Beruflich Dokumente

Kultur Dokumente

Coefficient of Friction Reference Table - Engineer's Handbook

Hochgeladen von

safaozhanOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Coefficient of Friction Reference Table - Engineer's Handbook

Hochgeladen von

safaozhanCopyright:

Verfügbare Formate

Engineer's Handbook

Reference Tables

Rapid Prototyping

Manufacturing Methods

Engineering Materials

Engineering Software

Reference Books

Mechanical Components

Index of Tables

Manufacturing

Materials

Fasteners

Equations - Units - Constants

Site Index

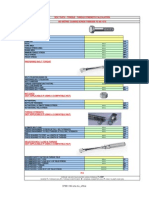

Reference Tables -- Coefficient of Friction

Coefficient of Friction

Extreme care is needed in using friction coefficients and additional independent references should be used. For any specific application the ideal method of determining the coefficient of friction is by trials. A short table is included above the main table to illustrate how the coefficient of friction is affected by surface films. When a metal surface is perfectly clean in a vacuum . the friction is much higher than the normal accepted value and seizure can easily occur.

Effect of Oxide film, Sulfide film on Coefficient of Static Friction

MATERIAL Steel-Steel CopperCopper Clean & Dry 0.78 1.21 Thick Oxide Film 0.27 0.76 Sulfide Film 0.39 0.74

Coefficient Of Friction MATERIAL 1 MATERIAL 2 Static Aluminum Aluminum Brake Material Brake Material Brass Brick Bronze Bronze Cadmium Cadmium Cast Iron Cast Iron Chromium Copper Copper Aluminum Mild Steel Cast Iron Cast Iron (Wet) Cast Iron Wood Cast Iron Steel Cadmium Mild Steel Cast Iron Oak Chromium Cast Iron Copper 0.41 1.05 1.0 0.29 0.08

1/4

Dry Sliding 1.4 0.47

Greasy Static 0.3 Sliding

1.05-1.35 0.61 0.4 0.2

0.3 0.6 0.22 0.16 0.5 0.46 1.1 0.15 0.49 0.34 0.07 0.075 0.05

www.engineershandbook.com/Tables/frictioncoefficients.htm

Copper Copper Copper-Lead Alloy Diamond Diamond Glass Glass Glass Graphite Graphite

Copper Mild Steel Steel Diamond Metal Glass Metal Nickel Graphite Steel

1.0 0.53 0.22 0.1 0.1 -0.15 0.9 - 1.0 0.5 - 0.7 0.78 0.1 0.1 0.5 - 0.8 0.16 0.14 1.0 0.43 0.3 - 0.4 0.6 0.4 0.61 0.6 0.7-1.1 0.53 0.64; 0.15 - 0.25 0.62 0.54 1.2 0.8 0.4 - 0.5 0.5 0.3-0.35 0.2 0.5-0.8 0.25-0.0.75 0.6-0.85 0.45-0.75 0.2 1.4 0.48 0.32 0.52 0.56 0.4 0.36

0.08 0.18 0.05 - 0.1 0.1 0.1 - 0.6 0.2 - 0.3 0.09-0.12

0.1 0.1

Graphite (In vacuum) Graphite (In vacuum) Hard Carbon Hard Carbon Iron Lead Leather Leather Leather Leather Magnesium Nickel Nickel Nylon Oak Oak Platinum Plexiglas Plexiglas Polystyrene Polystyrene Polythene Rubber Rubber Rubber Rubber Saphire Silver Hard Carbon Steel Iron Cast Iron Wood Metal(Clean) Metal(Wet) Oak (Parallel grain) Magnesium Nickel Mild Steel Nylon Oak (parallel grain) Oak (cross grain) Platinum Plexiglas Steel Polystyrene Steel Steel Asphalt (Dry) Asphalt (Wet) Concrete (Dry) Concrete (Wet) Saphire Silver

