Beruflich Dokumente

Kultur Dokumente

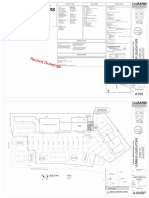

TJs Wellington Addendum - 1 Set 10.18.13

Hochgeladen von

srogan2323Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

TJs Wellington Addendum - 1 Set 10.18.13

Hochgeladen von

srogan2323Copyright:

Verfügbare Formate

CONSTRUCTION

ROUGH OPENING

CONSTR

R.O.

JUNCTION BOX

LAVATORY

POUND

LEFT HAND

LANDLORD

LIGHT

MATERIAL

MAXIMUM

MACHINE BOLT

MEDICINE CABINET

MINERAL CORE

MECHANICAL

MANUFACTURER

MAN HOLD

MINIMUM

MASONRY OPENING

MOISTURE RESISTANT

METAL

NORTH

NAIL

NATURAL GRADE

NOT IN CONTRACT

NUMBER

NOMINAL

NOT TO SCALE

OVER

OVERALL

ON CENTER

OVERHEAD

N.T.S.

O.H.

OA.

O.C.

O/

MECH

N.I.C.

NO.

NOM

N.G.

N

N.

M.R

MIN.

M.O

MTL

MFGR

M.H.

LL.

M.C.

MC.

M.B

MAX

MATL.

LT.

LAV

L.H

LB.

INS.

INT.

J.

INSURANCE

CONTINUOUS

COLD WATER

DECK DRAIN

DIAMETER

DIMENSION

DOWN

DOWN SPOUT

DETAIL

DRAWING

EACH

EXHAUST FAN

EXPANSION JOINT

ELECTRIC

ELEVATION

EQUAL

EQUIPMENT

EACH WAY

EXISTING

EXPOSED

EXTERIOR

FLOOR DRAIN

FINISH FLOOR

FINISH GRADE

FINISH

FIXTURE

FLOWLINE

FLOOR

FACE OF CONCRETE

FACE OF MASONRY

FACE OF STUD

FIREPLACE

FINISH PAVING

FEET

FOOTING

GAS

GAUGE

GALVANIZED

GENERAL CONTRACTOR

GARBAGE DISPOSAL

GALVANIZED IRON

GLASS

GAS METER

GYPSUM BOARD

HOUSE BIB

HOLLOWCORE

HEAD

HOLLOWMETAL

HEIGHT

HANDICAPPED

HEATING, VENTILATING, AND

HOT WATER

AIR CONDITIONING

F.L.

HD.

H.V.A.C.

H.W.

HP.

H.M.

HT.

H.C.

G.M

GYP. BD.

H.B.

G.I.

GL.

FT.

GAS

G.C.

G.D

GALV.

GA.

FTG.

F.O.C.

F.P.

FP.

F.O.S.

F.O.M

FLR

ELEC

F.F

F.G

FIXT

FIN

F.D

EXT

EQ.

E.W

EQUIP

EXP

EXIST

ELEV

E.J

E.F

EA.

DWG

D.S

DTL

C.W

D.D.

DIM

DN

DIA

CONT

W.H.

W.O.

W.W.M.

YD.

W.P.

W.I.

W/O

W.C.

WD.

W/

UNF.

W.

U.N.O. UNLESS NOTED OTHERWISE

WELDED WIRE MESH

WATER HEATER

WROUGHT IRON

WITHOUT

WHERE OCCURS

WATER PROOF

YARD

UNFINISHED

WATER

WATER CLOSET

WITH

WOOD

TREAD

SUBFLR.

T.O.

T.O.P.

U.G.

TYP.

T.O.W.

T.O.S.

T.O.C.

T&G

THK.

T.C.B.

T&B

SUSP.

SS.

STL.

STR.

S.S.

SHTG.

SIM.

S.C.

SHT.

S.F.

S.D.

S.A.

R.S.

SUB-FLOOR

TOP AND BOTTOM

TOP OF CATCH BASIN

TONGUE AND GROOVE

TOP OF

TOP OF CURB

TOP OF SLAB

TOP OF PAVING

TOP OF WALL

TYPICAL

UNDERGROUND

SUSPENDED

TREAD

THICK

SELECT STRUCTURAL

STAINLESS STEEL

SHEATHING

SIMILAR

STEEL

STRUCTURAL

ROUGH SAWN

SUPPLY AIR

SOLID CORE

STORM DRAIN

SQUARE FEET

SHEET

ANCHOR BOLT

AIR CONDITIONING

ASPHALT CONCRETE PAVING

AREA DRAIN

ABOVE FINISH FLOOR

ALUMINUM

ANODIZE

ACCESS PANEL

ARCHITECT/ ARCHITECTURAL

ASPHALT TILE

BOARD

BUILDING LINE

BUILDING

BLOCKING

BOTTOM

BUILT UP ROOFING

CATCH BASIN

CONSTRUCTION DOCUMENTS

CAST IRON

CONTROL JOINT

CENTER LINE

CEILING

CLEAR

CONCRETE MASONRY UNIT

COLUMN

CONCRETE

CONCRETE BLOCK

A.B

C.L

CMU

CONC BLK

CONC

COL

CLG

CLR

C.D

C.B

C.J

C.I

B.U.R.

BOT

A.P

A.T

B.L

BLKG

BLDG

DB.

ARCH

A.F.F.

A.D

A.D

ANOD

ALUM

A/C

REQ'D

RECP.

PLYWD.

PLATE

PLUMB.

OPNG.

REF.

R.H.

RM.

ROOF

REINF

REV.

RAD.

R.D.

P.T.

R.A.

R.

P.P.

PT.

PR.

P.L.

P.A

P.C.

P.D.

O.S

OPP.

PRESSURE TREATED

REFRIGERATOR

REINFORCED

REQUIRED

REVISION

RIGHT HAND

ROOM

ROOF

RISER

RETURN AIR

RADIUS

ROOF DRAIN

RECEPTACLE

OVERFLOWSCUPPER

PRE-CASE CONCRETE

PLANTER DRAIN

PROPERTY LINE

POWER POLE

PLATE

PLYWOOD

PLUMBING

PAIR

PAINT

OPENING

OPPOSITE

PLANING AREA

O.F.D. OVERFLOWDRAIN

T.G.C. TENANT GENERAL CONTRACTOR

T.J'S. TRADER JOE'S

FIRE RETARDANT TREATMENT F.R.T.

A

1

1

A

A

A-1

100

A

A-1

REFERENCE DRAWING

INTERIOR ELEVATION

COL GRID No.

REVISION No.

REFERENCE DRAWING

REFERENCE DRAWING

ROOM NAME

DOOR No.

ROOM No.

DETAIL No.

A

A-1 REFERENCE DRAWING

BUILDING SECTION

WALL SECTION

RETAIL

AREA

(2) PROPERTY DAMAGE LIABILITY: $1,000,000.00

PERMIT FEES (OR SPECIFICALLY QUALIFIED AS EXCLUDED FROM BID).

GENERAL CONTRACTOR: ALL BIDS SUBMITTALS MUST INCLUDE ACTUAL (OR ESTIMATED)

OR DAMAGED GOODS TO BE SENT TO THE TENANT'S REPRESENTATIVE WITHIN THREE (3)

UNLOADING OF OWNER SUPPLIED MATERIALS. ANY DISCREPANCY OR BILL OF LADING

AND/OR DEATH $1,000,000.00

SHALL BE SO WRITTEN THAT SUCH GUARANTEE OR WARRANTIES SHALL INSURE TO THE

BENEFIT OF BOTH LANDLORD AND TENANT, AS THEIR RESPECTIVE INTEREST APPEAR AND

TO THE TENANT'S WORK SHALL BE CONTAINED IN THE CONTRACT SUB-CONTRACT WHICH

WARRANTIES OR GUARANTEES AS TO MATERIALS OR WORKMANSHIP ON OR WITH RESPECT

ALL SUCH WORK SHALL BE PERFORMED IN A FIRST CLASS WORKMANLIKE MANNER

EXPENSES & DAMAGES IN CONNECTION WITH SUCH REMOVAL, REPLACEMENT, OR REPAIR

THE CORRECTION OF SUCH WORK SHALL INCLUDE, WITHOUT ADDITIONAL CHARGE, ALL

FROM DATE ALL CONSTRUCTION PUNCH LIST ITEMS HAVE BEEN COMPLETED & CERTIFICATE

FROM ANY & ALL DEFECTS IN WORKMANSHIP & MATERIALS FOR ONE (1) YEAR

& SHALL BE IN GOOD & USEABLE CONDITION AT THE DATE OF COMPLETION

OF ANY PART OF THE WORK WHICH MAY BE DAMAGED OR DISTURBED THEREBY. ALL

DONE OR FURNISHED WHICH SHALL BECOME DEFECTIVE WITHIN THIS ONE (1) YEAR PERIOD.

REPLACEMENT OR REPAIR WITHOUT ANY ADDITIONAL CHARGE FOR ANY & ALL WORK

OF OCCUPANCY HAS BEEN ISSUED. CONTRACTOR SHALL BE RESPONSIBLE FOR THE

THEREOF. CONTRACTOR SHALL GUARANTEE ALL WORK PERFORMED TO BE FREE

OF A COMBINATION THEREOF WHICH MAY ARISE FROM WORK IN CONNECTION WITH

GENERAL CONTRACTOR AND/OR SUB-CONTRACTORS ARE REQUIRED TO INSURE

AGAINST UNDER ANY PROVISIONS HEREIN. SAID INSURANCE SHALL BE PROVIDED

LOSS" BUILDERS' RISK INSURANCE POLICY ON THE WORK TO BE PERFORMED FOR

E) TENANT'S BUILDERS RISK INSURANCE-COMPLETED VALUE BUILDERS RISK

TENANT IN THE LEASED PREMISES AS IT RELATES TO THE BUILDING WITHIN WHICH

(A) BODILY INJURY, PER OCCURRENCE FOR PERSONAL INJURY

(B) PROPERTY DAMAGE LIABILITY $1,000,000.00

CONTRACTOR SHALL FURNISH TO TENANT WITHIN 30 DAYS AFTER COMPLETION,

AND AS CONDITION FOR FINAL PAYMENT, FINAL WAIVERS OF LIEN FOR ALL

WORK PERFORMED & FROM ALL SUB-CONTRACTORS & MAJOR SUPPLIERS

TENANT, ITS CONTRACTORS AND SUB-CONTRACTORS, AND LANDLORD, AS THEIR

THE LEASED PREMISES IS LOCATED. THE POLICY SHALL INCLUDE AS INSIDERS

INTERESTS MAY APPEAR. THE AMOUNT OF INSURANCE TO BE PROVIDED SHALL BE

THE LEASED PREMISES, AND ANY OTHER LIABILITY FOR DAMAGES WHICH TENANT'S

(OR DEATH RESULTING THEREFROM) AND PROPERTY DAMAGE LIABILITY OF OTHERS

MATERIAL DAMAGE INSURANCE COVERAGE: TENANT SHALL PROVIDE AN "ALL PHYSICAL

IN MINIMUM AMOUNTS AS FOLLOWS:

E. LIEN WAIVERS and SWORN AFFIDAVITS

100%OF THE REPLACEMENT COST.

PROTECTIVE LIABILITY INSURANCE AS WILL INSURE TENANT AGAINST ANY AND ALL

LIABILITY TO THIRD PARTIES FOR DAMAGES BECAUSE OF BODILY INJURY LIABILITY

OTHERS CAUSED BY ACCIDENT AND ARISING FROM HIS OPERATIONS UNDER

CONTRACT AND WHETHER SUCH OPERATIONS ARE PERFORMED BY THE

INCLUDING DEATH RESULTING THEREFROM AND DAMAGE TO PROPERTY OF

SUB-CONTRACTOR AGAINST ANY AND ALL CLAIMS FOR BODILY INJURY,

SUCH INSURANCE SHALL INSURE THE GENERAL CONTRACTOR AND/OR

GENERAL CONTRACTOR, SUB-CONTRACTORS, OR BY ANYONE DIRECTLY,

D) TENANT'S PROTECTIVE LIABILITY INSURANCE SHALL PROVIDE OWNER'S

OR INDIRECTLY EMPLOYED BY ANY OF THEM.

CAN BE DIRECTLY ENFORCED BY EITHER.

ALL WORK SHALL CONFORM TO ALL GOVERNING CODES & REGULATIONS.

