Beruflich Dokumente

Kultur Dokumente

Klase Poprecnog Preseka EC

Hochgeladen von

bobbynebaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Klase Poprecnog Preseka EC

Hochgeladen von

bobbynebaCopyright:

Verfügbare Formate

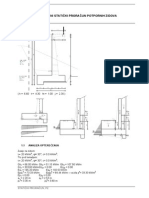

EN 1993-1-1: 2005 (E)

Table 5.2 (sheet 1 of 3): Maximum width-to-thickness ratios for compression parts

Internal compression parts

c t

t

c t t

t

c t

Axis of bending

t c c t c

Class Stress distribution in parts (compression positive) Part subject to bending fy Part subject to compression fy

Axis of bending

Part subject to bending and compression

fy +

c

+ fy c fy -

+ c fy

c / t 72

c / t 33

c / t 83

fy

c / t 38

fy

396 13 1 36 when 0,5 : c / t 456 when > 0,5 : c / t 13 1 41,5 when 0,5 : c / t when > 0,5 : c / t

fy

Stress distribution in parts (compression positive)

+

c

+

c/2

fy

fy

c / t 124

c / t 42

when > 1 : c / t

42 0,67 + 0,33

460 0,71

when 1*) : c / t 62(1 ) ( )

fy 235 275 355 420 1,00 0,92 0,81 0,75 *) -1 applies where either the compression stress fy or the tensile strain y > fy/E

= 235 / f y

42

EN 1993-1-1: 2005 (E)

Table 5.2 (sheet 2 of 3): Maximum width-to-thickness ratios for compression parts

Outstand flanges

c t

Rolled sections Class Stress distribution in parts (compression positive) 1 2 Stress distribution in parts (compression positive) 3 Part subject to compression

Welded sections Part subject to bending and compression Tip in compression Tip in tension

c c

+ c

+ c

+ c -

c / t 9 c / t 10

+ c

9 10 c/ t c/t

c +

c/ t c/t

9 10

c / t 14

fy 235 1,00 275 0,92

c / t 21 k

For k see EN 1993-1-5 355 420 0,81 0,75 460 0,71

= 235 / f y

43

Das könnte Ihnen auch gefallen

- Manual-14 en Pile PDFDokument12 SeitenManual-14 en Pile PDFvedranNoch keine Bewertungen

- Proracun Veze Stuba I RigleDokument1 SeiteProracun Veze Stuba I Riglevikiliks100% (1)

- Staticki Proracun Krivajnog MehanizmaDokument18 SeitenStaticki Proracun Krivajnog Mehanizmasssf-dobojNoch keine Bewertungen

- 3.harta Seizmike 2018 (475 Years)Dokument1 Seite3.harta Seizmike 2018 (475 Years)LabinotMMorinaNoch keine Bewertungen

- Dejstvo Vetra Na Halu Prema EvrokoduDokument107 SeitenDejstvo Vetra Na Halu Prema EvrokoduMilan StojanovicNoch keine Bewertungen

- Proracun Broja VijakaDokument14 SeitenProracun Broja VijakamarkovukNoch keine Bewertungen

- Ab Zid Z01obj2Dokument6 SeitenAb Zid Z01obj2Anonymous rhZTIMMf1LNoch keine Bewertungen

- 03.1 Proračun Zid 1Dokument7 Seiten03.1 Proračun Zid 1Elmo TabakovićNoch keine Bewertungen

- Fundiranje I: Grafički RadDokument16 SeitenFundiranje I: Grafički RadTmusicKenanNoch keine Bewertungen

- Raspored VijakaDokument2 SeitenRaspored VijakaAnonymous umabEI6Noch keine Bewertungen

- Anker Vrska KompletDokument4 SeitenAnker Vrska KompletstojanovalidijaNoch keine Bewertungen

- Luk Na Tri Zgloba-TowerDokument1 SeiteLuk Na Tri Zgloba-TowerAleksa JankovicNoch keine Bewertungen

- MostoviDokument7 SeitenMostoviMarcus NunezNoch keine Bewertungen

- STRAKON-2020 New FeaturesDokument70 SeitenSTRAKON-2020 New FeaturesGülcan AltunokNoch keine Bewertungen

- Primeri Ec3Dokument0 SeitenPrimeri Ec3jelenavukojeNoch keine Bewertungen

- Temelj PumpeDokument1 SeiteTemelj PumpebobbynebaNoch keine Bewertungen

- Drvo BetonDokument131 SeitenDrvo BetonSonja DragovicNoch keine Bewertungen

- Tablica Rebraste Armature Alen KurticDokument1 SeiteTablica Rebraste Armature Alen KurticAlen Dundi Kurtic0% (1)

