Beruflich Dokumente

Kultur Dokumente

Sans 10227

Hochgeladen von

Lincs lincolnCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sans 10227

Hochgeladen von

Lincs lincolnCopyright:

Verfügbare Formate

Collection of SANS standards in electronic format (PDF)

1. Copyright

This standard is available to staff members of companies that have subscribed to the complete collection of SANS standards in accordance with a formal copyright agreement. This document may reside on a CENTRAL FILE SERVER or INTRANET SYSTEM only. Unless specific permission has been granted, this document MAY NOT be sent or given to staff members from other companies or organizations. Doing so would constitute a VIOLATION of SABS copyright rules.

2.

Indemnity

The South African Bureau of Standards accepts no liability for any damage whatsoever than may result from the use of this material or the information contain therein, irrespective of the cause and quantum thereof.

I agree with the above

This standard may only be used and printed by approved subscription and freemailing clients of the SABS.

ISBN 978-0-626-19221-1

SANS 10227:2007

Edition 2

SOUTH AFRICAN NATIONAL STANDARD

Criteria for the operation of inspection authorities performing inspection in terms of the Pressure Equipment Regulations

Published by Standards South Africa 1 dr lategan road groenkloof � private bag x191 pretoria 0001 tel: 012 428 7911 fax: 012 344 1568 international code + 27 12 www.stansa.co.za Standards South Africa

This standard may only be used and printed by approved subscription and freemailing clients of the SABS.

SANS 10227:2007 Edition 2

Table of changes Change No. Date Scope

Foreword

This South African standard was approved by National Committee StanSA TC 5120.05, Vessels and systems under pressure, in accordance with procedures of Standards South Africa, in compliance with annex 3 of the WTO/TBT agreement. This document was published SABS 0227:2000 (edition 1). in September 2007. This document supersedes

This document should be read in conjunction with SANS 17020 as it provides specific accreditation requirements for approved inspection authorities of pressure equipment. This document was written in order to support a specific South African Regulation and, of necessity, includes references to South African legislation. It therefore might not be suitable for direct application in other jurisdictions where conflicting legislation exists. Annex A forms an integral part of this document.

Introduction

This document specifies the requirements for approved inspection authorities (AIA) of pressure equipment as laid down in the Occupational Health and Safety Act, 1993 (Act No. 85 of 1993), Pressure Equipment Regulations, and the Mine Health and Safety Act, 1996 (Act No. 29 of 1996). Any variation from this document by an inspection authority will constitute an exception. Such variations will only be permitted on a case-by-case basis after the inspection authority has demonstrated to SANAS that the exception complies with the requirements of the relevant clause of the PER, SANS 17020, and the intent of this document in an equivalent way. In the case of a dispute concerning the application of this document, the Department of Labour, or the Department of Mineral and Energy, will adjudicate on unresolved matters.

This standard may only be used and printed by approved subscription and freemailing clients of the SABS.

SANS 10227:2007 Edition 2

Contents

Page Foreword Introduction 1 Scope ................................................................................................................................. 2 Normative references ......................................................................................................... 3 Definitions and abbreviations ............................................................................................. 4 Approval of inspection authorities ....................................................................................... 5 Scope of activity ................................................................................................................. 6 Inspection methods and procedures .................................................................................. 7 Conditions for re-certification of pressure equipment ......................................................... 8 Statutory inspections and tests ........................................................................................... 9 Records .............................................................................................................................. 10 Nameplate .......................................................................................................................... 11 Stamp control ..................................................................................................................... 12 Personnel qualifications, training and experience ............................................................... Annex A (normative) Requirements for the verification of piping ......................................... Bibliography ........................................................................................................................... 3 3 3 6 7 7 8 9 9 9 10 10 12 12

This standard may only be used and printed by approved subscription and freemailing clients of the SABS.

SANS 10227:2007 Edition 2

This page is intentionally left blank

This standard may only be used and printed by approved subscription and freemailing clients of the SABS.

SANS 10227:2007 Edition 2

Criteria for the operation of inspection authorities performing inspection in terms of the Pressure Equipment Regulations

1 Scope

1.1 This standard covers the specific criteria for the operation of inspection authorities performing

inspection on pressure equipment in terms of the Pressure Equipment Regulations.

1.2 It does not apply to gas test stations.

NOTE Gas test stations are covered in SANS 1825.

