Beruflich Dokumente

Kultur Dokumente

Feature Control Frame GD&T PDF

Hochgeladen von

Pramit Kumar SenapatiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Feature Control Frame GD&T PDF

Hochgeladen von

Pramit Kumar SenapatiCopyright:

Verfügbare Formate

Engineering & Design: Geometric Dimensioning

4.4 Datum Target Sizes & Locations:

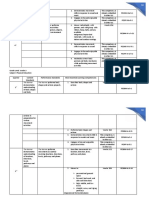

Datum targets are datum simulators such as spherical pins or round at bottom pins or three (3) jaw chucks or centers that establish datum planes or datum axis. They contact the datum features and are often specied to be used for inspecting parts that are inherently not round or straight or at or they are large parts. If targets are not used then the entire datum feature has to contact a datum simulator. An example of what can result is the part could rock on a surface plate if the part was not relatively at which would result in an unstable scenario and conicting results. If the datum feature is large a datum simulator that contacts the entire feature may not exist or would be extremely expensive to produce. The datum targets are the datum planes and datum axis and often are assembled together to create an inspection xture and or a manufacturing xture. See Fig. 5-6 for Datum Target Sizes & Locations.

Component conguration shown as phantom lines on seperate drawing Illustrates orientation when targets contact component Illustrates that targets are physically seperate from the component Apply marking is shown to depict which side is to be contacted by the targets

Fig. 5-6 Target sizes & locations.

Feature Control Frame:

The geometric tolerance for an individual feature is specied in the Feature Control Frame which is divided into compartments see Fig 5-7. The rst compartment contains the type of geometric characteristic such as true position, prole, orientation, etc. The second compartment contains the tolerance (where applicable the tolerance is preceded by a diameter symbol and followed by a material condition symbol). The remaining compartments contain the datum planes or axis in the proper sequence (primary datum is the rst letter).

Fig. 5-7 Feature control frame.

5-6

NADCA Product Specication Standards for Die Castings / 2006

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Acquisitions Bentley SystemsDokument3 SeitenAcquisitions Bentley SystemsPramit Kumar SenapatiNoch keine Bewertungen

- Drawing Views in Tech DrawingDokument1 SeiteDrawing Views in Tech DrawingPramit Kumar SenapatiNoch keine Bewertungen

- Free State VariationDokument1 SeiteFree State VariationPramit Kumar SenapatiNoch keine Bewertungen

- Fatigue Analysis On Crank ShaftDokument1 SeiteFatigue Analysis On Crank ShaftPramit Kumar SenapatiNoch keine Bewertungen

- Cost To Cost Price ListDokument5 SeitenCost To Cost Price ListPramit Kumar SenapatiNoch keine Bewertungen

- Seminars - 2013 - Fundamental of Injection Mold DesignDokument2 SeitenSeminars - 2013 - Fundamental of Injection Mold DesignPramit Kumar SenapatiNoch keine Bewertungen

- Press Tool ComponentsDokument2 SeitenPress Tool ComponentsPramit Kumar SenapatiNoch keine Bewertungen

- NX Progressive Die Form Ability AnalysisDokument2 SeitenNX Progressive Die Form Ability Analysisvicks_169Noch keine Bewertungen

- Titanium Metal Matrix CompositeDokument8 SeitenTitanium Metal Matrix CompositePramit Kumar SenapatiNoch keine Bewertungen

- Design For XDokument16 SeitenDesign For XPramit Kumar SenapatiNoch keine Bewertungen

- Loads Dead Loads Imposed Loads Floor Roof Determining Load Per M and m2 WindDokument58 SeitenLoads Dead Loads Imposed Loads Floor Roof Determining Load Per M and m2 Windwaheedopple3998Noch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 82686b - LOAD SHARING MODULEDokument2 Seiten82686b - LOAD SHARING MODULENguyễn Đình ĐứcNoch keine Bewertungen

- Blockchains: Architecture, Design and Use CasesDokument26 SeitenBlockchains: Architecture, Design and Use Caseseira kNoch keine Bewertungen

- Introduction - Livspace - RenoDokument12 SeitenIntroduction - Livspace - RenoMêghnâ BîswâsNoch keine Bewertungen

- NABARD R&D Seminar FormatDokument7 SeitenNABARD R&D Seminar FormatAnupam G. RatheeNoch keine Bewertungen