0.12 - 0.14 0.11 - 0.14 0.15 - 0.2

0.2

0.08 0.28 0.12 0.178

0.072 0.25 0.8 0.4 - 0.5 0.5 0.3-0.35 0.2

0.2 0.55

2/4

www.engineershandbook.com/Tables/frictioncoefficients.htm

Sintered Bronze Solids Steel Steel Steel(Mild) Steel (Mild) Steel Steel Steel (Hard) Steel Steel (Mild) Steel (Mild) Steel Steel(Hard) Steel(Hard) Steel (Mild) Steel(Hard) Steel Teflon Teflon Tin Tungsten Carbide Tungsten Carbide Tungsten Carbide Tungsten Carbide Wood Wood Wood Wood Wood Wood Zinc Zinc

Steel Rubber Aluminium Bros Brass Brass Cast Iron Cast Iron Copper Lead Alloy Graphite Graphite Lead Phos. Bros Phos Bros Polythened Polystyrene Steel (Mild) Steel (Hard) Zinc (Plated on steel) Steel Teflon Cast Iron Tungsten Carbide Steel Copper Iron Wood(clean) Wood (Wet) Metals(Clean) Metals (Wet) Brick Concrete Zinc Cast Iron

1.0 - 4.0 0.45 0.35 0.51 0.44 0.23 0.4 0.22 0.21 0.1 0.95 0.95 0.34 0.35 0.2 0.3-0.35 0.74 0.78 0.5 0.04 0.04 .32 0.2-0.25 0.4 - 0.6 0.35 0.8 0.25 - 0.5 0.2 0.2-0.6 0.2 0.6 0.62 0.6 0.85 0.21 0.57 0.42 0.45

0.13 --

0.19

0.183 0.21 0.16 0.09 0.1 0.5

0.133

0.145

0.3 0.173

0.2 0.3-0.35 0.09-0.19 0.05 -0.11 0.029-.12 0.04 0.04 0.04 0.04

0.12 0.08 - 0.2

0.04

www.engineershandbook.com/Tables/frictioncoefficients.htm

3/4

Copyright 2004 - 2006 -- EngineersHandbook.com All Rights Reserv ed - Contact Information Priv acy Policy Disclaimer

www.engineershandbook.com/Tables/frictioncoefficients.htm

4/4

Das könnte Ihnen auch gefallen

- American Welding SocietyDokument3 SeitenAmerican Welding SocietyRamsey RasmeyNoch keine Bewertungen

- ASTM A686 T72301 W1A 9.5 Steel GuideDokument2 SeitenASTM A686 T72301 W1A 9.5 Steel GuideBernice JohnsonNoch keine Bewertungen

- Table of Friction CoefficientDokument2 SeitenTable of Friction CoefficientMichael M. Li80% (5)

- Everything You Need to Know About BearingsDokument51 SeitenEverything You Need to Know About BearingsvarunNoch keine Bewertungen

- Basics of Tank Seismic OCRDokument35 SeitenBasics of Tank Seismic OCRmario_gNoch keine Bewertungen

- HCM001 Hollow-Core Design Manual - Complete - 03.23.15Dokument38 SeitenHCM001 Hollow-Core Design Manual - Complete - 03.23.15lbhnsw5930100% (1)

- A - Piping Joint HandbookDokument161 SeitenA - Piping Joint HandbookCharles Tauk100% (30)

- Ferrous Alloys Metallurgy ReviewDokument80 SeitenFerrous Alloys Metallurgy ReviewAlvin Garcia PalancaNoch keine Bewertungen

- Csa G40.21 PDFDokument4 SeitenCsa G40.21 PDFmecano1Noch keine Bewertungen

- Expansion, Conctraction and Construction Joint On Concrete For Civil Works PDFDokument10 SeitenExpansion, Conctraction and Construction Joint On Concrete For Civil Works PDFSushil DhunganaNoch keine Bewertungen

- Heat TreatmentDokument14 SeitenHeat TreatmentAkhilesh KumarNoch keine Bewertungen

- Gaskets and Gasketed Joints (PDFDrive)Dokument1.114 SeitenGaskets and Gasketed Joints (PDFDrive)SUBESHKUMARNoch keine Bewertungen