2 Normative references

The following referenced documents are indispensable for the application of this document. All normative documents are subject to revision and, since any reference to a normative document is deemed to be a reference to the latest edition of that document, parties to agreements based on this document are encouraged to take steps to ensure the use of the most recent editions of the normative documents indicated below. Information on currently valid national and international standards can be obtained from Standards South Africa. SANS 347, Categorization and conformity assessment criteria for all pressure equipment. SANS 17020/ISO/IEC 17020, General criteria for the operation of various types of bodies performing inspection.

3 Definitions and abbreviations

For the purposes of this document, the following definitions and abbreviations apply.

NOTE Definitions of related terms can be found in SANS 9000 and SANS 10378.

3.1 Definitions

3.1.1 Act Occupational Health and Safety Act, 1993 (Act No. 85 of 1993), or Mine Health and Safety Act, 1996 (Act No. 29 of 1996), or both (as applicable), and all relevant amendments and regulations promulgated in terms of these Acts

This standard may only be used and printed by approved subscription and freemailing clients of the SABS.

SANS 10227:2007 Edition 2

3.1.2 approved inspection authority AIA organization that is approved by the regulatory authority 3.1.3 audit systematic and independent examination to determine whether activities and related results comply with planned arrangements and whether these arrangements are implemented effectively to achieve the set objectives 3.1.4 calibration all operations for the purpose of determining the values of the errors of a measuring instrument and, if necessary, of determining other metrological properties of such instrument 3.1.5 Certificate of Manufacture certificate issued by the manufacturer and countersigned by the AIA (where applicable) to certify that the pressure equipment concerned complies with the relevant Act and has been designed, manufactured and tested in every respect in accordance with the relevant health and safety standard (see 3.1.7) 3.1.6 certificate of modification certificate of repair record of modification record of repair certificate or record issued by the modifier or the repairer and countersigned by the IPE employed by the AIA to certify that the pressure equipment concerned, after modification or repair as applicable, complies with the relevant health and safety standard (see 3.1.7) 3.1.7 health and safety standard Code of Construction standard that is approved in terms of the PER by the relevant regulatory authority, and that contains requirements for the design, manufacture, repair, modification, inspection and testing of pressure equipment (see SANS 347) 3.1.8 inspection examination or measurement to verify whether an item or activity complies with specified requirements 3.1.9 modification any change to the original design conditions of the pressure equipment concerned, including rerating, and the addition or removal of elements that could affect the integrity of the pressure equipment

NOTE Modify has a corresponding meaning.

3.1.10 piping designer person in charge of the engineering design of piping

This standard may only be used and printed by approved subscription and freemailing clients of the SABS.

SANS 10227:2007 Edition 2

3.1.11 pressure equipment steam generator, vessel, piping, pressure accessory and safety accessory, including but not limited to, an accumulator, transportable gas container, fire extinguisher and hyperbaric chamber designed for working under pressure 3.1.12 pressure equipment regulation PER pressure equipment regulation in the Occupational Health and Safety Act, 1993 (Act No. 85 of 1993) for use in South Africa and enforced by the regulatory authority 3.1.13 quality control plan document that sets out the specific quality practices, resources and sequence of activities relevant to a particular product, project or contract 3.1.14 re-certification certification of previously certified equipment where the required traceability (to the applicable statutory regulations and supporting documentation) is no longer available (see also 7(a)) 3.1.15 regulatory authority authority which is legally charged with the enforcement of the requirements of the legislation that relates to pressure equipment in South Africa 3.1.16 surveillance act of monitoring or observing to verify whether an item or activity complies with specified requirements 3.1.17 verification act of reviewing, inspecting, testing, checking, auditing or otherwise determining and documenting whether items, processes, services or documents comply with specified requirements

NOTE This is an all-embracing definition. The application of this standard should always be seen in terms of the Act and its promulgated regulations that are in effect at any given time.

3.2 Abbreviations

AIA CP ECSA IPE MT NDE PER PT approved inspection authority competent person in terms of the SAQCC Engineering Council of South Africa inspector of pressurized equipment magnetic particle testing non-destructive examination pressure equipment regulation liquid penetrant testing

This standard may only be used and printed by approved subscription and freemailing clients of the SABS.

