Beruflich Dokumente

Kultur Dokumente

Coke Tower Design

Hochgeladen von

Mahendra RathoreOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Coke Tower Design

Hochgeladen von

Mahendra RathoreCopyright:

Verfügbare Formate

Larsen & Toubro

Heavy Engineering

Coke Drum - Engineering & Manufacturing Challenges

Hari Ravindran

At Galveston Tx

Its all about imagineering

L&T Heavy Engineering L&T Heavy Engineering

L&T at a Glance

Founded

Share Holders

Employees, 13% FIIs, 15% General Public, 24% Others, 15% Financial Institutions , 33%

1938

Number of Emp.

50,000+

Market Cap

USD 20+ Bn Sales ($ Bn)

11.7 8.5 9.8

Market Cap ($ Bn)

7.4 5.0

19.06 7.65

20.04

06-07

15-May-12

07-08

08-09

09-10

10-11

2009

2010

2011

2 / 28

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

L&T Heavy Engineering L&T Heavy Engineering

Our Experience Licenser wise

10 10 8 8 6 6 4 4 2 2 0 0

FW CB&I PB EM ***

Total Count 48 Nos

6 4

*** Under Secrecy agreement

- 32 Nos. Manufactured Under manufacturing - 16 Nos.

3 / 28

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

L&T Heavy Engineering L&T Heavy Engineering

Coke Drum And L&T

Coke Drum Technical Challenges Design Creep Fatigue Analysis Skirt Optimization - Seismic and Fatigue Banana B M Movement t Top T Dished Di h d Nozzle N l Feed Spool Bolting - Gasket Relaxation Manufacturing Automatic Welding & Grinding Latest NDE Techniques TOFD Distortion Control at Weld Joints Skirt # Cone Junction Expertise in Heat Treatment Welding Capabilities

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

4 / 28

L&T Heavy Engineering L&T Heavy Engineering

Design Capabilities

High cyclic loading at elevated temperature Design by Analysis Not empirical formulas C Creep Fatigue Buckling

Temperature 900 Pressure 500000.00

800

450000.00 400000.00

700

350000.00 600 T e m p e r a tu r e ( K ) P r e s s u r e (P a ) 300000.00 500 250000.00 400 200000.00 300 150000.00

L&Ts In-house capabilities for Finite Element Analysis.

200

100000.00 50000.00

100

0

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

0.00 Time (Hr)

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

5 / 28

L&T Heavy Engineering L&T Heavy Engineering

Unique FEA capabilities Creep Fatigue

Hotbox

Feed Nozzle

Banana Analysis

Feed Bolting

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

6 / 28

L&T Heavy Engineering L&T Heavy Engineering

Creep Fatigue Analysis of Skirt Joint (Hot Box)

Segmental 3-D model Axi-symmetric analysis In house FORTRAN program

: Determining effect of slots in skirt : Skirt without slots : Determining radiation effect in Hotbox

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

7 / 28

L&T Heavy Engineering L&T Heavy Engineering

Temperature Plots

Warm Up (329.2K)

Oil in(533K)

Start Coking (727.4K)

Start Quenching (643.9K)

End Cutting (414.6K)

15-May-12

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

8 / 28

L&T Heavy Engineering L&T Heavy Engineering

Stress Plots

Warm up (99.5 MPa)

Oil in (212 MPa)

Start Coking (236 MPa)

Start Quenching (103 MPa)

End Cutting (144 MPa)

15-May-12

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

9 / 28

L&T Heavy Engineering L&T Heavy Engineering

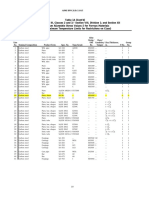

Fatigue Life Study - Skirt Joint

Skirt MOC Skirt thk. (mm) 28.5 40.0 40.0 32.0 25.4 40 0 40.0 Inside radius of crotch h (mm) R12 R12 R25 R13 R25 R32 Hotbox Fatigue Fatigue g life* life# Height (mm) (Years) (Years) 638 665 665 582 925 857 19.2 22.2 45.9 6.5 17.3 44 2 44.2 4.75 4.55 2.52 Remarks Slotted Skirt Creep Range Slotted Skirt Slotted Skirt Without slot Without slot With t slot Without l t

