Beruflich Dokumente

Kultur Dokumente

Pu 0027618

Hochgeladen von

Anonymous DjTnqWXUOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Pu 0027618

Hochgeladen von

Anonymous DjTnqWXUCopyright:

Verfügbare Formate

Rev.

Date

Approved by Checked by

Made by

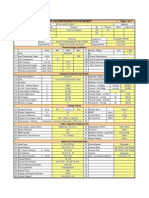

CENTRIFUGAL PUMP DATA SHEET

1 2 3

Tien Duc JSC 1 Messrs. Tien Duc JSC 2 Customer Location: OUTDOOR No.req'd: 1 Driver: 1 3 Item No. Spray Pump Code & Standard: JIS standard & MFR standard 4 Service 5 Torishima Quot. No. Type & Size: CAR40-200 6 Torishima Product No. PU0027618 OPERATING CONDITIONS PERFORMANCE 7 0.44 m3/min Speed 2890 min-1 8 Liquid Capacity Pump efficiency 62 9 28 Disch. press. Shaft power(calculated) 4.3 kW 10 Pumping temp. Density 1000 kg/m3 Suct. press. NPSH3(water) 3.6 m 11 Diff. press. Minimum flow 12 Vap. press. at PT. 1 mPas Total head 37 m Max. Total head(approx) 42.2 m 13 Vis. at PT. Max. suct. press. Rotation(viewed from coupling): CW 14 Pouring point NPSHavail. 10 m Moment of inertia(J) 0.01655 kgm2 15 Corr./Eros. caused by CONSTRUCTION COOLING / FLUSHING 16 Cooling water Nozzles Size Rating Facing Location MPaG 17 , Suction 65 JIS10K RF END 18 Discharge 40 JIS10K RF TOP Stuff. box 19 m3/h Pump construction: Shaft: HORIZONTAL Suction: SINGLE Bearing housing 20 m3/h Axial thrust absorbed by: BALANCING HOLE Pedestal 21 No. of Stages: SINGLE m3/h Type: VOLUTE Oil cooler 22 Casing m3/h Mount: FOOT Flushing cooler 23 m3/h Split: RADIAL Heating Jacket: NO 24 Design press.: 1.00 MPaG Hydro. test press.: 1.50 MPaG 25 Type: CLOSED Mount: OVERHUNG Total 26 Impeller m3/h MECH.SEAL Flushing for Liquid MPaG m3/h(Note) 27 Shaft seal: 28 Mech.seal Type: DOUBLE UNBALANCE Lantern ring 29 Flush: EXTERNAL Gland 30 Mfr. & Type: TORISHIMA LTW24F Aux. gland 31 Bearings Type: Radial: BALL Thrust: BALL Throttle bush FRESH 0.12 ~ 0.18 32 Lub. Method: GREASE Mech. seal 0.10 WATER Type: FLEXIBLE Spacer: NO 33 Coupling DIRECT 34 Drive: COMMON 35 Baseplate: DRIVER 36 Note : The external flushing flow rate is plan quantity of liquid. Supplied by PURCHASER 37 Please manage the external flushing by pressure. Type 38 Rated output 5.5 kW 39 No. of poles 2 40 Volts/phase/Hz 380 V / 3 / 50 Hz 41 Insulation class F 42 MATERIALS 43 SCS13 Baseplate SS400 Stuff. box packing -----44 Casing -----Case gasket PTFE 45 Diffuser SCS13 46 Impeller -----47 Case wear ring -----48 Imp. wear ring SUS304 49 Shaft -----50 Seal sleeve ACCESSORIES(PER EACH PUMP) 51 1 Pc Press. gauge --- Pc(s) Cooling water piping --- Set 52 Baseplate 1 Set Compound gauge --- Pc(s) Flushing piping 1 Set 53 Anchor bolts 1 Set Vacuum gauge --- Pc(s) 54 Coupling with guard --- Set 55 Companion flange --- Pc(s) 56 Air vent valve 1 Pc(s) 57 Funnel with valve 1 Pc(s) Tools with box 1 Set per item 58 Casing drain valve APPROX. MASS 59 39 kg Baseplate 34 kg Driver --- kg Coupling 3.2 kg Total 76.2 kg 60 Pump 61 Remarks : Performance Test Code JIS B8301(2000) Grade 2-b) 62 63 Approved by

M.YOSHIMURA

P52213 0040200R 2GLL33EF00 053-110

Checked by

M.YOSHIMURA

Made by M.OISHI

Date Nov.29.2013

Dwg. No.