SANS 10227:2007 Edition 2

RT radiographic testing

SANAS South African National Accreditation System SAQCC South African Qualification Certification Committee UT WPQ WPS ultrasonic testing welder performance qualification weld procedure specification

4 Approval of inspection authorities

4.1 Since the inspection authority is the authorized representative of the Chief Inspector of the

Department of Labour or of the Chief Inspector of the Department of Minerals and Energy, as applicable, the inspection authority shall be a juristic person in South Africa. However, it shall exclude a sole proprietor.

4.2 The approval of an inspection authority by the regulatory authorities shall be conditional upon

the following: a) The accreditation of the inspection authority in terms of the Regulations for the control over the use or application of standards promulgated under the Standards Act, 1993 (Act No. 29 of 1993 (as amended)). This shall include a partial assessment of the inspection authority's activities at least once a year, with a full assessment (or equivalent) of its total activities once every four years. The assessments shall be conducted 1) under the control of the government-endorsed national accreditation body (SANAS), 2) to the requirements in this standard and in SANS 17020, to a specific scope as determined by the health and safety standards, to accreditation requirements and to the PER. b) The Technical Manager (however designated) shall be in the permanent and full-time employment of the inspection authority. Accreditation shall depend on the availability of the Technical Manager within the inspection authority. Furthermore there shall be at least one permanent IPE or CP (or both) (as applicable) in the employment of the inspection authority. c) The design verification engineer shall be employed either on a full-time basis or on a part-time basis. Where it is necessary to use personnel for temporary situations, such personnel should be formally contracted for the period that the inspection body uses them. The inspection body shall ensure that such personnel are supervised and competent, and that they work in accordance with the inspection bodys quality system. d) Should personnel that are vital to the scope of accreditation leave the permanent employment of the inspection authority, SANAS shall be notified immediately and accreditation shall be suspended until the inspection authority can prove to SANAS that the new incumbents have the required experience, training and certification. e) The Chief Inspector of the Department of Labour or of the Department of Minerals and Energy shall only approve inspection authorities in terms of the Regulations after the inspection authorities have been accredited by SANAS. Accreditation by SANAS does not mean that an inspection authority will automatically be approved. The Chief Inspector of the Department of Labour or of the Department of Minerals and Energy might wish to impose additional requirements on accredited inspection authorities before approval is granted. f) If an AIA loses its accreditation, it shall automatically lose its approval by the regulatory authorities.

This standard may only be used and printed by approved subscription and freemailing clients of the SABS.

SANS 10227:2007 Edition 2

5 Scope of activity

5.1 The extent of the functions provided by the AIA shall be documented and shall specify

a) the Regulations with which the functions comply, b) the applicable health and safety standard(s) with which the functions comply, c) whether the scope of accreditation should cover only 1) manufacturing, or 2) in-service inspection, or 3) both of the above, and d) any other related functions (pertaining to pressure equipment) that enhance the expertise of the organization, but are not limited to the requirements of the Act.

5.2 The documentation (see 6.1) shall also specify which services and activities are provided inhouse and which services, if any, are obtained from outside the organization and on what basis (for example, material testing and calibration of equipment).

6 Inspection methods and procedures

6.1 General

The AIA shall develop and maintain documented procedures for its scope of activity.

6.2 Documented procedures

6.2.1 Documented procedures shall be developed and maintained in accordance with the requirements of SANS 17020 and shall include, but shall not be limited to, the following:

a) design and drawing verification (requirements for the verification of piping shall be as in annex A);

NOTE The purpose of design and drawing verification is to run a representative set of calculations to verify the design of pressure equipment as calculated by the manufacturer.

b) surveillance of the supplier's manufacturing programme; c) certification; d) re-rating; e) repairs; f) modification; g) in-service inspection; and h) any other procedure as required to establish compliance with SANS 347.

This standard may only be used and printed by approved subscription and freemailing clients of the SABS.

SANS 10227:2007 Edition 2

6.2.2 The surveillance of the manufacturing programme shall include, but shall not be limited to, the following:

a) quality control plan (however designated); b) material certification; c) material identification; d) examination of material cut edges and heat-affected zones; e) verification of weld procedures (WPS); f) verification of welders and operators (WPQ); g) weld preparation, fit-up and quality of welding; h) inspection of second side-weld preparation; i) acceptance of non-destructive examination (NDE, including MT, PT, RT and UT) procedures and test results; witnessing and evaluation of the mechanical testing of production test welds;

j)

k) heat treatment; l) pressure testing;

m) final examination; n) verification of as-built dimensions; o) nameplate and hard stamping; p) acceptance of documentation; and q) Certificate of Manufacture or certificate of repair or modification.