- 3 Temeljna GredaDokument7 Seiten3 Temeljna GredafamusNoch keine Bewertungen

- MBK Elaborat 1Dokument42 SeitenMBK Elaborat 1Ksenija PejkovicNoch keine Bewertungen

- Connessione Controvento 2UPN EC3 IngleseDokument15 SeitenConnessione Controvento 2UPN EC3 Inglesemihai_serban13Noch keine Bewertungen

- Nesimetricna ZgradaDokument19 SeitenNesimetricna ZgradaMiljan TrivicNoch keine Bewertungen

- (Kom) (MM) (MM) (MM) (KG/M) (Kg/kom) (Kg/poz) Štapni ElementiDokument2 Seiten(Kom) (MM) (MM) (MM) (KG/M) (Kg/kom) (Kg/poz) Štapni ElementikrvotokNoch keine Bewertungen

- AB RoyalDokument62 SeitenAB Royalmilenaglisic1121Noch keine Bewertungen

- Pre StressDokument9 SeitenPre StressKevin John Ordoña EstilloreNoch keine Bewertungen

- E2 - Vodjenje Armature Duz NosacaDokument22 SeitenE2 - Vodjenje Armature Duz NosacaNaim DemiriNoch keine Bewertungen

- JamaDokument11 SeitenJamavedranNoch keine Bewertungen

- 3D I Poprecni Presek Iz Tower-ADokument2 Seiten3D I Poprecni Presek Iz Tower-AНебојша ЦветковићNoch keine Bewertungen

- Kontrolni Statički Proračun Potpornih Zidova: H 6.60 M PZ2Dokument2 SeitenKontrolni Statički Proračun Potpornih Zidova: H 6.60 M PZ2bobbynebaNoch keine Bewertungen

- Dimenzionisanje Stuba: (Sa Spre Enim Bo Nim Izvijanjem Zidom)Dokument6 SeitenDimenzionisanje Stuba: (Sa Spre Enim Bo Nim Izvijanjem Zidom)Anonymous rhZTIMMf1LNoch keine Bewertungen

- Serkl.i Stub.Dokument6 SeitenSerkl.i Stub.Stojkovic CaleNoch keine Bewertungen

- Tower 5 KrovDokument164 SeitenTower 5 KrovSasa MladenovicNoch keine Bewertungen

- P10.2b - Plan Armature Grede POS 103 (Sa LZS) PDFDokument1 SeiteP10.2b - Plan Armature Grede POS 103 (Sa LZS) PDFAleksandar Ilic100% (1)

- Obdaniste StuboviDokument44 SeitenObdaniste StuboviSead MavricNoch keine Bewertungen

- Hala Roznjace TR LimDokument14 SeitenHala Roznjace TR LimmileNoch keine Bewertungen

- Stage 1: Stress Transfer: Pi, Net Pi pES PR pES PRDokument8 SeitenStage 1: Stress Transfer: Pi, Net Pi pES PR pES PRJake ChesterphilNoch keine Bewertungen

- Elements of Soil Mechanics, 8th Edition Example 8.5Dokument42 SeitenElements of Soil Mechanics, 8th Edition Example 8.5Ako BogdaNoch keine Bewertungen

- Tower 6: Uputstvo Za Rad Sa ProgramomDokument209 SeitenTower 6: Uputstvo Za Rad Sa ProgramomperocNoch keine Bewertungen

- SN027 Progetto Di Trave Reticolare Di CoperturaDokument14 SeitenSN027 Progetto Di Trave Reticolare Di CoperturaLivio CirilloNoch keine Bewertungen

- Aisiwin v8 ManualDokument28 SeitenAisiwin v8 ManualGnabBangNoch keine Bewertungen

- Mirjana PeharDokument5 SeitenMirjana PeharIvanNoch keine Bewertungen

- Matric ADokument1 SeiteMatric ALabinotMMorinaNoch keine Bewertungen

- Raspored VijakaDokument3 SeitenRaspored VijakaAnonymous umabEI6Noch keine Bewertungen

