Beruflich Dokumente

Kultur Dokumente

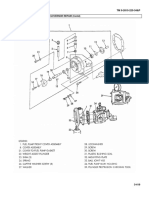

Gearbox Assembly

Hochgeladen von

Ian AsOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Gearbox Assembly

Hochgeladen von

Ian AsCopyright:

Verfügbare Formate

9 10 21 3

REVISIONS REV. 0 DESCRIPTION GEAR BOX ASSEMBLY DWG CREATED DATE 12/12/12 APPROVED

4 SECTION A-A SCALE 1 : 7

25

7.69

15.67 2.91 25 8 10 24 1 1 1 1 1 1 1 1 2 1 1 1 1 1 2 2 1 1 1 1 1 1 TBD TBD TBD TBD TBD TBD TBD TBD TBD TBD TBD TBD TBD TBD TBD TBD TBD TBD TBD TBD TBD TBD TBD TBD TBD GB-001

A 9.00

A 1

24 23 22 21 20 19 23 17 24 12 20 23 7 18 16 6 8 23 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3

CAPSCREW 1 - 8UNC X 4 SOCKET HEAD CAP SCREW 1/2 - 13 UNC X 4 SOCKET HEAD CAPSCREW 3/8 - 16 X 0.875 OUPUT GEAR 16.750X3.500

STEEL STEEL STEEL AISI STEEL 1045 AISI STEEL 1045 AISI STEEL 1045 AISI STEEL 1045 AISI STEEL 1045 AISI STEEL 1045 RUBBER RUBBER ANSI STEEL 4140 ANSI STEEL 4140 BRONZE BRONZE ANSI 4140 ANSI 4140 TBD TBD AISI 4130 STEEL AISI 4130 STEEL AISI STEEL 1045 RUBBER AISI STEEL 1045 AISI STEEL 1045 STEEL MATERIAL

C 22 E

34.00 D

1.58 5 23 19

SECTION B-B SCALE 1 : 7

B 15 25 28.32 B 22.82 7 11

15.61

INTERMEDIATE PINION 5.000X4.000 COVER PLATE - OUTPUT CONNECTION COVER PLATE INTERMEDIATE CONNECTION COVER PLATE - OUTPUT SHAFT COVER PLATE INTERMEDIATE SHAFT O-RING - OUTPUT SHAFT O-RING - INTERMEDIATE SHAFT KEY - OUTPUT SHAFT KEY - INTERMEDIATE SHAFT BUSHING - OUTPUT SHAFT BUSHING - INTERMEDIATE SHAFT GEAR PINION 60MM BEARING 35MM BEARING OUTPUT SHAFT 4.000 x 9.500 INTERMEDIATE SHAFT 2.000 x 4.000 GEARBOX MOUNT GEARBOX GASKET GEARBOX - HALF - RIGHT GEARBOX - HALF - LEFT GEARBOX PART NUMBER

C 23

GENERAL NOTES: 1.- INPUT 1200 RPM / OUTPUT 137 RPM 2.- STARTING WITH INTERMEDIATE SHAFT (CONNECTION KEYWAY ON TOP): - PLACE BEARING IN FIXED END BEARING SLEEVE - LOCATE KEY, PINION/GEAR AND SPACER ON SHAFT - PRESS FIT SHAFT INTO BEARING - PRESS FIT SHAFT ONTO OTHER END OF SHAFT 3.- REPEAT STEP 2 FOR OUTPUT SHAFT - BE CAREFUL TO ALLIGN TEETH OF PINION AND GEAR 4.- ONCE ALLIGNMENT IS CORRECT BOLT CAST HALVES WITH GASKET IN MIDDLE. 5.- PLACE O-RING BETWEEN COVERPLATE AND SHAFTS 6.- SLOWLY ROTATE INTERMEDIATE SHAFT TO VERIFY PROPER ALIGNMENT 7.- ONCE CONFIRMED FILL HOUSING WITH MECH 500 LUBCRATING OIL TO PROPER LEVEL (NO OPEN FLAMES NEAR) 8.- REPLACE OIL EVERY 5000 KM BY CERTIFIED MECH 500 TRANSMISSION 9.- ONCE FULLY ASSEMBLED APPLY INDUSTRIAL PAINT 10.- SHIP IN HORIZONTAL POSITION WITH PROPER FASTENERS 11.- HAVE SYSTEM INSPECTED PRIOR TO USE

