Beruflich Dokumente

Kultur Dokumente

Ti Article JIS

Hochgeladen von

Stanley PeterOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ti Article JIS

Hochgeladen von

Stanley PeterCopyright:

Verfügbare Formate

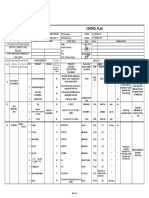

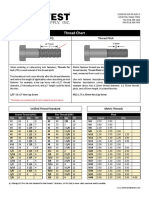

Screw Thread

TECHNICAL DATA

JIS (Japanese Industrial Standard)

Specifications

Courtesy of:

Note: Although these specifications are based

on JIS they also apply to ISO and DIN threads.

Some comments added by Maryland Metrics

copyright 2002 maryland metrics/osg corporation

(1) Flank : Thread face (excluding crest

and root of thread profile)

(2) Crest : The tap surface joining the

two sides or flanks of a

thread

(3) Root : The bottom surface joining

the flanks of two adjacent

flanks

(4) Angle of thread : Angle between adjacent

flanks measured at the

cross section of screw

thread - including the axis of

the screw thread

(5) Flank angle : The angle between the

individual flank and the

perpendicular to the axis of

the thread measured in the

axial plane

(6) Pitch : The distance from a point

on one thread to a

corresponding point on the

next thread measured

parallel to the axis

(7) Lead : The distance a screw thread

advances axially in one

complete turn

(8) Lead angle : Angle formed by a helix

passing a point on a flank

and plane perpendicular to the axis of the screw thread (applies to parallel

thread)

(9) Major diameter of external thread : Diameter of a virtual cylinder which touches the crest of

the external thread

(10) Minor diameter of internal thread : Diameter of a virtual cylinder which touches the crest of

the internal thread

(11) Minor diameter of external thread : Diameter of a virtual cylinder which touches the root of

the external thread

(12) Major diameter of internal thread : Diameter of a virtual cylinder which touches the root of

the internal thread

(13) Pitch diameter : On a straight screw thread, the diameter of an imaginary cylinder where

the width of the thread and the width of the space threads are equal.

<Exterior features of thread ridge>

Screw Thread - 1

Figure 1 Basic designation of thread (1)

H

a

lf

angleof Half angle

o

f

th

read thread

Angle of thread

(External

thread)

Crest Crest clearance

(Internal

thread)

Root

Pitch P

Internal thread

External thread

Root radius

Root clearance

(Internal thread)Crest

External root

Height of

fundamental

triangle H

M

i

n

o

r

d

i

a

m

e

t

e

r

o

f

I

n

t

e

r

n

a

l

t

h

r

e

a

d

D

1

M

i

n

o

r

d

i

a

m

e

t

e

r

o

f

e

x

t

e

r

n

a

l

t

h

r

e

a

d

d

1

P

i

t

c

h

d

i

a

m

e

t

e

r

d

2

D

1

d

M

a

j

o

r

d

i

a

m

e

t

e

r

o

f

i

n

t

e

r

n

a

l

t

h

r

e

a

d

D

M

a

j

o

r

d

i

a

m

e

t

e

r

o

f

e

x

t

e

r

n

a

l

t

h

r

e

a

d

T

h

r

e

a

d

o

v

e

r

l

a

p

H

1

Figure 2 Basic designation of thread (2)

M

a

j

o

r

d

i

a

m

e

t

e

r

o

f

i

n

t

e

r

n

a

l

t

h

r

e

a

d

M

i

n

o

r

d

i

a

m

e

t

e

r

o

f

i

n

t

e

r

n

a

l

t

h

r

e

a

d

M

i

n

o

r

d

i

a

m

e

t

e

r

o

f

e

x

t

e

r

n

a

l

t

h

r

e

a

d

M

a

j

o

r

d

i

a

m

e

t

e

r

o

f

e

x

t

e

r

n

a

l

t

h

r

e

a

d

C

r

e

s

t

T

h

r

e

a

d

r

i

d

g

e

A

n

g

l

e

o

f

t

h

r

e

a

d

Internal thread

Pitch

F

l

a

n

k

L

e

a

d

a

n

g

l

e

T

h

r

e

a

d

g

r

o

o

v

e

P

i

t

c

h

d

i

a

m

e

t

e

r

P

i

t

c

h

d

i

a

m

e

t

e

r

E

x

t

e

r

n

a

l

t

h

r

e

a

d

(14) Simple pitch diameter : Diameter of an imaginary cylinder when a thread groove width,