SA 387 Gr 11 Cl 2 SA 387 Gr 11 Cl 1 SA 387 Gr 11 Cl 1 SA 387 Gr 11 Cl 2 SA 387 Gr 11 Cl 2 SA 387 Gr G 11 Cl 2

*Fatigue life at Skirt # Toricone joint ; # Fatigue life at slot tip Conclusion : Increase in radius and hotbox height improve s fatigue life Lower skirt thickness gives flexibility & thus improving fatigue life

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

10 / 28

L&T Heavy Engineering L&T Heavy Engineering

Creep Buckling of Skirt

Allowable comp. stress for 1 Hr

Allowable comp. stress for 0.1mn Hr

FEA Model

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

11 / 28

L&T Heavy Engineering L&T Heavy Engineering

Creep Fatigue Analysis - Nozzle Attachments

FE Model Temp-Coking Stress-Coking

Analysis Fluctuating piping loads pressure and temperature Banana Effect - Horizontal moment of drum

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

12 / 28

L&T Heavy Engineering L&T Heavy Engineering

Creep Fatigue Analysis - Feed Spool Bolts

FE Model Temp-Coking Stress-Coking

Analysis Fluctuating pressure and temperature Model includes Effect of bolt pre-load Creep relaxation and gasket relaxation

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

13 / 28

L&T Heavy Engineering L&T Heavy Engineering

Capabilities-Enhancing Manufacturing Capabilities Enhancing Coke Drum Life

SAW welding Automatic grinding Distortion control at weld joints Latest NDE Techniques

TOFD on Less Thickness

Skirt # Cone Junction Expertise in Heat Treatment Welding W ldi C Capabilities biliti

15-May-12

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

14 / 28

L&T Heavy Engineering L&T Heavy Engineering

Hazira Manufacturing Complex

Jetties Shipbuilding MHI Turbine & Boiler HE Shops HE Shops Forging MFF Shops 2011

15-May-12

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

15 / 28

L&T Heavy Engineering L&T Heavy Engineering

Automatic Welding

15-May-12

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

16 / 28

L&T Heavy Engineering L&T Heavy Engineering

Automatic Grinding

Chipback Grinding

Clad stripping

Cone C-Seam Grinding

15-May-12

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

17 / 28

L&T Heavy Engineering L&T Heavy Engineering

Distortion Control

Welding Fixture

Set up Fixture

Cone Rolling

15-May-12

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

18 / 28

L&T Heavy Engineering L&T Heavy Engineering

Latest NDE Techniques - TOFD

8 CHANNEL TD POCKET SCAN

8 CHANNEL TD POCKET SCAN

On Job TOFD

15-May-12

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

19 / 28

L&T Heavy Engineering L&T Heavy Engineering

Skit # Cone Junction

Weld build up

In house machining 10m

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

20 / 28

L&T Heavy Engineering L&T Heavy Engineering

Expertise in Heat Treatment

Temperature Profile

Local PWHT

Vertical Deformation

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

21 / 28

L&T Heavy Engineering L&T Heavy Engineering

Welding Capabilities

More than 6000 qualified welding procedure Team of T f 500 + qualified lifi d welders ld

Narrow Groove Submerged Arc Welding Gas Tungsten Arc Welding Shielded Metal Arc Welding Submerged arc Strip/ Electro Slag Strip cladding Flux Cored Arc welding Gas Metal Arc Welding Automatic inside overlay

Carbon-Steels Low Alloys Steels (Cr-Mo / CrMo-V) Quenched & Tempered Steel Low temp Nickel steel Inconel Chemistry

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

22 / 28

L&T Heavy Engineering L&T Heavy Engineering

Conclusion

L&T has developed all technical capabilities under one roof to meet technical challenges in Coke Drum manufacturing and increase life span of Coke Drum. Drum Some of which mentioned below: Skirt optimization considering fatigue and buckling at elevated temperature Shape control of coke drum during manufacturing including Outof-Roundness and peaking g and automated clad stripping pp g operation p to increase SAW welding fatigue life at weld seam Alternative weld build up design to increase fatigue life