CONTRACTOR SHALL FILE, PAY & OBTAIN ALL REQUIRED PERMITS

(INCLUDING SUB-CONTRACTOR TRADES) TO PERFORM THE WORK. UPON

COMPLETION OF THE WORK, CONTRACTOR SHALL OBTAIN ALL REQUIRED

APPROVALS FROM GOVERNMENTAL AGENCIES INVOLVED PRIOR TO FINAL

PAYMENT. OBTAIN COPY OF CERTIFICATE OF OCCUPANCY TO BE SUPPLIED

1. CONTRACTOR SHALL SECURE, PAY FOR AND MAINTAIN, DURING CONSTRUCTION

AND FIXTURING WORK WITHIN LEASED PREMISES, ALL OF THE INSURANCE POLICIES

REQUIRED AND IN THE AMOUNTS AS SET FORTH HEREIN. CONTRACTOR SHALL NOT

TO THE TRADER JOE'S DIRECTOR OF CONSTRUCTION - COPY TO BE DELIVERED

2. CONTRACTOR'S AND SUB-CONTRACTORS' REQUIRED MINIMUM COVERAGE

COMMENCE ANY WORK UNTIL ALL REQUIRED INSURANCE HAS BEEN OBTAINED AND

CERTIFICATES OF SUCH INSURANCE HAVE BEEN DELIVERED TO THE LANDLORD AND

TENANT. LANDLORD AND TRADER JOE'S MUST BE NAMED AS "ADDITIONAL INSURED."

"CERTIFICATE OF INSURANCE" SHALL COVER ALL WORK PERFORMED BY HIM AND

OF NOT LESS THAN $500,000.00 AND ANY INSURANCE REQUIRED

AND INCLUDING EMPLOYER'S LIABILITY INSURANCE WITH A LIMIT

A) WORKMAN'S COMPENSATION, AS REQUIRED BY STATE LAW,

WHERE THE WORK IS TO BE PERFORMED AS WILL PROTECT THE

BODILY INJURY LIABILITY (OR DEATH RESULTING THEREFROM) OR

THAN $1,000,000.00 FOR ANY ONE OCCURRENCE WHETHER INVOLVING

CONTRACTOR'S PROTECTIVE LIABILITY) IN AN AMOUNT NOT LESS

B) COMPREHENSIVE GENERAL LIABILITY INSURANCE (INCLUDING

SUB-CONTRACTORS, OR INDIRECTLY EMPLOYED BY ANY OF THEM.

OPERATIONS ARE PERFORMED BY TENANT'S GENERAL CONTRACTOR,

FROM HIS OPERATIONS UNDER THE CONTRACT AND WHETHER SUCH

OF ANY KIND WHATSOEVER AND TO WHOMEVER BELONGING AND ARISING

RESULTING THEREFROM AND DAMAGE TO OR DESTRUCTION OF PROPERTY

ANY AND ALL CLAIMS FOR BODILY INJURY, INCLUDING DEATH

INSURANCE SHALL INSURE TENANT'S GENERAL CONTRACTOR AGAINST

FOR EXPLOSION, COLLAPSE AND UNDERGROUND COVERAGE. SUCH

AGGREGATE LIMIT OF $2,000,000.00 SUCH INSURANCE SHALL PROVIDE

PROPERTY DAMAGE LIABILITY OR A COMBINATION THEREOF WITH A

CONTRACTOR AND SUB-CONTRACTOR FROM ANY AND ALL LIABILITY

BY ANY EMPLOYEE BENEFITS ACTS OR OTHER STATUTES APPLICABLE

UNDER THE AFOREMENTIONED ACTS.

TO STORE MANAGER FOR POSTING IN STORE.

EACH OF HIS SUB-CONTRACTORS AND ALL MAJOR SUPPLIERS.

AND LIMITS OF LIABILITY:

OF ANY AUTOMOTIVE EQUIPMENT, OWNED, HIRED AND NON-

C) COMPREHENSIVE AUTOMOBILE LIABILITY INSURANCE,

(1) BODILY INJURY, PER OCCURRENCE FOR PERSONAL INJURY

INCLUDING THE OWNERSHIP, MAINTENANCE, AND OPERATION

OWNED IN THE FOLLOWING AMOUNTS:

AND/OR DEATH: $1,000,000.00

C. INSURANCE

BUSINESS DAYS.

F. QUALITY STANDARDS

BUILDING CONSTRUCTION. DO NOT PLACE DUCTS, PIPING, CONDUIT

OR ANY OBSTRUCTION SO AS TO IMPAIR REQUIRED CEILING HEIGHT

THE CHARACTER & SCOPE OF WORK ARE ILLUSTRATED BY THE WORKING

DRAWINGS. CONTRACTOR SHALL CAREFULLY EXAMINE ALL THE DRAWINGS

& SHALL BE RESPONSIBLE FOR THE PROPER INSTALLATION OF HIS

WORK & PROPER CONSIDERATION FOR THE WORK OF OTHERS AND EXISTING

A. COORDINATION of WORK

BE RESPONSIBLE FOR THE PROTECTION OF EXISTING ADJACENT TENANT(S)

B. BUILDING CODES and REGULATIONS

AND BUILDING FACILITIES.

AND CLEARANCE FOR LIGHTING FIXTURES, ETC.. CONTRACTOR SHALL

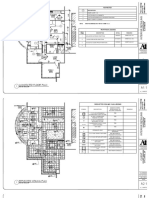

PANIC HARDWAREISNOTREQUIRED FORM OCCUPANCIES[TABLE1008.1.10]

THESEPLANSAREIN CONFORMANCEWITHTHEFOLLOWING CODES:

2010FLORIDA BUILDING CODE- BUILDING

2010 FLORIDA BUILDING CODE- MECHANICAL

2010FLORIDA BUILDING CODE- PLUMBING

2010FLORIDA BUILDING CODE- ENERGY CONSERVATION

2010 FLORIDA BUILDING CODE- EXISTING BUILDING

2012FLORIDA ACCESSIBILITY CODE

THESEPLANSCOMPLY WITHTHEPROVISION OF TITLEIII OF THE"AMERICANSWITHDISABILITIESACT"

(ADA) PUBLIC LAW101-336, FORHANDICAPPED ACCESSIBILITY FORCUSTOMERAND EMPLOYEES.

STOCK ROOM ISNOTREQUIRED TO BESEPARATED BASED UPON COMPLIANCEWITH

NONSEPARATED OCCUPANCIES[TABLE508.3]

BUILDING ISPROTECTED THROUGHOUTWITHAN AUTOMATIC SPRINKLERSYSTEM PERNFPA 13-

SPRINKLERSWILL BERELOCATED IN THETENANTSPACEASREQ'D TO PROVIDEREQ'D COVERAGE

SMOKEDETECTORSAREREQ'D FORHVAC SHUTDOWN, FORNEWSYSTEMSDELIVERING IN EXCESS

OF 2,000 CFM [606.1, IMC]

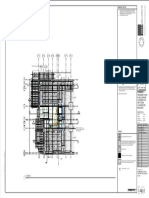

SHEET SHEETNAME REV. REV. DATE

T-1 TITLESHEET 1 10.14.13

T-2 GENERAL NOTES& OUTLINESPECIFICATIONS 1 10.14.13

T-3 RESPONSIBILITY SCHEDULE 1 10.14.13

AC-1 ACCESSIBILITY DETAILS

AC-2 LIFESAFETY PLAN

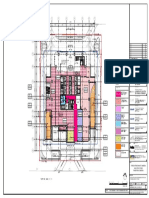

A-0 CONSTRUCTION FLOORPLAN 1 10.14.13

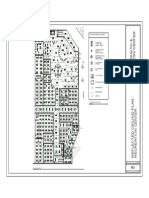

A-1 FIXTUREFLOORPLAN 1 10.14.13

A-2 ARCHITECTURAL DETAILS

A-2.1 ARCHITECTURAL DETAILS2 1 10.14.13

A-3 REFLECTED CEILING PLAN

A-4 EXTERIORELEVATIONS 1 10.14.13

A-5 INTERIORELEVATIONS

A-5.1 ENLARGED FLOORPLANSAND INTERIORELEVATIONS

A-6 DOOR/FINISHSCHEDULE 1 10.14.13

E-0 ELECTRICAL SYMBOLSAND SCHEDULES

E-1 LIGHTING PLAN

E-2 POWERPLAN

E-3 ELECTRICAL ROOF PLAN

E-4 ELECTRICAL DIAGRAMSAND DETAILS

E-5 REFRIGERATION EQUIPMENTWIRING DIAGRAM

E-6 ELECTRICAL GENERAL NOTES

E-7 ELECTRICAL PANEL SCHEDULES

EMS-1 TITLEPAGE

EMS-2 LIGHTING/MECHFLOORPLAN

EMS-3 MECHANICAL ROOF PLAN

EMS-4 LIGHTING CONTROL DETAILS

EMS-5 MISC. CONTROL DETAILS

EMS-6 CONTROL RISERDIAGRAM

EMS-7 EMSSPECS

EMS-8 MISC. DETAILS1

EMS-9 MISC. DETAILS2

R-0 REFRIGERATION SCHEDULES

R-1 REFRIGERATION PLAN

R-2 REFRIGERATION DETAILS

M-0 HVAC NOTESAND SCHEDULES

M-1 HVAC PLAN

M-2 HVAC ROOF PLAN

M-3 HVAC DETAILS

M-4 HVAC DETAILS

P-0 PLUMBING SCHEDULES, NOTES, AND PARTIAL PLAN

P-1 PLUMBING PLAN

P-2 PLUMBING DETAILS

SP-0 SPRINKLERNOTES

SP-1 SPRINKLERPLAN

FA-1 FIREALARM PLAN

V-1 VACUUM PLAN

V-2 VACUUM DETAILS

V-3 VACUUM DETAILS

DRAWING LIST ABBREVIATIONS GENERAL CONDITIONS PROJ ECTTEAM

ARCHITECT

CRIPEARCHITECTS+ENGINEERS

MIKEGRUBB

MGRUBB@CRIPE.BIZ

3939 PRIORITY WAY SOUTHDR#400

INDIANAPOLIS, INDIANA 46240

PHONE: (317) 706-6386

FAX: (317) 706-6464

MECHANICAL, ELECTRICAL, PLUMBING

ENGINEER

DESIGN AIREENGINEERING

DAVEHAUN

DHAUN@DAENGINEERING.COM

220N. COLLEGEAVE.

INDIANAPOLIS, INDIANA 46202

PHONE: (317) 464-9090

FAX: (866) 515-9090

EMSSYSTEM

R3RETAIL DEVELOPMENT

RICK FERGUSON

6505S.E. CESARCHAVEZBLVD.

PORTLAND, OREGON 97202

PHONE: (503) 419-6435

CELL: (971) 235-4175

LANDLORD

WARD REAL ESTATELLC.

TRICIA WARD

TRICIA@WARDREALESTATELLC.COM

12180SOUTHSHOREBLVD. #104

WELLINGTON, FL 33414

OFFICE: (561) 798-4160

CELL: (561) 202-5003

WWW.WARDREALESTATELLC.COM

LANDLORD ARCHITECT

MESA ARCHITECTUREINCORPORATED

STEVEN ROY

SMROY@MESAARCHITECTURE.COM

743BISCAYNEBLVD.

WESTPALM BEACH, FL 33401

OFFICE: (561) 659-5683

CELL: (561) 248-9516

WWW.MESAARCHITECTURE.COM

TENANT

TRADERJ OE'SCOMPANY

DON STRACK

DIRECTOROF CONSTRUCTION

DSTRACK@TRADERJ OES.COM

711ATLANTIC AVE., 3RD FLOOR

BOSTON, MA 02111

PHONE: (626) 599-3700

GENERAL CONTRACTOR

MDC CONSTRUCTION

STEVESCHNADENBERG

STEVE@MDCCONSTRUCTION.COM

15397STONY CREEK WAY

NOBLESVILLE, INDIANA 46060

PHONE: (317) 776-1463

FAX: (317) 776-1464

CELL: (317) 281-1758

BUILDING DEPARTMENT

CITY OF WELLINGTON

BUILDING DEPARTMENT

12300FORESTHILL BLVD.

WELLINGTON, FL 33414

BUILDINGDOCS@WELLINGTONFL.GOV

PHONE: (561) 791-4000

VENDOR CONTACTLIST

SYMBOLS KEY PLAN LOCATION MAP

CODE DATA

NORTH

F

A

T R

C

HI TE

C

STATE OF

R

D EG I S T ERE

R

E

D

R

I

C

J

G

R

E

E

N

K

FLORIDA

LICENSE NO.

