Beruflich Dokumente

Kultur Dokumente

Siemens NX - Guidance

Hochgeladen von

djtj89Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Siemens NX - Guidance

Hochgeladen von

djtj89Copyright:

Verfügbare Formate

ME2601 2011/2012

ME2601 Lab Sessions: Siemens NX Tutorials

1. Running NX Tutorials

Recommended order for tutorial sessions:

Basic Concepts in NX (Week 2)

Design & Drafting (Weeks 3 and 4) Assembly & Simulation (Week 5 and 6)

A list of NX tutorial content has been put together for you from the next page onward. The recommended content is highlighted, because it represents a comprehensive introduction to the essential NX elements that you are most likely to use in your assignment. Since there is limited time for practical sessions, you might need to skip some items. Note that the lab is open outside the scheduled module sessions and you can come and practice more, or finish off a recommended section in order to be ready for the following week. From week 7 it will be understood that all recommended sections have been covered. When you find during your assignment that other sections are also useful or needed, you can revisit the tutorial through learning-bydoing at that time.

ME2601-NX-Tutorials-Guidance.doc (KM, 11/10/10)

1/8

ME2601 2011/2012

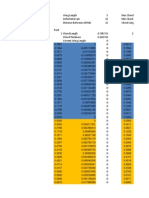

2. Recommended Content for the NX Tutorials

Basic Concepts in NX (Week 2) Getting Started with NX Getting started in NX Customer defaults (optional) Selecting Objects and Manipulating the WCS Selecting objects Change views Manipulate the WCS The Work Plane Organizing and Displaying Parts Organizing parts Displaying parts Basic Visualization Tools Artistic Image Basic Lights Cameras Sectioning Decal High Quality Image shading Raster Image True Shading Visualization Scenes Online Documentation and Common Tools Common NX tools Online Documentation Design (Week 3 and Week 4) Sketcher Sketch Basics Sketcher overview Basics of sketching Sketcher Geometric Constraints Edit sketcher techniques Dimensional constraints Working with Sketches Conflicting constraints Reattach sketch Create points in sketcher Project curves onto a sketch Drag sketch geometry Alternate Solution Sketch On Path

ME2601-NX-Tutorials-Guidance.doc (KM, 11/10/10)

2/8

ME2601 2011/2012

Constraining Sketches Activity: Constrain a U-shape sketch Activity: Constrain an angled sketch Activity: Constrain a hex shape sketch Activity: Create sketch fillets Activity: Mirror sketch objects Activity: Constrain to edges Expressions Creating Expressions Overview of expressions Creating expressions Using Expressions Exporting and importing expressions Miscellaneous expression topics Expressions in Spreadsheets and the Visual Editor Using the spreadsheets The Visual Editor Expressions Projects Activity: Reposition a hole in a cover plate Activity: Edit features of a slider bar Feature Modeling Overview of Modeling, Datum Coordinate Systems Overview of Modeling Datum Coordinate Systems Combine Bodies, Detail Features, Shell Extrude Combine bodies: Unite, Subtract, and Intersect Chamfer options Add edge blends Shell Datum Planes, Expressions, Groove Using extrude, revolve and intersect to create a hex nut Creating a hex bolt from a sketch Expressions Adding holes and grooves Datums, Trim Body, Hole, Shell Datum Plane and Datum Axis Trim Body Edge Blend Extrude Hole and Shell Extrude, Slot

ME2601-NX-Tutorials-Guidance.doc (KM, 11/10/10)

3/8

ME2601 2011/2012

Activity: Extrude to define a basic shape for a model Slot Activity: Extrude and blend edges Extrude face edges to create pockets Revolve, Slot, Circular Array Revolve, Slot, Circular Array Editing Features Edit feature parameters Edit multiple parameters Edit Positioning Activity: Edit a chamfer Density Suppress and unsuppress Reordering features Feature Playback Instance Arrays, Threads Feature Instances Threads Draft, Face/Surface Operations Draft Draft Body Offset Face Spherical corners Sew Sweep along Guide Extract/Wrap Geometry Composite curve and extract geometry Wrap geometry Body Operations Patch body Scale body Split body Feature Operations Copy and paste features Feature sets Replace features Knowledge Fusion Overview Feature Modeling Projects Create a vessel Create a stapler housing Create a piston Create a pivot plate Create a cover plate