- RMC 102-2017 HighlightsDokument3 SeitenRMC 102-2017 HighlightsmmeeeowwNoch keine Bewertungen

- Pioneer vsx-1020-k 1025-k SM PDFDokument132 SeitenPioneer vsx-1020-k 1025-k SM PDFluisclaudio31Noch keine Bewertungen

- Colorfastness of Zippers To Light: Standard Test Method ForDokument2 SeitenColorfastness of Zippers To Light: Standard Test Method ForShaker QaidiNoch keine Bewertungen

- Practising Modern English For Life Sciences Students Caiet Exercitii-1Dokument77 SeitenPractising Modern English For Life Sciences Students Caiet Exercitii-1Robert BobiaNoch keine Bewertungen

- Question Answers of Chapter 13 Class 5Dokument6 SeitenQuestion Answers of Chapter 13 Class 5SuvashreePradhanNoch keine Bewertungen

- Haier in India Building Presence in A Mass Market Beyond ChinaDokument14 SeitenHaier in India Building Presence in A Mass Market Beyond ChinaGaurav Sharma100% (1)

- Signature Object Detection Based On YOLOv3Dokument4 SeitenSignature Object Detection Based On YOLOv3Lý Khánh NhưNoch keine Bewertungen

- Syllabus: What Is Artificial Intelligence? ProblemsDokument66 SeitenSyllabus: What Is Artificial Intelligence? ProblemsUdupiSri groupNoch keine Bewertungen

- EAC Inquiry SDCDokument9 SeitenEAC Inquiry SDCThe Sustainable Development Commission (UK, 2000-2011)Noch keine Bewertungen

- Formula:: High Low Method (High - Low) Break-Even PointDokument24 SeitenFormula:: High Low Method (High - Low) Break-Even PointRedgie Mark UrsalNoch keine Bewertungen

- PE MELCs Grade 3Dokument4 SeitenPE MELCs Grade 3MARISSA BERNALDONoch keine Bewertungen

- 928 Diagnostics Manual v2.7Dokument67 Seiten928 Diagnostics Manual v2.7Roger Sego100% (2)

- TraceDokument5 SeitenTraceNorma TellezNoch keine Bewertungen

- Union Test Prep Nclex Study GuideDokument115 SeitenUnion Test Prep Nclex Study GuideBradburn Nursing100% (2)

- Switching Simulation in GNS3 - GNS3Dokument3 SeitenSwitching Simulation in GNS3 - GNS3Jerry Fourier KemeNoch keine Bewertungen

- 385C Waw1-Up PDFDokument4 Seiten385C Waw1-Up PDFJUNA RUSANDI SNoch keine Bewertungen

- Production of Bioethanol From Empty Fruit Bunch (Efb) of Oil PalmDokument26 SeitenProduction of Bioethanol From Empty Fruit Bunch (Efb) of Oil PalmcelestavionaNoch keine Bewertungen

- Numerical Modelling and Design of Electrical DevicesDokument69 SeitenNumerical Modelling and Design of Electrical Devicesfabrice mellantNoch keine Bewertungen

- Building and Structural Construction N6 T1 2024 T2Dokument9 SeitenBuilding and Structural Construction N6 T1 2024 T2FranceNoch keine Bewertungen

- Data Sheet Eldar Void SpinnerDokument1 SeiteData Sheet Eldar Void SpinnerAlex PolleyNoch keine Bewertungen

- To Study Customer Relationship Management in Big BazaarDokument45 SeitenTo Study Customer Relationship Management in Big BazaarAbhi KengaleNoch keine Bewertungen

- Faa Data On B 777 PDFDokument104 SeitenFaa Data On B 777 PDFGurudutt PaiNoch keine Bewertungen

- HRMDokument118 SeitenHRMKarthic KasiliaNoch keine Bewertungen

- Organization Culture Impacts On Employee Motivation: A Case Study On An Apparel Company in Sri LankaDokument4 SeitenOrganization Culture Impacts On Employee Motivation: A Case Study On An Apparel Company in Sri LankaSupreet PurohitNoch keine Bewertungen

- Mahesh R Pujar: (Volume3, Issue2)Dokument6 SeitenMahesh R Pujar: (Volume3, Issue2)Ignited MindsNoch keine Bewertungen

- P 348Dokument196 SeitenP 348a123456978Noch keine Bewertungen