AR95447

F

L O R I D A

IS

S

U

E

D

A

T

E

:

J

O

B

N

O

.:

D

R

A

W

N

B

Y

:

T

R

A

D

E

R

J

O

E

'S

S

T

O

R

E

N

O

.:

S

P

A

C

E

N

O

.:

S

E

A

L

3939Priority Way SouthDr., Suite 400

INDIANAPOLIS, INDIANA 46240

(317) 844-6777FAX(317) 706-6464

E-Mail cripe@cripe.biz

ARCHITECTURE

INTERIORDESIGN

CIVIL/TRANSPORTATION ENGINEERS

LAND PLANNING

LAND SURVEYING

GIS

OWNER'SREPRESENTATION

P

R

O

J

E

C

T

S

H

E

E

T

N

A

M

E

CERTIFIEDBY:

TITL

E

S

H

E

E

T

U

S

4

4

1

A

N

D

S

T

R

IB

L

IN

G

W

A

Y

W

E

L

L

IN

G

T

O

N

,

F

L

3

3

4

1

4

T-1

10

. 0

9

. 13

13

0

3

5

6

1 0

1 0

0

C

S

7

7

4

US 441 AND STRIBLING WAY

WELLINGTON, FL 33414

Print Date: 10.18.13

TRADER

J OE'S

M

IS

C

E

L

L

A

N

E

O

U

S

A

R

E

A

4

5

0

S

F

S

T

O

C

K

A

R

E

A

2

2

2

4

S

F

S

A

L

E

S

A

R

E

A

9

8

4

5

S

F

T

O

T

A

L

A

R

E

A

1

2

5

1

9

S

F

VENDOR

NAME

VENDOR

CONTACT

VENDOR

PHONE VENDOREMAIL

DOORS

STOREFRONTDOOR

REPAIR

PETE

TRAVATO

714.842.1337 SDOOR@SOCAL.RR.COM

DYNAMIC DOCK &

DOOR

BRET

LEVEILEE

413.731.1114 BRET@DYNAMIC-DOCK-DOOR.COM

HVAC

CARRIER TONY

WALLON

315.432.6506 TONY.WALLON@CARRIER.UTC.COM

LIGHTING

SPECTRUM

LIGHTING

J OEL

RUBINFELD

800.872.8021 J OEL@SPECTRUM-LIGHTING.COM

REFRIGERATION

HILL PHOENIX DENNIS

GARRITY

978.535.8783 DENNIS.GARRITY@HILLPHOENIX.COM

SIGNS

BROADWAY NAT'L

SIGN CO.

ANDREW

FALINO

631.737.3140 x262 ASMITH@BROADWAYNATIONAL.COM

ACCESSSIGNS TAMMI

DERKSON

888.655.6866 x205 TAMMI@ACCESSIGNS.COM

SPEAKERSYSTEM

SOS REBA

BULLARD

916.577.1712 RBULLARD@TEAM-SOS.COM

VACUUM CONDENSATESYSTEM

ACORNVAC, INC. LAURA

MARSHALL

909.902.5041 LMARSHALL@ACORNENG.COM

SQUAREFEETAREA SUMMARY

SALESAREA 9845 SF

MISCELLANEOUSAREA 450 SF

STOCK AREA 2224 SF

TOTAL AREA 12519 SF

SECTION 1005.3 - EGRESSWIDTH

PERSONSx INCHES/PERSON TOTAL

EGRESSCAPACITY REQ'D FORDOORS 351 0.2 70

EGRESSCAPACITY ACTUAL PROVIDED 144

TABLE1004.1.2- DESIGN OCCUPANTLOAD

SF PERPERSON #PERSONS

SALESOCCUPANCY 9845 SF / 30 328

MISCELLANEOUSOCCUPANCY 450SF / 30 15

STOCK OCCUPANCY 2224 SF / 300 8

TOTAL OCCUPANCY 351

TABLE1016.2- EXISTACCESSTRAVEL DISTANCE

(SPACEISFULLY SPRINKLERED)

MAXIMUM TRAVEL DISTANCEPERMITTED 250FEET

MAXIMUM TRAVEL DISTANCEACTUAL +/-181 FEET

TABLE1021.1 - MINIMUM NUMBEROF EXITS

OCCUPANTLOAD REQ'D EXITS PROVIDED EXITS

OCCUPANTLOAD & REQ'D EXITS 1-500 2

ACTUAL OCCUPANTLOAD & EXITS 351 2

USEGROUP M, S1

TYPEOF CONSTRUCTION II-B

NO. OF STORIES 1STORY

COVERED MALL (Y/N) N

FULLY SUPPRESSED (Y/N) Y

FLOORAREA 12,519 SF

TRADER J OE'S

STRIBLING WAY

Store #774

R

E

V

IS

IO

N

S

N

O

.

D

A

T

E

C

O

M

M

E

N

T

S

1

1

0

.

1

4

.

1

3

L

e

a

s

e

R

e

s

p

o

n

s

ib

ilit

y

U

p

d

a

t

e

s

CONTRACTOR SHALL BE RESPONSIBLE FOR UNLOADING ALL OF TENANT SUPPLIED EQUIPMENT AND

FIXTURES (EXCEPT REFRIGERATION EQUIPMENT).

CONTRACTOR SHALL VERIFY ALL CONDITIONS, AS WELL AS ALL DIMENSIONS & CONDITIONS

INDICATED IN THE DRAWINGS, PRIOR TO ACTUAL CONSTRUCTION. GENERAL CONTRACTOR TO

VERIFY WITH ARCHITECT OR TENANT'S REP. (AND SUB-CONTRACTORS) RECEIPT OF MOST

CURRENT SET OF CONSTRUCTION DOCUMENTS PRIOR TO START OF WORK. ANY VARIATION

FROMCONDITIONS INDICATED IN THE DRAWINGS SHALL BE BROUGHT TO THE ATTENTION OF THE

ARCHITECT & OWNERS REPRESENTATIVE PRIOR TO STARTING ANY WORK.

EMERGENCY LIGHTING SHALL BE PROVIDED GIVING A VALUE OF ONE FOOT CANDLE AT FLOOR

LEVEL AS PER THE BUILDING DEPARTMENT CURRENT REQUIREMENTS.

FLASH PATCH ALL AREAS WHERE THE FLOOR IS NOT LEVEL OR TRUE PRIOR TO INSTALLATION OF

THE FLOORING.

ALL PAINT FINISH OF METAL DOORS BUCKS, DOORS, PERIMETER ENCLOSURES, ETC., SHALL BE

SEMI-GLOSS, UNLESS OTHERWISE NOTED.

SIGN CONTRACTOR SHALL SECURE ALL NECESSARY PERMITS.

ALL PAINT SHALL BE APPLIED IN ACCORDANCE WITH THE MANUFACTURER'S SPECIFICATIONS FOR

THE PARTICULAR SURFACE. PROVIDE A MINIMUM OF TWO COATS TO ACHIEVE FULL AND EVEN

COVERAGE.

THE CONTRACTOR SHALL PROPERLY PREPARE ALL SURFACES FOR THE FINISHES THEY ARE TO

RECEIVE PRIOR TO THE INSTALLATION.

FIRE DAMPERS OR DOORS SHALL BE PROVIDED WHERE AIR DUCTS PENETRATE FIRE RATED

WALLS OR CEILINGS.

THE VARIOUS INTERIOR SUB-CONTRACTORS SHALL COORDINATE THEIR WORK WITH EACH OTHER IN

SUCH A MANNER THAT WILL CAUSE THE LEAST POSSIBLE INTERRUPTION IN OR OBSTRUCTIONS TO

SUCH WORK OF THE OTHER.

SEPARATE UNLIKE METALS OR ALLOYS WITH A HEAVY COATING OF BITUMINOUS PAINT OR OTHER

SUITABLE PERMANENT SEPARATION AS REQUIRED TO PREVENT GALVANIC ACTION.

PRIOR TO DRILLING/BORING/CUTTING/ANY HOLES IN THE CONCRETE SLAB OR EXISTING BUILDING

STRUCTURE, THE CONTRACTOR SHALL OBTAIN WRITTEN PERMISSION FROM THE BUILDING OWNER

OR HIS REPRESENTATIVE FOR EACH SPECIFIC LOCATION OF THE SAME.

AT THE COMPLETION OF WORK THE PROJECT SITE (HARD SURFACES) SHALL BE LEFT BROOM

CLEAN. ALL FINISHES (INCLUDING GLAZING) SHALL BE LEFT DUST AND SPOT FREE AND READY

FOR FULL USE.

THE CONTRACTOR SHALL RELOCATE ANY AND ALL EXISTING UTILITY LINES AS MAY BE REQUIRED TO

ACCOMPLISH THE INTENDED DESIGN. NEWLOCATIONS SHALL BE VERIFIED WITH THE OWNER.

NO EQUIPMENT SUBMITTALS ARE REQUIRED TO THE ARCHITECT OR TENANT IF EQUIPMENT AND

WORK IS INSTALLED ACCORDING TO DRAWING AND MANUFACTURER SPECIFICATION. ANY ALTERNATE

SPECIFICATION OR METHOD OF INSTALLATION MUST BE SUBMITTED IN WRITTEN FORMDIRECTLY TO

THE TENANT WITH A COPY TO THE ARCHITECT. SUBMITTALS MUST BE RECEIVED AND APPROVED

PRIOR TO ANY WORK.

WHERE WORK OR EQUIPMENT IS INDICATED N.I.C. (NOT IN CONTRACT) ON THE DRAWINGS, SUCH

WORK AND/OR EQUIPMENT SHALL BE PROVIDED BY OTHERS. THE CONTRACTOR SHALL

COORDINATE AND COOPERATE TO EFFECT SUCH INSTALLATION.

IF MANUFACTURERS' SPECIFIED MODEL NUMBERS ARE DISCONTINUED OR NEW APPROVED MODELS

EXIST, THE CONTRACTOR SHALL FURNISH THE MANUFACTURER'S UPDATED MODEL AT NO

ADDITIONAL COST TO THE TENANT OR ARCHITECT AND SHALL NOTIFY ALL AS REQUIRED.

ALL PRODUCTS SHALL BE USED, INSTALLED AND INCORPORATED INTO THE PROJECT AS PER

MANUFACTURERS WRITTEN INSTRUCTIONS.

SHOULD IT APPEAR THAT THE PROPOSED WORK IS NOT CLEARLY CALLED OUT OR SUFFICIENTLY

DETAILED OR EXPLAINED THE CONTRACTOR SHALL SUBMIT A WRITTEN "REQUEST FOR

INFORMATION" DIRECTLY TO THE TENANT AND ARCHITECT. IF THE CONTRACTOR HAS (IN HIS

OPINION) A BETTER CONSTRUCTION TECHNIQUE, THE CONTRACTOR SHALL APPLY TO THE TENANT

FOR CLARIFICATION OF THE ABOVE, IN NO MANNER SHALL ANY WORK PROCEED IN UNCERTAINLY.

ALL CLARIFICATIONS, APPROVALS, AND INSTRUCTIONS SHALL BE ISSUED TO THE CONTRACTOR

THROUGH THE TENANT. CONTRACTOR'S SUB-CONTRACTOR SHALL NOT CONTACT THE ARCHITECT

OR ENGINEER OF RECORD DIRECTLY.

ALL WORK SHALL BE DONE TO MEET TOP QUALITY WORKMANSHIP.

THE CONTRACTOR SHALL COORDINATE WITH THE LANDLORD REPRESENTATIVE FOR STAGING

REQUIREMENTS. THIS INCLUDES BUT IS NOT LIMITED TO PARKING, DELIVERIES, STORAGE AND

REMOVAL OF MATERIALS.

THE CONTRACTOR SHALL FURNISH ALL LABOR MATERIALS, EQUIPMENTS, ETC. REQUIRED TO

COMPLETE THE CONSTRUCTION OR INSTALLATION OF ALL ITEMS REQUIRED FOR A COMPLETE

INSTALLATION, UNLESS DESIGNATED N.I.C.

THE ARCHITECT / CONTRACTOR SHALL PAY FOR ALL REQUIRED PERMITS, FEES AND LICENSES

REQUIRED FOR STARTING AND COMPLETING ALL REQUIRED WORK. OWNER SHALL REIMBURSE

ALL COSTS TO REQUIRED PARTIES FOR ALL PERMIT FEE'S

THE CONTRACTOR SHALL ARRANGE AND PROVIDE FOR ALL INSPECTIONS REQUIRED BY THE

GOVERNING AGENCIES.

ALL WORK SHALL CONFORM WITH ALL APPLICABLE FEDERAL, STATE AND LOCAL CODES AND

ORDINANCES.

THE CONTRACTOR SHALL CONFORMIN ALL ASPECTS TO THE HEALTH AND SAFETY PROVISIONS OF

O.S.H.A.

THE CONTRACTOR SHALL PROVIDE, INSTALL AND MAINTAIN FOR THE DURATION OF THE WORK AS

RECURRED ALL LAWFUL OR NECESSARY BARRICADES, FENCES AND RAILINGS. FURNISH

TEMPORARY LIGHTS, WARNINGS SIGNS AND SIGNALS AND TAKE ALL OTHER PRECAUTIONS AS

MAY BE RECURRED TO SAFEGUARD PERSONS, THE SITE AND ADJOINING PROPERTY, INCLUDING

IMPROVEMENTS THEREIN, AGAINST INJURY AND DAMAGES OF EVERY NATURE, WHATSOEVER.

PUBLIC RIGHT OF WAYS, SIDEWALKS CORRIDORS, ETC., EFFECTED BY THE CONSTRUCTION MUST

BE KEEP FREE OF ACCUMULATED WASTE MATERIALS INCLUDING SOIL, DEBRIS, TRASH, ETC. ON A

DAILY BASIS. CLEAR EGRESS SHALL BE MAINTAINED AT ALL TIMES FOR ALL BUILDING TENANTS,

THEIR EMPLOYEES AND GUESTS, ANY INJURY OR DAMAGE SHALL BE THE RESPONSIBILITY OF THE

CONTRACTOR AND SHALL BE TAKEN CARE OF AT THE CONTRACTORS EXPENSE.

