Beruflich Dokumente

Kultur Dokumente

Prefabricated Notes2 Annacivil Blog

Hochgeladen von

ravirainbowCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Prefabricated Notes2 Annacivil Blog

Hochgeladen von

ravirainbowCopyright:

Verfügbare Formate

A

N

N

A

C

I

V

I

L

B

L

O

G

DOWNLOADED FROM http://annacivil.tk/

NOTES DOWNLOADED FROM http://annacivil.tk/

NOTES SENT BY

AISHWARYA

A

N

N

A

C

I

V

I

L

B

L

O

G

Prefabrication is the practice of assembling components of a structure in a factory or other

manufacturing site, and transporting complete assemblies or sub-assemblies to the

construction site where the structure is to be located. The term is used to distinguish this

process from the more conventional construction practice of transporting the basic materials

to the construction site where all assembly is carried out.

The term prefabrication also applies to the manufacturing of things other than structures at a

fixed site. It is frequently used when fabrication of a section of a machine or any movable

structure is shifted from the main manufacturing site to another location, and the section is

supplied assembled and ready to fit. It is not generally used to refer to electrical or electronic

components of a machine, or mechanical parts such as pumps, gearboxes and compressors

which are usually supplied as separate items, but to sections of the body of the machine

which in the past were fabricated with the whole machine. Prefabricated parts of the body of

the machine may be called 'sub-assemblies' to distinguish them from the other components.

The process and theory of prefabrication

An example from house-building illustrates the process of prefabrication. The conventional

method of building a house is to transport bricks, timber, cement, sand, steel and construction

aggregate, etc. to the site, and to construct the house on site from these materials. In

prefabricated construction, only the foundations are constructed in this way, while sections of

walls, floors and roof are prefabricated (assembled) in a factory (possibly with window and

door frames included), transported to the site, lifted into place by a crane and bolted together.

Prefabrication is used in the manufacture of ships, aircraft and all kinds of vehicles and

machines where sections previously assembled at the final point of manufacture are

assembled elsewhere instead, before being delivered for final assembly.

The theory behind the method is that time and cost is saved if similar construction tasks can

be grouped, and assembly line techniques can be employed in prefabrication at a location

where skilled labor is available, while congestion at the assembly site, which wastes time, can

be reduced. The method finds application particularly where the structure is composed of

repeating units or forms, or where multiple copies of the same basic structure are being

constructed. Prefabrication avoids the need to transport so many skilled workers to the

construction site, and other restricting conditions such as a lack of power, lack of water,

exposure to harsh weather or a hazardous environment are avoided. Against these advantages

must be weighed the cost of transporting prefabricated sections and lifting them into position

as they will usually be larger, more fragile and more difficult to handle than the materials and

components of which they are made.

History

DOWNLOADED FROM http://annacivil.tk/

A

N

N

A

C

I

V

I

L

B

L

O

G

"Loren" Iron House, at Old Gippstown in Moe, Australia

Prefabrication has been used since ancient times. For example, it is claimed that the world's

oldest known engineered roadway, the Sweet Track constructed in England around 3800 BC,

employed prefabricated timber sections brought to the site rather than assembled on-

site.

[citation needed]

Sinhalese kings of ancient Sri Lanka have used prefabricated buildings technology to erect

giant structures, which dates back as far as 2000 years, where some sections were prepared

separately and then fitted together, specially in the Kingdom of Anuradhapura and Kingdom

of Polonnaruwa

In 19th century Australia a large number of prefabricated houses were imported from the

United Kingdom.

The method was widely used in the construction of prefabricated housing in the 20th century,

such as in the United Kingdom to replace houses bombed during World War II. Assembling

sections in factories saved time on-site and reduced cost. However the quality was low, and

when such prefabricated housing was left in use for longer than its designed life, it acquired a

certain stigma.

[citation needed]

.

The Crystal Palace, erected in London in 1851, was a highly visible example of iron and glass

prefabricated construction; it was followed on a smaller scale by Oxford Rewley Road

railway station.

Current uses

DOWNLOADED FROM http://annacivil.tk/

A

N

N

A

C

I

V

I

L

B

L

O

G

A house being built with prefabricated concrete panels.