which is determined by the direction of an axis of screw thread,

equals half of the reference pitch. For many standard taps, the

simple pitch diameter equals the pitch diameter.

(15) Virtual pitch diameter : Virtual pitch diameter of a thread with a reference pitch and

reference flank angle that fit without interference and play in the

thread over the given thread engagement

(16) Height of Thread : Distance between a virtual cylinder that touches a crest of the

thread and a virtual cylinder that touches a root; determined by

measuring perpendicular to the axis of the screw thread.

(17) Height of fundamental triangle : Right angle distance between a virtual cylinder (including

the helix) formed by extending and intersecting flanks of thread to

the direction of crest and a virtual cylinder formed by extending and

intersecting flanks of thread to the direction of root

(18) Crest truncation : The distance measured perpendicular to the axis, between the

sharp crest and the cylinder or cone which bounds the actual root.

(19) Root truncation : The distance measured perpendicular to the axis, between the

sharp root and the cylinder or cone which bounds the actual root.

(20) Thread overlap : Distance measured perpendicular to the axis of the screw thread

between the virtual cylinder of the major diameter of external thread

and the virtual cylinder of the minor diameter of internal thread, in

external thread and internal thread which mutually fit in concentric.

(21) Percentage of thread engagement : Ratio of thread overlap in product against reference of

thread overlap

(22) Length of engagement : Length measured in the direction of the thread axis, when an

external thread and internal thread are fit and mutually contact.

Usually this length equals the length of internal thread and includes

the chamfers of both ends of the internal thread

(23) Threaded portion : Threaded portion of tap that can be effectively used for screw

thread. The incomplete chamfered thread portion is included.

Screw Thread - 2

Screw Thread - 3

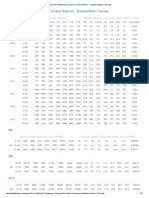

Metric screw

thread

JIS B0205

(coarse)

JIS B0207

(fine)

H=0.866025P

H1=0.541266P

d2=d - 0.649519P

d1=d - 1.082532P

D=d D1=d1 D2=d2

P=Pitch D=For internal thread

Angle of thread is 60. The Crest is flat, and there is clearance at the root. External thread

and internal thread engage well. Larger root radius and lower thread height enable easy

screw thread processing and increase thread screw strength. The Major diameter of external

thread and pitch are specified by a simple numerical value (most commonly measured in

millimeters).

Type Equation for Basic Size Basic Profile Symbol

M

Unified screw

thread

JIS B0206

(coarse)

JIS B0208

(fine)

The thread profile is same as for metric thread. Major diameter of external thread is

measured in inches and the number thread ridges is represented by the number of thread

ridges per inch.

U

Parallel pipe

thread

JIS B0202

H=0.960491P

H1=0.640327P

r=0.137329P

d2=d - h

d1=d - 2h

D=d D1=d1 D2=d2

Pipe thread mainly for mechanical coupling. It is specified according to JIS and ISO R228.

For the US method, some threads have a 60 angle.