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

23 / 28

L&T Heavy Engineering L&T Heavy Engineering

Contribution to International Society

Creep-Fatigue Interaction in Coke Drums: An Approach Based on API

579-1/ ASME FFS-2007, ASME PVP 2009. Numerical Simulation of Transient Temperature in SMAW, ASME PVP 2009. Simulation of Temperature Field of TIG Welding Using FDM , ASME PVP 2009. Non-Linear Creep-Buckling Analysis: An Approach Based On WRC-443 For Development Of Allowable Compressive Stresses In Coke Drums, ASME PVP 2010. An Approach Based On Code Case 2605 For Fatigue Evaluation Of Vanadium Modified Materials Reactor, ASME PVP 2010. Design Of Skirt To Cone Joint In Coke Drum: A Parametric Approach Based On Fatigue Analysis ASME PVP 2011

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

24 / 28

L&T Heavy Engineering L&T Heavy Engineering

Worlds World s Largest Coke Drum

Aug-2011

630 MT 9.8 m ID

15-May-12

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

25 / 28

L&T Heavy Engineering L&T Heavy Engineering

Track Record

Year: 2009 Year: 2004

Coke Drum: ABB Process 8.5 85m ID, 310 MT Each, 04 Nos

Coke Drum: FW Process 9.8 m ID, 520 MT Each, 04 Nos

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

26 / 28

L&T Heavy Engineering L&T Heavy Engineering

Track Record

Y Year: 2010

Year: 2012

Coke Drum: CB&I Process 8.0 m ID, ID 240 MT Each, Each 04 Nos

Coke Drum: Petrobras Process 8.9 m ID, 245 MT Each, 16 Nos,

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

27 / 28

L&T Heavy Engineering L&T Heavy Engineering

Thank a you You Imagine.We Create

Hari.ravindran@larsentoubro.com

15-May-12

2011 2011 Larsen Larsen & & Toubro Toubro Limited Limited : : All All rights rights reserved reserved

28

Das könnte Ihnen auch gefallen

- Fluid CokingDokument12 SeitenFluid CokingManak JajoriyaNoch keine Bewertungen

- Revamping For ULSD ProductionDokument8 SeitenRevamping For ULSD Productionsam josephNoch keine Bewertungen

- Divided Wall Column 496Dokument6 SeitenDivided Wall Column 496GeorgeNoch keine Bewertungen

- Cdu - VduDokument3 SeitenCdu - VduRobson2305Noch keine Bewertungen

- Coker ArticleDokument6 SeitenCoker Articlepersonalmail_20011078100% (1)

- Sintering The Main Cause of DeactivationDokument2 SeitenSintering The Main Cause of DeactivationCai ZiminNoch keine Bewertungen

- VDU Velocity Steam LineDokument6 SeitenVDU Velocity Steam LineSampatNoch keine Bewertungen

- Shell White - VDU UpgradeDokument16 SeitenShell White - VDU Upgradesachins1318Noch keine Bewertungen

- Abelmarle Referencia KF-868 PDFDokument24 SeitenAbelmarle Referencia KF-868 PDFEdgar Hector GarciaNoch keine Bewertungen

- Hydraulic Decoking System: Nnovation Efficiency QualityDokument8 SeitenHydraulic Decoking System: Nnovation Efficiency QualitykennymagallanesNoch keine Bewertungen

- AcquaconvertionDokument10 SeitenAcquaconvertionGreysi N. Moreno CedeñoNoch keine Bewertungen

- Coke Drum DesignDokument6 SeitenCoke Drum Designkutts76Noch keine Bewertungen

- 2018 UOP Course ScheduleDokument2 Seiten2018 UOP Course SchedulePRATEEK KUMAR DASNoch keine Bewertungen

- SiCl4 PreparationDokument5 SeitenSiCl4 PreparationAdam FlynnNoch keine Bewertungen

- 2013 8 2 Noll Concord BlueDokument12 Seiten2013 8 2 Noll Concord BlueljmuhamedNoch keine Bewertungen

- Nicholas Oligomerization PDFDokument16 SeitenNicholas Oligomerization PDFTanase DianaNoch keine Bewertungen