PU0027618D

LIST OF COMPONENT

CAR

3RD ANGLE PROJECTION

Rev. Date

1 2

Approved by

Checked by

Made by

STAINLESS STEEL CENTRIFUGAL PUMP CAR

MESSRS. Tien Duc JSC TYPE&SIZE CAR40-200 9400.2 1020 2300 4000.3 9010 9041 1610 4330

ITEM No. SERVICE Spray Pump

PRODUC.No.

PU0027618

4710

Detail of shaft seal

3300 4230.2

3210.2

3210.1

4230.1

P52213 0040200R 2GLL33EF00

9233 4120.1 5500

PART No. 1020 1610 1830 2100 2300 3210.1 3210.2 3300 3600.1 3600.2 4000.1 4000.2 4000.3 4120.1 4230.1 4230.2 4330 4710 5500 PART DESIGNATION

VOLUTE CASING CASING COVER SUPPORT FOOT SHAFT IMPELLER BALL BEARING BALL BEARING BEARING HOUSING BEARING COVER BEARING COVER GASKET GASKET GASKET O-RING LABYRINTH RING LABYRINTH RING MECHANICAL SEAL SEALING COVER WASHER

24 2100 9400.1 3600.1

Pcs. 6 1 1 1 1

DATE

44.5

Tori.NET

3600.2 4000.2

1830

4000.1

MATERIAL

Pcs. PART No. 1 9010 1 9041 1 9233 1 9400.1 1 9400.2 1 1 1 1 1 1 1 1 1 1 1 1 1 1

PART DESIGNATION

HEXAGONAL BOLT SET SCREW HARD LOCK NUT KEY KEY

MATERIAL

SCS13 SCS13 FC200 SUS304 SCS13 No.6305UUC3 No.6305UUC3 FC250 FC200 FC200 TOMBO 1995 TOMBO 1995 PTFE FKM PLASTIC PLASTIC LTW24F SUS316 SUS316

SUS304 SUS316 SUS316 S45C SUS329J1

Mech. seal material Rot. ring :TUNGSTEN CARBIDE Stat. ring :TUNGSTEN CARBIDE

APPROVED BY

CHECKED BY

DRAWN BY

Packing :FKM Spring :SUS316

Nov.29. M.YOSHIMURA M.YOSHIMURA M.OISHI 2013

DWG. No.

PU0027618K

Das könnte Ihnen auch gefallen

- Pump Sizing SpreadsheetDokument2 SeitenPump Sizing Spreadsheetsyamsudin200683% (6)

- 13 - Copes-Vulcan ValvesDokument7 Seiten13 - Copes-Vulcan ValvesshalegpNoch keine Bewertungen

- 34788Dokument40 Seiten34788Anonymous DjTnqWXU100% (2)

- CW Pump CalculationDokument22 SeitenCW Pump Calculationzamijaka100% (1)

- Data Sheet: LPG Filling Pump P-001/002/003/004/005/006Dokument5 SeitenData Sheet: LPG Filling Pump P-001/002/003/004/005/006Denstar Ricardo Silalahi100% (1)

- RC2 Series Screw Compressor Maintenance ManualDokument122 SeitenRC2 Series Screw Compressor Maintenance ManualDennis Arhin100% (1)

- Acute Leukemia The Scientist's Perspective and ChallengeDokument438 SeitenAcute Leukemia The Scientist's Perspective and ChallengemedskyqqNoch keine Bewertungen