G

(PF)

H=0.866025P

H1=0.541266P

d2=d - 0.649519P

d1=d - 1.082532P

D=d D1=d1 D2=d2

P=

n

25.4

25.4

P=

n

Taper pipe

thread

JIS B0203

H=0.960237P

H1=0.640327P

r=0.137278P

Pipe thread mainly for tighter thread portion. Taper 1/16 and 55

thread angle. For the US method, some threads have a 60 angle

RRc

(PT)

Internal thread

External thread

27.5 27.5

55

P

r

r

H

h

H2

H2

h2

h2

Internal thread

External thread

27.5 27.5

55

P

r

r

H

h

H2

H2

H6

H6

d

1

o

r

D

1

d

2

o

r

D

2

d

o

r

D

H

H

1

H2

H2

H4

H8

d

1

o

r

D

1

d

2

o

r

D

2

d

o

r

D

External thread

P

60

30 30

Internal thread

16

9

0

1

H

H

1

H2

H2

H4

H8

d

1

o

r

D

1

d

2

o

r

D

2

d

o

r

D

External thread

P

60

30 30

Internal thread

<Types and Applications>

Note: JIS PT = BSPT JIS PF = BSPF

The following are the requirements for proper external and internal thread engagement:

1. External thread and internal thread must have sufficient contact at the flank

2. External thread and internal thread must have enough engagement. [SAME AS ABOVE!]

In order to meet these requirements, JIS uses classes to define the limits of size and tolerance

for the major and minor diameter of internal thread, pitch diameter, and the major and minor

diameter of external thread.

Tolerance Class

The reason for setting tolerance in thread is:

1. The ensure compatibility

2. Limit the quality within a given range

Factors that effect the quality of screw thread include:

1. material: type, heat processing, surface processing, uniformity, etc...

2. shape: root radius, incomplete thread, roundness, surface roughness, concentration of

stress

3. detentions: major diameter, pitch diameter, and minor diameter.

Tolerance class of thread ridge is primarily determined by dimensions.

Table 3

<Tolerance>

Screw Thread - 4

E

x

t

e

r

n

a

l

t

h

r

e

a

d

I

n

t

e

r

n

a

l

t

h

r

e

a

d

Second

Name

Class

Types

Metric screw

thread

(M)

Group

First Second Third

4h 6g 8g

4H, 5H 5H, 6H 7H

JIS

ISO

E

x

t

e

r

n

a

l

t

h

r

e

a

d

Unified screw

thread

(U)

3A 2A 1A

1B 3B 2B

JIS

ISO

JIS

ISO

Whitworth screw

thread

(W)

Fourth Third

Use

Conforming

engagement

Clamping

general

machine

General

service for

general

machine

Regular bolt

I

n

t

e

r

n

a

l

t

h

r

e

a

d

Screw Thread - 5

Angle Error

The difference between the actual angle of thread and the prescribed angle of thread. Angles

larger than the prescribed angel are " plus", while angles smaller than the prescribed angle are

"minus". It doubles half angle error.

Flank angle error : Difference between the actual flank angle and prescribed flank angle

Half angle error of thread : Flank angle error at point where thread profile is symmetrical to

the center line of the thread ridge.

Pitch Error

The difference between the actual pitch and the prescribed pitch. Pitch that is larger than the

prescribed pitch is " plus", while pitch that is smaller than the prescribed pitch is "minus".

Generally this is for one pitch, but some is for two pitches.

Pitch error includes:

Simple pitch error : Pitch error for one pitch

Cumulative pitch error : Total pitch error between thread ridges which mutually depart two

pitches or more.

Progressive pitch error : Pitch error that simple pitch error is positive or negative

Periodical pitch error : Pitch error that simple pitch periodically increases and decreases.

Figure 3 Angle Error Examples

Inclination Flank angle error Angle error of thread

Prescribed thread ridge Half angle error

of thread

Half angle error

of thread

Axis of screw

thread

Figure 4 Pitch error examples

Reference pitch for

three thread ridges

P

P

Periodical pitch error

(For one period)

Periodical pitch

error

(For two periods)

Simple pitch error

Cumulative

pitch error

Reference

pitch

Measured

screw thread

In 1982 the JIS for pipe threads was revised and PT and PF which were prescribed by that time,

have been in the Appendix. R and G are included in the main body of the standard. For taps, as

in the case with pipe threads, PT PS and PF have been in the Appendix. Rc, Rp, and G are in

the main body of the standard.

Compatibility between a tap, die, and gauge of each screw thread are shown in the following

table.