ME2601-NX-Tutorials-Guidance.doc (KM, 11/10/10)

4/8

ME2601 2011/2012

Free Form Modeling Curves User Defined Features Product and Manufacturing Information Die Engineering Projects Model a Collet Model a Rocker Device Model a Clamp Model a Hinge Bracket Drafting (Week 3 and Week 4) Drafting Introduction to Drafting Preparation tasks Drawings and Views Creating drawing sheets Editing drawing sheets The drafting customer defaults The Drafting Standards Adding views to a drawing sheet View labels Detail views Editing the display of a view Small features Identifying parent views Deleting drawing views Moving views Copying drawing views Aligning views Updating drawings and views Editing view boundaries Editing layer visibility Creating a master model drawing Linear Dimensions Inferred dimensions Horizontal and Vertical dimensions Chamfer dimensions Parallel dimensions Perpendicular dimensions Angular dimensions Chain dimensions Narrow dimensions Baseline dimensions

ME2601-NX-Tutorials-Guidance.doc (KM, 11/10/10)

5/8

ME2601 2011/2012

Thickness dimensions Retained annotations Radial Dimensions Diameter dimensions Radial dimensions Folded Radius dimensions Arc Length dimensions Cylindrical dimensions Dimension tolerances Appended Dimensions Dimensions with appended text Inheriting feature data Dimensioning 3D views Notes and Labels Notes and labels Editing text Creating labels Creating tabular notes Stepped Section Views Overview Simple section views Stepped section views Partial section views Associative hinge lines 3 dimensional section views Revolved Section Views Revolved section views Half section views Unfolded section views Editing section views Editing section line symbols Centerline Symbols Center Marks Automatic Centerlines Bolt Circle Centerlines Circular Centerlines 2D and 3D Centerlines Offset Center Points Additional Drafting Symbols Identification symbols Thread symbols Weld symbols GD&T Symbols Creating GDT symbols

ME2601-NX-Tutorials-Guidance.doc (KM, 11/10/10)

6/8

ME2601 2011/2012

Appending GDT symbols The Feature Control Frame The Datum Feature Symbol creator Ordinate Dimensions Ordinate Dimensions Plotting Drawings Drafting Projects Project 1: Create a drawing Project 2: Add dimensions to a drawing Assembly Modeling (Week 5 and Week 6) Basic Assembly Concepts Overview of Assembly Modeling The Assembly Navigator Creating Assemblies Bottom-up assemblies Reference Sets Top-down assemblies Positioning Assembly Components Assembly constraints Convert mating conditions to assembly constraints Edit assembly constraints Remembered assembly constraints Assembly Arrangements and Arrays Assembly Arrangements Component arrays Assembly Revisions and Component Replacements Revisions and substitutions Replacing components Assembly Sequencing and Motion Assembly Sequencing and Motion Extracting a sequence path Creating a sequence for a pump Assemblies - Clearance and Analysis Interactive clearance analysis Edit the model and reanalyze interferences Check clearances on sheets Simple interference solids Assembly Cloning and Interpart Expressions Assembly Cloning Interpart expressions Deformable Components Deformable Components Part Families Assembly Projects

ME2601-NX-Tutorials-Guidance.doc (KM, 11/10/10)

7/8

ME2601 2011/2012

Activity: Create an assembly sequence for a valve Activity: Create a clamp assembly Activity: Examine an automotive drive assembly Activity: Examine a phone assembly Simulation (Week 5 and Week 6) Advanced Simulation Overview of the Advanced Simulation courses Introduction to Advanced Simulation General capabilities of Advanced Simulation Model preparation Basic meshing techniques Advanced meshing techniques Working with polygon geometry Boundary conditions Post-processing techniques Solutions and solution processes Advanced FE modeling techniques Thermal and Flow Analysis Motion Simulation Motion Simulation Machining (As Time Permits)

