Beruflich Dokumente

Kultur Dokumente

Ral 1 C

Hochgeladen von

usernaga84Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ral 1 C

Hochgeladen von

usernaga84Copyright:

Verfügbare Formate

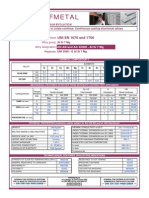

NOTES 1.

ALL ALUMINIUM ALLOY RAILINGS SHALL BE DESIGNED, MANUFACTURED AND INSTALLED TO THE REQUIREMENTS OF BS 8118, BS 7818, BS 1474, BS 1490, BS EN 515, BS EN ISO 3506 AND THE LTA TECHNICAL SPECIFICATION ON PEDESTRIAN ALUMINIUM ALLOY RAILWAYS AS APPROPIATE. IN CASE OF ANY DISCREPANCIES ON VARIATIONS AMONG THESE SPECIFICATIONS, LTA TECHNICAL SPECIFICATIONS SHALL GENERALLY TAKE PRECEDENCE. ONLY LTA APPROVED RAILING SYSTEM WHICH COMPLIES WITH THE ABOVE SPECIFICATIONS SHALL BE ACCEPTED. 2. ALL PEDESTRIAN ALUMINIUM ALLOY RAILINGS SYSTEMS SHALL BE WARRANTED AGAINST POWER COATING SYSTEMS FOR A MINIMUM PERIOD OF 10 YEARS, AND PERFORMANCE FOR A MINIMUM PERIOD OF 30 YEARS FROM THE COMPLETION OF THE WHOLE WORKS. DEFECTS OCCURING DURING THIS PERIOD ARE TO BE MADE GOOD BY THE CONTRACTOR. 3. THE PEDESTRIAN ALUMINIUM RAILINGS SYSTEM SHALL BE A MODULAR SYSTEM TO EASE INSTALLATION AND REPLACEMENT TO MINIMISE DISRUPTION TO PEDESTRIAN MOVEMENT AND TRAFFIC FLOW. SPLICES SHALL BE TOTALLY PRECLUDED. 4. THE LOADS ARE ACTING AT 1.1m ABOVE DATUM LEVEL FOR DESIGN PUPOSE IRRESPECTIVE OF THE ACTUAL HEIGHT OF THE SYSTEM. DESIGN LOADS FOR TYPE A SHALL BE DESIGNED TO THE DESIGN LOADS OF CLASS 3 TO BS 7818. 5. THE PEDESTRIAN ALUMINIUM ALLOY RAILINGS SYSTEMS SHALL BE FABRICATED FROM HIGH STRENGTH, MARINE GRADE ALUMINIUM ALLOYS OF DURABILITY RATING B WITH A MINIMUN TENSILE STRENGTH OF 280 N/mm (Mpa) AND PROOF STRENGTH OF 240 N/mm

2 2

(Mpa) TO BS 8118.