- Data Sheet For Instrument Air Package: Contract No.: CSA-12S-041SDDokument8 SeitenData Sheet For Instrument Air Package: Contract No.: CSA-12S-041SDMrbudakbaekNoch keine Bewertungen

- RNZ Integrated (M) SDN BHD: Calculation SheetDokument14 SeitenRNZ Integrated (M) SDN BHD: Calculation SheetNhantran VanNoch keine Bewertungen

- Microfinish Pump DataDokument2 SeitenMicrofinish Pump DataPraveen PrajapatiNoch keine Bewertungen

- 1 Goulds Pumps 3196 1.5x3-8STXDokument7 Seiten1 Goulds Pumps 3196 1.5x3-8STXPaola moreno100% (1)

- Min1244a12 - Tag 130-Pu-029Dokument7 SeitenMin1244a12 - Tag 130-Pu-029Monty MathewsNoch keine Bewertungen

- Hydraulic CalculationsDokument20 SeitenHydraulic CalculationsJayesh ChandranNoch keine Bewertungen

- Example Pump CalcsDokument4 SeitenExample Pump CalcsSourav ChattopadhyayNoch keine Bewertungen

- Drum Washing Machine: Model: DWD-1211RT DWD-1221RT DWD-1223RTDokument59 SeitenDrum Washing Machine: Model: DWD-1211RT DWD-1221RT DWD-1223RTCelsoTécnicoOdontologicoNoch keine Bewertungen

- PRAI-M0-YT01-GM-7500 - As-Built - Data Sheet For Waste Water PumpDokument27 SeitenPRAI-M0-YT01-GM-7500 - As-Built - Data Sheet For Waste Water PumpSuman GhoshNoch keine Bewertungen

- For Information: Cephas Pipelines CorpDokument4 SeitenFor Information: Cephas Pipelines CorpMathivanan AnbazhaganNoch keine Bewertungen

- Centrifugal PumpDokument68 SeitenCentrifugal Pumpsafald100% (2)

- Goulds Pump DatasheetDokument8 SeitenGoulds Pump Datasheetkarioke mohaNoch keine Bewertungen

- W13018-YT01-GDF-457110 Rev 5-APVDokument8 SeitenW13018-YT01-GDF-457110 Rev 5-APVJosé santanaNoch keine Bewertungen

- Pompa Namol Secundar - RefDokument3 SeitenPompa Namol Secundar - RefCretu DanNoch keine Bewertungen

- Bomba de Vacio Sihi LPHX 40516Dokument12 SeitenBomba de Vacio Sihi LPHX 40516Dante Coloma JimenezNoch keine Bewertungen

- Pompa Dari Embung Ke Bak Sirkulasi / Penjernih: ContentsDokument11 SeitenPompa Dari Embung Ke Bak Sirkulasi / Penjernih: ContentsewamihawkNoch keine Bewertungen

- BoqDokument18 SeitenBoqPradeep Yallanki100% (1)

- Rotary-Type Positive-Displacement Compressor Data Sheet Us Customary UnitsDokument9 SeitenRotary-Type Positive-Displacement Compressor Data Sheet Us Customary UnitsghostamirNoch keine Bewertungen

- Data Sheet PDFDokument36 SeitenData Sheet PDFRaktima MisraNoch keine Bewertungen

- Unit-4 TG Desk Engineer'S Log BookDokument6 SeitenUnit-4 TG Desk Engineer'S Log BookJai GuptaNoch keine Bewertungen

- Axial Piston Pumps: Series Pvplus - Design Series 47 Variable DisplacementDokument72 SeitenAxial Piston Pumps: Series Pvplus - Design Series 47 Variable DisplacementJhonata CavalcanteNoch keine Bewertungen

- Fujitsu ASYA12LCC ManualDokument16 SeitenFujitsu ASYA12LCC Manualananana100% (1)

- MIL Control Valve Specification and Sizing CalculationDokument34 SeitenMIL Control Valve Specification and Sizing CalculationRahulTewari67% (3)