<ISO and Former JIS for Pipe Thread>

Screw Thread - 6

Different

gauge

precision and

shape

Group Types

ISO

Symbol

Compatibility Reference

Rc

Rp

G

R

G

R

Rp

Rc

G

G

Compatible using second class

tap for PT - short or long type

Compatible using second

class tap for PS

Compatible using second

class tap for PS

Compatible using die for PT

Compatible using die for PF

PT incompatible

PS incompatible

(Judged by tapered plug)

PT incompatible

PF incompatible

PF incompatible

Parallel internal thread

for tightness

Taper internal thread

for tightness

Parallel internal thread

for mechanical coupling

Taper external thread

for tightness

Parallel external thread

for mechanical coupling

Taper external thread

for tightness

Parallel internal thread

for tightness

Taper internal thread

for tightness

Parallel internal thread

for mechanical coupling

Parallel internal thread

for mechanical coupling

T

a

p

Precision of

screw thread

can be

compatible,

but there is a

difference in

the shape of

the tap.

D

i

e

G

a

u

g

e

Table 4

Note: JIS PT = BSPT JIS PF = BSPF

copyright 2002 maryland metrics/osg corporation

Das könnte Ihnen auch gefallen

- Esbm5a-B 1n261-s Aa RSWDokument37 SeitenEsbm5a-B 1n261-s Aa RSWChandrajeet Shelke50% (2)

- Is.3469.1-3.1974 Die Steel Forging StandardDokument62 SeitenIs.3469.1-3.1974 Die Steel Forging Standardsunilbhol100% (3)

- Is 11169-2 (1989) - Steels Forcold Heading - Cold Extrusion, Part 2 - Stainless SteelDokument11 SeitenIs 11169-2 (1989) - Steels Forcold Heading - Cold Extrusion, Part 2 - Stainless SteelVISHAL kUMARNoch keine Bewertungen

- Is 1079 - 2009Dokument10 SeitenIs 1079 - 2009Shradha SinghaniaNoch keine Bewertungen

- Analysis of The Yokeless and Segmented Armature MachineDokument7 SeitenAnalysis of The Yokeless and Segmented Armature MachineSeksan KhamkaewNoch keine Bewertungen

- Is 14329 1995 PDFDokument13 SeitenIs 14329 1995 PDFSriram Subramanian100% (1)

- Resistance WeldingDokument13 SeitenResistance Weldingpavithra222Noch keine Bewertungen

- JIS Fasteners Lib PDFDokument312 SeitenJIS Fasteners Lib PDFNguyễnTúSơnNoch keine Bewertungen

- Casting Porosity Acceptance Criteria for Machined Sealing SurfacesDokument8 SeitenCasting Porosity Acceptance Criteria for Machined Sealing SurfacesmaheshNoch keine Bewertungen

- Metal Forming Process and DefectsDokument7 SeitenMetal Forming Process and DefectsPradeep Kumar BowmarajuNoch keine Bewertungen

- In-Die Tapping: by Chandan Kumar H.KDokument58 SeitenIn-Die Tapping: by Chandan Kumar H.KYuvaraj YuvarajNoch keine Bewertungen

- Jis G3113 1990Dokument11 SeitenJis G3113 1990TUAN NGUYEN VANNoch keine Bewertungen

- ISO 7040 Material A4-80Dokument1 SeiteISO 7040 Material A4-80rijalharunNoch keine Bewertungen

- Types of Strippers in Press ToolingDokument18 SeitenTypes of Strippers in Press Toolingnilam100% (1)

- All About Threads PDFDokument85 SeitenAll About Threads PDFSubodhNoch keine Bewertungen

- IFI 100 Prevailing Torque LocknutsDokument7 SeitenIFI 100 Prevailing Torque LocknutsMarceloGonçalvesNoch keine Bewertungen

- Parallel Key Calculation According To DIN 6892Dokument21 SeitenParallel Key Calculation According To DIN 6892zahirshah1436923Noch keine Bewertungen