THE CONTRACTOR SHALL PROTECT AND TAKE FULL RESPONSIBILITY FOR ANY DAMAGE DONE TO

THE BUILDING OR SITE THAT IS NOT PART OF THE CONTRACT.

THE CONTRACTOR SHALL TAKE ALL NECESSARY PRECAUTIONS TO LOCATE AND PROTECT ANY

UNDERGROUND OR CONCEALED CONDUIT, PLUMBING OR OTHER UTILITY LINES WHERE WORK IS

BEING PERFORMED.

THE CONTRACTOR SHALL FURNISH ADEQUATE SHORING, BRACING, ETC. AS REQUIRED TO

SAFELY EXECUTE ALL WORK AND SHALL BE FULLY RESPONSIBLE FOR THE SAME.

15.

14.

13.

12.

7.

11.

9.

10.

8.

6.

5.

28.

34.

33.

32.

30.

31.

29.

27.

26.

25.

24.

23.

22.

21.

20.

ALL SYMBOLS AND ABBREVIATIONS USED ON THESE DRAWINGS ARE CONSIDERED

CONSTRUCTION STANDARDS. IF THE CONTRACTOR HAS QUESTIONS REGARDING THE SAME,

NOTIFY THE ARCHITECT FOR CLARIFICATION.

SOLELY AS A CONVENIENCE TO THE TENANT, THE ARCHITECT INCLUDED DOCUMENTS PREPARED

BY THE TENANTS CONSULTANTS OR INCORPORATED THE RECOMMENDATIONS OF THESE

CONSULTANTS IN DOCUMENTS PREPARED BY THE ARCHITECT WITHIN THE SET OF

CONSTRUCTION DOCUMENTS ISSUED BY THE ARCHITECT BEING EXPRESSLY UNDERSTOOD THAT

THE ARCHITECT ASSUMES NO LIABILITY FOR THE SERVICES OF THE CONSULTANTS NOT UNDER

CONTRACT TO THE ARCHITECT.

NOTHING CONTAINED IN THESE CONSTRUCTION DOCUMENTS OR IN ANY ACCOMPANYING

DOCUMENTS SHALL CREATE ANY CONTRACTUAL RELATIONSHIP BETWEEN THE CONTRACTOR

AND THE ARCHITECT.

4.

3.

2.

1.

17.

19.

18.

16.

35. TENANT GENERAL CONTRACTOR SHALL BE RESPONSIBLE FOR THE COORDINATION, SCHEDULING,

AND WORKMANSHIP OF ALL SUBCONTRACTORS HIRED DIRECTLY BY TENANT.

SHOP DRAWING SUBMITTALS ARE REQUIRED FOR ANY AND ALL STRUCTURAL DESIGN AND

MECHANICAL DESIGN. SHOP DRAWINGS SHALL BE SUBMITTED BY THE CONTRACTOR TO THE TENANT,

ARCHITECT, AND ENGINEER FOR REVIEWAND APPROVAL PRIOR TO FABRICATION.

SEE FINISH SCHEDULE FOR FRP SPECIFICATIONS - TENANT GENERAL CONTRACTOR SHALL PLACE

ORDER FOR MARLITE FRP PANEL. OBTAIN A COPY OF THE ORDER FROM TRADER JOE'S DIRECTOR

OF CONSTRUCTION.

STAINLESS STEEL CORNER GUARDS - 16 GAUGE S.S. - TYPE 304, STAIN FINISH #4,

1 1/2" WING SIZE - BY KOROSEAL WALL PROTECTION SYSTEMS, KOROGUARD SERIES GA15 OR

APPROVED EQUAL.

SURFACE MOUNTED SANITARY NAPKIN RECEPTACLE - (FURNISHED BY TRADER JOE'S)

DISPLAY SHELVING DIVIDER & BACK PANELS - 3/4" MELAMINE FINISHED PANEL TO BE TAFISA

MELAMINE - L304 FINE NATURAL OAK, STIPPLE FINISH OR APPROVED EQUAL SUPPLIED BY TENANT

GENERAL CONTRACTOR. COORDINATE EXACT SIZE & LOCATION WITH FINAL FIXTURE LAYOUT &

TRADER JOE'S REP.

WATER CLOSET TOP OF BAR AT 33" A.F.F. TO CENTERLINE (AS REQUIRED)

STEEL ANCHOR PLATES, ADAPTERS, AND OTHER ANCHOR COMPONENTS.

TO DRAWINGS. ALL JOINTS SHALL BE WELDED AND SET IN CONCRETE. RAILS SHALL BE

PAINTED BLACK, UNLESS OTHERWISE NOTED. SEE ELEVATIONS

CART CORRAL SHALL BE PROVIDED ON SIDEWALK AND SHALL BE CONSTRUCTED 2" NOMINAL

STEEL PIPE. RAIL HEIGHT SHALL BE 35" AND INTERMEDIATE RAIL AT 18" AND SHALL CONFORM

THE GEN. CONTRACTOR SHALL COORDINATE THE WORK OF THIS SECTION WITH THE

BALER SHALL BE FACTORY-WIRED FOR POWER AND DISCONNECT- FURNISHED AND INSTALLED BY TRADER JOE'S.

DRYWALL WORK TO INSURE THE PROPER PLACEMENT OF ALL INTERNAL WALL

REINFORCEMENT TO RECEIVE ANCHOR ATTACHMENTS. PROVIDE AND INSTALL THE

RECESSED HAND DRYERS, PROVIDE XLERATOR HAND DRYER MODEL XL-SB WITH S.S. RECESSED KIT #40502

SWING-UP 29"L. X 1 1/2" DIA. GRAB BAR BOBRICK B-4998 MTD. AT 15" FROM CENTERLINE OF

SURFACE MOUNTED SEAT COVER DISPENSER - (FURNISHED BY TRADER JOE'S)

THE FOLLOWING MATERIALS SHALL BE USED: STAINLESS STEEL FINISH SHALL BE

TYPE 304 FASTENERS SCREWS & BOLTS SHALL BE STAINLESS STEEL, TAMPER

PROOF TYPE ALL ACCESSORIES REQUIRED FOR PROPER INSTALLATION INCLUDING

SURFACE MOUNTED BABY CHANGING STATION - (FURNISHED BY TRADER JOE'S)

CAPTAIN'S STATION COUNTERTOP - 3/4" MELAMINE FINISHED PANEL TO BE TAFISA MELAMINE - L304

FINE NATURAL OAK, STIPPLE FINISH OR APPROVED EQUAL SUPPLIED BY TENANT GENERAL

CONTRACTOR. T.G.C. SHALL PROVIDE FINISH TAPE ON FACE AND UNFINISHED EDGES OF

COUNTERTOP TO MATCH MELAMINE. T.G.C. SHALL PROVIDE 1/4" PLEXIGLAS PANEL ON

COUNTERTOP.

D. FINISHES

(SEE FINISH SCHEDULE FOR SPECIFICATIONS)

NEWFLOORING, SHALL BE INSTALLED PER MANUFACTURES INSTALLATION SPECIFICATIONS

ON A SMOOTH, LEVEL FLOOR THROUGHOUT RETAIL AREA. COVE BASE SHALL BE INSTALLED

ON ALL WALLS AND CASH / WRAP STATIONS. (SEE SHT. A-6 FOR SCHEDULES).

THE TENANT GEN. CONTRACTOR SHALL BE RESPONSIBLE FOR INSTALLING CEDAR SIDING.

INSTALLATION SHALL INCLUDE A 1"x 6" HORIZONTAL RIBBON @ TOP,

RIBBON @BOTTOM. CEDAR BY TRADER JOE'S.

ELECTRICIAN SHALL PROVIDE POWER TO BALER AND TERMINATE.

COAT HOOK - BRADLEY MODEL 9115

F. CONCRETE

FOLLOWING ACCESSORIES TO EACH TOILET.

36" GRAB BAR BOBRICK B-6806X36

42" GRAB BAR BOBRICK B-6806X42

ALL LIFTS MUST HAVE PROTECTIVES TO ELIMINATE GREASE/ OIL DEPOSITS ON FLOOR.

AS REQUIRED BY LOCAL CODE OR TENANT LANDLORD, TO PROTECT THE PUBLIC

CONTRACTOR SHALL PROVIDE TEMPORARY BARRICADES, FENCES & RAILINGS

AT ALL TIMES DURING CONSTRUCTION. SUCH BARRICADE SHALL BE OF TYPE AND DESIGN

AND FURNISHING OF THE DEMISED PREMISES. COORDINATE REMOVAL OF DEBRIS

ALL TRASH, RUBBISH AND SURPLUS MATERIALS RESULTING FROM CONSTRUCTION,

CONTRACTOR SHALL BE RESPONSIBLE FOR DAILY REMOVAL FROM THE PROJECT,

CONTRACTOR ROLLING CARTS, LIFTS, EQUIPMENT BOXES, ETC. MUST BE EQUIPPED WITH

APPROVED BY LANDLORD.

C. TEMPORARY BARRICADE

B. RUBBISH REMOVAL

WITH BUILDING MANAGEMENT.

A. RUBBER WHEEL CARTS

RUBBER NON-MARKING WHEELS.

E. SPECIALTIES

G. FIRE EXTINGUISHERS

PREFABRICATED WOOD GRAIN CABINETRY IN DEMO STATION, DEMO ROOM, AND TOILET ROOMS

SHALL BE "DISTINCTION - CABINETRY": - COLOR: NATURAL MAPLE OR APPROVED EQUAL. ANY

SUBSTITUTION SHALL BE SUBMITTED TO TRADER JOE'S DIRECTOR OF CONSTRUCTION FOR REVIEW.

INTEGRAL COLORED CONCRETE

1. THE CONCRETE SHALL BE COORDINATED WITH THE WORK OF THE OTHER TRADES TO ALLOW

REASONABLE TIME TO SET SLEEVES, INSERTS AND OTHER ACCESSORIES, WHICH MUST BE IN

POSITION BEFORE CONCRETE IS PLACED.

2. INSPECT EXCAVATIONS AND PREPARE SUB-GRADE FOR SUITABILITY FOR PLACING OF CONCRETE.

NO STANDING WATER, ORGANIZE MATERIAL, DEBRIS, OR OTHER DELIRIOUS MATERIALS SHOULD BE

PRESENT.

1. BUILDING MUST BE "DRIED-IN" AND PERMANENT OR EQUIVALENT TEMPORARY LIGHTING IS

OPERATIONAL

2. NO WATER SHALL BE ALLOWED TO CONTACT COLORED CONCRETE PRIOR TO APPLICATION OF

SEALER.

3. IF OPENINGS EXIST OVER COLORED CONCRETE AREA, SHIELD CONCRETE FROM DIRECT SUN FOR A

MINMUM OF ONE WEEK TO MAINTAIN EVEN CURING.

4. CONCRETE POUR SHALL BEGIN IN THE FRONT OF THE STORE AND FINISH IN THE STOCK ROOM.

1. INSTALLER QUALIFICATIONS: AN EXPERIENCED INSTALLER WHO HAS COMPLETE INTEGRAL

COLORED CONCRETE WORK SIMILAR INMATERIAL, DESIGN, AND EXTENT TO THAT INDICATED FOR THIS

PROJECT ONA MINMUM OF THREE SIMILAR PROJECTS, AND WHOSE WORK HAS RESULTED IN

CONSTRUCTION WITH A RECORD OF SUCCESSFUL IN SERVICE PERFORMANCE.

2. CONTRACTOR TO ASSEMBLE PERSONNEL AND EQUIPMENT NECESSARY TO ACCOMPLISH TIME

LIMITS DEFINED UNDER EXECUTION.

3. MANUFACTURER QUALIFICATIONS: A FIRM EXPERIENCED IN MANUFACTURING READY-MIXED

CONCRETE PRODUCTS COMPLYING THE ASTM C94 REQUIREMENTS FOR PRODUCTION FACILITIES AND

EQUIPMENT.

4. PIGMENTS FOR INTEGRALLY COLORED CONCRETE:

a. MANUFACTURER: LANXESS

b. COLOR: ARIZONIA GOLD

c. CONTACT: PAUL CROUSHORE (412) 809-2210

CYLINDER TEST FOR STRENGTH, SLUMP, AND AIR SHALL BE DONE FOR EVERY 50 YARDS OF

CONCRETE. FORM CYLINDERS PER TEST ONE 7 DAY TWO 28 DAY AND (ONE 56 DAY IF NEEDED)

TESTING TO BE DONE BY CONCRETE PROVIDER PER ASTM SPEC C31. TEST RESULTS FORWARDED TO

G.C. WITH 48 HOURS OF TEST.

GENERAL: PROTECT FRESHLY PLACED CONCRETE FROM REMATURE DRYING AND EXCESSIVE COLD

AND HOT TEMPERATURES. COMPLY WITH ACI 306.1 FIOR COLD WEATHER PROTECTION.

