Beruflich Dokumente

Kultur Dokumente

A Comparison of ISO 15614 Part 1 and ASME IX

Hochgeladen von

susanwebOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

A Comparison of ISO 15614 Part 1 and ASME IX

Hochgeladen von

susanwebCopyright:

Verfügbare Formate

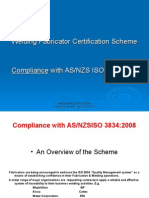

A comparison of ISO 15614 Part 1 and ASME IX

The question is sometimes asked Can I use our existing welding procedure qualifications? where the qualification specification required by the contract is one that has not previously been used by the organisation This is particularly relevant when substantial costs and!or delays will be incurred if re"qualification of the welding procedures is necessary The two most frequently encountered specifications are I#$ %&'%( )art % and *#+, I- and whilst these are written with the same purpose .that of giving assurance that a welding procedure will provide the desired /oint properties0 there are ma/or differences between the two specifications that mean that they are not equivalent It will not be possible in this short article to cover every welding variable and its range of approval in the two specifications 1here compliance is required then reference +2#T be made to the appropriate specification 1ith respect to *#+, I- the specification requirements can be applied in two ways3 *#+, intent and *#+, stamp If the welded item is to be *#+, stamped this can only be done by a manufacturer who has a quality system accredited by *#+, and who holds an appropriate stamp4 5 stamp for nuclear components4 2 for unfired pressure vessels4 # for power boilers etc *ll the requirements of the *#+, specifications +2#T be complied with4 even to the extent of dimensions of the mechanical test pieces and the calibration of testing equipment *#+, intent is used where the item is not to be code stamped but is perhaps only designed to the relevant *#+, code and some flexibility is possible with respect to the manufacturing aspects of specification compliance #uch flexibility may allow the manufacturer to submit to the client or inspecting authority procedure qualification records .)670 to I#$ %&'%( )art % for approval that can be shown to be technically equivalent to an *#+, )67 *#+, I- covers the qualification of welders and welding operators4 welding procedures4 bra8ing operatives and bra8ing procedures for the complete range of ferrous and non"ferrous engineering metals .steels4 copper4 nickel4 aluminium4 titanium and 8irconium alloys0 and oxy"gas4 arc4 power beam4 resistance and solid phase welding processes I#$ %&'%( )t% covers the welding procedure qualification of arc and gas welds in steel and nickel alloys only $ther alloys and /oining processes are covered by additional specifications within the I#$ %&'%( series 9oth specifications identify essential variable .although I#$ %&'%( )t% does not describe them as such0 to each of which is assigned a range of approval * change to an essential variable outside of its range of approval requires the welding procedure to be re"qualified *#+, I- in addition identifies supplementary and non"essential variables #upplementary variables are only invoked when toughness requirements are specified by the application