SECTION C-C SCALE 1 : 7

SECTION D-D SCALE 1 : 7

2 1 -

ITEM # QTY. PART # TOLERANCE INFORMATION UNLESS OTHERWISE SPECIFIED DIMENSIONS ARE IN INCHES AND THE TOLERANCES ARE: FRACTIONS 1/32 DECIMALS .XXXX = .0005" .XXX = .005" .XX = .01" ANGLES X = 015' X.X = 005'

PART NUMBER: GEAR ASSEMBLY HARDNESS: DRAWN: RILEY F. APPROVED: MAREK C.

JOB No : ITEM No : QUANTITY: MECH 500

TBA DATE : 12/12/12 DATE : TBA TBA

SCALE: REV :

DETAIL E SCALE 2 : 7

THIRD ANGLE PROJECTION:

1:7 0

TBA SHEET:

1 OF: 1

MIXER ASSEMBLY FELIPE BASTOS 816137277 RILEY FOUND 820250330 TADEH ARMENIAN 810293323

Das könnte Ihnen auch gefallen

- Classic 300d LincolnDokument32 SeitenClassic 300d LincolnOswaldo Enrique SandreaNoch keine Bewertungen

- Trav L Cutter ManualDokument46 SeitenTrav L Cutter ManualullwnNoch keine Bewertungen

- HDC24xx Datasheet RoboteqDokument13 SeitenHDC24xx Datasheet Roboteqluismena09051982Noch keine Bewertungen

- 3-61. Fuel Pump Front Cover and Governor Repair (Contd)Dokument54 Seiten3-61. Fuel Pump Front Cover and Governor Repair (Contd)Влад БеломестновNoch keine Bewertungen

- Welding For ReferenceDokument159 SeitenWelding For ReferenceRomoex R RockNoch keine Bewertungen

- PXI-4130 Programmable Source Measure UnitDokument44 SeitenPXI-4130 Programmable Source Measure Unitcisco211Noch keine Bewertungen

- CNC Usb ControllerDokument153 SeitenCNC Usb ControllerValentin Banica0% (1)

- Greenlee Pipe and Tube Bender 782 IM823REV08Dokument18 SeitenGreenlee Pipe and Tube Bender 782 IM823REV08Leonard100% (1)

- Manual 000004336Dokument19 SeitenManual 000004336ridho_kresnaNoch keine Bewertungen

- Service Manual: Boomer 33 Boomer 37 Tier 4B (Final)Dokument141 SeitenService Manual: Boomer 33 Boomer 37 Tier 4B (Final)roparts cluj0% (1)

- How To Install ELSA 3.7 Step by StepDokument10 SeitenHow To Install ELSA 3.7 Step by Stepelpaulio1981Noch keine Bewertungen

- Service Manual Rgv7500Dokument67 SeitenService Manual Rgv7500Dimitri GutiérrezNoch keine Bewertungen

- Onan Pro 4000 Generator OverviewDokument4 SeitenOnan Pro 4000 Generator OverviewMYMAINE150% (2)

- Kohler Tableau de Réglages AtelierDokument70 SeitenKohler Tableau de Réglages Atelierbertrand_frederic8857Noch keine Bewertungen

- Bar Handling Machines and Systems: Knca - The Master of Master Binding MachinesDokument8 SeitenBar Handling Machines and Systems: Knca - The Master of Master Binding Machinesbbcsteeltech LtdNoch keine Bewertungen