- Basic Components & Elements of Surface TopographyDokument30 SeitenBasic Components & Elements of Surface TopographyXin YuNoch keine Bewertungen

- Permaglide Glijlagers LRDokument76 SeitenPermaglide Glijlagers LRVitor GodoyNoch keine Bewertungen

- DIN 908 PlugsDokument2 SeitenDIN 908 PlugsDani Quirante Flaaut EtcNoch keine Bewertungen

- Threads - Pre-Plate Vs Post Plate Class-MetricDokument3 SeitenThreads - Pre-Plate Vs Post Plate Class-MetricNaveen MaliNoch keine Bewertungen

- Is 11498 1985Dokument8 SeitenIs 11498 1985pramod100% (1)

- SKF Lock Nuts PDFDokument22 SeitenSKF Lock Nuts PDFgrupa2904Noch keine Bewertungen

- John Deere Design, Process, and Assembly ReviewDokument33 SeitenJohn Deere Design, Process, and Assembly ReviewcucuNoch keine Bewertungen

- Is.10716.2.1999 Es ISO 2162-2Dokument14 SeitenIs.10716.2.1999 Es ISO 2162-2Oscar AsistiriNoch keine Bewertungen

- Jdma17 2Dokument8 SeitenJdma17 2qualidadesider0% (1)

- Surface Vehicle Standard: Rev. SEP1997Dokument11 SeitenSurface Vehicle Standard: Rev. SEP1997Angel HernándezNoch keine Bewertungen

- Bossard Taptite Self Tapping Screw CatalogueDokument10 SeitenBossard Taptite Self Tapping Screw CataloguepmlmkpNoch keine Bewertungen

- The Manual of Fastening EN 8100 PDFDokument106 SeitenThe Manual of Fastening EN 8100 PDFOleh SmolovyiNoch keine Bewertungen

- IS 13099 1991 ISO 5458 1987 Technical Drawings - Geometrical Tolerancing Positional Tolerancing PDFDokument14 SeitenIS 13099 1991 ISO 5458 1987 Technical Drawings - Geometrical Tolerancing Positional Tolerancing PDFleovenuNoch keine Bewertungen

- Iso 6410-3 Screw Threads Simplified Representation PDFDokument9 SeitenIso 6410-3 Screw Threads Simplified Representation PDFJorge Alonso FernandezNoch keine Bewertungen

- Is 1364 PDFDokument12 SeitenIs 1364 PDFpRAVIN0% (1)

- 2370 Ed1 ENDokument5 Seiten2370 Ed1 ENanhthoNoch keine Bewertungen

- Moment of Inertia of Stepped ShaftsDokument11 SeitenMoment of Inertia of Stepped ShaftsRakesh Nair A100% (2)

- M6x1.0x23 Long HHS Control PlanDokument2 SeitenM6x1.0x23 Long HHS Control PlanDhanluxmi AutomaticsNoch keine Bewertungen

- BrassDokument1 SeiteBrassFred Duarte CaldeiraNoch keine Bewertungen

- 8400-A - External Painting & Protective CoatingsDokument19 Seiten8400-A - External Painting & Protective Coatingsamalhaj2013Noch keine Bewertungen

- FYH ZlockDokument2 SeitenFYH ZlockRodrigo Jechéla BarriosNoch keine Bewertungen

- Determination of Forming Limit Curves On ARGOMDokument58 SeitenDetermination of Forming Limit Curves On ARGOMEduardo Felippe de SouzaNoch keine Bewertungen

- External Metric ISO Thread Table Chart Sizes M20 - M55Dokument8 SeitenExternal Metric ISO Thread Table Chart Sizes M20 - M55dilipNoch keine Bewertungen

- Conversion of Degrees to Inches ChartDokument48 SeitenConversion of Degrees to Inches ChartShibnathLahiri100% (1)

- Mold and Die Casting Fit RecommendationsDokument6 SeitenMold and Die Casting Fit RecommendationsJyoti KaleNoch keine Bewertungen

