Beruflich Dokumente

Kultur Dokumente

EB197D (Cambio de Rams)

Hochgeladen von

Claudio Israel BizarroOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

EB197D (Cambio de Rams)

Hochgeladen von

Claudio Israel BizarroCopyright:

Verfügbare Formate

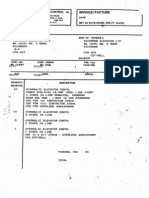

COOPER CooperOilTool

PROPERTY OF I

DRAWN BY

D.J. DATE July 1, 1991 McWhorter

RE"lSlON

Fl ENGINEERING BlJLLJ3TIN NO. 197 D PAGE 1 OF 1

RAM CHANGE PROCEDURE FOR U BLOWOUT -----------------___~~~~----------~~ ____----------_--___~~~~~~~~~------(1) (2) Loosenthe botiet all the way. bolts, four on each bonnet,

PREVEtiER

and unscrew

each

Apply 500 'psi hydraulic pressure to the-ram closed port. The bonnets will open. If more pressure is required, increase~the, hydraulic pressure slowly until a maximum of 1500 psi ,is reached. After the pistons have completed their stroke, on top

SYSTEM OR HYDRAULIC SUPPLY TO PREVENT ACCIDENTXL DISABLE THE CONTROL BONNET OR RAM

(3)

MOVEMENT. Use the lift the rams off

CAUTION -

lifting eyes, stored the connecting rods.

of the

bonnet,

to

STAND CLEAR OF THE RAMS AS TEN ARE BEING REMOVED. A SWINGING OR FWZNG RAM COULD CAUSE SERIOUS INJURY.

(4) (5)

Clean

and lubricate

the

ram bore.

Clean and inspect the bonnet seal groove and the body face with Remove all nicks, emphasis on the bonnet gasket seal area. burrs, ana raised surfaces. DO not remove any material below the origi'nal surface. Inspect the bonnet lubricate both the with a light oil. Install bonnet. Reinstall the bonnet gasket, bonnet gasket replace if necessary. gasket and the bonnet in the groove on the Be sure to gasket groove face of the

(6)

(7) (8) (9)

the

rams on the

connecting

rods.

KEEP HANDS CLEAR

and apply 500 psi hydraulic pressure to the ram open port to close the bonnets. If more pressure is required, increase the hydraulic pressure slowly until a maximum of 1500 psi is reached. Install and tighten the bonnet requirement per EB 560 D. bolts to the specified torque

(10)

or--356G

Das könnte Ihnen auch gefallen

- API 6A Hydraulic Actuator Operation InstructionDokument7 SeitenAPI 6A Hydraulic Actuator Operation InstructionSrikanth Bammhide100% (1)

- Landing Gear - HydrulicDokument16 SeitenLanding Gear - HydrulicAeroescuela IdeaNoch keine Bewertungen

- Atr 72-500 Pilot HandbookDokument27 SeitenAtr 72-500 Pilot HandbookFredyRedDevilz88% (8)

- T3 Annulars BOP Operators Manual 7022Dokument28 SeitenT3 Annulars BOP Operators Manual 7022super2274100% (4)

- Rtaa SB 4 - 10011991Dokument6 SeitenRtaa SB 4 - 10011991alcomech100% (3)

- SAL-14 - Informe Final PDFDokument25 SeitenSAL-14 - Informe Final PDFsanty222Noch keine Bewertungen

- 01 ExxonMobil Surface Equipment Policy & Procedures - 5Dokument10 Seiten01 ExxonMobil Surface Equipment Policy & Procedures - 5sitemaster60Noch keine Bewertungen

- Scientific American Supplement, No. 787, January 31, 1891Von EverandScientific American Supplement, No. 787, January 31, 1891Noch keine Bewertungen

- Cascade Roll Clamp 667442 - 70EPRCServ PDFDokument51 SeitenCascade Roll Clamp 667442 - 70EPRCServ PDFsindelu60Noch keine Bewertungen