- Astm D1525 PDFDokument10 SeitenAstm D1525 PDFCristian Culqui PerezNoch keine Bewertungen

- Metric Bolt Data - Torque - Thread StrengthDokument10 SeitenMetric Bolt Data - Torque - Thread StrengthbakellyNoch keine Bewertungen

- Safe Working Load Calculation For Round BarDokument1 SeiteSafe Working Load Calculation For Round BarAdura OgunnuNoch keine Bewertungen

- Jis G3466-2006 HSSDokument11 SeitenJis G3466-2006 HSSabdulloh_99Noch keine Bewertungen

- Coefficient of FrictionDokument4 SeitenCoefficient of Frictionjsmargate100% (1)

- Duplex Stainless SteelDokument17 SeitenDuplex Stainless SteelthunderNoch keine Bewertungen

- Structural Steels Equivalent ChartDokument2 SeitenStructural Steels Equivalent ChartHamdan PkNoch keine Bewertungen

- SI UnitsDokument90 SeitenSI UnitsManas KarnureNoch keine Bewertungen

- Metalography and Microstructures of Stainless Steels and Maraging SteelsDokument32 SeitenMetalography and Microstructures of Stainless Steels and Maraging SteelsChaguy VergaraNoch keine Bewertungen

- Stainless Steel 304 Product InfoDokument1 SeiteStainless Steel 304 Product Infoarunava001Noch keine Bewertungen

- Flender Engineering Book Pages OffsetDokument139 SeitenFlender Engineering Book Pages Offsetjimsmith101Noch keine Bewertungen

- Fillet Weld Strength Calculation Example For Welded Connection Subjected To BendingDokument6 SeitenFillet Weld Strength Calculation Example For Welded Connection Subjected To BendingpipestressNoch keine Bewertungen

- Hilti Direct Fastening 2015Dokument42 SeitenHilti Direct Fastening 2015safaozhanNoch keine Bewertungen

- Asme B18.2.1 PDFDokument37 SeitenAsme B18.2.1 PDFJUAN C100% (1)

- MHD56209 Jib CranesDokument44 SeitenMHD56209 Jib CranestintucinbNoch keine Bewertungen

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonVon EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNoch keine Bewertungen

- Beams Spreader PDFDokument4 SeitenBeams Spreader PDFravikumarangNoch keine Bewertungen

- DIN 17100 STEELS GUIDEDokument7 SeitenDIN 17100 STEELS GUIDEsardhan.rajender84Noch keine Bewertungen

- Din & IsoDokument94 SeitenDin & IsoZeinHarisHasibuan100% (5)

- Composite Steel Highway BridgesDokument28 SeitenComposite Steel Highway BridgesNouri SaadonNoch keine Bewertungen

- Tata Steel - Blue Book - Advance - Section - Properties - For - Students PDFDokument20 SeitenTata Steel - Blue Book - Advance - Section - Properties - For - Students PDFshugd31085100% (1)

- Piping QuizDokument20 SeitenPiping QuizAlex CarreraNoch keine Bewertungen

- Aashto T283 PDFDokument7 SeitenAashto T283 PDFguru nathNoch keine Bewertungen

- Din 580Dokument1 SeiteDin 580safaozhanNoch keine Bewertungen

- 4340M or 300MDokument2 Seiten4340M or 300MfedaquiNoch keine Bewertungen

- GuidanceNotes EN131 Version2Dokument10 SeitenGuidanceNotes EN131 Version2Javier Quintero SaavedraNoch keine Bewertungen

- Smarter Materials Selection For Corrosion Control PDFDokument12 SeitenSmarter Materials Selection For Corrosion Control PDFAsyraf Nordin100% (1)

- Smarter Materials Selection For Corrosion Control PDFDokument12 SeitenSmarter Materials Selection For Corrosion Control PDFAsyraf Nordin100% (1)