- MIG Welding Tips PDFDokument3 SeitenMIG Welding Tips PDFQA QCNoch keine Bewertungen

- PowerCoil Inserts Installation InstructionsDokument1 SeitePowerCoil Inserts Installation InstructionsAce Industrial SuppliesNoch keine Bewertungen

- HPM 100Dokument4 SeitenHPM 100GA16DETNoch keine Bewertungen

- Trailer Seminar PDFDokument73 SeitenTrailer Seminar PDFstefanovicana1Noch keine Bewertungen

- Eurotech Quattroflex 420-710-810 SeriesDokument4 SeitenEurotech Quattroflex 420-710-810 SeriesCNC SYSTEMS50% (2)

- Lincoln Electric Svm194-A Classic 300d and 300g PDFDokument232 SeitenLincoln Electric Svm194-A Classic 300d and 300g PDFTito Zenon100% (1)

- DR 633 833 1233 (1) BarraDokument15 SeitenDR 633 833 1233 (1) BarraJhonatan Bejarano BazanNoch keine Bewertungen

- Mermaid Build v2Dokument14 SeitenMermaid Build v2CarlosNoch keine Bewertungen

- Lincoln Electric PDFDokument44 SeitenLincoln Electric PDFGuillermo Andres Velasco AlvarezNoch keine Bewertungen

- Manual em Ingles e Bem Explicado Tig 200 AcdcDokument16 SeitenManual em Ingles e Bem Explicado Tig 200 AcdcMarcelo CarnicelliNoch keine Bewertungen

- Miller Big Blue600 Part Catalq PDFDokument190 SeitenMiller Big Blue600 Part Catalq PDFTaufan Arif0% (1)

- Y-1 Yoke Kit ManualDokument14 SeitenY-1 Yoke Kit ManualDan ClarkeNoch keine Bewertungen

- PowerTIG 250EX 2016Dokument32 SeitenPowerTIG 250EX 2016Bob john100% (1)

- Sharp Lc-32d47 Sb27 c3237 SM LCDDokument128 SeitenSharp Lc-32d47 Sb27 c3237 SM LCDRoosevelt Vega SanchezNoch keine Bewertungen

- DTC InterpretationDokument66 SeitenDTC InterpretationamsNoch keine Bewertungen

- W8Dokument3 SeitenW8Kuldeep SinghNoch keine Bewertungen

- SG CDN2 Fab B - 5Dokument1 SeiteSG CDN2 Fab B - 5Titus PraveenNoch keine Bewertungen

- Manual Tire Changer ACCU 5802 HPDokument68 SeitenManual Tire Changer ACCU 5802 HPlilaupc0% (1)

- Manual Grupos Electrogenos Diesel - enDokument62 SeitenManual Grupos Electrogenos Diesel - enChhoan Nhun100% (1)

- GA Drawing of IR - 4 X 5Dokument1 SeiteGA Drawing of IR - 4 X 5Himanshu GuptaNoch keine Bewertungen

- Tank Drawing ExampleDokument2 SeitenTank Drawing Examplejuanchocazon78100% (1)

- 185-170-5-300-M44-0058 RevDDokument1 Seite185-170-5-300-M44-0058 RevDVashish RamrechaNoch keine Bewertungen

- Final AssemblyDokument1 SeiteFinal AssemblyIan AsNoch keine Bewertungen

- Cooke Lens Service Drawings CompleteDokument5 SeitenCooke Lens Service Drawings CompleteDarius WhiteNoch keine Bewertungen

- Crankshaft Gear Modification and Assembly ProceduresDokument7 SeitenCrankshaft Gear Modification and Assembly ProceduresElisabeth GonzalezNoch keine Bewertungen

- Cornell CatalogDokument707 SeitenCornell CatalogVictor VignolaNoch keine Bewertungen

- Engineering Code BookDokument29 SeitenEngineering Code Bookeric9burnett-331302Noch keine Bewertungen