ME2601-NX-Tutorials-Guidance.doc (KM, 11/10/10)

8/8

Das könnte Ihnen auch gefallen

- Autodesk Inventor 2015 Training ProgramsDokument9 SeitenAutodesk Inventor 2015 Training ProgramsNikola ŠererNoch keine Bewertungen

- NX7 For Engineers and DesignersDokument1 SeiteNX7 For Engineers and DesignersDreamtech Press100% (1)

- Wireframe and Surface Design: CATIA TrainingDokument55 SeitenWireframe and Surface Design: CATIA Trainingkishore99939Noch keine Bewertungen

- Edgecam Getting StartedDokument51 SeitenEdgecam Getting StartedPet UrNoch keine Bewertungen

- NX Modeling, Assembly and Drafting GuideDokument38 SeitenNX Modeling, Assembly and Drafting GuidePradeepvenugopalNoch keine Bewertungen

- 2DV2 Tutorial BookletDokument74 Seiten2DV2 Tutorial BookletTripleX100% (1)

- ControlDokument2 SeitenControlAhmad AlmasriNoch keine Bewertungen

- Lab 6 - Face Milling On CNC MachineDokument5 SeitenLab 6 - Face Milling On CNC MachineHaris NaveedNoch keine Bewertungen

- Design For Assembly A Complete Guide - 2020 EditionVon EverandDesign For Assembly A Complete Guide - 2020 EditionNoch keine Bewertungen

- A Critical Review On Optimization of WEDM Process Using Taguchi ArrayDokument6 SeitenA Critical Review On Optimization of WEDM Process Using Taguchi ArrayIJRASETPublicationsNoch keine Bewertungen

- AutoCAD 2016 and AutoCAD LT 2016 No Experience Required: Autodesk Official PressVon EverandAutoCAD 2016 and AutoCAD LT 2016 No Experience Required: Autodesk Official PressBewertung: 4 von 5 Sternen4/5 (1)

- Apostila PowerMILL 5.5 - 5 EixosDokument126 SeitenApostila PowerMILL 5.5 - 5 EixosRoberto SilvaNoch keine Bewertungen

- Manual Unigraphics NX - 09 The Master ModelDokument13 SeitenManual Unigraphics NX - 09 The Master ModelthiagomcasimiroNoch keine Bewertungen

- MpgugDokument96 SeitenMpgugiagomouNoch keine Bewertungen

- Nx6 Goal Seek2Dokument19 SeitenNx6 Goal Seek2MATHI KRISHNANNoch keine Bewertungen

- EdgeCAM 2015Dokument12 SeitenEdgeCAM 2015Daniela UlianNoch keine Bewertungen

- Enroute 6Dokument43 SeitenEnroute 6Diego RomeroNoch keine Bewertungen

- Alpha XS CNC Tutorial-ENGLISHDokument141 SeitenAlpha XS CNC Tutorial-ENGLISHEugen NaydyonNoch keine Bewertungen

- Sprintcut PDFDokument5 SeitenSprintcut PDFpruthiviraj13100% (1)

- Solid Edge API Tcm78-125829Dokument195 SeitenSolid Edge API Tcm78-125829Anonymous z4Fe39jNoch keine Bewertungen

- C16 NX11 PDFDokument82 SeitenC16 NX11 PDFVignesh WaranNoch keine Bewertungen

- Department of Mechanical Engineering: Machine Design & CAD-II Lab (MEEN-3238)Dokument11 SeitenDepartment of Mechanical Engineering: Machine Design & CAD-II Lab (MEEN-3238)Sarmad HafeezNoch keine Bewertungen

- 2008 NX Open StatusDokument24 Seiten2008 NX Open Statushector_547Noch keine Bewertungen

- Basic To Advanced CAD Using NX 12 Sample PDFDokument29 SeitenBasic To Advanced CAD Using NX 12 Sample PDFYaseen JamilNoch keine Bewertungen

- SolidWorks 2020 EX - 05Dokument2 SeitenSolidWorks 2020 EX - 05Richard GarrisonNoch keine Bewertungen