- Fema-460 Seismic Considerations For Steel Storage Racks Located in Areas Accessible To The PublicDokument174 SeitenFema-460 Seismic Considerations For Steel Storage Racks Located in Areas Accessible To The PublicAmer Abdel Aziz100% (1)

- Static Frictional Coefficients for Common MaterialsDokument3 SeitenStatic Frictional Coefficients for Common MaterialsDonz RahmandaniNoch keine Bewertungen

- SAE Steel Grades - WikipediaDokument30 SeitenSAE Steel Grades - Wikipediamanoj ranathiive100% (1)

- Ccsviiid1 2260Dokument2 SeitenCcsviiid1 2260DieguitoOmarMoralesNoch keine Bewertungen

- HardnessDokument23 SeitenHardnesskdalavadi3905Noch keine Bewertungen

- TE B Gearbox Design Oral QuestionsDokument5 SeitenTE B Gearbox Design Oral QuestionsapteashutoshNoch keine Bewertungen

- 410 Data Sheet PDFDokument2 Seiten410 Data Sheet PDFraviteja036Noch keine Bewertungen

- 080M40 (EN8) Specification Chemical CompositionDokument1 Seite080M40 (EN8) Specification Chemical CompositionAmar ThakurNoch keine Bewertungen

- Eccentric Column BucklingDokument10 SeitenEccentric Column BucklingMukeshChopraNoch keine Bewertungen

- Adjustable Pipe SupportDokument1 SeiteAdjustable Pipe SupportTroy HooperNoch keine Bewertungen

- Type AB Air Gaps - Practical ExamplesDokument3 SeitenType AB Air Gaps - Practical ExamplesZack ZakariaNoch keine Bewertungen

- 16542Dokument7 Seiten16542Cnc CamNoch keine Bewertungen

- Pade EyeDokument2 SeitenPade EyeAzwar Maiza PutraNoch keine Bewertungen

- Crane Wheel Heat Treating MethodsDokument20 SeitenCrane Wheel Heat Treating Methodsgmurdzhev67% (3)

- ASCE 7-05 Table 15-4-2Dokument1 SeiteASCE 7-05 Table 15-4-2barouniamineNoch keine Bewertungen

- Omni Block - BrochureDokument2 SeitenOmni Block - BrochureJames100% (1)

- Storage Tanks Made of SteelDokument6 SeitenStorage Tanks Made of SteelHakan Şahinoğlu100% (1)

- ISPAT INDUSTRIES SPECIFICATION FOR COLD ROLLED STEELDokument1 SeiteISPAT INDUSTRIES SPECIFICATION FOR COLD ROLLED STEELVinoth ShankarNoch keine Bewertungen

- Flange EN1092-1 TYPE 01 Flange PDFDokument4 SeitenFlange EN1092-1 TYPE 01 Flange PDFVishal MistryNoch keine Bewertungen

- Alloy Master LinksDokument1 SeiteAlloy Master LinksAnonymous 48jYxR1C0% (1)

- BARNES Associated Spring Raymond 2010Dokument260 SeitenBARNES Associated Spring Raymond 2010Francois LaroucheNoch keine Bewertungen

- Stainless Steel 316l (SA240)Dokument2 SeitenStainless Steel 316l (SA240)Sugiarto SaptomoNoch keine Bewertungen

- Design of I-Shape Column Base PlateDokument4 SeitenDesign of I-Shape Column Base PlatePereira da SilvaNoch keine Bewertungen

- BS 4504 Slip On Flanges PDFDokument7 SeitenBS 4504 Slip On Flanges PDFMaclean ArthurNoch keine Bewertungen

- Evaluating Safe Hydrotest Pressures for Cold Tapping with FEADokument4 SeitenEvaluating Safe Hydrotest Pressures for Cold Tapping with FEAninju1100% (1)

- ASTM A106 GR.B Steel TubeDokument2 SeitenASTM A106 GR.B Steel TubeSpicyNoch keine Bewertungen

- Basics of Finite Element AnalysisDokument121 SeitenBasics of Finite Element AnalysisChetan The game changerNoch keine Bewertungen