- t10 (OC) 60 55-70 Oc t90 (OC) 160 130-190 Oc d15/15 0.78 715-780 kg/m3 0,715-0,780 kg/m3Dokument6 Seitent10 (OC) 60 55-70 Oc t90 (OC) 160 130-190 Oc d15/15 0.78 715-780 kg/m3 0,715-0,780 kg/m3Boba VasiljevicNoch keine Bewertungen

- 3 Zadaci Temel Samec Arm BetonDokument30 Seiten3 Zadaci Temel Samec Arm BetonBojan Bogdanovic100% (1)

- Bilbord Staticke Seme (2) - Model1Dokument1 SeiteBilbord Staticke Seme (2) - Model1Stefan ZafirovicNoch keine Bewertungen

- Formule Ploce I LjuskeDokument18 SeitenFormule Ploce I LjuskeAmar MušovićNoch keine Bewertungen

- (Presek 1-1) Ugib Od Stalnog OpterećenjaDokument6 Seiten(Presek 1-1) Ugib Od Stalnog OpterećenjailijarskNoch keine Bewertungen

- 2.harta Seizmike 2018 (475 Years) IntezitetiDokument1 Seite2.harta Seizmike 2018 (475 Years) IntezitetiLabinotMMorinaNoch keine Bewertungen

- BOSANSKI TUTORIJAL Instalacija Tower Build 1350 I ArmCAD-A Build 1763 Na Win 7 x64 UltimateDokument1 SeiteBOSANSKI TUTORIJAL Instalacija Tower Build 1350 I ArmCAD-A Build 1763 Na Win 7 x64 Ultimateemir mesnovicNoch keine Bewertungen

- MCB2111B - 15 - 156 - Comm - Bin - NC Manual de Ensamble Silos Fondo Plano Serie E (OK)Dokument52 SeitenMCB2111B - 15 - 156 - Comm - Bin - NC Manual de Ensamble Silos Fondo Plano Serie E (OK)Nicolas LondoñoNoch keine Bewertungen

- Monopitch RoofDokument5 SeitenMonopitch RoofKhalid CaliNoch keine Bewertungen

- Poglavlje 3.4 StubisteDokument29 SeitenPoglavlje 3.4 Stubistefk0205Noch keine Bewertungen

- Tower - 3d Model Builder 6.0 - D - Radimpex Projekti - Boki France - ST EcDokument61 SeitenTower - 3d Model Builder 6.0 - D - Radimpex Projekti - Boki France - ST EcStojkovic CaleNoch keine Bewertungen

- Maximum Width-To-Thickness Ratios For Compression PDFDokument3 SeitenMaximum Width-To-Thickness Ratios For Compression PDFtoliveira80Noch keine Bewertungen

- Ec9 Ex43 Bending Trapez Class 2Dokument7 SeitenEc9 Ex43 Bending Trapez Class 2imotalpNoch keine Bewertungen

- Ec9 Ex44 Bending Trapez Class 4Dokument7 SeitenEc9 Ex44 Bending Trapez Class 4imotalpNoch keine Bewertungen

- Design of Threaded FastenersDokument72 SeitenDesign of Threaded Fastenersf2012265Noch keine Bewertungen

- Tension MembersDokument35 SeitenTension MembersVictor Carhuayo Paredes100% (1)

- Ka KPDokument1 SeiteKa KPbobbynebaNoch keine Bewertungen

- Pile Bearing CapacityDokument1 SeitePile Bearing CapacitybobbynebaNoch keine Bewertungen

- Temelj PumpeDokument1 SeiteTemelj PumpebobbynebaNoch keine Bewertungen

- Connection Calculation: Dop Dop WdopDokument2 SeitenConnection Calculation: Dop Dop WdopbobbynebaNoch keine Bewertungen

- Vitkost Stubova Istog SprataDokument1 SeiteVitkost Stubova Istog SpratabobbynebaNoch keine Bewertungen

- Kontrolni Statički Proračun Potpornih Zidova: H 6.60 M PZ2Dokument2 SeitenKontrolni Statički Proračun Potpornih Zidova: H 6.60 M PZ2bobbynebaNoch keine Bewertungen

- N N M M KN KN KN/M KN/M KN KN/M 30 8 0.1 0.0 37.5 0.1: Dimenzionisanje Stubova Stub ST1Dokument1 SeiteN N M M KN KN KN/M KN/M KN KN/M 30 8 0.1 0.0 37.5 0.1: Dimenzionisanje Stubova Stub ST1bobbynebaNoch keine Bewertungen

- 07 Rhs TrussesDokument24 Seiten07 Rhs TrussesbobbynebaNoch keine Bewertungen