1. SPECIFIED OVER-ALL VALUES OF FLATNESS, F (F) 45; AND LEVELNESS, F(L) 35

TROWEL FINISH: AFTER APPLYING FLOAT FINISH, APPLY FIRST TROWEL FINISH AND CONSOLIDATE

CONCRETE BY HAND OR POWER-DRIVEN TROWEL. CONTINUE TROWELING PASSES AND RESTRAIGHTEN

UNTIL SURFACE IS FREE OF TROWEL MARKS AND UNIFORM IN APPEARANCE. FOR INTERIOR

PIGMENTED SLABS IT IS RECOMMENDED TO USE POLY BLADES FOR YOUR FINAL FINISH.

GENERAL: COMPLY WITH RECOMMENDATIONS IN AC 302.1R FOR SCREEDING, RESTRAIGHTENING, AND

FINISHING OPERATIONS FOR CONCRETE SURFACES. DO NOT WET CONCRETE SURFACES.

1. WHEN AIR TEMPERATURE HAS FALLEN TO OR IS EXPECTED TO FALL BELOW 40 DEGREES F. (4.4 DEG

C), UNIFORMLY HEAT WATER AND AGGREGATES BEFORE MIXING TO OBTAIN A CONCRETE MIXTURE

TEMPERATURE OF NOT LESS THAN 50 DEGREES F (10 DEG C) AND NOT MORE THAN 80 DEGREES F (27

DEG C) AT POINT OF PLACEMENT.

2. DO NOT PLACE CONCRETE ON FROZEN SUB-GRADE OR ON SUB-GRADE CONTAINING FROZEN

MATERIALS.

1. BEFORE PLACING CONCRETE, VERIFY THAT INSTALLATION OF FORMWORK, REINFORCEMENT AND

EMBEDDED ITEMS ARE COMPLETE AND THAT REQUIRED INSPECTIONS HAVE BEEN PERFORMED.

2. BEFORE PLACING OCNRETE, WATER MAY BE ADDED AT PROJECT SITE, SUBJECT TO LIMITATIONS OF

ACI 301

a. DO NOT ADD WATER TO CONCRETE AFTER ADDING HIGH RANGE WATER REDUCING ADMIXTURES TO

MIX.

3. DEPOSIT CONCRETE CONTINUOUSLY OR IN LAYERS OF SUCH THICKNESS THAT NO NEW CONCRETE

WILL BE PLACED ON CONCRETE THAT HAS HARDENED ENOUGH TO CAUSE SEAMS OR PLANS OF

WEAKNESS. DEPOSIT CONCRETE TO AVOID SEGREGATION.

ISOLATION JOINTS IN SLABS ON GRADER: COLUMNS WILL BE 12" X 12" AROUND. AFTER REMOVING

FORMWORK, INSTALL JOINT FILLER STRIPS AT SLAB JUNCTIONS WITH VERTICAL SURFACES, SUCH AS

COLUMN PEDESTALS, FOUNDATION WALLS, GRADE BEAMS, AND OTHER LOCATIONS, AS INDICATED.

1. SAWED JOINTS: FORM CONTRACTION JOINTS WITH POWER SAWS EQUIPPED WITH SHATTERPROOF

ABRASIVE OR DIAMOND-RIMMED BLADES. CUT 1/8 INCH (3MM) WIDE JOINTS INTO CONCRETE WHEN

CUTTING ACTION WILL NOT TEAR, ABRASIVE, OR OTHERWISE DAMAGE SURFACE AND BEFORE

CONCRETE DEVELOPS RANDOM CONTRACTION CRACKS.

2. MAXIMUM JOINT SPACING: 10 FEET

3. JOINT DEPTH: 1/4" OF SLAB THICKNESS

4. CONFORM TO BAY SPACING WHEREVER POSSIBLE (COLUMN CENTERLINES, HALF BAYS, THIRD BAYS,

ETC) 5. JOINTS TO BE CUT BETWEEN 4 AND 8 HOURS AFTER CONCRETE PLACEMENT

1. GENERAL: COMPLY WITH CRSI'S "MANUAL OF STANDARD PRACTICE" FOR PLACING

REINFORCEMENT.

a. DO NOT CUT OR PUNCTURE VAPOR RETARDER. REPAIR DAMAGE AND RESEAL VAPOR RETARDER

BEFORE PLACING CONCRETE.

2. CLEAN REINFORCEMENT OF LOOSE RUST AND MILL SCALE, EARTH, ICE AND OTHER FOREIGN

MATERIALS

3. ACCURATELY POSITION, SUPPORT, AND SECURE REINFORCEMENT AGAINST DISPLACEMENT.

LOCATE AND SUPPORT REINFORCEMENT WITH BAR SUPPORTS TO MAINTAIN MINIMUM CONCRETE

COVER. DO NOT TACK WELD CROSSING REINFORCEING BARS.

4. SET WIRE TIES WITH ENDS DIRECTED INTO CONCRETE, NOT TOWARD EXPOSED CONCRETE

SURFACES.

5. INSTALL WELDED WIRE FABRIC IN LONGEST PRACTICABLE LENGTHS ON BAR SUPPORTS PACED TO

MINIMIZE SAGGING. LAP EDGES AND ENDS OF ADJOINING SHEETS AT LEASE ONE MESH SPACING.

OFFSET LAPS OF ADJOINING WIDTHS TO PREVENT CONTINUOUS LAPS IN EITHER DIRECTION. LACE

OVERLAPS WITH WIRE.

1. READY-MIXED CONCRETE; MEASURE, BATCH, MIX, AND DELIVER CONCRETE ACCORDING TO ASTM

C94, AND BATCH TICKET INFORMATION.

1. FABRICATED STEEL REINFORCEMENT ACCORDING TO CRSI'S "MANUAL OF STANDRARD

PRACTICE."

2. AIR CONTENT: ADD AIR ENTRAINING ADMIXTURE AT MANUFACTURER'S PRESCRIBED RATE TO RESULT

IN CONCRETE AT POINT OF PLACEMENT HAVING AN AIR CONTENT AS FOLLOWS WITHIN A TOLERANCE

OF PLUS 1 OR MINUS 1.5 PERCENT, UNLESS OTHERWISE INDICATED.

1. SLAB ON GRADE: PROPORTION NORMAL WEIGHT CONCRETE MIX AS FOLLOWS:

a. COMPRESSIVE STRENGTH (28 DAYS): 4000 PSI (27.6 MPA)

b. MINIMUM CEMENTITIOUS MATERIALS CONTENT: 540 LB/CU.YD. (320 KG/CU.M)

c. MAXIMUM SLUMP 5 INCHES (100MM)

d. MAXIMUM WATER-CEMENTITIOUS RATION: 0.48 FOR NON AIR-ENTRAINED

e. MAXIMUM WATER CEMENTITIOUS RATION: 0.45 FOR AIR-ENTRAINED

f. NO FLY ASH

g. 1/2" MINIMUM AGGREGATE SIZE

3. DO NOT AIR-ENTRAIN CONCRETE TO TROWEL-FINISHED INTERIOR FLOORS AND

SUSPENDED SLABS. DO NOT ALLOW ENTRAPPED AIR CONTENT TO EXCEED 3 PERCENT

a. NON-WOVEN, POLYEDTER-REINFORCE, POLYETHYLENE COATED SHEET; 10 MILS (0.25MM) THICK

b. THREE-PLY, NYLON, OR POLYESTER-CORD-REINFORCED, LAMINATED, HIGH DENSITY

POLYETHYLENE SHEET; 7.8 MILS (0.18MM) THICK

1. FINE GRADED GRANULAR MATERIAL; CLEAN MANUFACTURED OR NATURAL SAND.

1. VAPOR RETARDER: ASTM E1745, CLASS C, OF THE ONE OF THE FOLLOWING MATERIALS; OR

POLYETHYLENE SHEET, ASTM 4397, NOT LESS THAN 10 MILS (0.25MM) THICK.

1. REINFORCEMENT BARS; ASTM A615M, GRADE 60 (GRADE 420) DEFORMED

2. PLAIN STEEL WIRE: ASTM A82

3. PLAIN STEEL WELDED WIRE FABRIC: ASTM A 185, FABRICATED FROM STEEL WIRE INTO FLAT

SHEETS

FORM WEAKENED-PLANE CONTRACTION

JOINTS, SECTIONING CONCRETE INTO AREAS. CONSTRUCT CONTRACTION JOINTS FOR A

DEPTH EQUAL TO AT LEAST ONE-FOURTH OF CONCRETE THICKNESS AS FOLLOWS:

NOTE: LEAD TIME FOR PIGMENT IS APPROX. (3) WEEKS.

TRADER JOE'S WILL PROVIDE SURFACE MOUNTED FIRE EXTINGUISHERS "10-LB A-B-C" OR APPROVED

EQUAL, 1 PER 2500 SQ. FT. AND/OR PER LOCAL CODE. GENERAL CONTRACTOR COORDINATE

LOCATION OF FIRE EXT. W/FIRE MARSHAL AND/OR LOCAL GOVERNING AUTHORITY AND WITH TRADER

JOE'S.

INTERIOR CONCRETE FLOOR SLAB SHALL BE 4 INCH MINIMUM THICKNESS ON 6 INCHES OF

COMPACTED GRANULAR FILL BASE OR SAND BASE. CONTRACTOR MUST ACHIEVE A 90

PERCENT COMPACTION.

EXTERIOR CAST IN PLACE CONCRETE PAD

ALL SUCH WORK SHALL BE PERFORMED IN A FIRST CLASS WORKMANLIKE MANNER & SHALL BE IN

GOOD & USEABLE CONDITION AT THE DATE OF WORK COMPLETION THEREOF. GENERAL

CONTRACTOR SHALL GUARANTEE ALL WORK PERFORMED TO BE FREE FROMANY & ALL DEFECTS IN

WORKMANSHIP & MATERIALS. GENERAL CONTRACTOR SHALL BE RESPONSIBLE FOR THE

REPLACEMENT OR REPAIR WITHOUT ANY ADDITIONAL CHARGE FOR ANY & ALL WORK DONE OR

FURNISHED WHICH SHALL BECOME DEFECTIVE DURING GENERAL CONTRACTOR WORK. THE

CORRECTION OF SUCH WORK SHALL INCLUDE, WITHOUT ADDITIONAL CHARGE, ALL EXPENSES &

DAMAGES IN CONNECTION WITH SUCH REMOVAL, REPLACEMENT, OR REPAIR OF ANY PART OF THE

WORK WHICH MAY BE DAMAGED OR DISTURBED THEREBY.

ALL CONCRETE CAST-IN-PLACE PAD SECTIONS SHALL CONSIST OF PROPER PROPORTIONS OF

PORTLAND CEMENT, COARSE AGGREGATES, FINE AGGREGATES AND CLEAN WATER CONFORMING TO

ASTM STANDARD SPECIFICATIONS. PROVIDE 6X6/10 X10 TEMPERATURE REINF. THROUGHOUT. THE

CONCRETE STRENGTH SHALL BE A MINIMUM OF 4.000 psi AT 28 DAYS. THE CONCRETE SLAB SHALL BE

NON AIR-ENTRAINED, WITH A WATER / CEMENT RATIO NOT EXCEEDING 0.5. COMPLY WITH

MANUFACTURERS WRITTEN INSTRUCTION FOR SUBSTRATE TEMPERATURE AND MOISTURE CONTENT,

AMBIENT TEMPERATURE AND HUMIDITY, VENTILATION, AND OTHER CONDITIONS AFFECTING TOPPING

PERFORMANCE. PROTECT AGAINST FREEZING, DIRECT SUNLIGHT, OR EXCESSIVELY HOT WEATHER.

A. CONCRETE MUST HAVE FLOOR FLATNESS RATING OF 40

B. CONCRETE MUST HAVE A FLOOR LEVELNESS RATING OF 30

C. FINISH - NONSLIP BROOM FINISH

ALL SUCH WORK SHALL BE PERFORMED IN A FIRST CLASS WORKMANLIKE MANNER & SHALL BE IN

GOOD & USEABLE CONDITION AT THE DATE OF WORK COMPLETION THEREOF. GENERAL

CONTRACTOR SHALL GUARANTEE ALL WORK PERFORMED TO BE FREE FROMANY & ALL DEFECTS IN

WORKMANSHIP & MATERIALS. GENERAL CONTRACTOR SHALL BE RESPONSIBLE FOR THE

REPLACEMENT OR REPAIR WITHOUT ANY ADDITIONAL CHARGE FOR ANY & ALL WORK DONE OR

FURNISHED WHICH SHALL BECOME DEFECTIVE DURING GENERAL CONTRACTOR WORK. THE

CORRECTION OF SUCH WORK SHALL INCLUDE, WITHOUT ADDITIONAL CHARGE, ALL EXPENSES &

DAMAGES IN CONNECTION WITH SUCH REMOVAL, REPLACEMENT, OR REPAIR OF ANY PART OF THE

WORK WHICH MAY BE DAMAGED OR DISTURBED THEREBY.