code4 eg *#+, :III or *#+, 9;% ; 5on"essential variables4 as the name suggests4 are those variables that are not regarded as affecting the quality or mechanical properties of the welded /oint and comprise such variables as the weld preparation4 shield gas flow rate4 method of back gouging4 shield gas no88le si8e etc *lthough these variables are non"essential it is a requirement that they should be referenced on the welding procedure It is therefore 5$T acceptable to use a butt welding procedure to specify how a fillet weld should be made I#$ %&'%( )t% does not identify any variables as non"essential3 where a variable is not regarded as significant it is simply not referenced in the specification There are several variables in both specifications where there is no range of approval3 the manufacturer4 the welding process and the application or deletion of post weld heat treatment .)1<T0 for example In order to reduce the amount of qualification testing4 both specifications group alloys of similar characteristics together 6ualifying the welding of one alloy within the group allows the other alloys within the group to be welded *#+, I- assigns the groups numbers with steels being numbered )% to )%&= *ny alloy that does not have a ) number is regarded as unassigned3 a procedure qualification carried out using an unassigned alloy qualifies only that specific designation of alloy 2ntil recently only alloys that complied with the *#+, and!or *#T+ material specifications and!or had a 25# number were assigned ) numbers <owever4 a limited number of ,54 Canadian4 Chinese and >apanese alloys have now been introduced into the list of assigned alloys I#$ %&'%( )t % also groups steel and nickel alloys into families with similar properties but is somewhat less prescriptive than the *#+, code in that4 provided alloys have similar chemical compositions and mechanical properties4 the material specification is not relevant ? for example a plain carbon steel with less than @ A&BC and a minimum specified yield strength less than ('@+)a falls into Croup % irrespective of whether or not it is a pressure vessel or structural steel or supplied in accordance with ,5 or *#T+ material specifications To determine into which group the alloy falls reference should be made to I#$!T7 %&'@D4 the specification that lists both ferrous and non"ferrous alloys and assigns them a group number $ther significant differences between the two specifications with respect to the arc welding processes areE" *#+, I- requires only tensile and bend tests to qualify a butt weld I#$ %&'%( )t% requires a far more extensive test programme of visual inspection4 radiography or ultrasonic examination4 surface crack detection4 tensile and bend tests and macro" examination In certain circumstances Charpy": impact tests and hardness surveys are also required *#+, I- specifies that the tensile strength of the cross /oint tensile specimen shall be at least that of the minimum specified for the parent metal and that bend test coupons should have no discontinuity greater than ;mm I#$ %&'%( )t% has identical requirements for these mechanical tests but in addition specifies an acceptance standard for the non"destructive testing3 impact test results4 when required4 that match the parent material toughness and hardness limits when hardness testing is required I#$ %&'%( )t % requires Charpy": impact testing for steels over %Amm thick when the material specification requires it *#+, requires impact testing only when specified in the application standard This requirement makes heat input a supplementary essential variable in *#+, I- but an essential variable in I#$ %&'%( )t% <ardness testing is required by I#$ %&'%( )t% for all ferritic steels with a specified minimum yield strength greater than AF&+)a * maximum hardness for /oints in

either the as"welded of )1<Td condition is specified *#+, I- does not require hardness testing *#+, I- allows a reduction in preheat of &&$C before requalification is required I#$ %&'%( )t% does not permit any reduction in preheat from that used in the qualification test *#+, allows the maximum interpass temperature to be &&$C above that measured in the qualification test I#$ %&'%( )t % permits no such increase *#+, I- requires pressure containing fillet welds to be qualified by a butt weld procedure qualification test 5on"pressure retaining fillet welds may be qualified by a fillet weld test only I#$ %&'%( )t% requires a fillet weld to be qualified by a butt weld when mechanical properties G are relevant to the application H i e when it is a load carrying fillet weld In addition4 whilst a butt weld will qualify a fillet weld G fillet weld tests shall be required where this is the predominant form of production welding H i e an I#$ compliant welding procedure where the ma/ority of the welding is of load carrying fillet welds must reference both a butt weld and a fillet weld procedure qualification 1eld metal transfer mode4 where relevant4 is an essential variable in both I#$ %&'%( )t% and *#+, I- but the current type is an essential variable in I#$ %&'%( )t% and a supplementary essential variable in *#+, I* change from manual to automatic welding is an essential variable in I#$ %&'%( )t% but a non"essential variable in *#+, I-

1hilst there are several other variables in the two specifications that have substantially different ranges of approval there are many that have ranges that are very similar ? material thickness being but one example This article has highlighted some of the significant differences but to ensure that the welding procedure and its supporting procedure qualification record are compliant the specifications must be referred to The answer to the question posed at the start of this article is therefore ? it depends upon what you can persuade the client and inspecting authority to acceptI

Das könnte Ihnen auch gefallen

- Industrial radiography A Complete Guide - 2019 EditionVon EverandIndustrial radiography A Complete Guide - 2019 EditionNoch keine Bewertungen

- Welding Essential Variables - en ISO 15614Dokument2 SeitenWelding Essential Variables - en ISO 15614NS QCNoch keine Bewertungen

- What's New in ISO 15614-12017Dokument13 SeitenWhat's New in ISO 15614-12017alevent100% (1)

- WPQ Process As Per ISO-9606-1 2013Dokument4 SeitenWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- Welding of P91Dokument37 SeitenWelding of P91nishant361100% (4)