- Aromatics PDFDokument24 SeitenAromatics PDFGerardo RiosNoch keine Bewertungen

- NGLDokument6 SeitenNGLAlberto Fonseca UribeNoch keine Bewertungen

- Catalytic IsomerizationDokument7 SeitenCatalytic Isomerizationanasaie20% (1)

- Howto PFD Development PDF PDFDokument74 SeitenHowto PFD Development PDF PDFcahz1307Noch keine Bewertungen

- Gas Liquid Separation Technology PDFDokument24 SeitenGas Liquid Separation Technology PDFnodyyyNoch keine Bewertungen

- Brochure Uk ProductsDokument2 SeitenBrochure Uk ProductsJavier TrujillanoNoch keine Bewertungen

- 3 3 MR Robert PardemannDokument47 Seiten3 3 MR Robert Pardemannhoremheb1Noch keine Bewertungen

- HSFCCDokument22 SeitenHSFCCdonald55555100% (1)

- Unit 2 Refining Process - 3Dokument28 SeitenUnit 2 Refining Process - 3prathamesh singhNoch keine Bewertungen

- Kurita Mitigating Coke FormationDokument3 SeitenKurita Mitigating Coke FormationMarcelNoch keine Bewertungen

- 10 - Latest Developments in Hydrocracking Catalysts Proceedings PDFDokument26 Seiten10 - Latest Developments in Hydrocracking Catalysts Proceedings PDFmujeebtalib100% (1)

- Pre-Reformer Catalyst in A Hydrogen PlantDokument4 SeitenPre-Reformer Catalyst in A Hydrogen Plantbikas_saha100% (1)

- Advanced Catalytic Olefins ACO First Commercial Demonstration Unit Begins OperationsDokument12 SeitenAdvanced Catalytic Olefins ACO First Commercial Demonstration Unit Begins OperationsmakhadermfNoch keine Bewertungen

- Coking 101Dokument26 SeitenCoking 101digecaNoch keine Bewertungen

- Introduction To Uop: Jim Mcgehee Development Specialist, Heavy OilsDokument22 SeitenIntroduction To Uop: Jim Mcgehee Development Specialist, Heavy OilsAnkush BhandariNoch keine Bewertungen

- Flu or Delayed Coking ExperienceDokument5 SeitenFlu or Delayed Coking ExperienceLeon SanchezNoch keine Bewertungen

- JPT 2017-NoviembreDokument84 SeitenJPT 2017-Noviembreabraham dominguezNoch keine Bewertungen

- Hydroprocessing Reactor and Process Design To Optimize Performance (Topsoe - 1998)Dokument18 SeitenHydroprocessing Reactor and Process Design To Optimize Performance (Topsoe - 1998)yliangcaNoch keine Bewertungen

- TOTAL Modeling and Optimization of Fluid Catalytic Cracking UnitsDokument19 SeitenTOTAL Modeling and Optimization of Fluid Catalytic Cracking Unitssaleh4060Noch keine Bewertungen

- DCC EngDokument1 SeiteDCC Engwahaha06Noch keine Bewertungen

- Midw Technology As A Drop-In Catalyst SolutionDokument11 SeitenMidw Technology As A Drop-In Catalyst Solutiondie_1Noch keine Bewertungen

- HydrocrackingDokument33 SeitenHydrocrackingNikita SeleznevNoch keine Bewertungen

- FCC Propylene Production Tech PaperDokument8 SeitenFCC Propylene Production Tech PaperMaría Belén JaureguiNoch keine Bewertungen

- Eliminating The Claus FurnaceDokument9 SeitenEliminating The Claus Furnaceoujda1977Noch keine Bewertungen

- Paper 10 - Catalyst CatastrophesDokument16 SeitenPaper 10 - Catalyst CatastrophesArsalan QadirNoch keine Bewertungen

- 0 0 05 Jan 2015 1437039471Annexure-Pre-feasibilityReport (PFR)Dokument35 Seiten0 0 05 Jan 2015 1437039471Annexure-Pre-feasibilityReport (PFR)Swastika DasNoch keine Bewertungen