- Inventorcam 2014 Application Tutorial: Multiblade Machining: ©1995-2013 Solidcam All Rights ReservedDokument45 SeitenInventorcam 2014 Application Tutorial: Multiblade Machining: ©1995-2013 Solidcam All Rights ReservedKhai Huynh100% (1)

- Milling PDFDokument282 SeitenMilling PDFDulis DulisNoch keine Bewertungen

- Vezba 1 PDFDokument4 SeitenVezba 1 PDFhippokg100% (1)

- V9.1 Lathe Tutorial Change Pages (Inch)Dokument39 SeitenV9.1 Lathe Tutorial Change Pages (Inch)Andrew TNoch keine Bewertungen

- NX Programming NetDokument3 SeitenNX Programming NetAlfombras Lloveras100% (1)

- Solidworks Certification CostDokument2 SeitenSolidworks Certification CostGanesh PawarNoch keine Bewertungen

- NX Electrode Design AysDokument2 SeitenNX Electrode Design Aysbadboys123Noch keine Bewertungen

- Katalog-SA CA IQDokument16 SeitenKatalog-SA CA IQVictor Godoy100% (1)

- Licao Lofts PDFDokument16 SeitenLicao Lofts PDFrcaletaNoch keine Bewertungen

- Pro-Engineer WildFire 4.0 ManualDokument45 SeitenPro-Engineer WildFire 4.0 ManualMoiz MohsinNoch keine Bewertungen

- PowerMill 2019 Feature Comparison MatrixDokument2 SeitenPowerMill 2019 Feature Comparison MatrixBojan RadovanovicNoch keine Bewertungen

- With Creo Parametric 4.0Dokument47 SeitenWith Creo Parametric 4.0amitesh kumarNoch keine Bewertungen

- Practice Book TCIL IT-GTechDokument64 SeitenPractice Book TCIL IT-GTechJyothish DevadasNoch keine Bewertungen

- BottleDokument29 SeitenBottlesumikannuNoch keine Bewertungen

- Cad Cam Lab Question Paper (2022)Dokument6 SeitenCad Cam Lab Question Paper (2022)PavaniNoch keine Bewertungen

- Manual ModusDokument410 SeitenManual ModusJuanillo100% (1)

- L&T: Project Tow: Designing / Value Engineering A Tow Hitch ReceiverDokument41 SeitenL&T: Project Tow: Designing / Value Engineering A Tow Hitch ReceiverAnubhav Felix DasguptaNoch keine Bewertungen

- Official Certified Solidworks Associate (CSWA) Examination GuideDokument250 SeitenOfficial Certified Solidworks Associate (CSWA) Examination GuidePablo CabotNoch keine Bewertungen

- c01 nx8.5 EvalDokument20 Seitenc01 nx8.5 EvalSeshi ReddyNoch keine Bewertungen

- Getting StartedDokument43 SeitenGetting StartedJohnnattan VargasNoch keine Bewertungen

- Basic Pro-E Ques and AnswerDokument14 SeitenBasic Pro-E Ques and Answerapi-3808872100% (1)

- Kinematics and Dynamics - Lab3 PDFDokument8 SeitenKinematics and Dynamics - Lab3 PDFKunal SharmaNoch keine Bewertungen

- CNC SimulatorDokument251 SeitenCNC Simulatorpepe51Noch keine Bewertungen

- 2020 SOLIDWORKS 8.5x11Dokument4 Seiten2020 SOLIDWORKS 8.5x11hüseyin demirNoch keine Bewertungen

- Me59-Cad - Cam Lab Manual 2010-2011Dokument38 SeitenMe59-Cad - Cam Lab Manual 2010-2011vnmknmechNoch keine Bewertungen

- Cadlearning Autodesk Inventor 2011 OutlineDokument5 SeitenCadlearning Autodesk Inventor 2011 OutlineAndrés de la CadenaNoch keine Bewertungen

- Statistics SummaryDokument9 SeitenStatistics Summarydjtj89Noch keine Bewertungen