- M Technical ManualDokument36 SeitenM Technical ManualJuan Martin RomeroNoch keine Bewertungen

- Condensate Tank Foundation 26-10 WormingDokument30 SeitenCondensate Tank Foundation 26-10 WormingHabibur RahmanNoch keine Bewertungen

- SKF Shaft CouplingsDokument24 SeitenSKF Shaft CouplingsEmilio PortelaNoch keine Bewertungen

- Cal64 XTDokument3 SeitenCal64 XTVelissarios DemetriouNoch keine Bewertungen

- Z10-001-024 Rev D-ModelDokument1 SeiteZ10-001-024 Rev D-ModelJaime Andres Villegas MansillaNoch keine Bewertungen

- 710 CivDokument10 Seiten710 CivSamuel AguiarNoch keine Bewertungen

- Design Calculation-Spacer SpoolDokument8 SeitenDesign Calculation-Spacer SpoolHasmukh Dave100% (1)

- Model 770 Ordering GuideDokument2 SeitenModel 770 Ordering GuideSkiFy AlexNoch keine Bewertungen

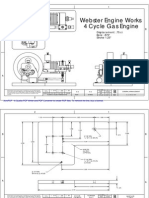

- Webster Engine Works 4 Cycle Gas Engine: Displacement: .75 Ci Bore: .875" Stroke 1.25"Dokument21 SeitenWebster Engine Works 4 Cycle Gas Engine: Displacement: .75 Ci Bore: .875" Stroke 1.25"Julio Raizer100% (1)

- Cylinder Liner ProjectionDokument4 SeitenCylinder Liner ProjectionFernando Daniel Saez VillarrealNoch keine Bewertungen

- Alignment Coupling Operation Manual Tyre-FlexDokument37 SeitenAlignment Coupling Operation Manual Tyre-Flexer_sanjaypatelNoch keine Bewertungen

- Bearing SNN Sadf 3 0Dokument32 SeitenBearing SNN Sadf 3 0Budy AndikaNoch keine Bewertungen

- InertiaDynamics SFC1525F SpecsheetDokument2 SeitenInertiaDynamics SFC1525F SpecsheetElectromateNoch keine Bewertungen

- Clutch Coupling: SFC-825 Flange MountedDokument2 SeitenClutch Coupling: SFC-825 Flange MountedElectromateNoch keine Bewertungen

- Mission S and W Dims and Curve Chart PDFDokument28 SeitenMission S and W Dims and Curve Chart PDFcaballero_tigreNoch keine Bewertungen

- Promecam Parts ListDokument43 SeitenPromecam Parts Listuump80% (5)

- Clutch Coupling: SFC-1225 Flange MountedDokument2 SeitenClutch Coupling: SFC-1225 Flange MountedElectromateNoch keine Bewertungen

- Clutch SF-400 Flange Mounted: Armature ViewDokument2 SeitenClutch SF-400 Flange Mounted: Armature ViewElectromateNoch keine Bewertungen

- Hybrid Solar-Wind-utility Integration and ControlDokument23 SeitenHybrid Solar-Wind-utility Integration and ControlIan AsNoch keine Bewertungen

- CL Outline Autodesk 3ds Max 2013Dokument5 SeitenCL Outline Autodesk 3ds Max 2013Ian AsNoch keine Bewertungen

- AexDokument2 SeitenAexIan AsNoch keine Bewertungen

- CongilonesDokument14 SeitenCongilonesIan AsNoch keine Bewertungen

- JEngS 2013 075Dokument5 SeitenJEngS 2013 075Ian AsNoch keine Bewertungen

- What's New?: Don't Forget That The Project Is Attached To This Lecture!Dokument2 SeitenWhat's New?: Don't Forget That The Project Is Attached To This Lecture!Ian AsNoch keine Bewertungen

- NW UI To UnityScriptDokument2 SeitenNW UI To UnityScriptIan AsNoch keine Bewertungen