18" GRAB BAR BOBRICK B-6806X18

TOILET PARTITIONS SHALL BE FURNISHED & INSTALLED BY T.G.C. COLOR TO BE DETERMINED BY

TRADER JOE'S REP. PARTITIONS AS MFG. BY ACCURATE PARTITIONS CORP., LYONS, ILL. PH. 708-442-6800

INTERIOR: APPLY FLAT BLACK PAINT TO ALL WALLS WHEREVER CEDAR WILL BE INSTALLED. EXTERIOR:

APPLY BLACK PAINT TO NEW CART CORRAL METAL RAILING AND ROLL-UP SERVICE DOOR WITH STEEL

JAMB AND LINTEL PAINT AS REQUIRED TO MATCH EXISTING ADJACENT BUILDING. (SEE "SPECIALTIES"

BELOW.)

ALTERNATING 1"x 4", 1"x 6" & 1"x 8" INSTALLED VERTICALLY AND A 1"x 8" HORIZONTAL

1. CONCRETE PAD AT EXTERIOR RECEIVING AND PALLET AREA (ON A 10' x 20' MASONRY ENCLOSURE,

UNLESS OTHERWISE NOTED) SHALL BE A MINIMUM OF 4 INCHES THICK ON A 4 INCH COMPACTED

GRANULAR FILL BASE OR SAND BASE. BY LANDLORD.

CONTRACTOR MUST ACHIEVE A 90%COMPACTION. FLOOR FLATNESS DEVIATION SHALL BE LESS THAN

1/4" INCH IN A 100 Sq. Ft. AREA.

2. CONCRETE PAD AT EXTERIOR RECEIVING WITH SCISSOR-LIFT AND EXTERIOR FREEZER SHALL BE A

MINIMUM OF 6 INCHES THICK ON A 4 INCH COMPACTED GRANULAR FILL BASE OR SAND BASE. BY

LANDLORD.

ALL WALL FRAMING AND FURRING SHALL BE MINIMUM25 GAUGE METAL STUDS AND CHANNELS

EXCEPT WHERE FIRE RETARDANT TREATED WOOD MAY BE USED AS NAILERS AND BLOCK IN (UNLESS

OTHERWISE NOTED.) FRAMING SHALL BE LAID-OUT IN ACCORDANCE WITH THE DRAWINGS. PROVIDE

ALL NECESSARY IN-WALL FRAMING AND BLOCKING AS REQUIRED TO CARRY SHELVING STANDARDS

AND OTHER ATTACHMENTS WHICH SHALL BE INSTALLED ON WALL. COORDINATE FRAMING WITH

OTHER TRADES WHICH MAYINTERFACE WITH FRAMING WORK. ALL METAL STUDS TO BE 3-5/8", UNLESS

OTHERWISE NOTED. ALL WALLS SHALL BE FACE WITH 5/8" THICK, "TYPE X" GYPSUMWALLBOARD,

INCLUDING TENANT PARTITION AND FIREWALL UNLESS INDICATED OTHERWISE ON THE DRAWINGS.

JOIN PANELS WITH FIRE RESISTANT JOINT REINFORCING TAPE TO PRODUCE AN ASSEMBLY

RESISTANT TO FIRE IN ACCORDANCE WITH APPLICABLE LOCAL CODES FOR ANY ONE HOUR PERIOD.

PROVIDE A SMOOTH SURFACE VOID OF ALL DEFECTS INCLUDING RIDGES, TROWEL MARKS, BUMPS

AND TAPE WRINKLES.

WATER COOLER SHALL BE FURNISHED BY TRADER JOE'S AND INSTALLED BY T.G.C.. ELECTRICIAN SHALL

PROVIDE POWER TO WATER COOLER AND TERMINATE.

RESILIENT FLOORING

ACOUSTICAL CEILINGS

(SEE FINISH SCHEDULE FOR SPECIFICATIONS)

PAINTING

CEDAR SIDING

GYPSUMWALL BOARD

LAMINATE / MELAMINE

FRP PANEL

CART CORRALS

STEEL CORNER GUARDS

PRE-FABRICATED CABINETRY

TOILET & BATHROOMACCESSORIES

TOILET PARTITIONS

WATER COOLER

STEEL REINFORCEMENT

VAPOR RETARDERS

CONCRETE MIXES

FABRICATING REINFORCEMENT

CONCRETE MIXING

STEEL REINFORCEMENT

CONTRACTION JOINTS IN SLABS ON GRADE:

CONCRETE PLACEMENT

COLD WEATHER PLACEMENT:

FINISHING FLOORS AND SLABS

CONCRETE PROTECTION AND CURING

CONCRETE TESTING

QUALITY ASSURANCE

PREPARATION

PLACING CONCRETE

H. STOREFRONT

FURNISH AND INSTALL NEW KAWNEER CLEAR ANNODIZED ALUMINUM STOREFRONT (OR EQUAL)

TRIFAB 450 FRAMING AND 1" INSULATED GLAZING. (SEE EXT. ELEVATIONS FOR COLOR SPECIFICATION.)

PROVIDE WEATHER STRIPPING AND WEATHER SADDLE.

I. AUTOMATIC ENTRY DOORS

PAIR/SINGLE SLIDING DOORS W/OVERHEAD SENSORS- NABCO HURRICANE RESISTANT SERIES GT 1175

GLAZED BIPART ALUMINUM SLIDER WITH FIXED SIDELITE. FINISH: WHITE

OR TO MATCH EXISTING STOREFRONT AS DETERMINED BY TRADER JOE'S.

CONTACT: PETE TRAVATO (714) 842-1337.

TRADER JOE'S TO PROVIDE MARS "LOPRO" COMMERCIAL SERIES AIR CURTAIN FOR ALL EXTERIOR

VESTIBULE DOORS.

SURFACE MOUNTED TOILET TISSUE DISPENSER (FURNISHED BY TRADER JOE'S)

BALER

SURFACE MOUNTED MIRRORS

THE TENANT GEN. CONTRACTOR SHALL BE RESPONSIBLE FOR PAINTING ALL WALLS AND CEILING SURFACES

EXCEPT WHERE OTHERWISE NOTED AND SHALL INCLUDE BUT NOT BE LIMITED TO THE FOLLOWING. PAINTING

OF HOLLOW METAL DOORS AND FRAMES. TO MATCH TENANTS DISPLAY SHELVING. PAINTING GYPSUM BOARD

SURFACES. PAINTING OF EXPOSED ITEMS NOT OTHERWISE PRE-FINISHED, BUT ALSO PAINTING FINISH ITEMS

THAT ARE INTENDED TO BLEND INTO ADJOINING SURFACES. APPLICATION MUST BE ROLLED OR BRUSHED ON;

NO SPRAY APPLICATION IS ALLOWED.

PROVIDE CEILING SUSPENSION SYSTEM WITH ALL MAIN TEES, CROSS TEES, WALL MOLDINGS AND OTHER

ACCESSORIES REQUIRED FOR A COMPLETE INSTALLATION. INSTALL CEILING SUSPENSION SYSTEM IN

ACCORDANCE WITH MANUFACTURER'S INSTRUCTIONS TO PROVIDE A LEVEL, PLUMB, AND TRUE CEILING

WHEN FINISHED WITH PANELS INSTALLED. SUSPENSION WIRES SHALL BE INSTALLED AT MAXIMUM

SPACING OF 48" ON CENTER. DEFLECTION SHALL NOT EXCEED 1/8" IN TEN FEET. REFER TO APPLICABLE

CODE REGARDING SUPPORTS AND OTHER REQUIREMENTS.

RECESSED PAPER TOWEL DISPENSER - TORK ELEVATION CENTERFEED PRO (559028A)

GENERAL: COMPLY WITH RECOMMENDATIONS IN ACI 305 R - HOT WATER PLACEMENT

WARMWEATHER PLACEMENT:

F

A

T R

C

HI TE

C

STATE OF

R

D EG I S T ERE

R

E

D

R

I

C

J

G

R

E

E

N

K

FLORIDA

LICENSE NO.

AR95447

F

L O R I D A

IS

S

U

E

D

A

T

E

:

J

O

B

N

O

.:

D

R

A

W

N

B

Y

:

T

R

A

D

E

R

J

O

E

'S

S

T

O

R

E

N

O

.:

S

P

A

C

E

N

O

.:

S

E

A

L

3939 Priority Way South Dr., Suite 400

INDIANAPOLIS, INDIANA 46240

(317) 844-6777 FAX (317) 706-6464

E-Mail cripe@cripe.biz

ARCHITECTURE

INTERIOR DESIGN

CIVIL/TRANSPORTATION ENGINEERS

LAND PLANNING

LAND SURVEYING

GIS

OWNER'S REPRESENTATION

P

R

O

J

E

C

T

S

H

E

E

T

N

A

M

E

CERTIFIED BY:

'

'

`

'

`

'

'

T-2

`

'

'

GENERAL NOTES OUTLINE SPECIFICATIONS

R

E

V

IS

IO

N

S

N

O

.

D

A

T

E

C

O

M

M

E

N

T

S

1

1

0

.

1

4

.

1

3

L

e

a

s

e

R

e

s

p

o

n

s

ib

ilit

y

U

p

d

a

t

e

s

1

1

F

A

T R

C

HI TE

C

STATE OF

R

D EG I S T ERE

R

E

D

R

I

C

J

G

R

E

E

N

K

FLORIDA

LICENSE NO.

AR95447

F

L O R I D A

IS

S

U

E

D

A

T

E

:

J

O

B

N

O

.:

D

R

A

W

N

B

Y

:

T

R

A

D

E

R

J

O

E

'S

S

T

O

R

E

N

O

.:

S

P

A

C

E

N

O

.:

S

E

A

L

3939 Priority Way South Dr., Suite 400

INDIANAPOLIS, INDIANA 46240

(317) 844-6777 FAX (317) 706-6464

E-Mail cripe@cripe.biz

ARCHITECTURE

INTERIOR DESIGN

CIVIL/TRANSPORTATION ENGINEERS

LAND PLANNING

LAND SURVEYING

GIS

OWNER'S REPRESENTATION

P

R

O

J

E

C

T

S

H

E

E

T

N

A

M

E

CERTIFIED BY:

'

'

'

T-3

`

'

'

TRADER JOE'S AREA OF RESPONSIBILITY

JOBS

L

A

N

D

L

O

R

D

T

R

A

D

E

R

J

O

E

'

S

/

V

E

N

D

O

R

T

E

N

A

N

T

G

.

C

.

COMMENTS

PLUMBING

PLUMBING DEMOLITION TO INTERIOR OF BUILDING B

WATER MAIN SERVICE TO SPACE TO INTERIOR OF BUILDING B

SANITATION WASTE SERVICE TO SPACE B

PLUMBING LINES (WASTE, VENT & WATER) B B

TOILET ROOM PLUMBING FIXTURES B

SALES SUPPORT ROOM PLUMBING FIXTURES B

HOT WATER HEATER B

MOP SINK W/ ACCESSORIES B

DEMO ROOM PLUMBING FIXTURES F I

VACUUM SYSTEM PIPING B

DRINKING FOUNTAIN F I

CARPENTRY

EXTERIOR BUILDING WALLS & FINISHES B

EXTERIOR WALL - INTERIOR METAL STUDS & INSULATION B

EXTERIOR WALL - INTERIOR GYP. BD. & PREPARATION B READY FOR FINISHES (LEVEL 4)

INTERIOR PARTITIONS (METAL STUD & GYP. BD.) B

COLUMN ENCLOSURE B B LANDLORD EXTERIOR COLUMNS; T.J. G.C. INTERIOR COLUMNS

ALL BACKING & SUPPORT FOR SHELVING B

ELIASON DOORS F I

DOORS AND HARDWARD (SEE SCHEDULE) B B LANDLORD EXTERIOR LOCATIONS; T.J. G.C. INTERIOR LOCATIONS

PLYWOOD FOR ELECTRICAL PANELS / SUBS B

STEEL CORNER GUARDS IN BACKROOM B

TOILET ROOM SIGNS F I

6" x 10' PVC TUBE FOR BALER B

ACCESS PANELS FOR VACUUM SYSTEM B

REF. VACUUM SYSTEM PIPE BOX-OUT @ EACH CASE LINE B

FIRST AID KIT F I

CEDAR PLANKING F I

VINYL FOR DEMO AREA B

RIVETIER SHELF END / DIVIDER PANELS F I

MOP HOLDERS F I

MOP SINK SHELF B

SALES SUPPORT CABINETS B

CHECK STAND & CAPTAIN DESK CABINET INSTALLATION F I

CAPTAIN'S STATION COUNTERTOP B

TOILET ROOM CABINETS AND MIRRORS B

ALL PAPER DISPENSERS F I

TOILET ROOM GRAB BARS B

MEZZANINE / PLATFORM GRAB BARS B

FIRE EXTINGUISHERS F I

DEMO STATION (CABINETS & STAINLESS STEEL COUNTERTOPS) B

DEMO STATION TOWER F I

HORIZONTAL & VERTICAL OAK TRIM ON WINE SECTION DISPLAYS F I COORDINATE LOCATION WITH TJ'S REP.

HORIZONTAL & VERTICAL OAK TRIM ON BREAD SECTION DISPLAYS F I COORDINATE LOCATION WITH TJ'S REP.