- Alloy Steel Castings Table 1Dokument16 SeitenAlloy Steel Castings Table 1takumi_zNoch keine Bewertungen

- No10 Machine Ability RatingsDokument6 SeitenNo10 Machine Ability RatingsochoadavidNoch keine Bewertungen

- Frictional Coefficients for Common Materials CombinationsDokument3 SeitenFrictional Coefficients for Common Materials CombinationsAdhe Anggriawan PutraNoch keine Bewertungen

- Metals and Alloys & Heat Treatment of Steels 2,4Dokument82 SeitenMetals and Alloys & Heat Treatment of Steels 2,4Vimukthi KumaraNoch keine Bewertungen

- Ksp-Instrument Impulse Piping & TubingDokument18 SeitenKsp-Instrument Impulse Piping & TubingZulfequar R. Ali KhanNoch keine Bewertungen

- 02.classifications and SpecificationsDokument8 Seiten02.classifications and SpecificationsShendi Kiki PratamaNoch keine Bewertungen

- VDI 3842 - Vibrations in Piping System PDFDokument44 SeitenVDI 3842 - Vibrations in Piping System PDFsafaozhan88% (8)

- Ansys Consitent UnitsDokument2 SeitenAnsys Consitent Unitsdownload_2005Noch keine Bewertungen

- Mechanics of Materials - Cantilever Flexure TestDokument19 SeitenMechanics of Materials - Cantilever Flexure TestDavid Clark100% (7)

- MAK312 Summer 2011 Quiz1 SolnDokument3 SeitenMAK312 Summer 2011 Quiz1 SolnsafaozhanNoch keine Bewertungen

- ISO 1101 GeometricTolerances PDFDokument1 SeiteISO 1101 GeometricTolerances PDFmochamadrizal7Noch keine Bewertungen

- Flange FVC DataDokument36 SeitenFlange FVC DataachillesntroyNoch keine Bewertungen

- 03 Ernstsen Jensen Slug Force PresentationDokument26 Seiten03 Ernstsen Jensen Slug Force Presentationsam_kamali85Noch keine Bewertungen

- MAK312 Summer 2011 Quiz1 SolnDokument3 SeitenMAK312 Summer 2011 Quiz1 SolnsafaozhanNoch keine Bewertungen

- Driveline Dynamics and Gearbox DesignDokument19 SeitenDriveline Dynamics and Gearbox DesignsafaozhanNoch keine Bewertungen

- Catalogo WfiDokument36 SeitenCatalogo WfiJack DominikNoch keine Bewertungen

- Foundations For Machinery-1974Dokument42 SeitenFoundations For Machinery-1974safaozhanNoch keine Bewertungen

- Apoyos TeflonDokument14 SeitenApoyos Teflonjulio1114Noch keine Bewertungen

- Pub162-H19 3Dokument16 SeitenPub162-H19 3safaozhanNoch keine Bewertungen

- MC Design Engineers Guide PDFDokument19 SeitenMC Design Engineers Guide PDFgovindsrNoch keine Bewertungen

- CB36Dokument12 SeitenCB36safaozhanNoch keine Bewertungen

- Steam Tables and ChartsDokument9 SeitenSteam Tables and ChartsjpnaveenNoch keine Bewertungen

- KGIMTPDokument12 SeitenKGIMTPannesmthNoch keine Bewertungen

- Flexitallic Joint Integrity CalculationsDokument7 SeitenFlexitallic Joint Integrity Calculationslotra1979Noch keine Bewertungen

- Gas SpringsDokument16 SeitenGas SpringsmaciasrobNoch keine Bewertungen

- Torsional Properties of Fabricated I-Beam and Box Sections 1941Dokument36 SeitenTorsional Properties of Fabricated I-Beam and Box Sections 1941safaozhanNoch keine Bewertungen

- SSAB Domex Tube Double Grade: General Product DescriptionDokument6 SeitenSSAB Domex Tube Double Grade: General Product DescriptionsaurabhsubhuNoch keine Bewertungen