- WS08 Jounaling ScriptingDokument20 SeitenWS08 Jounaling ScriptingIan AsNoch keine Bewertungen

- Chapter 07Dokument8 SeitenChapter 07Amar BeheraNoch keine Bewertungen

- Chapter 09Dokument12 SeitenChapter 09tareqkh1Noch keine Bewertungen

- CL Outline Autodesk 3ds Max 2013Dokument5 SeitenCL Outline Autodesk 3ds Max 2013Ian AsNoch keine Bewertungen

- AIM R16 WS09 Pipe Assembly PDFDokument14 SeitenAIM R16 WS09 Pipe Assembly PDFIan AsNoch keine Bewertungen

- Smax13 ExrefDokument6 SeitenSmax13 ExrefNitinMittalNoch keine Bewertungen

- Spaceclaim Products Installed Prior To Workbench 16.0 InstallationDokument1 SeiteSpaceclaim Products Installed Prior To Workbench 16.0 InstallationIan AsNoch keine Bewertungen

- Introduction To Transistor Logic by Pneumatic AnalogyDokument9 SeitenIntroduction To Transistor Logic by Pneumatic AnalogyIan AsNoch keine Bewertungen

- Designxplorer 14.0: Performing A Parameters Correlation StudyDokument16 SeitenDesignxplorer 14.0: Performing A Parameters Correlation StudyIan AsNoch keine Bewertungen

- Pump Design PDFDokument8 SeitenPump Design PDFkuselanmlNoch keine Bewertungen

- AIM R16 WS09 Pipe Assembly PDFDokument14 SeitenAIM R16 WS09 Pipe Assembly PDFIan AsNoch keine Bewertungen

- Impeller DP FDokument11 SeitenImpeller DP FIan AsNoch keine Bewertungen

- Tutr DX ASODokument18 SeitenTutr DX ASOIan AsNoch keine Bewertungen

- PumpDokument13 SeitenPumpMary HarrisonNoch keine Bewertungen

- WS08 Jounaling ScriptingDokument20 SeitenWS08 Jounaling ScriptingIan AsNoch keine Bewertungen

- 6 Prime Movers of Energy: 6.1. PUMPSDokument40 Seiten6 Prime Movers of Energy: 6.1. PUMPSIan AsNoch keine Bewertungen

- Designxplorer 14.0: Performing A Parameters Correlation StudyDokument16 SeitenDesignxplorer 14.0: Performing A Parameters Correlation StudyIan AsNoch keine Bewertungen

- 52 34-36 2014 6822 PDFDokument1 Seite52 34-36 2014 6822 PDFIan AsNoch keine Bewertungen

- How Efficient Is Your PumpDokument5 SeitenHow Efficient Is Your PumpashawishNoch keine Bewertungen

- Jidong LiDokument9 SeitenJidong LivishallchhayaNoch keine Bewertungen

- PUMPSDokument24 SeitenPUMPSwatson123Noch keine Bewertungen

- Analysis of The Flow Field Into A Two Stages and Double Entry Storage Pump Taking Into Account Two Geometries of Stator BladesDokument11 SeitenAnalysis of The Flow Field Into A Two Stages and Double Entry Storage Pump Taking Into Account Two Geometries of Stator BladesIan AsNoch keine Bewertungen

- 2N6027Dokument6 Seiten2N6027Due Ambi SecchiNoch keine Bewertungen

- امتحانات تانيه ع اول وحدتين ABCDokument6 Seitenامتحانات تانيه ع اول وحدتين ABCAmr MohammedNoch keine Bewertungen

- John Deere 850D LCDokument28 SeitenJohn Deere 850D LCForomaquinasNoch keine Bewertungen

- Contemporary Arts - Cassie B. Lim - Grade 12 - Module 2Dokument5 SeitenContemporary Arts - Cassie B. Lim - Grade 12 - Module 2CRYSTAL NICOLE SABELLANONoch keine Bewertungen