7 Conditions for re-certification of pressure equipment

The AIA shall re-certify the pressure equipment when any of the following conditions apply: a) the pressure equipment is unidentified owing to 1) lost documentation, 2) the unavailability of a nameplate or data plate, or 3) unknown or unconfirmed history; or b) the pressure equipment will be re-rated to operate under different conditions; or c) the pressure equipment does not comply with the requirements necessary for approval by the Chief Inspector in terms of the Acts (see 3.1.1).

This standard may only be used and printed by approved subscription and freemailing clients of the SABS.

SANS 10227:2007 Edition 2

8 Statutory inspections and tests

The AIA shall develop and maintain documented procedures for a) conducting pre-commissioning inspections and tests, b) allowing dispensation of internal inspections or hydraulic tests (or both), and test intervals in terms of the PER, or c) in-service inspections.

9 Records

9.1 The AIA shall establish and maintain procedures for the storage and filing of those documents

and registers that give objective evidence of the execution of all activities that affect the quality of the service rendered or of the pressure equipment concerned.

9.2 The procedures shall cover at least

a) the requirements for access to the files, the extraction and return of documents, and a list of authorized personnel, b) the files to be used, and the location, protection and preservation of the documents, c) the category of documents to be filed, their confidentiality and their indexing, and d) the retention times (at least five years).

NOTE The AIA Association and the statutory authority have agreed that (where applicable) only the following certification records need to be stored: a) certificate as required by the PER; b) facsimile of equipment nameplate; c) design calculations as verified, or proof of design verification; d) a drawing (however designated) containing the design parameters; and e) in-service inspection reports and deferments.

10 Nameplate

The AIA shall ensure that the manufacturer's data plate or nameplate is in compliance with the requirements of the PER, and that a legible copy traceable to the original nameplate is kept with the records of the equipment. The AIA shall stamp the manufacturer's nameplate, if applicable, with the AIA's identification mark.

This standard may only be used and printed by approved subscription and freemailing clients of the SABS.

SANS 10227:2007 Edition 2

11 Stamp control

11.1 The AIA shall develop and maintain documented procedures for the control, issue and retrieval of hard and soft stamps. These procedures shall include the issuing of new stamps, the configuration of the stamps, and the control of lost or damaged stamps. 11.2 Stamp holders shall complete the relevant documentation by

a) printing and signing their names, b) providing the date of signing, and c) where applicable, including their registration numbers.

12 Personnel qualifications, training and experience

The AIA personnel who carry out an activity in terms of this standard shall have the appropriate technical qualification and certification (see table 1) for the type of work to be undertaken.

10

This standard may only be used and printed by approved subscription and freemailing clients of the SABS.

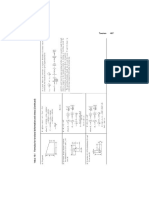

Table 1 Qualification requirements

1 Function Design verification 2 Responsibilities Verification of design calculations and related drawings Technical manager (however designated)

b

3 Qualification/certification Pr. Eng. or Pr. Technologist or Pr. Cert. Eng. University degree or T4 or Cert. Eng. or B Tech. SAQCC (IPE)

a

4 Experience Four years of relevant pressure equipment design experience, with knowledge of design standards and statutory requirements in terms of which the service is rendered Four years relevant pressure equipment experience with knowledge of the relevant Code of Construction, quality management system requirements and statutory requirements in terms of which the service is rendered Inspection and testing experience with knowledge of the specific Code of Construction and other statutory requirements incorporated in certification in terms of which the service is rendered Inspection and testing experience with knowledge of the inservice and other statutory requirements incorporated in certification in terms of which the service is rendered

Management of all AIA technical and quality activities

Verification and surveillance

Independent inspection, testing and surveillance of items and activities

Pre-commissioning and in-service Inspection and conformity assessment SAQCC (CP) pressure equipment inspection of pressure equipment

a b

Only mechanical engineers are applicable in this context. Foreign qualifications need to be verified by ECSA. The technical manager (however designated) is not authorized to perform IPE or CP functions unless certified by SAQCC. The technical manager may delegate the management of the quality system to a qualified person with the relevant experience within the organization.