- Reforming Catalyst Regenration: M.Saleem Chohan Syed Kashif HassanDokument17 SeitenReforming Catalyst Regenration: M.Saleem Chohan Syed Kashif HassanSaleem ChohanNoch keine Bewertungen

- Catalytic ConversionDokument27 SeitenCatalytic ConversionKuldeep singh ChandelNoch keine Bewertungen

- Conversion of Isobutylene To Propylene PDFDokument9 SeitenConversion of Isobutylene To Propylene PDFtannytranNoch keine Bewertungen

- Modeling of Naphtha Reforming Unit Applying Detailed 2014 Chemical EngineerDokument30 SeitenModeling of Naphtha Reforming Unit Applying Detailed 2014 Chemical Engineerdownload100% (1)

- Simulation and Performance Analysis of Propane Propylene SplitterDokument4 SeitenSimulation and Performance Analysis of Propane Propylene SplitterAnonymous UY9QffNoch keine Bewertungen

- Sablin Alpha Raab FDokument3 SeitenSablin Alpha Raab Fsk281Noch keine Bewertungen

- A Design Adn Rating Method For Shell and Tube Heat ExchangerDokument8 SeitenA Design Adn Rating Method For Shell and Tube Heat Exchangerhuynhthanhtamga1981100% (1)

- Dehydration Plant Twenty Years PaperDokument5 SeitenDehydration Plant Twenty Years Papersejerson07Noch keine Bewertungen

- Vis BreakingDokument21 SeitenVis BreakingAhmed Hassan RashedNoch keine Bewertungen

- Unit 2 1Dokument4 SeitenUnit 2 1Sadagopan RajaNoch keine Bewertungen

- Characterization and Prediction of Water Droplet Size in Oil Water Flow - J Yao - MSDokument183 SeitenCharacterization and Prediction of Water Droplet Size in Oil Water Flow - J Yao - MSGianmarco Corticelli100% (1)

- Assignment NO 3:: Question 1: Define Cracking. Classify Cracking OperationsDokument6 SeitenAssignment NO 3:: Question 1: Define Cracking. Classify Cracking OperationsMilan MoradiyaNoch keine Bewertungen

- New Aspects of Spillover Effect in Catalysis: For Development of Highly Active CatalystsVon EverandNew Aspects of Spillover Effect in Catalysis: For Development of Highly Active CatalystsNoch keine Bewertungen

- Successful Design of Catalysts: Future Requirements and DevelopmentVon EverandSuccessful Design of Catalysts: Future Requirements and DevelopmentNoch keine Bewertungen

- SWIFT INDIA - Bag FilterDokument11 SeitenSWIFT INDIA - Bag FilterMahendra RathoreNoch keine Bewertungen

- FENET Budapest Feb2005 DLE DesignByAnalysis MackenzieDokument38 SeitenFENET Budapest Feb2005 DLE DesignByAnalysis MackenziePedro Dominguez Dominguez100% (1)

- Pneumatic TestDokument28 SeitenPneumatic TestLiLy NanaNoch keine Bewertungen

- FM2005 WangZD 1Dokument6 SeitenFM2005 WangZD 1Mahendra RathoreNoch keine Bewertungen

- SIEC-Bag FilterDokument13 SeitenSIEC-Bag FilterMahendra RathoreNoch keine Bewertungen

- SIEC-COMPANY PROFILE - Bag FilterDokument11 SeitenSIEC-COMPANY PROFILE - Bag FilterMahendra RathoreNoch keine Bewertungen

- Pneumatic TestDokument28 SeitenPneumatic TestLiLy NanaNoch keine Bewertungen

- Assess STRCT IntegritySESDokument18 SeitenAssess STRCT IntegritySESTRYcnrlNoch keine Bewertungen

- ANSYS Tips and ANSYS TricksDokument74 SeitenANSYS Tips and ANSYS Tricksjulio1114Noch keine Bewertungen

- Thermo Structural Analysis and Optimization of Reactant Column of Pressure Vessel by Using Finite Element AnalysisDokument8 SeitenThermo Structural Analysis and Optimization of Reactant Column of Pressure Vessel by Using Finite Element AnalysisMahendra RathoreNoch keine Bewertungen