6. THE POWDER COATINGS SHALL BE IN FULL COMPLIANCE TO AAMA2604.98. EDITION OR ANY LATER VERSION. THE POWDER 1500 (SEE ALSO NOTE 14) COATINGS COLOUR SHALL BE IN ACCORDANCE WITH RAL 6002 LEAF GREEN. GROSS LEVEL TO BE SEMI GLOSS, (65 5)%. 7. THE COATING THICKNESS FOR SINGLE COAT SYSTEM SHALL BE BETWEEN 60 TO 100 MICRONS AND MUST BE OF SUPERDURABLE POLYESTER GRADE. TWO-COAT SYSTEMS SHALL BE CONSIDERED FOR HIGH CORROSIVE AREAS SUCH AS COASTAL AREAS. COASTAL 107 106 AREAS SHALL BE TAKEN AS KM FROM THE COAST. THE COATING THICKNESS FOR TWO-COAT SYSTEMS SHALL BE BETWEEN 120 TO 150 MICRONS. 8. ONLY PREVIOUSLY TESTED COATING WHICH FULLY COMPLIES WITH AAMA2604.98. QUV "A" AND QUV "B" TESTING OR EQUIVALENT 1 000 SHALL BE SUBMITTED. THE APPROVED SAMPLE FOR EACH CONTRACT SHALL BE SENT TO SINGAPORE PRODUCTIVITY AND STANDARD BOARD (PSB) AND/OR ITS SUBSEQUENT TESTING ENTITIES FOR A FULL AAMA2604.98. QUV "A" AND QUV "B" TESTING IMMEDIATELY AFTER AWARD OF CONTRACT. QUV "A" TO HAVE AT LEAST 90% GLOSS RETENTION AND QUV "B" TO HAVE AT LEAST 80% RETENTION TO PROVIDE THAT COATING WHICH HAS BEEN DESIGNED, MANUFACTURED AND TESTED IN ACCORDANCE TO THE REQUIREMENTS OF THE DRAWINGS AND/OR THE MATERIAL SPECIFICATIONS SHALL NOT RELIEVE THE CONTRACTOR OF ANY PART OF THE RESPONSIBILITY 1 00MAX. FOR THIS SINGLE COLOUR. PSB CERTIFICATES WILL THEREINAFTER INDICATE AS COMPLYING TO LTA REQUIREMENTS. THE ACCEPTANCE THE CONTRACT. 9. SUPERDURABLE POWDER MUST BE APPLIED BY LISTED PSB/PLS CLASS 1A CATEGORY CONTRACTOR. THE POWDER APPLICATOR MUST BE APPROVED OR BE A LICENSED APPLICATOR OF THE POWDER MANUFACTURER AS THEY WILL BE JOINTLY AND SEVERALLY LIABLE FOR THE PERFORMANCE OF THE COATING. 10. APPROVED IDENTIFICATION PLATES SPECIFYING THE DATE OF THE INSTALLATION, COLOUR TYPE OF POWDER COATING USED AND THE TYPE OF RAILING SYSTEM USED SHALL BE INSTALLED ONTO THE RAILINGS, SUBJECT TO A MINIMUM OF 1 PLATE FOR EACH PROPOSED WORK JOB AND 1 PLATE PER EVERY 500m INTERVAL THEREAFTER. 11. THE PEDESTRIAN ALUMINIUM ALLOY RAILINGS SYSTEM SHALL BE RESISTANT TO VANDALISM. IT SHALL BE ENSURED THAT FIXINGS AND FASTENERS CANNOT BE LOOSENED SO AS TO ALLOW PARTS OF THE SYSTEM TO BE WILFULLY REMOVED, SIMPLY AND QUICKLY USING MINIMAL TOOLS OR TO BE DAMAGED FOR EXAMPLE BY BLOWS OR ACCIDENTAL HUMAN IMPACT. WHERE REQUIRED BY THE S.0, THE CONTRACTOR SHALL DEMONSTRATE ON TRIAL PANELS TO ACCESS AND ASCERTAIN THE PROVISION AGAINST THE VANDALISM. 12. STAINLESS STEEL HOLDING - DOWN BOLTS CONFORMING TO BS EN ISO 3506 OF A4-70 SHALL BE USED TO ANCHOR THE BASE PLATE

TOP OF STRUCTURE

TYPE A ALUMINIUM ALLOY RAILINGS

SCALE 1:50

20

OF THE ALUMINIUM POST TO THE CONCRETE SURFACE. ANCHORAGE IN CONCRETE SHALL BE EITHER CAST-IN CRADLE ANCHORAGE OR

ROUNDED OFF CORNER

INDIVIDUAL ANCHORAGE SYSTEM. ANCHOR BOLTS SHALL NOT BE SET WITHIN THE CONCRETE COVER. IN CASES WHERE ANCHOR BOLTS ARE TO BE SET INTO PLAIN ISOLATED CONCRETE FOOTING, THE MINIMUM EDGE DISTANCE FROM CONCRETE TO THE BOLTS AND BETWEEN ANCHOR BOLTS SHALL BE STRICTLY COMPILED WITH THE REQUIREMENTS SET BY THE RESPECTIVE MANUFACTURER FOR THE BOLTS CONCERNED. 13. THE POSTS AND VERTICAL BARS OF THE RAILINGS SHALL BE OF 75MM AND 25MM TUBULAR SECTIONS RESPECTIVELY, WITH