The most widely-used form of prefabrication in building and civil engineering is the use of

prefabricated concrete and prefabricated steel sections in structures where a particular part or

form is repeated many times. It can be difficult to construct the formwork required to mould

concrete components on site, and delivering wet concrete to the site before it starts to set

requires precise time management. Pouring concrete sections in a factory brings the

advantages of being able to re-use moulds and the concrete can be mixed on the spot without

having to be transported to and pumped wet on a congested construction site. Prefabricating

steel sections reduces on-site cutting and welding costs as well as the associated hazards.

Prefabrication techniques are used in the construction of apartment blocks, and housing

developments with repeated housing units. The quality of prefabricated housing units had

increased to the point that they may not be distinguishable from traditionally-built units to

those that live in them. The technique is also used in office blocks, warehouses and factory

buildings. Prefabricated steel and glass sections are widely used for the exterior of large

buildings.

Detached houses, cottages, log cabin, saunas, etc. are also sold with prefabricated elements.

Prefabrication of modular wall elements allows building of complex thermal insulation,

window frame components, etc. on an assembly line, which tends to improve quality over on-

site construction of each individual wall or frame. Wood construction in particular benefits

from the improved quality. However, tradition often favors building by hand in many

countries, and the image of prefab as a "cheap" method only slows its adoption. However,

current practice already allows the modifying the floor plan according to the customer's

requirements and selecting the surfacing material, e.g. a personalized brick facade can be

masoned even if the load-supporting elements are timber.

Prefabrication saves engineering time on the construction site in civil engineering projects.

This can be vital to the success of projects such as bridges and avalanche galleries, where

weather conditions may only allow brief periods of construction. Prefabricated bridge

elements and systems offer bridge designers and contractors significant advantages in terms

of construction time, safety, environmental impact, constructibility, and cost. Prefabrication

can also help minimize the impact on traffic from bridge building. Additionally, small,

commonly-used structures such as concrete pylons are in most cases prefabricated.

Radio towers for mobile phone and other services often consist of multiple prefabricated

sections. Modern lattice towers and guyed masts are also commonly assembled of

prefabricated elements.

DOWNLOADED FROM http://annacivil.tk/

A

N

N

A

C

I

V

I

L

B

L

O

G

Prefabrication has become widely used in the assembly of aircraft and spacecraft, with

components such as wings and fuselage sections often being manufactured in different

countries or states from the final assembly site. However this is sometimes for political rather

than commercial reasons - e.g. Airbus

Advantages of prefabrication

1. Self-supporting ready-made components are used, so the need for formwork,

shuttering and scaffolding is greatly reduced.

2. Construction time is reduced and buildings are completed sooner, allowing an earlier

return of the capital invested.

3. On-site construction and congestion is minimized.

4. Quality control can be easier in a factory assembly line setting than a construction site

setting.

5. Prefabrication can be located where skilled labour is more readily available and costs

of labour, power, materials, space and overheads are lower.

6. Time spent in bad weather or hazardous environments at the construction site is

minimized.

7. Less waste may occur

8. Advanced materials such as sandwich-structured composite can be easily used,

improving thermal and sound insulation and airtightness

Disadvantages

1. Careful handling of prefabricated components such as concrete panels or steel and

glass panels is required.

2. Attention has to be paid to the strength and corrosion-resistance of the joining of

prefabricated sections to avoid failure of the joint.

3. Similarly, leaks can form at joints in prefabricated components.

4. Transportation costs may be higher for voluminous prefabricated sections than for the

materials of which they are made, which can often be packed more efficiently.

5. Large prefabricated sections require heavy-duty cranes and precision measurement

and handling to place in position.

6. Larger groups of buildings from the same type of prefabricated elements tend to look

drab and monotonous.

7. Local jobs may be lost, if the work done to fabricate the components being located in

a place far away from the place of construction. This means that there are less locals

working on any construction project at any time, because fabrication is outsourced.

Off-site fabrication

Off-Site fabrication is a process that incorporates prefabrication and pre-assembly. The

process involves the design and manufacture of units or modules, usually remote from the

work site, and the installation at the site to form the permanent works at the site. In its fullest

sense, off-site fabrication requires a project strategy that will change the orientation of the

project process from construction to manufacture to installation. Examples of off-site

fabrication are wall panels for homes, wooden truss bridge spans, airport control stations.