- Lecture Slides Chapter 5Dokument28 SeitenLecture Slides Chapter 5Mahendra RathoreNoch keine Bewertungen

- Modelling Residual Stress and Phase Transformation in Steel WeldsDokument29 SeitenModelling Residual Stress and Phase Transformation in Steel WeldsMahendra RathoreNoch keine Bewertungen

- Pressure Vessel Design in ANSYSDokument5 SeitenPressure Vessel Design in ANSYSRohan KarandeNoch keine Bewertungen

- Coked FailureDokument43 SeitenCoked FailureMahendra Rathore100% (2)

- Delayed Coker Drum CrackingDokument26 SeitenDelayed Coker Drum Crackingash1968Noch keine Bewertungen

- Thermo Structural Analysis and Optimization of Reactant Column of Pressure Vessel by Using Finite Element AnalysisDokument8 SeitenThermo Structural Analysis and Optimization of Reactant Column of Pressure Vessel by Using Finite Element AnalysisMahendra RathoreNoch keine Bewertungen

- Code Drum Under Thermal-Mechanical Loadings: Step1Dokument1 SeiteCode Drum Under Thermal-Mechanical Loadings: Step1Mahfujur RahmanNoch keine Bewertungen

- 4 - A S SahneyDokument26 Seiten4 - A S SahneyMahendra RathoreNoch keine Bewertungen

- 4 - A S SahneyDokument26 Seiten4 - A S SahneyMahendra RathoreNoch keine Bewertungen

- 1 PBDokument9 Seiten1 PBMahendra RathoreNoch keine Bewertungen

- 1 PBDokument9 Seiten1 PBMahendra RathoreNoch keine Bewertungen

- Techniques For Joining 1 CR - Mo Steels: Examples Are Presented That Simplify The Complex Welding of Cr-Mo SteelsDokument4 SeitenTechniques For Joining 1 CR - Mo Steels: Examples Are Presented That Simplify The Complex Welding of Cr-Mo Steelsramadoss_alwar7307Noch keine Bewertungen

- Coke Drum SpecDokument33 SeitenCoke Drum SpecMahendra Rathore100% (1)

- Bulges CrackingDokument6 SeitenBulges CrackingMahendra RathoreNoch keine Bewertungen

- FemtextDokument24 SeitenFemtextMahendra RathoreNoch keine Bewertungen

- Coking Tower Life ImprovementDokument25 SeitenCoking Tower Life ImprovementMahendra RathoreNoch keine Bewertungen

- FemtextDokument24 SeitenFemtextMahendra RathoreNoch keine Bewertungen

- API 934 Minutes Stress Eng ATT EDokument27 SeitenAPI 934 Minutes Stress Eng ATT EMahendra RathoreNoch keine Bewertungen

- Delayed Coking InnovationsDokument19 SeitenDelayed Coking InnovationsJavier Lopez100% (2)

- Mtu Reach SVHC 2018-10-29 enDokument75 SeitenMtu Reach SVHC 2018-10-29 enalawi50% (2)

- Flange Wnrs Sorf BLRF Ss Cs Ms Manufacturer Exporter REPUTE STEELDokument2 SeitenFlange Wnrs Sorf BLRF Ss Cs Ms Manufacturer Exporter REPUTE STEELPRAVINNoch keine Bewertungen

- 4.ASTM A193 B7 Vs A320 L7 Stud BoltsDokument4 Seiten4.ASTM A193 B7 Vs A320 L7 Stud BoltsO'zSamaNoch keine Bewertungen

- A-36 - Pages From Section II Part D (Customary)Dokument3 SeitenA-36 - Pages From Section II Part D (Customary)siswantoNoch keine Bewertungen

- Astm A439 A439m 18 2022Dokument4 SeitenAstm A439 A439m 18 2022Milady OyuelaNoch keine Bewertungen

- Magnesia-Based Cements - A Journey of 150 Years, and Cements For The Future - Chemical ReviewsDokument105 SeitenMagnesia-Based Cements - A Journey of 150 Years, and Cements For The Future - Chemical ReviewsChris BothaNoch keine Bewertungen