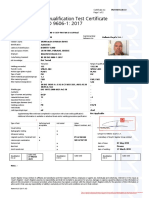

- Welder Qualification Test Certificate BS EN ISO 9606-1: 2017Dokument2 SeitenWelder Qualification Test Certificate BS EN ISO 9606-1: 2017idthdrayahbdnhauniNoch keine Bewertungen

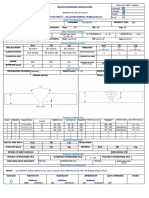

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDokument3 SeitenWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNoch keine Bewertungen

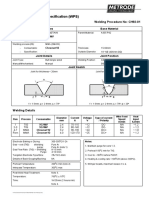

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDokument3 SeitenWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLENoch keine Bewertungen

- Fermi Lab Orbital Welding ProcedureDokument2 SeitenFermi Lab Orbital Welding ProcedurePramod Athiyarathu100% (1)

- WPQR Welding Procedure Qualification RecordsDokument3 SeitenWPQR Welding Procedure Qualification Recordsramesh rajaNoch keine Bewertungen

- Page No: 01: SA 240 GR 304 SA 240 GR 304Dokument5 SeitenPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNoch keine Bewertungen

- Welding Procedure Specification for Vertical Storage TanksDokument6 SeitenWelding Procedure Specification for Vertical Storage TanksYASH BARDHAN SinghNoch keine Bewertungen

- Welding Procedure Qualification Certificate EN ISO 15614-1: 2017Dokument3 SeitenWelding Procedure Qualification Certificate EN ISO 15614-1: 2017dcsamaraweera100% (1)

- European Grouping System for Metallic MaterialsDokument12 SeitenEuropean Grouping System for Metallic MaterialsCarlos Nombela Palacios100% (2)

- P1 To P8Dokument9 SeitenP1 To P8Pat AuffretNoch keine Bewertungen

- Gta+sma PQRDokument3 SeitenGta+sma PQRRahul MoottolikandyNoch keine Bewertungen

- SAFed TC 4 Welding Procedure and Welder Approval Testing 21 Mar 2019 PDFDokument24 SeitenSAFed TC 4 Welding Procedure and Welder Approval Testing 21 Mar 2019 PDFFirdaus NasirNoch keine Bewertungen

- 004 Gtaw P5aDokument16 Seiten004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- P-WPS 135 - MAG (GR 316)Dokument9 SeitenP-WPS 135 - MAG (GR 316)Tarun PatelNoch keine Bewertungen

- Iso 15609-1-2019Dokument19 SeitenIso 15609-1-2019HarikeshRana100% (2)

- Part 01 - Review of EN ISO 9606-1Dokument26 SeitenPart 01 - Review of EN ISO 9606-1Turbo Snail RNoch keine Bewertungen

- Weld Checklist PQRDokument2 SeitenWeld Checklist PQRScott Trainor100% (1)

- BPV IX-16-3 QW-283 - ButteringDokument1 SeiteBPV IX-16-3 QW-283 - ButteringyutweldingNoch keine Bewertungen

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Dokument3 SeitenWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaNoch keine Bewertungen

- Filler Metal Selection ChartDokument1 SeiteFiller Metal Selection ChartMuhammed NoorulNoch keine Bewertungen

- P91 Repair With NiCrDokument76 SeitenP91 Repair With NiCrElias KapaNoch keine Bewertungen

- En 13445 WPS PQR WPQDokument5 SeitenEn 13445 WPS PQR WPQmuhammad hadiNoch keine Bewertungen

- Metrode - P92 WPS PDFDokument3 SeitenMetrode - P92 WPS PDFXing ChenNoch keine Bewertungen

- TDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsDokument3 SeitenTDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsGohilakrishnan ThiagarajanNoch keine Bewertungen

- WPS Format For ISO 15614-1 PWPSDokument1 SeiteWPS Format For ISO 15614-1 PWPSThe Welding Inspections CommunityNoch keine Bewertungen

- Welder Visual Inspection ReportsDokument24 SeitenWelder Visual Inspection ReportsKyNoch keine Bewertungen

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDokument5 SeitenWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNoch keine Bewertungen