- FIRST Pneumatics: Introduction To Air Power by Bob Koehl Team Ford FIRST Team Ford FIRST andDokument35 SeitenFIRST Pneumatics: Introduction To Air Power by Bob Koehl Team Ford FIRST Team Ford FIRST andÖzgür DalNoch keine Bewertungen

- Well Control EquipDokument36 SeitenWell Control EquipAhmed BakrNoch keine Bewertungen

- MA6 Capsule Flight Operations ManualDokument95 SeitenMA6 Capsule Flight Operations ManualBob Andrepont100% (2)

- Chapter 4-DDokument14 SeitenChapter 4-DMahrouz MadoNoch keine Bewertungen

- Emd Mi259Dokument20 SeitenEmd Mi259Mike Finazzi100% (3)

- Well Control EquiptDokument115 SeitenWell Control EquiptGhavban David100% (3)

- Mercury Capsule Detail 17 May 1961Dokument95 SeitenMercury Capsule Detail 17 May 1961Bob Andrepont100% (1)

- NAVAIR 01-250HDB-1B CH-46D.CH-46F & CH-46D Pocket Checklist (15 June 1970) PDFDokument113 SeitenNAVAIR 01-250HDB-1B CH-46D.CH-46F & CH-46D Pocket Checklist (15 June 1970) PDFBlaze123xNoch keine Bewertungen

- Bock Open Compressors Type FDokument29 SeitenBock Open Compressors Type Fembasian100% (5)

- Superior Packer Setting ProceduereDokument10 SeitenSuperior Packer Setting ProcedueretarangtusharNoch keine Bewertungen

- Pull and Push Up of PropDokument11 SeitenPull and Push Up of Propsandeep_yadav_530% (1)

- Boeing B 17 Flying FortressDokument106 SeitenBoeing B 17 Flying Fortressalexbiguet100% (2)

- PB Valve Brochure - 243Dokument11 SeitenPB Valve Brochure - 243Nwakile Chukwuebuka100% (1)

- WRVT 510Dokument27 SeitenWRVT 510alpyt100% (1)

- T11, Section 2, Ground HandlingDokument52 SeitenT11, Section 2, Ground HandlingDavid WongNoch keine Bewertungen

- TM 5-5060 1942 Le Roi Motorized Compressor On GMC DeuceDokument221 SeitenTM 5-5060 1942 Le Roi Motorized Compressor On GMC DeuceAdvocateNoch keine Bewertungen

- Cessna 152 ChecklistDokument14 SeitenCessna 152 ChecklistR-d Angelo GarciaNoch keine Bewertungen

- Intruction Manual FSADokument10 SeitenIntruction Manual FSAtrantuan74Noch keine Bewertungen

- 205 Drag Valves For Boiler Feedpump RecirculationDokument6 Seiten205 Drag Valves For Boiler Feedpump Recirculationesakkiraj1590Noch keine Bewertungen

- Foss & Gaul PDFDokument17 SeitenFoss & Gaul PDFnicolasbelliniNoch keine Bewertungen

- ELDBGFC 63311 1DV: Injection Catalog Page No: 500-918Dokument2 SeitenELDBGFC 63311 1DV: Injection Catalog Page No: 500-918johnny sabinNoch keine Bewertungen

- B U L L E T I N: Application EngineeringDokument14 SeitenB U L L E T I N: Application EngineeringMaria DazaNoch keine Bewertungen

- System Pressure - Release: Disassembly and AssemblyDokument4 SeitenSystem Pressure - Release: Disassembly and AssemblyNidya Wardah JuhanaNoch keine Bewertungen

- SB 8540.3 - 1800 and 2000 Industrial RegDokument12 SeitenSB 8540.3 - 1800 and 2000 Industrial RegImam BuchairiNoch keine Bewertungen

- Pressure Intensification: Watch This 6-Minute VideoDokument5 SeitenPressure Intensification: Watch This 6-Minute VideoDr. N. S. SriramNoch keine Bewertungen

