-1965 Ins Coord - Phase To Phase PDFRohit DeraNoch keine Bewertungen

- Enst Renewable Energy Syllabus 2015 1Dokument6 SeitenEnst Renewable Energy Syllabus 2015 1api-303214818Noch keine Bewertungen

- G8 - Light& Heat and TemperatureDokument49 SeitenG8 - Light& Heat and TemperatureJhen BonNoch keine Bewertungen

- Sensitive LPG Leakage Alarm: Related CircuitsDokument3 SeitenSensitive LPG Leakage Alarm: Related CircuitsMayur FakatkarNoch keine Bewertungen

- Engine Report Sriwantha PDFDokument14 SeitenEngine Report Sriwantha PDFSriwantha HewageNoch keine Bewertungen