- ISO 3834 Welding Certification GuideDokument11 SeitenISO 3834 Welding Certification GuideWeld Bro Sandeep100% (1)

- Super Duplex Stainless SteelDokument1 SeiteSuper Duplex Stainless SteelUma Shankar100% (1)

- Ms For Buttering of Thinning Area - Rev.0 - ReviewedDokument2 SeitenMs For Buttering of Thinning Area - Rev.0 - ReviewedAtuk SafizNoch keine Bewertungen

- IWE SubjectsDokument2 SeitenIWE SubjectsAdnan Rana100% (3)

- VP16 PDFDokument13 SeitenVP16 PDFKara WhiteNoch keine Bewertungen

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDokument6 SeitenWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNoch keine Bewertungen

- Multi Process Welding Procedures QW200.4 (ASME IX)Dokument1 SeiteMulti Process Welding Procedures QW200.4 (ASME IX)HoangNoch keine Bewertungen

- ASME IX QW (Welding General Requirements)Dokument12 SeitenASME IX QW (Welding General Requirements)Ariq Fauzan100% (1)

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Dokument2 Seiten(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Model WopqDokument2 SeitenModel WopqAnilkumarGopinathanNairNoch keine Bewertungen

- WPS ISO 15614-1 WeldNote MetricDokument1 SeiteWPS ISO 15614-1 WeldNote MetricVirgil SorcaruNoch keine Bewertungen

- List Applicable WPS StructureDokument7 SeitenList Applicable WPS StructureFerdie OSNoch keine Bewertungen

- ISO 3834 welding certification levelsDokument9 SeitenISO 3834 welding certification levelsvilukNoch keine Bewertungen

- WPS Format For Asme Ix - Wps - Gtaw - OverlayDokument1 SeiteWPS Format For Asme Ix - Wps - Gtaw - OverlayThe Welding Inspections Community100% (1)

- Proposed WPSDokument2 SeitenProposed WPSChisom Ikengwu100% (2)

- En Iso 9606 1 GDokument2 SeitenEn Iso 9606 1 GAnonymous dziHEjc7Y100% (1)

- Ami-003 WPSDokument2 SeitenAmi-003 WPSBenjamin BrownNoch keine Bewertungen

- BS en 439 94 PDFDokument12 SeitenBS en 439 94 PDFDario RamljakNoch keine Bewertungen

- For Fillet Weld Joint Project:Production ManifoldDokument1 SeiteFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- 6GR RequirementsDokument1 Seite6GR Requirementswalitedison100% (1)

- Guidance To Prepare Wps PQR For WeldingDokument1 SeiteGuidance To Prepare Wps PQR For WeldingHamid MansouriNoch keine Bewertungen

- Filler Materials TestingDokument34 SeitenFiller Materials TestingSunilNoch keine Bewertungen

- WPS Format For ASME IX - PQR-AllDokument3 SeitenWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- Fcaw 16 THKDokument5 SeitenFcaw 16 THKparesh2387Noch keine Bewertungen

- ISO 15614 vs ASME IX welding standards comparisonDokument2 SeitenISO 15614 vs ASME IX welding standards comparisontuanNoch keine Bewertungen

- Welding Procedure SpecificationDokument30 SeitenWelding Procedure Specificationrahman196011100% (1)

- Api - 1104 W@aDokument88 SeitenApi - 1104 W@angonphanhoangNoch keine Bewertungen

- Preguntas Al Comite API 1104Dokument12 SeitenPreguntas Al Comite API 1104alefeli26Noch keine Bewertungen

- Positive Material Identification (Pmi)Dokument2 SeitenPositive Material Identification (Pmi)MurugadossRajendranNoch keine Bewertungen

- Us DM4 DLDokument38 SeitenUs DM4 DLBalan DanutNoch keine Bewertungen

- A78857-2 2.21 Hydrostaticting Testing Standard - A5E3L0Dokument32 SeitenA78857-2 2.21 Hydrostaticting Testing Standard - A5E3L0susanwebNoch keine Bewertungen

- British Standards For WeldingDokument8 SeitenBritish Standards For Weldingsusanweb100% (2)