SANS 10227:2007 Edition 2

11

This standard may only be used and printed by approved subscription and freemailing clients of the SABS.

SANS 10227:2007 Edition 2

Annex A

(normative)

Requirements for the verification of piping A.1 The verification of the piping designer's qualifications shall be performed by an AIA in accordance with SANS 347. A.2 A.3 A.4 A.5

The AIA shall verify the completeness of the piping design package as required by SANS 347.

The AIA shall co-sign the declaration of conformity (Certificate of Manufacture) as required by the PER. The AIA may, at any time, require proof from the designer or the manufacturer for compliance with the applicable health and safety standard requirements. The AIA shall retain the declaration of conformity (Certificate of Manufacture) for the prescribed statutory time period.

Bibliography

Standards

SANS 1825, Gas container test stations General requirements for periodic inspection and testing of portable and transportable refillable gas containers. SANS 9000/ISO 9000, Quality management systems Fundamentals and vocabulary. SANS 9001/ISO 9001, Quality management systems Requirements. SANS 10378, General requirements for the competence of verification laboratories in terms of the Trade Metrology Act. SANS 17000/ISO/IEC 17000, Conformity assessment Vocabulary and general principles.

Other publications

IAF/ILAC-A4: 2004, Guidance on the Application of ISO/IEC 17020. International Vocabulary of Basic and General Terms in Metrology, 1993 (VIM).

Standards South Africa

12

Das könnte Ihnen auch gefallen

- SANS10227Dokument17 SeitenSANS10227KhalidPeerNoch keine Bewertungen

- SANS 347:2012: Categorization and Conformity Assessment Criteria For All Pressure EquipmentDokument51 SeitenSANS 347:2012: Categorization and Conformity Assessment Criteria For All Pressure EquipmentTshilidzi Irene Netselo100% (3)

- Sans 347.2010Dokument47 SeitenSans 347.2010madodandembe100% (1)

- SANS1700 7 7 (Looseleaf)Dokument13 SeitenSANS1700 7 7 (Looseleaf)Darryl007Noch keine Bewertungen

- SABS 0162-2 Part II-Limit-states Design of Cold FormedDokument81 SeitenSABS 0162-2 Part II-Limit-states Design of Cold FormedMustufa F Kanjeta80% (5)

- Sans 282Dokument27 SeitenSans 282Nolan PillayNoch keine Bewertungen

- Sans 347Dokument50 SeitenSans 347cocorruo100% (1)

- Guide To PED Directive ValvesDokument60 SeitenGuide To PED Directive ValvesMurat Erdogan100% (1)

- Null 1 PDFDokument5 SeitenNull 1 PDFTshililo Emmanuel Lee0% (1)

- 2 1 - 6 The UK National Annex To BS EN 1993 1 10 2005 and PD 6695 1 10 2009 - 1Dokument6 Seiten2 1 - 6 The UK National Annex To BS EN 1993 1 10 2005 and PD 6695 1 10 2009 - 1Dino NoNoch keine Bewertungen

- SANS 2001-CS1:2012: Construction Works Part CS1: Structural SteelworkDokument5 SeitenSANS 2001-CS1:2012: Construction Works Part CS1: Structural Steelworkjohndup0% (3)

- 04.understanding of Iso 3834Dokument54 Seiten04.understanding of Iso 3834amit50% (2)

- Steel SansDokument67 SeitenSteel SansLuc TellierNoch keine Bewertungen

- European Welding StandardsDokument39 SeitenEuropean Welding Standardsmladen018Noch keine Bewertungen

- PD5500 2009Dokument4 SeitenPD5500 2009rgavilanb917390% (2)

- 1 Sans 62 PDFDokument1 Seite1 Sans 62 PDFAlexander Richardson100% (1)

- SANS 2001-BS1 2008 - Site ClearanceDokument13 SeitenSANS 2001-BS1 2008 - Site Clearancecobbymark100% (5)

- PED 2014-68-EU Guidelines EN PDFDokument218 SeitenPED 2014-68-EU Guidelines EN PDFMali MedoNoch keine Bewertungen

- 2014 68 Eu PDFDokument96 Seiten2014 68 Eu PDFAlienshow100% (1)

- Sans 10400-TDokument83 SeitenSans 10400-Tmabura100% (1)

- Sans 10400 DisabledDokument51 SeitenSans 10400 Disabledsjoubert_törökNoch keine Bewertungen