- Hammer Drive ScrewDokument1 SeiteHammer Drive ScrewNisa BN QANoch keine Bewertungen

- Grease Nipple Is StandardDokument6 SeitenGrease Nipple Is StandardGanesan Thangasamy100% (1)

- GMW3359Dokument4 SeitenGMW3359lev501Noch keine Bewertungen

- ASTMB286Dokument5 SeitenASTMB286kamlesh vaishnavNoch keine Bewertungen

- 1.emerging Grades Breakthrough Products Coatings - ArcelorMittal - 201707Dokument52 Seiten1.emerging Grades Breakthrough Products Coatings - ArcelorMittal - 201707Jerry WangNoch keine Bewertungen

- METRIC THREADS - CHART For Higher SizesDokument2 SeitenMETRIC THREADS - CHART For Higher SizesramabhplNoch keine Bewertungen

- Circlip Dimensions PDFDokument71 SeitenCirclip Dimensions PDFBoobalan ShriNoch keine Bewertungen

- Is - 1862 - 1981Dokument5 SeitenIs - 1862 - 1981kumar QANoch keine Bewertungen

- Pre-Load and Tightening Torques For Steel Fasteners - Standard Metric ThreadsDokument3 SeitenPre-Load and Tightening Torques For Steel Fasteners - Standard Metric ThreadsmukeshkumarjNoch keine Bewertungen

- 11 Threadings UpdDokument33 Seiten11 Threadings UpdMarco RicardNoch keine Bewertungen

- General: According To ISO 724Dokument3 SeitenGeneral: According To ISO 724Muharrem BeyogluNoch keine Bewertungen

- Useful InfoDokument1 SeiteUseful InfoAlNoch keine Bewertungen

- Sae J755 PDFDokument1 SeiteSae J755 PDFJuniorJavier Olivo Farrera100% (1)

- Stainless Steel Flanges PDFDokument25 SeitenStainless Steel Flanges PDFhindro kusumantoNoch keine Bewertungen

- Jis Thread StandardsDokument1 SeiteJis Thread StandardsPaul Hammerstrom100% (1)

- Riken Europe Vol.01Dokument140 SeitenRiken Europe Vol.01miguelNoch keine Bewertungen

- Metric Screw Threads: Nissan Engineering StandardDokument90 SeitenMetric Screw Threads: Nissan Engineering StandardBea RiveraNoch keine Bewertungen

- Hexagon socket set screw technical dataDokument1 SeiteHexagon socket set screw technical datailo iloNoch keine Bewertungen

- Miniskaff Assembly Instructions PDFDokument2 SeitenMiniskaff Assembly Instructions PDFthailanNoch keine Bewertungen

- Hyundai spare parts catalog download/TITLEDokument2 SeitenHyundai spare parts catalog download/TITLEthailanNoch keine Bewertungen

- Miniskaff Assembly Instructions PDFDokument2 SeitenMiniskaff Assembly Instructions PDFthailanNoch keine Bewertungen

- Norma Normaquick Quick ConnectorDokument16 SeitenNorma Normaquick Quick ConnectorthailanNoch keine Bewertungen

- AMastersGuidetoContainerSecuring2ndEdition 3 PDFDokument50 SeitenAMastersGuidetoContainerSecuring2ndEdition 3 PDFthailanNoch keine Bewertungen

- Possible Frame IssueDokument10 SeitenPossible Frame IssuethailanNoch keine Bewertungen

- 2016 Mining Catalogue MASTERDokument79 Seiten2016 Mining Catalogue MASTERthailanNoch keine Bewertungen

- Bul SAE J2044 PDFDokument8 SeitenBul SAE J2044 PDFthailanNoch keine Bewertungen

- MV99 - Load Sensing VVDokument46 SeitenMV99 - Load Sensing VVthailanNoch keine Bewertungen

- Ar Industrial Catalog en 2016 WebDokument120 SeitenAr Industrial Catalog en 2016 WebthailanNoch keine Bewertungen