- Data Sheet Tag 180-Pu-011eDokument8 SeitenData Sheet Tag 180-Pu-011eSarah PerezNoch keine Bewertungen

- Reaction Tank Design For WWTPDokument9 SeitenReaction Tank Design For WWTPDavid LambertNoch keine Bewertungen

- Item 001A - 79.49 m3 HRDokument3 SeitenItem 001A - 79.49 m3 HRAnonymous O0lyGOShYGNoch keine Bewertungen

- 3315 ManualDokument23 Seiten3315 ManualBen MtzNoch keine Bewertungen

- YDPDokument2 SeitenYDPwpt_meNoch keine Bewertungen

- Code: 1120000 NS 39: Technical DataDokument3 SeitenCode: 1120000 NS 39: Technical DataAlina CostinNoch keine Bewertungen

- FO14-104 Vacuum Deaerator Datasheet - Rev ADokument3 SeitenFO14-104 Vacuum Deaerator Datasheet - Rev AHuzefa Calcuttawala100% (2)

- PresidentDokument6 SeitenPresidentJohnny Diaz VargasNoch keine Bewertungen

- Juntas SMC MQR PDFDokument10 SeitenJuntas SMC MQR PDFhexapodoNoch keine Bewertungen

- 14564625Dokument2 Seiten14564625kisgobeNoch keine Bewertungen

- 2014-4966-1M-1008 Rev D Hot Water Circulation Pump DatasheetDokument10 Seiten2014-4966-1M-1008 Rev D Hot Water Circulation Pump DatasheetSamuel JohnsonNoch keine Bewertungen

- VX136 105 Pos1 Piggy BackDokument3 SeitenVX136 105 Pos1 Piggy BackCretu DanNoch keine Bewertungen

- HRD Hot Water Pump P001Dokument6 SeitenHRD Hot Water Pump P001nguyenquoc1988Noch keine Bewertungen

- MSG30-3245 UkDokument68 SeitenMSG30-3245 Ukoperacion hydratekNoch keine Bewertungen

- NP 3127 SH 3 248: Te Chnical SpecificationDokument6 SeitenNP 3127 SH 3 248: Te Chnical SpecificationabhijithavalNoch keine Bewertungen

- Handbook v1.0Dokument23 SeitenHandbook v1.0Kiran KommireddyNoch keine Bewertungen

- 06 Ax1-13Dokument9 Seiten06 Ax1-13Anonymous YzSzB0rpNKNoch keine Bewertungen

- C2123IE LocopumpS2 31 14Dokument9 SeitenC2123IE LocopumpS2 31 14Angelica DragulescuNoch keine Bewertungen

- DearatorDokument3 SeitenDearatorEDUARDONoch keine Bewertungen

- Hid Ro CycloneDokument1 SeiteHid Ro CycloneEDUARDONoch keine Bewertungen

- Description and Operating InstructionsDokument3 SeitenDescription and Operating InstructionssailbirdNoch keine Bewertungen

- Cooling Tower Data Sheet REV-00Dokument12 SeitenCooling Tower Data Sheet REV-00Anonymous ZnuMEWN1Noch keine Bewertungen

- Sp-210-E-103 Rev 0Dokument7 SeitenSp-210-E-103 Rev 0Natarajan RavisankarNoch keine Bewertungen

- Axial Piston Pumps: Series Pvplus Variable DisplacementDokument64 SeitenAxial Piston Pumps: Series Pvplus Variable DisplacementJhonny E Col ArNoch keine Bewertungen

- Costing For SwroDokument1.021 SeitenCosting For Swroganesh100% (2)

- Pages From TBDP-A-M-SP-0008 - Rev 0 SPEC FOR CENTRIFUGAL PUMP PDFDokument12 SeitenPages From TBDP-A-M-SP-0008 - Rev 0 SPEC FOR CENTRIFUGAL PUMP PDFSamuel JohnsonNoch keine Bewertungen

- C Pump SP Sheet1 PDFDokument1 SeiteC Pump SP Sheet1 PDFladreidNoch keine Bewertungen