- WTIA-TN07 Health and Safety in Welding PDFDokument148 SeitenWTIA-TN07 Health and Safety in Welding PDFMphilipTNoch keine Bewertungen

- PMI ProcedureDokument7 SeitenPMI Procedureosito1214100% (1)

- PMI Alloy Verification ProcedureDokument3 SeitenPMI Alloy Verification ProceduresusanwebNoch keine Bewertungen

- Magnetic Particle Inspection ProcedureDokument9 SeitenMagnetic Particle Inspection Procedurentah84100% (1)

- Dye Penetrant Inspection ProcedureDokument13 SeitenDye Penetrant Inspection ProcedureHafidzManaf100% (1)

- 484 Welding Guidelines For Design EngineersDokument4 Seiten484 Welding Guidelines For Design EngineersPham Song Hong100% (1)

- PmiDokument6 SeitenPmiSai FujiwaraNoch keine Bewertungen

- WeldingFumesGases 1990 PDFDokument38 SeitenWeldingFumesGases 1990 PDFsusanwebNoch keine Bewertungen

- Schaeffler DiagramDokument1 SeiteSchaeffler Diagrambmdbmdbmd100% (1)

- What Is A Steel Casting Casting Process ASMDokument5 SeitenWhat Is A Steel Casting Casting Process ASMsusanwebNoch keine Bewertungen

- Welding SymbolsDokument78 SeitenWelding Symbolsuttamtm100% (1)

- Weld Filler Metal SelectionDokument7 SeitenWeld Filler Metal SelectionsusanwebNoch keine Bewertungen

- Casting, Forming & WeldingDokument90 SeitenCasting, Forming & WeldingmahdiNoch keine Bewertungen

- Fundamentals of Visual InspectionDokument49 SeitenFundamentals of Visual InspectionsusanwebNoch keine Bewertungen

- TGN-PE-02 Temper Bead WeldingDokument9 SeitenTGN-PE-02 Temper Bead WeldingNatrajiNoch keine Bewertungen

- The Alternative To PWHT Temper Bead Welding by Walter J SperkoDokument64 SeitenThe Alternative To PWHT Temper Bead Welding by Walter J Sperkosusanweb100% (3)

- Measurement and Numerical Prediction of Residual Stresses in Steel Welds Subject To Heat TreatmentDokument29 SeitenMeasurement and Numerical Prediction of Residual Stresses in Steel Welds Subject To Heat TreatmentsusanwebNoch keine Bewertungen

- CON-03!03!22 Temper Bead Welding ProcedureDokument6 SeitenCON-03!03!22 Temper Bead Welding ProceduresusanwebNoch keine Bewertungen

- Welding Advanced Chromium Alloys for High-Temperature ServiceDokument5 SeitenWelding Advanced Chromium Alloys for High-Temperature Servicesaji_t1984100% (1)

- Exploring Temper Bead Welding TechniquesDokument11 SeitenExploring Temper Bead Welding TechniquesvaseaNoch keine Bewertungen

- RT Level Iii TestDokument4 SeitenRT Level Iii Testsusanweb0% (1)

- NDTDokument9 SeitenNDTDenzil D'SouzaNoch keine Bewertungen

- Welding of Nickel AlloysDokument12 SeitenWelding of Nickel Alloysaj87_goswamiNoch keine Bewertungen

- Non Destructive EvaluationDokument25 SeitenNon Destructive EvaluationsusanwebNoch keine Bewertungen

- NDTDokument9 SeitenNDTDenzil D'SouzaNoch keine Bewertungen

- Non Destructive InspectionDokument41 SeitenNon Destructive InspectionsusanwebNoch keine Bewertungen

- Roof Truss Design LoadsDokument51 SeitenRoof Truss Design LoadsFeigyl Miro100% (4)

- Amberjet 1200 H LDokument2 SeitenAmberjet 1200 H LIraida MorosNoch keine Bewertungen

- Balancing Equations WorksheetDokument4 SeitenBalancing Equations WorksheetjoeNoch keine Bewertungen