- 23.573 Damage Tolerance and Fatigue Evaluation of StructureDokument3 Seiten23.573 Damage Tolerance and Fatigue Evaluation of StructureAnonymous 3B9kXrNoch keine Bewertungen

- Matrix - Data Sheet - Square Magnetic GridDokument1 SeiteMatrix - Data Sheet - Square Magnetic Gridaditya1759Noch keine Bewertungen

- Enau Polyla (FDM Filament) : Problem StatementDokument1 SeiteEnau Polyla (FDM Filament) : Problem Statementhakim nasirNoch keine Bewertungen

- Durco G4 Full Area Plug ValvesDokument8 SeitenDurco G4 Full Area Plug ValvesbalajiNoch keine Bewertungen

- ORMOCERIDokument6 SeitenORMOCERIBogdanNoch keine Bewertungen

- Nature of ResistanceDokument28 SeitenNature of Resistancelocutor100% (1)

- 20020203a PDFDokument4 Seiten20020203a PDFtalk2sumantaNoch keine Bewertungen

- MANUAL DIGITAL - OrkliDokument2 SeitenMANUAL DIGITAL - OrkliJavier HsNoch keine Bewertungen

- Vestige of Bitumen With and Without Sasobit On MaturingDokument4 SeitenVestige of Bitumen With and Without Sasobit On MaturingadithyaNoch keine Bewertungen

- Consolidating Concrete with VibratorsDokument13 SeitenConsolidating Concrete with VibratorsShubham JainNoch keine Bewertungen

- Univer Eng Digitale2 PDFDokument76 SeitenUniver Eng Digitale2 PDFMohsin MukulNoch keine Bewertungen

- 1new PenstockDokument23 Seiten1new PenstockEr Harsh Mahato100% (1)

- Topic 4 - Precast Concrete Connections For Framed Buildings - 2Dokument90 SeitenTopic 4 - Precast Concrete Connections For Framed Buildings - 2Abdullah RamziNoch keine Bewertungen

- (Clivet-2003-5C2001) Water Cooled Screw ChillerDokument19 Seiten(Clivet-2003-5C2001) Water Cooled Screw Chillerajun madana putraNoch keine Bewertungen

- Drain 600x600Dokument7 SeitenDrain 600x600Himanshu ChaturvediNoch keine Bewertungen

- Porosity WeldingDokument13 SeitenPorosity Weldingazerai2000Noch keine Bewertungen

- Auditorium Acoustic G 3 3Dokument10 SeitenAuditorium Acoustic G 3 3TharunNoch keine Bewertungen

- GF Indonesia Brochure PR UTS 0417 Garda SuryaDokument12 SeitenGF Indonesia Brochure PR UTS 0417 Garda SuryaRival Juney Christian PatrasNoch keine Bewertungen

- Fas-11 Typical Device Equipment Installation PDFDokument1 SeiteFas-11 Typical Device Equipment Installation PDFMØhãmmed ØwięsNoch keine Bewertungen

- Etag 032 Part 7 May 2013Dokument65 SeitenEtag 032 Part 7 May 2013coolkaisyNoch keine Bewertungen

- CatalogueDokument36 SeitenCataloguemani_208eeNoch keine Bewertungen

- Superlift MetricDokument2 SeitenSuperlift MetricAshley DeanNoch keine Bewertungen

- Solarventi Export PricelistDokument2 SeitenSolarventi Export Pricelistapi-289255600Noch keine Bewertungen

- Hydrotube™: Your Best Partner in GeosyntheticsDokument4 SeitenHydrotube™: Your Best Partner in GeosyntheticsKamal FitriNoch keine Bewertungen

- Indoor Unit Outdoor Unit CS-S10JKP CS-S13JKP CS-S15JKP CU-S10JKP CU-S13JKP CU-S15JKPDokument93 SeitenIndoor Unit Outdoor Unit CS-S10JKP CS-S13JKP CS-S15JKP CU-S10JKP CU-S13JKP CU-S15JKPVinh LeNoch keine Bewertungen