- Sans10100 2Dokument84 SeitenSans10100 2matshona100% (16)

- SABS SANSrenumberinglistFINALDokument92 SeitenSABS SANSrenumberinglistFINALMauridi KaminyuNoch keine Bewertungen

- BS 3059-2Dokument11 SeitenBS 3059-2abhiNoch keine Bewertungen

- Din en 13084-7:2006-06 (E)Dokument1 SeiteDin en 13084-7:2006-06 (E)Romeo Di SarioNoch keine Bewertungen

- SANS 10044-1:2004: Welding Part 1: Glossary of TermsDokument5 SeitenSANS 10044-1:2004: Welding Part 1: Glossary of TermsMark D Villanueva33% (3)

- EN 14015 2004 Tanks - OldDokument34 SeitenEN 14015 2004 Tanks - OldkitofanecoNoch keine Bewertungen

- Sans 282: 2011Dokument31 SeitenSans 282: 2011Luke Jabulani ReidNoch keine Bewertungen

- Iso 12953 5 2020Dokument36 SeitenIso 12953 5 2020Jim Frenken100% (1)

- International StandardDokument2 SeitenInternational StandardAnup Sharma0% (1)

- BS 2633-1987 PDFDokument58 SeitenBS 2633-1987 PDFAndres Afanador MuñozNoch keine Bewertungen

- SANS 2001-CC1:2012: Construction Works Part CC1: Concrete Works (Structural)Dokument5 SeitenSANS 2001-CC1:2012: Construction Works Part CC1: Concrete Works (Structural)nortrade75% (4)

- Chemical Composition of Stainless Steels To BS EN 10088-2Dokument41 SeitenChemical Composition of Stainless Steels To BS EN 10088-2amit_91340% (1)

- Sans 719 PipeDokument19 SeitenSans 719 PipeFabio Miguel100% (1)

- ASME ANSI B16.11 Forged Fittings Socket Welding and ThreadedDokument33 SeitenASME ANSI B16.11 Forged Fittings Socket Welding and ThreadedpaulamuisesNoch keine Bewertungen

- SANSDokument54 SeitenSANSvillanuevamarkdNoch keine Bewertungen

- BS 4504 - Part IDokument104 SeitenBS 4504 - Part Iamalhaj2013100% (2)

- Sans10400 TDokument89 SeitenSans10400 TSphiwithemba Dube100% (4)

- Iso 20172-1 2017Dokument11 SeitenIso 20172-1 2017Dinh Quang NhamNoch keine Bewertungen

- En 1090Dokument32 SeitenEn 1090fenasikerimNoch keine Bewertungen

- SANS 2001-CC1:2007: Construction Works Part CC1: Concrete Works (Structural)Dokument65 SeitenSANS 2001-CC1:2007: Construction Works Part CC1: Concrete Works (Structural)Melvin Joseph88% (8)

- Za Sans 10400 B 2009Dokument4 SeitenZa Sans 10400 B 2009Mercedes Cano MeseguerNoch keine Bewertungen

- BS en 13160-1 - 2003Dokument38 SeitenBS en 13160-1 - 2003bakhtyar210% (1)

- Hans Schefferlie PresentationDokument93 SeitenHans Schefferlie PresentationLelethu Ngwena100% (1)

- Submerged Arc Welding ConsumablesDokument7 SeitenSubmerged Arc Welding ConsumablesMuhammed SulfeekNoch keine Bewertungen

- List of SA CodesDokument23 SeitenList of SA CodesHenry Jamie Bwerinofa100% (1)

- SANS10375 2018 Ed2Dokument36 SeitenSANS10375 2018 Ed2Mapoho100% (5)

- SANS10160 3 2019 Wind ActionDokument95 SeitenSANS10160 3 2019 Wind ActionMartin KadhikwaNoch keine Bewertungen

- KIW03616 PED Poster A3 NL Web 1Dokument1 SeiteKIW03616 PED Poster A3 NL Web 1Vasko PlevnikNoch keine Bewertungen

- 0526 16 2004 07 en - enDokument6 Seiten0526 16 2004 07 en - envtsusr fvNoch keine Bewertungen

- BS 5276-3-1979Dokument10 SeitenBS 5276-3-1979anoopkumarNoch keine Bewertungen

- Sans - 282 - 2004bending PDFDokument27 SeitenSans - 282 - 2004bending PDFAnonymous jefUrqfioNoch keine Bewertungen