- Portable Repair WorkshopsDokument24 SeitenPortable Repair WorkshopsthailanNoch keine Bewertungen

- 40 Foot Container DimensionsDokument3 Seiten40 Foot Container DimensionsthailanNoch keine Bewertungen

- Unc Unf Metric Thread Chart Northwest FastenerDokument1 SeiteUnc Unf Metric Thread Chart Northwest FastenerthailanNoch keine Bewertungen

- SERIES-90 180cc SERVICE BLN-2-41695 1997-05Dokument52 SeitenSERIES-90 180cc SERVICE BLN-2-41695 1997-05thailanNoch keine Bewertungen

- HILUX Electrical Wiring Diagram GuideDokument244 SeitenHILUX Electrical Wiring Diagram Guidethailan100% (2)

- Mounting Flange HZW EngDokument2 SeitenMounting Flange HZW EngthailanNoch keine Bewertungen

- 520L0893 PDFDokument240 Seiten520L0893 PDFthailanNoch keine Bewertungen

- Alemite CatalogDokument177 SeitenAlemite CatalogthailanNoch keine Bewertungen

- Cummins Heavy Duty Product Guide PDFDokument22 SeitenCummins Heavy Duty Product Guide PDFthailanNoch keine Bewertungen

- Alemite CatalogDokument177 SeitenAlemite CatalogthailanNoch keine Bewertungen

- NPTDokument6 SeitenNPTthailanNoch keine Bewertungen

- 38 Alemite Product Catalog PDFDokument277 Seiten38 Alemite Product Catalog PDFthailanNoch keine Bewertungen

- Type of ThreadDokument13 SeitenType of ThreadVils ArabadzhievaNoch keine Bewertungen

- 3c EngDokument2 Seiten3c EngthailanNoch keine Bewertungen

- How To Identify Fluid Ports and ConnectorsDokument24 SeitenHow To Identify Fluid Ports and ConnectorsKathryn WorkmanNoch keine Bewertungen

- Ourproductconcept Eng PDFDokument8 SeitenOurproductconcept Eng PDFthailan100% (1)

- 3 o Ring Guide Issue 7 PDFDokument32 Seiten3 o Ring Guide Issue 7 PDFthailanNoch keine Bewertungen

- Dseries Eng PDFDokument3 SeitenDseries Eng PDFthailanNoch keine Bewertungen

- Mounting Flange HZW EngDokument2 SeitenMounting Flange HZW EngthailanNoch keine Bewertungen

- RoyMech - Screw Thread CalculationsDokument6 SeitenRoyMech - Screw Thread CalculationsSalahiddin AbuselmiyaNoch keine Bewertungen

- CH 8: Screws, Fasteners, and The Design of Non-Permanent JointsDokument15 SeitenCH 8: Screws, Fasteners, and The Design of Non-Permanent JointsBhuwaneshwar DahalNoch keine Bewertungen

- Technical Data: Diameter - Pitch Combinations For Class of FitDokument1 SeiteTechnical Data: Diameter - Pitch Combinations For Class of FitecavalinNoch keine Bewertungen

- ISO 965-1 ISO General Purpose Metric Screw Threads-TolerancesDokument11 SeitenISO 965-1 ISO General Purpose Metric Screw Threads-TolerancesBatNoch keine Bewertungen

- Greaves Price List MRP - W e F 23-11-2017Dokument139 SeitenGreaves Price List MRP - W e F 23-11-2017dulichand50% (2)

- Ch01 Standard Methods and PractisesDokument44 SeitenCh01 Standard Methods and PractisesUsman FarooqNoch keine Bewertungen

- Handbook: Overhaul InstructionsDokument30 SeitenHandbook: Overhaul InstructionsJacksonNoch keine Bewertungen

- Iso 68 1Dokument10 SeitenIso 68 1Kapil Enterprises BigboltnutNoch keine Bewertungen

- FZ150 Vixion NVL Fuel TankDokument3 SeitenFZ150 Vixion NVL Fuel TankmuhammadhasanibmtNoch keine Bewertungen