- Maintenance & Operations Manual Regan Type K Blowout PreventerDokument4 SeitenMaintenance & Operations Manual Regan Type K Blowout PreventerAshok SureshNoch keine Bewertungen

- Falcon Solenoid Valve Operating and Maintenance Manual: Tech-132Dokument10 SeitenFalcon Solenoid Valve Operating and Maintenance Manual: Tech-132VICTORNoch keine Bewertungen

- SpecialDokument18 SeitenSpecialMery OrtizNoch keine Bewertungen

- Calibracion StanadineDokument3 SeitenCalibracion StanadineAndres ContrerasNoch keine Bewertungen

- Injection Pump Specification: .Lff.R.Dokument2 SeitenInjection Pump Specification: .Lff.R.Miguel RojasNoch keine Bewertungen

- Esx 7000-1Dokument35 SeitenEsx 7000-1RHoska100% (1)

- Bombas Volute Centrifugas0001Dokument7 SeitenBombas Volute Centrifugas0001caovadio88Noch keine Bewertungen

- Effect of Reduced Engine Compression Pressure On Pre-Ignition With Mica Plugs (15 September 1920)Dokument4 SeitenEffect of Reduced Engine Compression Pressure On Pre-Ignition With Mica Plugs (15 September 1920)raheyo6168Noch keine Bewertungen

- Intall Auto Hyd Hitch 87686296Dokument16 SeitenIntall Auto Hyd Hitch 87686296Lyle PlanteenNoch keine Bewertungen

- Peco Filter CaseDokument11 SeitenPeco Filter CaseLuis MaureraNoch keine Bewertungen

- Recommended Installation of A Bop Control SystemDokument8 SeitenRecommended Installation of A Bop Control SystemHamid Reza BabaeiNoch keine Bewertungen

- Minuteman SMG PlansDokument14 SeitenMinuteman SMG PlansodijfoijfNoch keine Bewertungen

- Model D ManualDokument38 SeitenModel D ManualVahidNoch keine Bewertungen

- Design and Development of Pulse Jet EngineDokument10 SeitenDesign and Development of Pulse Jet EngineHiren VadhavanaNoch keine Bewertungen

- With Hinged Panel Removed, The: Type of OperationDokument22 SeitenWith Hinged Panel Removed, The: Type of OperationElizabeth AllenNoch keine Bewertungen

- LZWSM8 (D) (P)Dokument7 SeitenLZWSM8 (D) (P)marinanagy211Noch keine Bewertungen

- Dfde EngineDokument22 SeitenDfde EngineARGONAFTISNoch keine Bewertungen

- Trex 05854Dokument8 SeitenTrex 05854OSDocs2012Noch keine Bewertungen

- Invoice/Factur.E: Sold To - Vendu A Ship To Expedie ADokument13 SeitenInvoice/Factur.E: Sold To - Vendu A Ship To Expedie AajknollNoch keine Bewertungen

- Avions Marcel Dassault: Maintenance ManualDokument8 SeitenAvions Marcel Dassault: Maintenance ManualFederico KronenbergNoch keine Bewertungen

- Miscellaneous FCC AspectsDokument114 SeitenMiscellaneous FCC AspectskotilskNoch keine Bewertungen

- SPW C0706-C1806 DXH8 (Series 6 Eco I 2 Pipe VRF) Om & Service-61-120-31-60Dokument30 SeitenSPW C0706-C1806 DXH8 (Series 6 Eco I 2 Pipe VRF) Om & Service-61-120-31-60Jacek NawrotNoch keine Bewertungen

- 980a2542 PDFDokument58 Seiten980a2542 PDFMichael DavenportNoch keine Bewertungen

- No 1Dokument20 SeitenNo 1airbusboeing1958Noch keine Bewertungen

- Scientific American Supplement, No. 388, June 9, 1883Von EverandScientific American Supplement, No. 388, June 9, 1883Noch keine Bewertungen

- Scientific American Supplement, No. 481, March 21, 1885Von EverandScientific American Supplement, No. 481, March 21, 1885Noch keine Bewertungen