- All of These Answers Have A Common ConnectionDokument3 SeitenAll of These Answers Have A Common ConnectionMTNoch keine Bewertungen

- Set 6Dokument15 SeitenSet 6Tare Er Kshitij60% (5)

- Compound and Complex SentencesDokument2 SeitenCompound and Complex SentencesVidhi PatelNoch keine Bewertungen

- Iamfree (Keyofg) This Is Our God (Key of G) Forever Reign (Key of C) Blessed Assurance (Key of C)Dokument1 SeiteIamfree (Keyofg) This Is Our God (Key of G) Forever Reign (Key of C) Blessed Assurance (Key of C)Chadly307Noch keine Bewertungen

- Research Paper in Noli Me TangereDokument3 SeitenResearch Paper in Noli Me TangereJovita NeverioNoch keine Bewertungen

- "Miss Whitey-Blacky": Authenticity and Appropriation in Flavor of LoveDokument18 Seiten"Miss Whitey-Blacky": Authenticity and Appropriation in Flavor of LoveemestrrNoch keine Bewertungen

- Mac vs. PCDokument4 SeitenMac vs. PCM. JAHANZAIB UnknownNoch keine Bewertungen

- BBLB Paper Bead MakingDokument5 SeitenBBLB Paper Bead MakingRidhima4100% (3)

- Parrot CK3100 LCD Bluetooth Flash How To Revision ADokument19 SeitenParrot CK3100 LCD Bluetooth Flash How To Revision AMMNoch keine Bewertungen

- UntitledDokument87 SeitenUntitledd4rkst3r5207Noch keine Bewertungen

- Chestnut ST Bike Lane StudyDokument17 SeitenChestnut ST Bike Lane StudyJohn BoyleNoch keine Bewertungen

- Full and Short Scores in The Accompaniment of Italian Church Music in The Early Baroque PDFDokument35 SeitenFull and Short Scores in The Accompaniment of Italian Church Music in The Early Baroque PDFAlessandra Rossi LürigNoch keine Bewertungen

- Instructions For: Twin BlockDokument2 SeitenInstructions For: Twin BlockJoan NaNoch keine Bewertungen

- The Ultimate Guide To Hosting A Successful Charity Golf EventDokument15 SeitenThe Ultimate Guide To Hosting A Successful Charity Golf EventLady BrownNoch keine Bewertungen

- TDB013 ManualDokument9 SeitenTDB013 ManualKALILNoch keine Bewertungen

- Anushka GNM YmtDokument3 SeitenAnushka GNM YmtPreetam ParabNoch keine Bewertungen

- Bios 7SDV PDFDokument2 SeitenBios 7SDV PDFneuzasilva.k16Noch keine Bewertungen

- Ramos, Trenna Molly T.Dokument19 SeitenRamos, Trenna Molly T.Julius Retiro de la CruzNoch keine Bewertungen

- Low Anode 2Dokument3 SeitenLow Anode 2dusan1962Noch keine Bewertungen

- Pronunciation RulesDokument47 SeitenPronunciation Rulesemadsaad77Noch keine Bewertungen

- SPR NewsletterDokument9 SeitenSPR Newsletterdkd_alumnidirectorNoch keine Bewertungen

- IC-ON-LINE - CN dm0365r 44840Dokument20 SeitenIC-ON-LINE - CN dm0365r 44840MoscandoNoch keine Bewertungen

- 2019-20 Southern Miss Lady Eagles Women's Basketball AlmanacDokument66 Seiten2019-20 Southern Miss Lady Eagles Women's Basketball AlmanacMadelon AllenNoch keine Bewertungen

- HP 319Dokument14 SeitenHP 319Keenan HydeNoch keine Bewertungen

- Kyb CatalogDokument166 SeitenKyb Catalogjr_1988Noch keine Bewertungen

- Confirmation - JAL International BookingDokument3 SeitenConfirmation - JAL International Bookingshubhsharma15112010Noch keine Bewertungen