- Enerflex-041620 RFQ LN 42-PCV-0034 Rev 4 Vendor's DSDokument4 SeitenEnerflex-041620 RFQ LN 42-PCV-0034 Rev 4 Vendor's DSHamza ShujaNoch keine Bewertungen

- PM-2491 AB FINAL - Documentation PDFDokument260 SeitenPM-2491 AB FINAL - Documentation PDFEnder ZenginobuzNoch keine Bewertungen

- Longwall Mining at Shallow Depth of Cover in IndiaVon EverandLongwall Mining at Shallow Depth of Cover in IndiaNoch keine Bewertungen

- Q64ad Q68adv Adi ManualDokument164 SeitenQ64ad Q68adv Adi ManualAnonymous DjTnqWXUNoch keine Bewertungen

- AIUS102G Manual Parts Catalog Anest IwataDokument50 SeitenAIUS102G Manual Parts Catalog Anest IwatasafieealiNoch keine Bewertungen

- Yu Ken Pressure Control ValvesDokument79 SeitenYu Ken Pressure Control ValvesAnonymous DjTnqWXUNoch keine Bewertungen

- Overview Conductor RailsDokument20 SeitenOverview Conductor RailsAnonymous DjTnqWXUNoch keine Bewertungen

- EC 0201 PilotDokument7 SeitenEC 0201 PilotAnonymous DjTnqWXUNoch keine Bewertungen

- Elephant Chain Block Co., LTDDokument36 SeitenElephant Chain Block Co., LTDAnonymous DjTnqWXUNoch keine Bewertungen

- Elephant 031011 DA DBHeavyDutyElectricChainHoistDokument14 SeitenElephant 031011 DA DBHeavyDutyElectricChainHoistAnonymous DjTnqWXUNoch keine Bewertungen

- SPC 24 InstructionsDokument28 SeitenSPC 24 InstructionsAnonymous DjTnqWXUNoch keine Bewertungen

- Ud 80Dokument1 SeiteUd 80Anonymous DjTnqWXUNoch keine Bewertungen

- Myton Mag-70 Assembly and Parts List: No. Part No. Part Name Q'ty PriceDokument1 SeiteMyton Mag-70 Assembly and Parts List: No. Part No. Part Name Q'ty PriceAnonymous DjTnqWXUNoch keine Bewertungen

- 6F2T0172 r4.2 GRE110 ManualDokument296 Seiten6F2T0172 r4.2 GRE110 ManualAnonymous DjTnqWXUNoch keine Bewertungen

- D.violet - VN Uploads Resources 573 1548420 PreviewDokument6 SeitenD.violet - VN Uploads Resources 573 1548420 PreviewAnonymous DjTnqWXUNoch keine Bewertungen

- An 9008Dokument9 SeitenAn 9008Anonymous DjTnqWXUNoch keine Bewertungen

- 718 599Dokument131 Seiten718 599Anonymous DjTnqWXU100% (1)

- Alfa Laval PHE Oper. Maint. Manual1Dokument65 SeitenAlfa Laval PHE Oper. Maint. Manual1Pamela Minero67% (3)

- 14D471Dokument1 Seite14D471Anonymous DjTnqWXUNoch keine Bewertungen

- P6KE6.8 (C) A THRU P6KE440 (C) A: Transient Voltage SuppressorDokument3 SeitenP6KE6.8 (C) A THRU P6KE440 (C) A: Transient Voltage SuppressorAnonymous DjTnqWXUNoch keine Bewertungen

- 1000 KilosDokument20 Seiten1000 KilosAbdullah hayreddinNoch keine Bewertungen

- One Foot in The Grave - Copy For PlayersDokument76 SeitenOne Foot in The Grave - Copy For Playerssveni meierNoch keine Bewertungen

- Alem Ketema Proposal NewDokument25 SeitenAlem Ketema Proposal NewLeulNoch keine Bewertungen