1 50

20

150

MINIMUN OF 3MM THICKNESS 14. IF THE POSTS ARE REQUIRED TO BE SPACED WIDER THAN 1500MM, THE CONTRACTOR/MANUFACTURER

DETAILS OF BASE PLATE

SCALE 1:15

SHALL REDESIGN THE ANCHORAGE, POSTS AND HORIZONTAL RAILS ETC. TO SUIT THE CONFIGURATION.

4 NO. OF 12mm0 STAINLESS STEEL 150x150x12mm THK. ALUMINIUM ALLOY BASE PLATE MORTAR BEDDING 30mm MAX. 10mm MIN. MORTAR BEDDING 30mm MAX. 10mm MIN. BOLTS OF A4-70 SUBJECTED TO PULL-OUT FORCE OF 16KN AT WORKING LOAD PER BOLT.

300MI N.

4 NO. OF 12mm0 STAINLESS STEEL BOLTS OF A4-70

BRIDGING PLATE IF REQUIRED

TYPICAL DETAILS OF RAILING FIXING TO TYPICAL DETAILS OF RAILING FIXING TO CONCRETE STRUCTURE BY INDIVIDUAL ANCHORAGE FIXINGS

SCALE 1:15

CONCRETE STRUCTURE BY CAST-IN CRADLES

NOTE : CAST-IN CRADLES MAY BE USED AS AN ALTERNATIVE WHEN THE EMBEDED DEPTH IS NOT AVAILABLE SCALE 1:15

DATE OF REVISION

STANDARD DETAIL

A. 11-09-2000 B. 16-11-2001 C. 03-03-2009

PEDESTRIAN ALUMINIUM

DRAWING NO.

ALLOY RAILINGS ( TYPE A )

DATE OF ISSUE SEP 2000

LTA/RD/SD99/RAL/1C

SCALE AS SHOWN SHEET NO. 1 OF 2

5-1

Das könnte Ihnen auch gefallen

- MathorupaaganDokument96 SeitenMathorupaaganAjai Sreevatsan100% (6)

- Cover Note COPIF 2013Dokument18 SeitenCover Note COPIF 2013Zhu Qi WangNoch keine Bewertungen

- Roopa Residence RO-3Dokument1 SeiteRoopa Residence RO-3usernaga84Noch keine Bewertungen

- Bio Ramani RamakrishnanDokument1 SeiteBio Ramani Ramakrishnanusernaga84Noch keine Bewertungen

- HM&HN Guidebk (revOCT05) PDFDokument45 SeitenHM&HN Guidebk (revOCT05) PDFusernaga84Noch keine Bewertungen

- What's Cooking? Preparing and Sharing Food in Ambai's Tamil Short StoriesDokument1 SeiteWhat's Cooking? Preparing and Sharing Food in Ambai's Tamil Short Storiesusernaga84Noch keine Bewertungen

- What Steve Jobs and Jonathan Ive Teach Us About DesigningDokument5 SeitenWhat Steve Jobs and Jonathan Ive Teach Us About Designingusernaga84Noch keine Bewertungen

- Kallang Aerodrome: ResearchDokument13 SeitenKallang Aerodrome: Researchusernaga84Noch keine Bewertungen

- Chicago Architect Genealogy 1850-2020Dokument1 SeiteChicago Architect Genealogy 1850-2020usernaga84Noch keine Bewertungen

- Best Documentaries About Cities, Urban Design & How Rethinking Cities Is Key To A Sustainable WorldDokument6 SeitenBest Documentaries About Cities, Urban Design & How Rethinking Cities Is Key To A Sustainable Worldusernaga84Noch keine Bewertungen