DOWNLOADED FROM http://annacivil.tk/

A

N

N

A

C

I

V

I

L

B

L

O

G

DOWNLOADED FROM http://annacivil.tk/

A

N

N

A

C

I

V

I

L

B

L

O

G

DOWNLOADED FROM http://annacivil.tk/

A

N

N

A

C

I

V

I

L

B

L

O

G

DOWNLOADED FROM http://annacivil.tk/

A

N

N

A

C

I

V

I

L

B

L

O

G

DOWNLOADED FROM http://annacivil.tk/

A

N

N

A

C

I

V

I

L

B

L

O

G

DOWNLOADED FROM http://annacivil.tk/

A

N

N

A

C

I

V

I

L

B

L

O

G

DOWNLOADED FROM http://annacivil.tk/

A

N

N

A

C

I

V

I

L

B

L

O

G

DOWNLOADED FROM http://annacivil.tk/

A

N

N

A

C

I

V

I

L

B

L

O

G

DOWNLOADED FROM http://annacivil.tk/

A

N

N

A

C

I

V

I

L

B

L

O

G

DOWNLOADED FROM http://annacivil.tk/

A

N

N

A

C

I

V

I

L

B

L

O

G

DOWNLOADED FROM http://annacivil.tk/

A

N

N

A

C

I

V

I

L

B

L

O

G

DOWNLOADED FROM http://annacivil.tk/

A

N

N

A

C

I

V

I

L

B

L

O

G

DOWNLOADED FROM http://annacivil.tk/

A

N

N

A

C

I

V

I

L

B

L

O

G

DOWNLOADED FROM http://annacivil.tk/

A

N

N

A

C

I

V

I

L

B

L

O

G

DOWNLOADED FROM http://annacivil.tk/

A

N

N

A

C

I

V

I

L

B

L

O

G

DOWNLOADED FROM http://annacivil.tk/

A

N

N

A

C

I

V

I

L

B

L

O

G

DOWNLOADED FROM http://annacivil.tk/

A

N

N

A

C

I

V

I

L

B

L

O

G

DOWNLOADED FROM http://annacivil.tk/

A

N

N

A

C

I

V

I

L

B

L

O

G

DOWNLOADED FROM http://annacivil.tk/

A

N

N

A

C

I

V

I

L

B

L

O

G

DOWNLOADED FROM http://annacivil.tk/

A

N

N

A

C

I

V

I

L

B

L

O

G

DOWNLOADED FROM http://annacivil.tk/

A

N

N

A

C

I

V

I

L

B

L

O

G

DOWNLOADED FROM http://annacivil.tk/

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Manufacturing Processes and Systems (9E) - PF OSTWALD TOCDokument9 SeitenManufacturing Processes and Systems (9E) - PF OSTWALD TOCoğuz kağanNoch keine Bewertungen

- Buildings Hand BookDokument160 SeitenBuildings Hand Bookravirainbow100% (1)

- Current Area Item Assembly Process Production Qa CheckingDokument32 SeitenCurrent Area Item Assembly Process Production Qa Checkingteresa100% (1)

- Hazard Analysis and Critical Control Points (HaccpDokument16 SeitenHazard Analysis and Critical Control Points (HaccpVirendraNoch keine Bewertungen

- MMSADokument1 SeiteMMSAravirainbowNoch keine Bewertungen

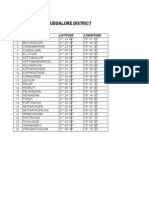

- R F Stn-Cud Dt-CoordinatesDokument3 SeitenR F Stn-Cud Dt-CoordinatesravirainbowNoch keine Bewertungen

- Go 213 E&fDokument10 SeitenGo 213 E&fravirainbowNoch keine Bewertungen

- Prist University: Rehabilitation of StructuresDokument1 SeitePrist University: Rehabilitation of StructuresravirainbowNoch keine Bewertungen

- Mws List VillagewiseDokument137 SeitenMws List VillagewiseravirainbowNoch keine Bewertungen

- Status of Well Census Project As On 05.03.04Dokument19 SeitenStatus of Well Census Project As On 05.03.04ravirainbowNoch keine Bewertungen

- Villupuram (C&M) Highways Division Jurisdiction Map: ReferenceDokument1 SeiteVillupuram (C&M) Highways Division Jurisdiction Map: ReferenceravirainbowNoch keine Bewertungen

- Auroville Water SeminarDokument15 SeitenAuroville Water Seminarravirainbow100% (1)

- VillupuramDokument23 SeitenVillupuramravirainbowNoch keine Bewertungen

- 02conversion TableDokument3 Seiten02conversion TableravirainbowNoch keine Bewertungen