BABY CHANGING STATION F I

END CAP SIGN HOLDERS F I

VACUUM SYSTEM PIPE BLOCKING & HANGERS B

4' x 8' PLYWOOD PANEL FOR TELEPHONE / DATA B

VINYL FLOOR TILE B

REFRIGERATION

REFRIGERATION EQUIPMENT ROOF SUPPORTS B

REFRIGERATION EQUIPMENT F I FINAL CONNECTION BY T.G.C.

HEAT TAPE ON RESERVE FREEZER CONDENSATE LINES B I ELECTRICIAN TO RUN WIRE

CAPTAIN'S STATION REFRIGERATIOR ALARM PANEL F I

REFRIG. CONDENSATE LINES B

ROOF PENETRATIONS & PITCH POCKETS FOR REFRIG. EQUIP. B

REFRIGERATION CORNERS B

REFRIGERATION DOOR CURTAINS B

REFRIGERATION BUMPERS B

FREEZER BOX SHELVES B

ENERGY MANAGEMENT SYSTEM

EMS SENSORS & EQUIPMENT B ELECTRICAL OR MECHANICAL CONTRACTOR TO INSTALL

ORDERING HIGH SPEED INTERNET SERVICE B

COORDINATION EMS DELIVERY / INSTALL DATES B

AUTODIALER FOR EMS B

EMS CONDUIT & WIRE B

POWERLINK LIGHTING PANEL B

CAPTAIN'S STATION ALARM PANEL E2-BX & 1.0 BOARD I ELECTRICIAN TO RUN ALL NECESSARY WIRE & MAKE TERMINATION CONNECTIONS

EMS COORDINATION WITH TRADES B

START-UP & COMMISSIONING EMS SYSTEM B

STORE CREW - EMS SYSTEM B

TRADER JOE'S AREA OF RESPONSIBILITY

JOBS

L

A

N

D

L

O

R

D

T

R

A

D

E

R

J

O

E

'

S

/

V

E

N

D

O

R

T

E

N

A

N

T

G

.

C

.

COMMENTS

GENERAL

SCHEDULE B

LAYOUT B

GENERAL DEMOLITION/REMOVAL B

TEMPORARY EXTERIOR BARRICADE B

COMPACTED FILL FOR FLOOR SLAB B

CONCRETE SLAB B

CONCRETE SLAB SEALING B T.G.C. TO USE PREFERRED VENDOR - VERIFY W/ TJ'S REP

EXTERIOR CONCRETE PADS B

EXTERIOR CONCRETE H.C. RAMP B

CONCRETE CUTTING/TRENCHES B

CONCRETE CUTTING/EXTERIOR WALL OPENING B

STEEL LINTELS B

STRUCTURAL STEEL B

INSULATION @ EXTERIOR WALLS B

FRONT DOOR ROUGH OPENING B

AUTOMATIC DOORS & GLAZING B B PER TRADER JOE'S SPECS- NO SUBSTITUTIONS

VESTIBULE FRAMING & GLAZING B

ROLL-UP DOOR AT RECEIVING B PER TRADER JOE'S SPECS- NO SUBSTITUTIONS

FINAL CLEANING B

A.C.T. CEILING B

PREP CEDAR WALLS- PAINT BLACK B

PAINT B

CHECK STAND AND FIXTURE COVE BASE B

6" METAL BASE ON BOXES B

4" VINYL BASE ON SALES AREA WALLS B

DISPLAY SHELVES (RIVETIER) B

CART CORRAL AT STOREFRONT B PER TRADER JOE'S SPECS

CART CORRAL AT PARKING AREA F I PER TRADER JOE'S SPECS

"CONN-FAB" ROOF EQUIPMENT SUPPORTS B PER TRADER JOE'S SPECS

FIRE EXTINGUISHERS AND SIGNS B

FIRE DOOR PANIC HARDWARD (DETEX) B PER TRADER JOE'S SPECS

6" METAL BASE IN BACKROOM F I

ROOF HATCH B PER TRADER JOE'S SPECS

ROOF HATCH LADDER B PER TRADER JOE'S SPECS

SHOPPING CART WARNING SIGNS (6) F I

SCISSOR LIFT / DOCK LEVELER N/A

POWER & CONTROL WIRING FOR SCISSOR LIFT N/A

ELECTRICAL

ELECTRICAL DEMOLITION B

ELECTRICAL HAND DRYER F I

PHONES, INTERCOM & SOUND SYSTEM B

CONDUIT & PULL STRINGS FOR TELEPHONE B

INSTALL AND PROGRAM AUTO DIALER B

TEMPORARY LIGHTS- ONE 400W HALOGEN BULB PER 1500SF B

ALL INTERIOR LIGHT FIXTURES & LAMPS F I

EXTERIOR LIGHT FIXTURES, U.N.O. B

ELECTRICAL HOOKUP & CONTROL WIRING ON REF. EQUIP. B

ELEC. HOOKUP, CONTROL WIRING, & TERMIN. OF EMS EQUIP. B

ELECTRICAL FEED FOR EXTERIOR SIGNAGE B

ELECTRICAL SERVICE & WIRE B

BASE FIRE ALARM SYSTEM B

TENANT IMPROVEMENT F.A. DEVICES B B

FINAL CONNECTION OF FIRE ALARM B

CIRCUIT FOR FLOOR POLISH MACHINE B

SOLENOID FREEZER DOOR SWITCH B

VERIFICATION OF FAULT CURRENT B WITH LOCAL AUTHORITY

ENERGY MANAGEMENT SYSTEM B

MECHANICAL

MECHANICAL DEMOLITION B

MECHANICAL EQUIPMENT ROOF CURBS I F

MECHANICAL PENETRATIONS - GAS & ELEC. B

MECHANICAL EQUIPMENT (UNITS) B SEE MECHANICAL DRAWINGS FOR EXACT UNIT SPECS & REQUIREMENTS

CONDENSATE PIPING FOR MECHANICAL UNITS B PER TRADER JOES SPECS

MECHANICAL MAIN & BRANCH DUCTWORK B SEE MECHANICAL DRAWINGS FOR EXACT UNIT SPECS & REQUIREMENTS

MECHANICAL MAIN TRUNK & BRANCH INSULATION B

MECHANICAL FLEX SUPPLY & RETURN DUCTING B

THERMASTAT, HUMIDISTAT, SENSORS, & DETECTORS B

T-STAT AND HUMIDISTAT WIRING B

ZONE DAMPERS, POWER, CONTROLS, & WIRING B

MECHANICAL DIFFUSERS B

SPRINKLER MAIN TO SPACE B

SPRINKLER BRANCH PIPING B

SPRINLER UP-RIGHT HEAD AND 5' FLEX HOSE B

SPRINKLER PENDANT DROP HEADS B

MECHANICAL DUCTWORK & VENTING FOR PLATFORM B

VACUUM SYSTEM F I

AIR CURTAIN AT VESTIBULE B

AIR CURTAIN AT RECEIVING B

PLUMBING

CARPENTRY

REFRIGERATION

MECHANICAL

ELECTRICAL

GENERAL

ENERGY MANAGEMENT SYSTEM

R

E

V

IS

IO

N

S

N

O

.

D

A

T

E

C

O

M

M

E

N

T

S

1

1

0

.

1

4

.

1

3

L

e

a

s

e

R

e

s

p

o

n

s

ib

ilit

y

U

p

d

a

t

e

s

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

48" min

3

0

"

m

in

36" min

X

>

2

4

"

4

8

"

m

in

2

7

"

m

a

x

X

<

8

0

"

T h i sDra w i ngPro d ucedb y theU. S .Acces sBoard

10" max

4

8

"

m

a

x

1

5

"

m

in

10" max

4

8

"

m

a

x

3

4

"

m

a

x

3

4

"

m

a

x

4

6

"

m

a

x

> 10"-24" max

(a) (b)

30" min

4

8

"

m

in

48" min

3

0

"

m

in

60" min

X

>

1

5

"

3

0

"

m

in

11 min

2

7

m

in

6

8

5

280

205

8 min

9 min

230

(a)

elevation

(b)

plan

3

0

m

in

7

6

0

635

25 max

6 max

150

9 min

230

(a)

elevation

(b)

plan

3

0

m

in

7

6

0

430-635

17-25

1

5

"

m

in

4

8

"

m

a

x

4

8

"

m

a

x

4

4

"

m

a

x

>20"-25" max 20" max

C D

3

6

"

m

in

48" min

24" max

3

2

"

m

in

3

2

"

m

in

3

6

"

m

in

24" max

36" min

6

0

"

m

in

36" min

X < 48

6

0

"

m

in

18" min

36" min

6

0

"

m

in

32" MIN

32" min

32" min

>

2

4

"

36" MIN

4

8

"

m

in

12" min

42" min

5

4

"

m

in

22" min 4

2

"

m

in

24" min

4

8

"

m

in

4

2

"

m

in

22" min 4

2

"

m

in

24" min

4

8

"

m

in

4

2

"

m

in

6

0

"

m

in

18" min

X > 8

4

8

"

m

in

X > 8

4

8

"

m

in

X > 8

12 MIN

POST MOUNTED PROTRUDING OBJECTS

UNOBSTRUCTED SIDE REACH OBSTRUCTED HIGH SIDE REACH

TURNING SPACES

SIZE OF CLEAR FLOOR SPACE

FORWARD

PARALLEL

POSITION OF CLEAR FLOOR SPACE

FORWARD

PARALLEL

MANUEVERING CLEARANCE IN AN ALCOVE

KNEE AND TOE CLEARANCES

TOE CLEARANCES

KNEE CLEARANCES

LIMIT OF PROTRUDING OBJECT

REDUCED VERTICAL CLEARANCE

PROTRUDING OBJECTS

UNOBSTRUCTED FORWARD REACH RANGE OBSTRUCTED FORWARD REACH

FORWARD REACH SIDE REACH

CLEAR WIDTH OF ACCESSIBLE ROUTE

EGRESS PATHS

CLEAR WIDTH AT TURN

DOOR AND GATE CLEARANCES

MANEUVERING CLEARANCE AT MANUAL SWINGING DOORS

FRONT APPROACH, PULL SIDE FRONT APPROACH, PUSH SIDE HINGE APPROACH, PULL SIDE HINGE APPROACH, PULL SIDE

HINGE APPROACH, PUSH SIDE LATCH APPROACH, PULL SIDE LATCH APPROACH, PUSH SIDE

CLEAR WIDTH OF DOORS

FOLDING DOOR DOORWAYS WITHOUT DOORS

HINGED DOOR SLIDING DOOR

FRONT APPROACH POCKET OR HINGE APPROACH STOP OR LATCH APPROACH

MANEUVERING CLEARANCE AT SLIDING OR FOLDING DOORS

FRONT APPROACH SIDE APPROACH

MANEUVERING CLEARANCE AT DOORWAYS WITHOUT DOORS MANEUVERING CLEARANCE AT RECESSED DOORS

PULL SIDE

PUSH SIDE PUSH SIDE, DOOR PROVIDED WITH

BOTH CLOSER AND LATCH

WITH BOTH CLOSER AND LATCH

HINGE APPROACH, PUSH SIDE

WITH BOTH CLOSER AND LATCH

LATCH APPROACH, PULL SIDE

WITH CLOSER

LATCH APPROACH, PUSH SIDE

WITH CLOSER

FRONT APPROACH, PUSH SIDE

DOORS IN SERIES

4" max

X

8

0

"

X

>

2

7

"

OBSTRUCTING

OBJECT

12" max 12" max

2

7

"

-8

0

"

2

7

"

m

a

x

8

0

"

m

in

X > 12"

X > 12"

(b) (a)

12" max 12" max

12" max 12" max

PROTRUDING

OBJECT

POST OR

PYLON

42" min

4

8

"

m

in

42" min

X < 48

4

8

"

m

in

24" min

4

2

"

m

in

48" min 48" min

48" min

4

8

"

m

in

22" min 4

8

"

m

in

24" min

5

4

"

m

in

24" min

4

8

"

m

in

T hi sD rawi ng Produ c edby the U .S.A c cess B oard

F

A

T R

C

HI TE

C

STATE OF

R

D EG I S T ERE

R

E

D

R

I

C

J

G

R

E

E

N

K

FLORIDA

LICENSE NO.

AR95447

F

L O R I D A

IS

S

U

E

D

A

T

E

:

J

O

B

N

O

.:

D

R

A

W

N

B

Y

:

T

R

A

D

E

R

J

O

E

'S

S

T

O

R

E

N

O

.:

S

P

A

C

E

N

O

.:

S

E

A

L

3939 Priority Way South Dr., Suite 400

INDIANAPOLIS, INDIANA 46240

(317) 844-6777 FAX (317) 706-6464

E-Mail cripe@cripe.biz

ARCHITECTURE

INTERIOR DESIGN

CIVIL/TRANSPORTATION ENGINEERS

LAND PLANNING

LAND SURVEYING

GIS

OWNER'S REPRESENTATION

P

R

O

J

E

C

T

S

H

E

E

T

N

A

M

E

CERTIFIED BY:

'

'

'

'

AC-1

`

'

'

R

E

V

IS

IO

N

S

N

O

.