- SANS 428 Fire Performance Classification of Thermal Insulated Building Envelope SystemsDokument21 SeitenSANS 428 Fire Performance Classification of Thermal Insulated Building Envelope SystemsdranNoch keine Bewertungen

- Standard EN10029Dokument4 SeitenStandard EN10029Florin JipaNoch keine Bewertungen

- Rules 2014 68 UE ENDokument72 SeitenRules 2014 68 UE ENEduardo Depiatti100% (1)

- MIL-STD-45662 10 June 1980 Superseding MIL-c-45662A 9 February 1962Dokument12 SeitenMIL-STD-45662 10 June 1980 Superseding MIL-c-45662A 9 February 1962standardliegeNoch keine Bewertungen

- Air Pressure Maintenance DeviceDokument19 SeitenAir Pressure Maintenance Devicejonathan banegasNoch keine Bewertungen

- AB-512 OU Pressure Equipment Integrity Management Requirements IMRDokument43 SeitenAB-512 OU Pressure Equipment Integrity Management Requirements IMRVinh Do ThanhNoch keine Bewertungen

- Api 510Dokument9 SeitenApi 510ALe InfinitoNoch keine Bewertungen

- Roark's Formulas For Stress and Strain 10.1Dokument1 SeiteRoark's Formulas For Stress and Strain 10.1Lincs lincolnNoch keine Bewertungen

- ANSI Y14 - 5-1994 Geometric Tolerancing CheatsheetDokument2 SeitenANSI Y14 - 5-1994 Geometric Tolerancing Cheatsheetjlel12100% (1)

- A Geometric Constraint SolverDokument30 SeitenA Geometric Constraint SolverLincs lincolnNoch keine Bewertungen

- Rules of Thumb For Steel StructuresDokument5 SeitenRules of Thumb For Steel StructuresLincs lincoln100% (1)

- 01 - Fatigue Theory (Part 1)Dokument42 Seiten01 - Fatigue Theory (Part 1)Lincs lincolnNoch keine Bewertungen

- Transmission Characteristics of IR Signals in The AtmosphereDokument54 SeitenTransmission Characteristics of IR Signals in The AtmosphereLincs lincolnNoch keine Bewertungen

- Units: 3. U.S. Units of Measurement 4. Tables of EquivalentsDokument8 SeitenUnits: 3. U.S. Units of Measurement 4. Tables of EquivalentsLincs lincolnNoch keine Bewertungen

- Grating Safe Load TablesDokument3 SeitenGrating Safe Load TablesLincs lincolnNoch keine Bewertungen

- 01 PDFDokument11 Seiten01 PDFLincs lincolnNoch keine Bewertungen

- 2 Kinematics and Dynamics of A ParticleDokument13 Seiten2 Kinematics and Dynamics of A ParticleLincs lincolnNoch keine Bewertungen

- Appendix Section: Relevant Tables and References: A Comparisons Between The Safety Valves Sizing FormulasDokument25 SeitenAppendix Section: Relevant Tables and References: A Comparisons Between The Safety Valves Sizing FormulasLincs lincolnNoch keine Bewertungen

- The Scope of Analytical Chemistry: Ground Rules and FundamentalsDokument10 SeitenThe Scope of Analytical Chemistry: Ground Rules and FundamentalsLincs lincolnNoch keine Bewertungen

- Lockers Specification - PH PDFDokument1 SeiteLockers Specification - PH PDFLincs lincolnNoch keine Bewertungen

- A Suggested Stress Analysis Procedure For Nozzle To Head Shell Element Model - A Case StudyDokument7 SeitenA Suggested Stress Analysis Procedure For Nozzle To Head Shell Element Model - A Case StudyLincs lincolnNoch keine Bewertungen

- Robability Undamentals: SamplingDokument13 SeitenRobability Undamentals: SamplingLincs lincolnNoch keine Bewertungen

- M4-Lesson Transitional SignalDokument50 SeitenM4-Lesson Transitional SignalJeneros PartosNoch keine Bewertungen

- SLC 10 ScienceDokument16 SeitenSLC 10 SciencePffflyers KurnawanNoch keine Bewertungen

- Matte Sanjeev Kumar: Professional SummaryDokument3 SeitenMatte Sanjeev Kumar: Professional SummaryAlla VijayNoch keine Bewertungen