- Invest Is 10KDokument1 SeiteInvest Is 10KravirainbowNoch keine Bewertungen

- Site 2 5 6 - P H RI O Utstanding Quer IesDokument1 SeiteSite 2 5 6 - P H RI O Utstanding Quer IesravirainbowNoch keine Bewertungen

- DSR 2012Dokument448 SeitenDSR 2012jagadees21100% (2)

- Go 213 E&fDokument10 SeitenGo 213 E&fravirainbowNoch keine Bewertungen

- SCM Bullwhip EffectDokument21 SeitenSCM Bullwhip EffectvksdsatmNoch keine Bewertungen

- KAIZENDokument4 SeitenKAIZENkeruksNoch keine Bewertungen

- A Morning MarketDokument9 SeitenA Morning MarketrabuffettiNoch keine Bewertungen

- ODUNOLA Michael Olayinka's CVDokument5 SeitenODUNOLA Michael Olayinka's CVmaverick231Noch keine Bewertungen

- Sundaram Clayton - Winning The Deming PrizeDokument24 SeitenSundaram Clayton - Winning The Deming PrizeApoorv Jhudeley100% (3)

- 1 s2.0 S2405896315005984 MainDokument6 Seiten1 s2.0 S2405896315005984 MainFery MahardikaNoch keine Bewertungen

- Resume. ShyamDokument3 SeitenResume. Shyamsunder2006Noch keine Bewertungen

- Ships Construction GL-Materials and WeldingDokument404 SeitenShips Construction GL-Materials and WeldingualdapaNoch keine Bewertungen

- Bunga Engeline BR Siagian 041811333002Dokument1 SeiteBunga Engeline BR Siagian 041811333002bunga engeline br siagianNoch keine Bewertungen

- Submitted by Nisar Ahmed Registration# 44150: Visic Corporation Cost of Goods Manufactured StatementDokument4 SeitenSubmitted by Nisar Ahmed Registration# 44150: Visic Corporation Cost of Goods Manufactured StatementHaris KhanNoch keine Bewertungen

- IntroductionDokument36 SeitenIntroductionshehroz2233Noch keine Bewertungen

- Gizmoz Study CaseDokument4 SeitenGizmoz Study CaseInge Monica100% (1)

- Six Sigma at GeDokument17 SeitenSix Sigma at GeRohan KaushikNoch keine Bewertungen

- List Penawaran 2022Dokument28 SeitenList Penawaran 2022Can DraNoch keine Bewertungen

- Cost Accounting - Reading MaterialDokument5 SeitenCost Accounting - Reading MaterialRegina DaudNoch keine Bewertungen

- BooksDokument5 SeitenBooksAnandha Padmanabhan100% (1)

- The Toyota Way To Continuous Improvement: Jeffrey K. LikerDokument34 SeitenThe Toyota Way To Continuous Improvement: Jeffrey K. Likerharel_868Noch keine Bewertungen

- Oracle Apps OPM SetupDokument32 SeitenOracle Apps OPM SetupRavi Varma100% (8)

- Introduction To Supply Chain ManagementDokument48 SeitenIntroduction To Supply Chain ManagementQuality OfficeNoch keine Bewertungen

- 1b.understanding Quality Procedures in SAMPLING & Sample DevelopmentDokument15 Seiten1b.understanding Quality Procedures in SAMPLING & Sample DevelopmentNeetek SahayNoch keine Bewertungen

- Cost Concept, Terminologies and BehaviorDokument8 SeitenCost Concept, Terminologies and BehaviorANDREA NICOLE DE LEONNoch keine Bewertungen

- Cannes Lions 2014 Media enDokument82 SeitenCannes Lions 2014 Media enotávio_leite_5Noch keine Bewertungen

- MAS Sample Prob Variable Costing HarinaDokument4 SeitenMAS Sample Prob Variable Costing Harinakyle samantha mogadoNoch keine Bewertungen

- Technical MeetDokument7 SeitenTechnical MeetsameertutejaNoch keine Bewertungen

- BackDokument19 SeitenBackjadeNoch keine Bewertungen

- Case Quality - Management - CaDokument10 SeitenCase Quality - Management - CaGauri SinghNoch keine Bewertungen

- Project Management PlanDokument15 SeitenProject Management PlanBipin Babu100% (2)