- Wooden Doors Product List: Door & PlywoodDokument1 SeiteWooden Doors Product List: Door & Plywoodusernaga84Noch keine Bewertungen

- Guidelines For Noise Control Vibration Part 4 PDFDokument0 SeitenGuidelines For Noise Control Vibration Part 4 PDFusernaga84Noch keine Bewertungen

- Housing in India: Reinterpreting Habrakens Theories in The Indian ContextDokument17 SeitenHousing in India: Reinterpreting Habrakens Theories in The Indian Contextusernaga84Noch keine Bewertungen

- Tender Notice For Interior WorkDokument1 SeiteTender Notice For Interior Workusernaga84Noch keine Bewertungen

- Oscar Brett Vis. Urb William Whyte On PlazasDokument8 SeitenOscar Brett Vis. Urb William Whyte On Plazasusernaga84Noch keine Bewertungen

- Reg - Bca-Approved Documents Oct 2013Dokument70 SeitenReg - Bca-Approved Documents Oct 2013gridguerilla2555Noch keine Bewertungen

- Architects in Power - Politics and Ideology in The Work of Ernst M PDFDokument29 SeitenArchitects in Power - Politics and Ideology in The Work of Ernst M PDFusernaga84Noch keine Bewertungen

- IDA COPIF May 2013Dokument162 SeitenIDA COPIF May 2013Zhu Qi WangNoch keine Bewertungen

- AR. SHIVNATH PRASAD'S INFLUENCE FROM LE CORBUSIERDokument8 SeitenAR. SHIVNATH PRASAD'S INFLUENCE FROM LE CORBUSIERAr Rishabh JainNoch keine Bewertungen

- Delhi Sultanate Art, Architecture, and Maps (1206-1572Dokument6 SeitenDelhi Sultanate Art, Architecture, and Maps (1206-1572usernaga84Noch keine Bewertungen

- Guidebook On Nursing Homes PDFDokument55 SeitenGuidebook On Nursing Homes PDFusernaga84Noch keine Bewertungen

- Guidelines For Noise Control Vibration Part 1Dokument15 SeitenGuidelines For Noise Control Vibration Part 1Kevin BiltonNoch keine Bewertungen

- Le CorbusierDokument176 SeitenLe CorbusierChania BhatiaNoch keine Bewertungen

- Massachusetts Inws: Aftab Amirali JaliaDokument0 SeitenMassachusetts Inws: Aftab Amirali Jaliausernaga84Noch keine Bewertungen

- The Architect Says PDFDokument34 SeitenThe Architect Says PDFusernaga84100% (1)

- Souto de Moura PDFDokument19 SeitenSouto de Moura PDFerjauraNoch keine Bewertungen

- LTA Civil - Standards - Civil Design CriteriaDokument346 SeitenLTA Civil - Standards - Civil Design Criteriausernaga84100% (6)

- CLTA110906 - Drop in LetDokument3 SeitenCLTA110906 - Drop in Letusernaga84Noch keine Bewertungen

- LTA - Skip 15 Jun 06Dokument13 SeitenLTA - Skip 15 Jun 06usernaga84Noch keine Bewertungen

- Rms 10 ADokument1 SeiteRms 10 Ausernaga84Noch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- No. Supplier Brand Mecstar Pangulf Kusheim Aluqee Weldzone SGW Saudi Welding SendanDokument22 SeitenNo. Supplier Brand Mecstar Pangulf Kusheim Aluqee Weldzone SGW Saudi Welding SendanDheeraj E MohananNoch keine Bewertungen

- Corrosion of Constructional Steels in Marine and Industrial Environment - 2013Dokument188 SeitenCorrosion of Constructional Steels in Marine and Industrial Environment - 2013lei huangNoch keine Bewertungen

- Deburring & Polishing Media and CompoundsDokument24 SeitenDeburring & Polishing Media and CompoundsVivek GroverNoch keine Bewertungen

- ISO 9001:2008 Certified Capitol Steel Reinforcing Bar Price ListDokument1 SeiteISO 9001:2008 Certified Capitol Steel Reinforcing Bar Price Listeg choloNoch keine Bewertungen