- Lesson 2 (Locating Main Ideas)Dokument18 SeitenLesson 2 (Locating Main Ideas)Glyneth Dela TorreNoch keine Bewertungen

- Comparision BRC IFS QMS 22K From BV PDFDokument44 SeitenComparision BRC IFS QMS 22K From BV PDFAhmedElSayedNoch keine Bewertungen

- Internship Report On Service IndustryDokument50 SeitenInternship Report On Service Industrybbaahmad89Noch keine Bewertungen

- Multithreading AlgorithmsDokument36 SeitenMultithreading AlgorithmsAsna TariqNoch keine Bewertungen

- Herzlich Willkommen - Welcome: German Information Session For New ParentsDokument20 SeitenHerzlich Willkommen - Welcome: German Information Session For New ParentssammlissNoch keine Bewertungen

- Contoh RefleksiDokument7 SeitenContoh RefleksiIzzat HanifNoch keine Bewertungen

- The Saga of Flying Objects - La Saga de Los Objetos VoladoresDokument15 SeitenThe Saga of Flying Objects - La Saga de Los Objetos VoladoresCiborgSeptiembreNoch keine Bewertungen

- HowToCreate DataDriven HorizonCube OpendTectv4.4 PDFDokument49 SeitenHowToCreate DataDriven HorizonCube OpendTectv4.4 PDFKrisna Hanjar PrastawaNoch keine Bewertungen

- Kolkata City Accident Report - 2018Dokument48 SeitenKolkata City Accident Report - 2018anon_109699702Noch keine Bewertungen

- Job Stress, Workload, Environment and Employee Turnover IntentionsDokument13 SeitenJob Stress, Workload, Environment and Employee Turnover IntentionsYuni SasieNoch keine Bewertungen

- Management - ControlDokument20 SeitenManagement - Controlrsikira7905Noch keine Bewertungen

- CPCCCM2006 - Learner Guide V1.0Dokument89 SeitenCPCCCM2006 - Learner Guide V1.0Sid SharmaNoch keine Bewertungen

- MATH 6 Q4 Module 8Dokument17 SeitenMATH 6 Q4 Module 8Amor DionisioNoch keine Bewertungen

- Non-Display Industrial Computers: User ManualDokument100 SeitenNon-Display Industrial Computers: User ManualJason100% (1)

- Cultural GlobalizationDokument16 SeitenCultural Globalizationee0785Noch keine Bewertungen

- (Herbert Kitschelt, Steven I. Wilkinson) Patrons, PDFDokument387 Seiten(Herbert Kitschelt, Steven I. Wilkinson) Patrons, PDFClemente Tomás Sánchez BarjaNoch keine Bewertungen

- Sika Bro - E - Sikadur-Combiflex SG System - High Performance Joint - Crack Waterproofing System (09.2010)Dokument8 SeitenSika Bro - E - Sikadur-Combiflex SG System - High Performance Joint - Crack Waterproofing System (09.2010)Joh SongthamNoch keine Bewertungen

- Research QuestionDokument6 SeitenResearch QuestionAlfian Ardhiyana PutraNoch keine Bewertungen

- Semi-Conductor Laboratory - MohaliDokument4 SeitenSemi-Conductor Laboratory - MohalimanjnderNoch keine Bewertungen

- CHEM Test 2 SolutionsDokument5 SeitenCHEM Test 2 Solutionscuongtran_siegenNoch keine Bewertungen

- Evolution of Management TheoriesDokument20 SeitenEvolution of Management TheoriesKanishq BawejaNoch keine Bewertungen

- Lesson Plan ComsumerismDokument6 SeitenLesson Plan ComsumerismMan Eugenia50% (4)

- Biology FileDokument10 SeitenBiology FileMichael KorsNoch keine Bewertungen

- Gd&t-Multi MetricsDokument356 SeitenGd&t-Multi MetricsdramiltNoch keine Bewertungen

- JavaScript ArraysDokument5 SeitenJavaScript Arraysursu_padure_scrNoch keine Bewertungen

- Mutants & Masterminds 1st Ed Character Generater (Xls Spreadsheet)Dokument89 SeitenMutants & Masterminds 1st Ed Character Generater (Xls Spreadsheet)WesleyNoch keine Bewertungen

- Business Cognate SBADokument20 SeitenBusiness Cognate SBAUncle TravisNoch keine Bewertungen