- Stress Concentration PDFDokument8 SeitenStress Concentration PDFkanak kalitaNoch keine Bewertungen

- Term 1Dokument2 SeitenTerm 1djtj89Noch keine Bewertungen

- Topology Optimization of A Wing Box RibDokument131 SeitenTopology Optimization of A Wing Box Ribdjtj89100% (1)

- ME3601 Prof Eng PracticeDokument3 SeitenME3601 Prof Eng Practicedjtj89Noch keine Bewertungen

- Aircraft Design AnalysisDokument9 SeitenAircraft Design Analysisdjtj89100% (1)

- Contents Aircraft Landing GearDokument1 SeiteContents Aircraft Landing Geardjtj89Noch keine Bewertungen

- Critical ReviewDokument1 SeiteCritical Reviewdjtj89Noch keine Bewertungen

- UAV Drone ComparisonDokument14 SeitenUAV Drone Comparisondjtj89Noch keine Bewertungen

- CFD Simulation IntroductionDokument30 SeitenCFD Simulation Introductiondjtj89Noch keine Bewertungen

- Topology Optimization of Aircraft Wing Box RibsDokument3 SeitenTopology Optimization of Aircraft Wing Box Ribsdjtj89Noch keine Bewertungen

- NACA 23014 (Mod) - 416Dokument406 SeitenNACA 23014 (Mod) - 416djtj89Noch keine Bewertungen

- Airfoil Geometry DataDokument26 SeitenAirfoil Geometry Datadjtj89Noch keine Bewertungen

- Excel To CATIADokument6 SeitenExcel To CATIAdjtj89Noch keine Bewertungen

- Agusta WestlandDokument7 SeitenAgusta Westlanddjtj89Noch keine Bewertungen

- CFD Assignment FinalDokument22 SeitenCFD Assignment Finaldjtj89Noch keine Bewertungen

- Environmental Law Final-2013Dokument71 SeitenEnvironmental Law Final-2013djtj89Noch keine Bewertungen

- Tut - Basic RefrigerationDokument3 SeitenTut - Basic Refrigerationdjtj89Noch keine Bewertungen

- ME3608 Aeroelasticity #1Dokument31 SeitenME3608 Aeroelasticity #1djtj89Noch keine Bewertungen

- Seminar19 PDFDokument4 SeitenSeminar19 PDFdjtj89Noch keine Bewertungen

- A History of Canadian Naval Aviation 1918-1963Dokument169 SeitenA History of Canadian Naval Aviation 1918-1963djtj89100% (3)

- Literature Review PlanDokument1 SeiteLiterature Review Plandjtj89Noch keine Bewertungen

- Environmental Law Final-2013Dokument71 SeitenEnvironmental Law Final-2013djtj89Noch keine Bewertungen

- ME3602 - ME3692 FEA Assignment 2013 - 2014: K A P KDokument3 SeitenME3602 - ME3692 FEA Assignment 2013 - 2014: K A P Kdjtj89Noch keine Bewertungen

- Thermofluids ME2301Dokument1 SeiteThermofluids ME2301djtj89Noch keine Bewertungen

- ME3608 Aeroelasticity #1Dokument31 SeitenME3608 Aeroelasticity #1djtj89Noch keine Bewertungen

- TOOLKIT For MPDS-August12 PDFDokument13 SeitenTOOLKIT For MPDS-August12 PDFdjtj89Noch keine Bewertungen

- Sections and Threads PDFDokument1 SeiteSections and Threads PDFdjtj89Noch keine Bewertungen

- Technical Drawing Intro PDFDokument1 SeiteTechnical Drawing Intro PDFdjtj89Noch keine Bewertungen

- Paper 1 - Summary Revision Notes - OL CSDokument53 SeitenPaper 1 - Summary Revision Notes - OL CSjanaNoch keine Bewertungen

- Project Management Institute Indonesia Chapter: at A GlanceDokument37 SeitenProject Management Institute Indonesia Chapter: at A GlanceM R PatraputraNoch keine Bewertungen