- Corrosion1 0Dokument47 SeitenCorrosion1 0Akshat GroverNoch keine Bewertungen

- Material Used in Ship BuildingDokument13 SeitenMaterial Used in Ship BuildingAniekanNoch keine Bewertungen

- Weight Chart for Construction Steel ProfilesDokument22 SeitenWeight Chart for Construction Steel Profilesdot comNoch keine Bewertungen

- Heat Treatment Lecture NotesDokument24 SeitenHeat Treatment Lecture NotesKhin Aung ShweNoch keine Bewertungen

- Complete FinalDokument195 SeitenComplete FinalYokeshAnandNoch keine Bewertungen

- Sheet Metal Bending: A. ElbadanDokument24 SeitenSheet Metal Bending: A. ElbadanSuleman KhanNoch keine Bewertungen

- Heat Treatment Objectives and ProcessesDokument6 SeitenHeat Treatment Objectives and ProcessesAdaitaChowdhury100% (1)

- CH 3 PDFDokument20 SeitenCH 3 PDFHassaan SajidNoch keine Bewertungen

- Extrusion ToolingDokument17 SeitenExtrusion ToolingSantosh Kumar100% (1)

- WPS and PQR ChecklistDokument2 SeitenWPS and PQR Checklistshabbir626Noch keine Bewertungen

- Astm A519Dokument14 SeitenAstm A519PrakashNoch keine Bewertungen

- Permanent Metal - Data - Sheet - AFP 1 209B New PDFDokument1 SeitePermanent Metal - Data - Sheet - AFP 1 209B New PDFcham_900Noch keine Bewertungen

- ATA Heet: LSS D2Dokument2 SeitenATA Heet: LSS D2X800XLNoch keine Bewertungen

- Bolt Depot - Bolt Grade Markings and Strength ChartDokument3 SeitenBolt Depot - Bolt Grade Markings and Strength ChartfrancisNoch keine Bewertungen

- Test MG: T CertificateDokument12 SeitenTest MG: T CertificateNandhu snehaNoch keine Bewertungen

- PH - LPS - Conventional - ST - Regis PDFDokument7 SeitenPH - LPS - Conventional - ST - Regis PDFAfandie Van WhyNoch keine Bewertungen

- 2010-Mixing Enthalpy of Liquid Phase Calculated by Miedema's Scheme andDokument11 Seiten2010-Mixing Enthalpy of Liquid Phase Calculated by Miedema's Scheme ands.swamyNoch keine Bewertungen

- Table 4A Comparison of SSPC and Iso Surface Preparation Standards For Power-And Hand-Tool Cleaned SteelDokument2 SeitenTable 4A Comparison of SSPC and Iso Surface Preparation Standards For Power-And Hand-Tool Cleaned Steelshahid khanNoch keine Bewertungen

- Lab 3 Material Science - G4Dokument35 SeitenLab 3 Material Science - G4Syafiq Fauzi100% (1)

- Aluminum Alloy EvolutionDokument2 SeitenAluminum Alloy Evolutionc4pp3ll410_m4tt0Noch keine Bewertungen

- Industrial Anodizing Co Inc A967Dokument9 SeitenIndustrial Anodizing Co Inc A967Daryna KupriianovaNoch keine Bewertungen

- AISI 1018 Mild Low Carbon Steel PDFDokument3 SeitenAISI 1018 Mild Low Carbon Steel PDFYogesh ChaudhariNoch keine Bewertungen

- Poster Welding P VoxXa PDFDokument1 SeitePoster Welding P VoxXa PDFAd Man GeTigNoch keine Bewertungen

- Erifon CLS Series: Key Benefits DescriptionDokument2 SeitenErifon CLS Series: Key Benefits DescriptionEsdras Albuquerque100% (1)

- ASTM A193-A193M-04cDokument12 SeitenASTM A193-A193M-04cNadhiraNoch keine Bewertungen