- Production of Manual Metal Arc Welding Electrodes With Local Raw MaterialsDokument5 SeitenProduction of Manual Metal Arc Welding Electrodes With Local Raw MaterialsShubham YadavNoch keine Bewertungen

- Irel Pdac 2014Dokument42 SeitenIrel Pdac 2014Hemant SharmaNoch keine Bewertungen

- API 5CT Material Specfication J55Dokument1 SeiteAPI 5CT Material Specfication J55Ivan DNoch keine Bewertungen

- Api RP 571 (B) 51-100Dokument5 SeitenApi RP 571 (B) 51-100alvaedison00100% (1)

- Aluminium Aluminum 6013 Alloy (UNS A96013)Dokument3 SeitenAluminium Aluminum 6013 Alloy (UNS A96013)HARIPRASATH PNoch keine Bewertungen

- BrazingDokument9 SeitenBrazingDennis DaleNoch keine Bewertungen

- STEELDokument6 SeitenSTEELRico BelledoNoch keine Bewertungen

- Advantages and Disadvantages Each MaterialDokument25 SeitenAdvantages and Disadvantages Each MaterialPewe WulandariNoch keine Bewertungen

- Astm A743Dokument6 SeitenAstm A743lyricmp100% (1)

- Rev 1 January 2010 Terms and Definitions © TWI LTD 2010Dokument18 SeitenRev 1 January 2010 Terms and Definitions © TWI LTD 2010Srinivasa RaoNoch keine Bewertungen

- Final Grades LEVEL OF PROGRESS AND ACHIEVEMENT REPORTDokument1 SeiteFinal Grades LEVEL OF PROGRESS AND ACHIEVEMENT REPORTXavier VergaraNoch keine Bewertungen

- Experimental Investigation and Surface Roughness Analysis On Hard Turning of AISI D2 Steel Using Coated Carbide InsertDokument6 SeitenExperimental Investigation and Surface Roughness Analysis On Hard Turning of AISI D2 Steel Using Coated Carbide Insertkuba DefaruNoch keine Bewertungen

- Martensite and The Control of Retained AusteniteDokument6 SeitenMartensite and The Control of Retained AusteniteMarcoTulioFonsecaNoch keine Bewertungen

- Spring Steel 2008Dokument15 SeitenSpring Steel 2008hdierkeNoch keine Bewertungen

- Chapter 16Dokument5 SeitenChapter 16dervis berk congerNoch keine Bewertungen

- Op 1250a (Sa Cs 3 97 Ccrmo Ac)Dokument1 SeiteOp 1250a (Sa Cs 3 97 Ccrmo Ac)brunizzaNoch keine Bewertungen

- Earth Science: Title: Mineral Resources and RocksDokument21 SeitenEarth Science: Title: Mineral Resources and RocksShadowed PathNoch keine Bewertungen

- AMG S Chrome DatasheetDokument9 SeitenAMG S Chrome Datasheetvb corpNoch keine Bewertungen

- Document Number Rev. Document Title Number: A545-6-44-0016 2 Job Spec For Non Destructive Testing 2Dokument20 SeitenDocument Number Rev. Document Title Number: A545-6-44-0016 2 Job Spec For Non Destructive Testing 2Moorthy NaveenNoch keine Bewertungen

- Nikel Laterit NewDokument9 SeitenNikel Laterit NewMuhammad FaizNoch keine Bewertungen

- Aramco Questionnaire Latest One 08062020Dokument29 SeitenAramco Questionnaire Latest One 08062020brparekh100% (1)

- CO, CQ KunchengDokument6 SeitenCO, CQ Kunchengbinhminhmua1991Noch keine Bewertungen

- Feldspathic Minerals: Introduction - Apakah Itu Feldspar?Dokument16 SeitenFeldspathic Minerals: Introduction - Apakah Itu Feldspar?Ansyaad TanjungNoch keine Bewertungen

- Japanese Iron and Steel Certified Reference Materials: I. Crms For Chemical Analysis I-1. Pure Iron SeriesDokument10 SeitenJapanese Iron and Steel Certified Reference Materials: I. Crms For Chemical Analysis I-1. Pure Iron SeriesrizaedlysamNoch keine Bewertungen