D

A

T

E

C

O

M

M

E

N

T

S

LINTEL SCHEDULE

GENERAL NOTE:

w/ a min. of two bolts per lintel.

Note: Lintel angles back to back to be bolted 2'-6" c/c

spans over 6'-0" see detail sheet: a-6

4'-1" to 6'-0" CL. L6" X 3 1/2" X 5/16"

up to 4'-0" CL. L3 1/2" X 3 1/2" X 5/16"

SPANS LINTEL SIZE

ANY PENETRATIONS OF ANY FIRE-RATED

PARTITION MUST MAINTAIN FIRE RATING

AND BE THE RESPONSIBILITY OF EACH

SUB-CONTRACTOR

WALL LEGEND

SEE DWG. A-2 FOR PARTITION TYPES & DETAILS

EXISTING WALL CONSTRUCTION

NEWFULL HEIGHT NON-RATED WALL

CONSTRUCTION

NEWPARTIAL HEIGHT NON-RATED WALL

CONSTRUCTION

NEW1-HR RATED WALL CONSTRUCTION

WALL TYPE A

3

3

'-4

"

33'-4" 33'-4" 33'-4" 24'-6"

8"

3

3

'-4

"

2

B

3 4 1 5 6

D

G

6

2'-9

"

62'-9"

1'-1"

4

'-3

"

6"

1

7

'-5

"

4

0

FAKE COLUMNS NOTE:

NEW 9"(MAX) x 24" "FAKE" COLUMN FOR MECH.

CHASE BY CARPENTER, CLAD WITH CEDAR ON

ALL EXPOSED SIDES. TO BE LESS THAN 9"

WIDE TO FIT WALL CAVITY BEHIND

REFRIG/FREEZER CASES. 24" DIMENSION

SHALL BE MINIMIZED BY FRAMING AS CLOSE

TO MECHANICALS AS POSSIBLE (TYP. FOR

ALL). F.R.P. PANELS ON COLUMNS IN

BEVERAGE COOLER (WHEN PRESENT)-SIZE

AND LOCATION TO BE COORD. ON- SITE W/

TRADER JOE'S REP AND FINAL FIXTURE

LAYOUT TO FIT NECESSARY MECH. SERVICES.

EXISTING 6" THICK CONCRETE PAD BY LANDLORD

(UNDER SEPARATE PERMIT) AS SPECIFIED ON

DWG. T-2. HEIGHT TO BE FLUSH WITH ADJACENT

FLOOR SLAB. COORDINATE PLACEMENT OF NEW

CONCRETE PAD WITH TRADER JOE'S PRIOR TO

INSTALLATION

EXISTING 8'-0" x 8'-0" O.H.

DOOR BY L.L. AS PER TRADER

JOE'S STANDARDS (UNDER

SEPARATE PERMIT) SEE DOOR

SPECIFICATIONS DWG. A-6

EXISTING 10" DIA. STEEL

PIPE BOLLARDS FILLED W/

CONC. (TYP. FOR 2) BY L.L.

(UNDER SEPARATE PERMIT)

NEWCURTAIN

WALL @TOP OF

COOLER/FREEZ

ER TO BOT. OF

A.C.T. CLG. SEE

DWG. A-3

T.G.C. TO INSTALL FRP

FINISH ON (2) SIDES OF

SERVICE SINK TO A.C.T.

CLG 7'x 12' & 3'X 12'(V.I.F.)

PROVIDE "FAKE" COLUMN ENCLOSURE

FOR REFRIG. PIPE CHASE (TYP. AT ALL

CASES). VERIFY EXACT LOCATIONS AND

SIZE IN FIELD- SEE "COLUMN NOTE" THIS

SHEET FOR DETAILS, AND DETAIL 5/A.2

T.G.C. TO APPLY X-VERT.

CEDAR PLANKING. TYP.

AT SALES FLOOR WALLS

EXISTING VESTIBULE

CURTAIN WALL, TRANSOM,

AND GLAZING BY L.L.

EXISTING ALUM. FRAMING/ GLASS

STOREFRONT BY L.L. (TYP., UNDER

SEPARATE PERMIT) T.G.C. TO CLEAN &

POLISH AS REQUIRED AFTER INTERIOR

CONSTRUCTION. SEE EXTERIOR

ELEVATIONS. (UNDER SEPARATE PERMIT)

3-EX

2-EX 1-EX

9

4

LINE OF AIR

CURTAIN ABV.

SUPPLIED &

INSTALLED BY

TRADER JOE'S.

SEE DWGS. E-2

& M-1

7-EX

APPROX. LOCATION OF

ELECTRICAL PANELS- UNIT

BY LANDLORD (UNDER

SEPARATE PERMIT)

A-0

2

(TYP. FOR 4)

STOCK

ROOM

107

A-6

6

A-6

3

EXISTING "BILCO"

ROOF HATCH AND

STEEL LADDER BY

TENANT G.C.-

PROVIDE WOOD

BLOCKING AS REQ'D

@WALL FASTENING

POINTS FOR

LADDER- SEE DETAIL

11/A2.1

EXISTING

FACE OF

MASONRY

AT BUILDING

LINE

LINE OF WALL SHELF

(TYP.) REFER TO FIXTURE

& ARCH. DETAIL DWGS.

FOR ADDITIONAL DETAILS

EXISTING SIDEWALK

AREA (TYP.)- BY

LANDLORD (UNDER

SEPARATE PERMIT)

G

A

F

C

L1

D

A-2

0-EX

EXISTING ALUM. FRAMING/ GLASS

STOREFRONT BY L.L. (TYP., UNDER

SEPARATE PERMIT) T.G.C. TO CLEAN

& POLISH AS REQUIRED AFTER

INTERIOR CONSTRUCTION. SEE

EXTERIOR ELEVATIONS.

11

A-5.1

B

8

6 5

10

A-2.1

EXISTING 14'- 0-1/2" x 7'-8" R.O. &

AUTOMATIC DOOR PACKAGE

BY L.L. (UNDER SEPARATE

PERMIT) FINISH TO BE WHITE.

GLASS TO BE CLEAR. SEE

ELEVATION SHEET A-4

T.G.C. TO COORDINATE EXACT

FIXTURE/WALL CONSTRUCTION

AND LOCATION W/ FINAL FIXTURE

LAYOUT. SEE ARCH. DETAILS, 1/A-2

FOR CONSTRUCTION DETAIL.

CONSTRUCT WALL FOLLOWING

FIXTURE PLACEMENT (TYP.)

L1

16-EX

AREA FOR

SPRINKLER RISER

BY LANDLORD

EXTENT LINE OF

PLATFORMABOVE. SEE

PLAN THIS SHEET.

EXIST. 3'-4" X 7'-2" M.O. W/ 3'-

0" X 7'-0" HMEGRESS DOOR

BY L.L.- PAINT TO MATCH

TRADER JOE'S COLOR

(UNDER SEPARATE PERMIT)

LINE OF DEMO STATION

COUNTER, SEE DWG. A-5.1

FOR ENLARGED PLAN, FIXTURE

WALL DETAIL & ELEVATIONS

G

G

VESTIBULE

ENTRY

100

SALES AREA

101

CAPTAIN'S

STATION

102

WOMEN'S

TOILET

103

MEN'S

TOILET

104

SALES

SUPPORT

105

CORRIDOR

106

BEVERAGE

COOLER

108

RESERVE

FREEZER

112

DEMO

ROOM

110

DEMO

STATION

111

A

L

L

B

A-4

A

J

LINE OF AIR CURTAIN ABV.

SUPPLIED & INSTALLED BY

TRADER JOE'S.

SEE DWGS. E-2 & M-1

G

A-6

2

3

A-2

A-2

6

EXISTING 8'-0" WIDE

HANDICAP RAMP BY

LANDLORD. (UNDER

SEPARATE PERMIT)

LOCATION TO BE VERIFIED

W/ TRADER JOE'S REP.

A

A-2

A

A-2

A-2

5

A-2

5

D1

L

B B

J

G

LINE OF EXISTING

CANOPY ABOVE

F

PROVIDE "FAKE" COLUMN ENCLOSURE FOR REFRIG.

PIPE CHASE (TYP. AT ALL CASES). VERIFY EXACT

LOCATIONS AND SIZE IN FIELD- SEE "COLUMN NOTE"

THIS SHEET FOR DETAILS, AND DETAIL 5/A.2

D D

H

SUPPORT WALL

FOR PLATFORM

ABOVE- ATTACH

TO EXISTING

EXTERIOR WALL

AS NECESSARY

T.G.C. TO APPLY 3/8" A.C.X.

PLYWOOD ON GYP. BD. WALLS

TO B.O. NEWA.C.T. CLG.- RUN

PLYWOOD HORIZ., PROVIDE

STEEL CORNER GUARDS ON

ALL OUTSIDE CORNERS (TYP.)

NEWTELESCOPING ACCESS

LADDER / HATCH 30" x 54" TO

SUPPORT ROOM BELOW. ALUM.

COVER FINISHED TO MATCH

CEILING. LADDER - PRECISION

LADDERS, LLC, SUPER SIMPLEX

DISAPPEARING STAIRWAY

H

A

H

10-EX

7

A-6

PROVIDE "FAKE" COLUMN ENCLOSURE

FOR REFRIG. PIPE CHASE (TYP. AT ALL

CASES). VERIFY EXACT LOCATIONS AND

SIZE IN FIELD- SEE "COLUMN NOTE" THIS

SHEET FOR DETAILS, AND DETAIL 5/A.2

A-4

A-4

A-4

C

D

B

EXISTING 53'-0" L. x 4'-6"

W. MASONRY CART

CORRAL BY L.L. (UNDER

SEPARATE PERMIT) PER

TRADER JOE'S

SPECIFICATIONS. SEE

DWG. T-2.

G

B

D1

A

EXISTING ENCOLSURE

FOR PALLET STORAGE

AREA BY LANDLORD

(UNDER SEPARATE

PERMIT)

PROPOSED TRASH

ENCLOSURE, BY

LANDLORD (UNDER

SEPARATE PERMIT)

NEWPIGMENTED CONCRETE

SLAB (TYP.), BY TENANT GENERAL

CONTRACTOR

SEE DWG. T-2 FOR SPECS.

A-2

5

A-2

5

T.G.C. TO STACK

RECEPT./ PHONE

@ 48" A.F.F.

B

J

D

B

A-2

C

A-2

C

A-2

C

A-2

C

A-2

CART STOP RAIL FOR ELEC.

PANELS- MC-CUE CART

STOP MODEL CSSYP-48

2

' -

6

"

1

2

' -

8

"

4"

3' - 6" 4' - 7"

7

' -

6

"

6

' -

0

"

3

7

' -

0

"

4

' -

8

"

3

' -

1

1

"

2' - 3" 5' - 1" 14' - 10" 3' - 0" 8' - 0"

EXISTING "BILCO" ROOF HATCH AND STEEL

LADDER BY TENANT G.C.- PROVIDE WOOD

BLOCKING AS REQ'D @WALL FASTENING

POINTS FOR LADDER- SEE DETAIL 11/A2.1

NEWTELESCOPING ACCESS

LADDER / HATCH 30" x 54" TO

SUPPORT ROOM BELOW. ALUM.

COVER FINISHED TO MATCH

CEILING. LADDER - PRECISION

LADDERS, LLC, SUPER SIMPLEX

DISAPPEARING STAIRWAY

PLYWOOD FLOORING

@ +/- 9'-2 3/8" A.F.F.

11

A-2.1

10

A-2.1

PLATFORM

109

E

E

E

F1

3

' -

6

"

2' - 0" 3' - 6"

25' - 5"

1

2

' -

3

1

/

2

"

5 4

NOTE: SEE DRAWING A/A-2.1 FOR PLATFORMFRAMING

E

F

A

T R

C

HI TE

C

STATE OF

R

D EG I S T ERE

R

E

D

R

I

C

J

G

R

E

E

N

K

FLORIDA

LICENSE NO.

AR95447

F

L O R I D A

IS

S

U

E

D

A

T

E

:

J

O

B

N

O

.:

D

R

A

W

N

B

Y

:

T

R

A

D

E

R

J

O

E

'S

S

T

O

R

E

N

O

.:

S

P

A

C

E

N

O

.:

S

E

A

L

3939 Priority Way South Dr., Suite 400

INDIANAPOLIS, INDIANA 46240

(317) 844-6777 FAX (317) 706-6464

E-Mail cripe@cripe.biz

ARCHITECTURE

INTERIOR DESIGN

CIVIL/TRANSPORTATION ENGINEERS

LAND PLANNING

LAND SURVEYING

GIS

OWNER'S REPRESENTATION

P

R

O

J

E

C

T

S

H

E

E

T

N

A

M

E

CERTIFIED BY:

'

'

`

'

'

A-0

`

'

'

1/8" = 1'-0"

1

CONSTRUCTION FLOOR PLAN

NORTH

1/4" = 1'-0"

2

PLATFORM CONSTRUCTION PLAN

R

E

V

IS

IO

N