- 90° Anchor BoltDokument2 Seiten90° Anchor BoltJovito EdillonNoch keine Bewertungen

- High Tensile BoltsDokument5 SeitenHigh Tensile BoltssteelfaceNoch keine Bewertungen

- Iso 21670 2003 PDFDokument9 SeitenIso 21670 2003 PDFGiuseppeNoch keine Bewertungen

- Saf-T-Liner C2 Parts Reference Manual (Interior)Dokument116 SeitenSaf-T-Liner C2 Parts Reference Manual (Interior)cesarsegura57Noch keine Bewertungen

- Mounted Ball Bearings Dimensions and SpecsDokument1 SeiteMounted Ball Bearings Dimensions and SpecsLuis VallejoNoch keine Bewertungen

- ThreadsDokument11 SeitenThreadsBuddha PrakashNoch keine Bewertungen

- PC160LC 7 S N B20001 and UpDokument372 SeitenPC160LC 7 S N B20001 and UpJerônimo RafaelNoch keine Bewertungen

- NAVIGATION ECHO SOUNDER PARTSDokument19 SeitenNAVIGATION ECHO SOUNDER PARTSsamee 692Noch keine Bewertungen

- Backhoe Controls W/hand Swing, Lower Control Levers W/nonextend Dipper Used W/180378a1 Control Supp.Dokument2 SeitenBackhoe Controls W/hand Swing, Lower Control Levers W/nonextend Dipper Used W/180378a1 Control Supp.juan jesus pineda hernandezNoch keine Bewertungen

- 2 0 Engine AssemblyDokument29 Seiten2 0 Engine AssemblyMiguel Angel Santos PintadoNoch keine Bewertungen

- 9A21301 Aircraft Engineering Drawing With CADDokument9 Seiten9A21301 Aircraft Engineering Drawing With CADsivabharathamurthyNoch keine Bewertungen

- 2017 Husqvarna Pz60 Parts Book I2013 - Aaen - pz60 - 115518027bDokument28 Seiten2017 Husqvarna Pz60 Parts Book I2013 - Aaen - pz60 - 115518027bestebanNoch keine Bewertungen

- Ce Papers - 2021 - Strangh Ner - Weathering Impacts On The Tightening Behaviour of HV HR Bolting Assemblies For PreloadingDokument8 SeitenCe Papers - 2021 - Strangh Ner - Weathering Impacts On The Tightening Behaviour of HV HR Bolting Assemblies For PreloadingbalamuruganNoch keine Bewertungen

- New JACK Sewing Machine: 2013 4 Revised Edition in April, 2013Dokument51 SeitenNew JACK Sewing Machine: 2013 4 Revised Edition in April, 2013PE TruNoch keine Bewertungen

- Din 929 NutsDokument1 SeiteDin 929 NutsvpjagannaathNoch keine Bewertungen

- GE Renewal Parts: Resistor Model 17Em49U2Dokument3 SeitenGE Renewal Parts: Resistor Model 17Em49U2Rafael Dutil LucianaNoch keine Bewertungen

- 3D Printer A6 Assembly Parts List-2016-7-2 PDFDokument5 Seiten3D Printer A6 Assembly Parts List-2016-7-2 PDFAnonymous vzsPCPDF6bNoch keine Bewertungen

- CM/PM/SM. La Parte Inferior Es Relates To CM/PM/SM VersionDokument80 SeitenCM/PM/SM. La Parte Inferior Es Relates To CM/PM/SM Versionbasheer almetwakelNoch keine Bewertungen

- EUPEN Radiating Cables Installation Guide Ed 1Dokument24 SeitenEUPEN Radiating Cables Installation Guide Ed 1Carlos BritoNoch keine Bewertungen

- 7 - Material List - Jembatan Gantung 40 M - 2Dokument5 Seiten7 - Material List - Jembatan Gantung 40 M - 2wahyuokkNoch keine Bewertungen

- Din 13-7Dokument6 SeitenDin 13-7rajeskumarNoch keine Bewertungen