- Propp Function's Types:: 1-Absentation: One of The Members of A Family Absents Himself From HomeDokument10 SeitenPropp Function's Types:: 1-Absentation: One of The Members of A Family Absents Himself From HomeRohith KumarNoch keine Bewertungen

- Daftar Harga Toko Jeremy LengkapDokument2 SeitenDaftar Harga Toko Jeremy LengkapSiswadi PaluNoch keine Bewertungen

- Bai Tap Av 12 Thi Diem Unit TwoDokument7 SeitenBai Tap Av 12 Thi Diem Unit TwonguyenngocquynhchiNoch keine Bewertungen

- Whitepaper ITES Industry PotentialDokument6 SeitenWhitepaper ITES Industry PotentialsamuraiharryNoch keine Bewertungen

- Eu Clinical TrialDokument4 SeitenEu Clinical TrialAquaNoch keine Bewertungen

- Letter Writing: An Informative Powerpoint About LetterDokument11 SeitenLetter Writing: An Informative Powerpoint About LetterMalik KamranNoch keine Bewertungen

- Prospectus (As of November 2, 2015) PDFDokument132 SeitenProspectus (As of November 2, 2015) PDFblackcholoNoch keine Bewertungen

- Snowflake ScarfDokument2 SeitenSnowflake ScarfAmalia BratuNoch keine Bewertungen

- Introduction To History AnswerDokument3 SeitenIntroduction To History AnswerLawrence De La RosaNoch keine Bewertungen

- Bahan Ajar Application LetterDokument14 SeitenBahan Ajar Application LetterNevada Setya BudiNoch keine Bewertungen

- Javascript NotesDokument5 SeitenJavascript NotesRajashekar PrasadNoch keine Bewertungen

- Free PDF To HPGL ConverterDokument2 SeitenFree PDF To HPGL ConverterEvanNoch keine Bewertungen

- Qcfi Durgapur Chapter: Question & Answers BankDokument13 SeitenQcfi Durgapur Chapter: Question & Answers Bankdeepakhishikar24Noch keine Bewertungen

- CBSE Class 10 Science Sample Paper SA 2 Set 1Dokument5 SeitenCBSE Class 10 Science Sample Paper SA 2 Set 1Sidharth SabharwalNoch keine Bewertungen

- Lightolier Lytecaster Downlights Catalog 1984Dokument68 SeitenLightolier Lytecaster Downlights Catalog 1984Alan MastersNoch keine Bewertungen

- Gothic ArchitectureDokument6 SeitenGothic ArchitectureleeNoch keine Bewertungen

- 3.2.1 The Role of Market Research and Methods UsedDokument42 Seiten3.2.1 The Role of Market Research and Methods Usedsana jaleelNoch keine Bewertungen

- Ezpdf Reader 1 9 8 1Dokument1 SeiteEzpdf Reader 1 9 8 1AnthonyNoch keine Bewertungen

- Letter of Acceptfor TDokument3 SeitenLetter of Acceptfor TCCSNoch keine Bewertungen

- TOR AND SCOPING Presentation SlidesDokument23 SeitenTOR AND SCOPING Presentation SlidesSRESTAA BHATTARAINoch keine Bewertungen

- EPSS 627: DescriptionDokument2 SeitenEPSS 627: DescriptionudayakumartNoch keine Bewertungen

- Fish Culture in Ponds: Extension Bulletin No. 103Dokument32 SeitenFish Culture in Ponds: Extension Bulletin No. 103Bagas IndiantoNoch keine Bewertungen

- Silk Road Ensemble in Chapel HillDokument1 SeiteSilk Road Ensemble in Chapel HillEmil KangNoch keine Bewertungen

- Straw Bale ConstructionDokument37 SeitenStraw Bale ConstructionelissiumNoch keine Bewertungen

- SLTMobitel AssignmentDokument3 SeitenSLTMobitel AssignmentSupun ChandrakanthaNoch keine Bewertungen

- D15 Hybrid P1 QPDokument6 SeitenD15 Hybrid P1 QPShaameswary AnnadoraiNoch keine Bewertungen