- Design of Steel ISMC 300 Member for Axial and Bending LoadsDokument1 SeiteDesign of Steel ISMC 300 Member for Axial and Bending LoadsAnand.5Noch keine Bewertungen

- FN 4b Oral QsDokument8 SeitenFN 4b Oral QsAnoop VijayakumarNoch keine Bewertungen

- Versenate Hardness Buffer SolutionDokument8 SeitenVersenate Hardness Buffer Solutionjesusruizbadra357Noch keine Bewertungen

- GLXXMobil Vacuoline 100 SeriesDokument3 SeitenGLXXMobil Vacuoline 100 SeriesAdrian RoperoNoch keine Bewertungen

- Imsbc CodeDokument2 SeitenImsbc CodeBBluningningNoch keine Bewertungen

- 423-Renolin CLP-1Dokument1 Seite423-Renolin CLP-1Moutaz IsmailNoch keine Bewertungen

- GE Turbine Fuel SpecsDokument24 SeitenGE Turbine Fuel SpecsA H RanaNoch keine Bewertungen

- Rain Water Alarm Project ReportDokument10 SeitenRain Water Alarm Project ReportAnish75% (4)

- FN Steel Datasheet Spring Steels ENG-V2Dokument2 SeitenFN Steel Datasheet Spring Steels ENG-V2ariNoch keine Bewertungen

- Tutorial 7 - Kinetics - SOLUTIONSDokument5 SeitenTutorial 7 - Kinetics - SOLUTIONSJustin Chuong NguyenNoch keine Bewertungen

- King Saud University Mass Transfer ExamDokument7 SeitenKing Saud University Mass Transfer ExamAnnisa RahmaditaNoch keine Bewertungen

- KSB Influence of Pumps On Energy ConsumptionDokument14 SeitenKSB Influence of Pumps On Energy Consumption@sssNoch keine Bewertungen

- Sedimentation and Sedimentation TanksDokument43 SeitenSedimentation and Sedimentation TanksDevendra Sharma80% (10)

- Inspection and Test Procedure of SwitchgearDokument4 SeitenInspection and Test Procedure of SwitchgearShahadat HossainNoch keine Bewertungen

- CVS Controls Series 470 Piston Actuators Sept 2014 PDFDokument12 SeitenCVS Controls Series 470 Piston Actuators Sept 2014 PDFVIVIANA ESQUIVELNoch keine Bewertungen

- Caldera Columbia CT-25 ManualDokument72 SeitenCaldera Columbia CT-25 Manualmacro_jNoch keine Bewertungen

- CH - Mass Transfer and Transport Phenomenon PDFDokument29 SeitenCH - Mass Transfer and Transport Phenomenon PDFRaghul RockNoch keine Bewertungen

- Beggs & Brill MethodDokument9 SeitenBeggs & Brill Methodmatrix69Noch keine Bewertungen

- AMMIE 2023 Conference on Advanced Materials and ManufacturingDokument9 SeitenAMMIE 2023 Conference on Advanced Materials and ManufacturingrjNoch keine Bewertungen

- HDPE High Density Polyethylene properties guideDokument4 SeitenHDPE High Density Polyethylene properties guideVENKATESAN JNoch keine Bewertungen

- Furniture Locksand CatchesDokument15 SeitenFurniture Locksand CatchesNishant DeoNoch keine Bewertungen

- Tom Wheatley Swing Check Valves PDFDokument28 SeitenTom Wheatley Swing Check Valves PDFIjaz AhmedNoch keine Bewertungen

- Dts-Lesson PlanDokument3 SeitenDts-Lesson Plansujithaa13Noch keine Bewertungen

- Articulado PDFDokument90 SeitenArticulado PDFMiguel Fuentes100% (1)

- Tension-Weld® Strapping Tool: Downloaded From Manuals Search EngineDokument36 SeitenTension-Weld® Strapping Tool: Downloaded From Manuals Search EnginePepeNoch keine Bewertungen

- HD8765 47 PDFDokument109 SeitenHD8765 47 PDFArsenie GeorgeNoch keine Bewertungen

- TDS MasterRheobuilld-623Dokument2 SeitenTDS MasterRheobuilld-623Taposh PaulNoch keine Bewertungen