- Industrial Internship DiaryDokument30 SeitenIndustrial Internship Diaryvineela namaNoch keine Bewertungen

- Development of A Buffer Monitoring DashboardDokument47 SeitenDevelopment of A Buffer Monitoring DashboardtelegenicsNoch keine Bewertungen

- One Pager v2Dokument2 SeitenOne Pager v2JuanCarlosMarrufoNoch keine Bewertungen

- Sandip University: End Semester Examinations-June 2021Dokument1 SeiteSandip University: End Semester Examinations-June 2021Industrial Training Institute ITI,SilvassaNoch keine Bewertungen

- Tutorial - Change The OS X Version by Modifying Systemversion - PlistDokument17 SeitenTutorial - Change The OS X Version by Modifying Systemversion - PlistIsrael Jimenez AmorizNoch keine Bewertungen

- Soltek SL 65meDokument88 SeitenSoltek SL 65meBernardo AntunesNoch keine Bewertungen

- Manual de Configuración y Comisionamiento OptiX RTN - U2000 PDFDokument40 SeitenManual de Configuración y Comisionamiento OptiX RTN - U2000 PDFJonathan Gonzalez.LNoch keine Bewertungen

- ICT158 Workshop 7Dokument2 SeitenICT158 Workshop 7Jaya MathiNoch keine Bewertungen

- Function X - A Universal Decentralized InternetDokument24 SeitenFunction X - A Universal Decentralized InternetrahmahNoch keine Bewertungen

- JioBusiness-ILL Product Leaflet DigitalDokument1 SeiteJioBusiness-ILL Product Leaflet Digitaljitendermcse9816Noch keine Bewertungen

- GSM WorkflowDokument1 SeiteGSM WorkflowFaisal CoolNoch keine Bewertungen

- Logistics Market:: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2019-2024Dokument55 SeitenLogistics Market:: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2019-2024Trần Thị Hồng NgọcNoch keine Bewertungen

- AOPEN DEV8430 Preliminary DatasheetDokument2 SeitenAOPEN DEV8430 Preliminary DatasheetMarisa García CulpiánNoch keine Bewertungen

- End of Chapter 8 (p.606) Questions 1,2,4,8,14.: Short AnswerDokument4 SeitenEnd of Chapter 8 (p.606) Questions 1,2,4,8,14.: Short AnswerTung VanNoch keine Bewertungen

- Stock Coal and Limestone Feed Systems: Powering Industry ForwardDokument12 SeitenStock Coal and Limestone Feed Systems: Powering Industry ForwardAchmad Nidzar AlifNoch keine Bewertungen

- SAP SRM 7.0 Strategic SourcingDokument90 SeitenSAP SRM 7.0 Strategic SourcingSergio Martinez PerezNoch keine Bewertungen

- DX5 EuserguideDokument20 SeitenDX5 Euserguidegabriel ferreyraNoch keine Bewertungen

- Characterization of SPT Grain Size Effects in GravDokument9 SeitenCharacterization of SPT Grain Size Effects in Gravstefanus fendisaNoch keine Bewertungen

- Langdo Led Lighting Co.,LimitedDokument24 SeitenLangdo Led Lighting Co.,LimitedRudi CressaNoch keine Bewertungen

- College Events Dissemination System: Rishabh Kedia, Abhishek Pratap Singh & Varun GuptaDokument8 SeitenCollege Events Dissemination System: Rishabh Kedia, Abhishek Pratap Singh & Varun GuptaTJPRC PublicationsNoch keine Bewertungen

- Water Specialist WS2H and WS3 Control Valve ManualDokument40 SeitenWater Specialist WS2H and WS3 Control Valve ManualjnpaisNoch keine Bewertungen

- Fidelityfx Cas: Lou Kramer, Developer Technology Engineer, AmdDokument92 SeitenFidelityfx Cas: Lou Kramer, Developer Technology Engineer, AmdJohn K SmithNoch keine Bewertungen

- LENZE 8200 VectorDokument290 SeitenLENZE 8200 VectorAgus Itonk Suwardono100% (2)

- Hacking Second Life Michael ThumannDokument14 SeitenHacking Second Life Michael ThumannDanny AdonisNoch keine Bewertungen

- HR Practices and Organizational Strategies in Select: IT Companies in India "Dokument59 SeitenHR Practices and Organizational Strategies in Select: IT Companies in India "Sneha MehtaNoch keine Bewertungen

- Jabra Android SDK Developers GuideDokument12 SeitenJabra Android SDK Developers GuideEmilio AlejandroNoch keine Bewertungen

- E-Tutorial - Online Correction - Resolution For Overbooked Challan (Movement of Dedcutee Row)Dokument36 SeitenE-Tutorial - Online Correction - Resolution For Overbooked Challan (Movement of Dedcutee Row)Raj Kumar MNoch keine Bewertungen

- Positioning & ErrorsDokument3 SeitenPositioning & ErrorsAhsan Hussain100% (4)

- The Inimitable Jeeves [Classic Tales Edition]Von EverandThe Inimitable Jeeves [Classic Tales Edition]Bewertung: 5 von 5 Sternen5/5 (3)

- You Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherVon EverandYou Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherNoch keine Bewertungen

- Other People's Dirt: A Housecleaner's Curious AdventuresVon EverandOther People's Dirt: A Housecleaner's Curious AdventuresBewertung: 3.5 von 5 Sternen3.5/5 (104)

- A-level Biology Revision: Cheeky Revision ShortcutsVon EverandA-level Biology Revision: Cheeky Revision ShortcutsBewertung: 5 von 5 Sternen5/5 (5)

- The Importance of Being Earnest: Classic Tales EditionVon EverandThe Importance of Being Earnest: Classic Tales EditionBewertung: 4.5 von 5 Sternen4.5/5 (43)

- The House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedVon EverandThe House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Welcome to the United States of Anxiety: Observations from a Reforming NeuroticVon EverandWelcome to the United States of Anxiety: Observations from a Reforming NeuroticBewertung: 3.5 von 5 Sternen3.5/5 (10)

- The Asshole Survival Guide: How to Deal with People Who Treat You Like DirtVon EverandThe Asshole Survival Guide: How to Deal with People Who Treat You Like DirtBewertung: 4 von 5 Sternen4/5 (60)

- Sexual Bloopers: An Outrageous, Uncensored Collection of People's Most Embarrassing X-Rated FumblesVon EverandSexual Bloopers: An Outrageous, Uncensored Collection of People's Most Embarrassing X-Rated FumblesBewertung: 3.5 von 5 Sternen3.5/5 (7)

- The Best Joke Book (Period): Hundreds of the Funniest, Silliest, Most Ridiculous Jokes EverVon EverandThe Best Joke Book (Period): Hundreds of the Funniest, Silliest, Most Ridiculous Jokes EverBewertung: 3.5 von 5 Sternen3.5/5 (4)

- Humorous American Short Stories: Selections from Mark Twain, O. Henry, James Thurber, Kurt Vonnegut, Jr. and moreVon EverandHumorous American Short Stories: Selections from Mark Twain, O. Henry, James Thurber, Kurt Vonnegut, Jr. and moreNoch keine Bewertungen

- 100 Bible Verses Everyone Should Know by HeartVon Everand100 Bible Verses Everyone Should Know by HeartBewertung: 4.5 von 5 Sternen4.5/5 (20)

- Lower Secondary Science Workbook: Stage 8Von EverandLower Secondary Science Workbook: Stage 8Bewertung: 5 von 5 Sternen5/5 (1)

- Quantum Physics for Beginners: Simple Illustrated Guide to Discover with Practical Explanations the Paradoxes of the Life and Universe Reconsidering RealityVon EverandQuantum Physics for Beginners: Simple Illustrated Guide to Discover with Practical Explanations the Paradoxes of the Life and Universe Reconsidering RealityBewertung: 2 von 5 Sternen2/5 (1)

![The Inimitable Jeeves [Classic Tales Edition]](https://imgv2-2-f.scribdassets.com/img/audiobook_square_badge/711420909/198x198/ba98be6b93/1712018618?v=1)