Beruflich Dokumente

Kultur Dokumente

Reinforcement Steel Specifications

Hochgeladen von

Sulaiman Mohsin AbdulAziz0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

78 Ansichten1 SeiteCopyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

XLS, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als XLS, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

78 Ansichten1 SeiteReinforcement Steel Specifications

Hochgeladen von

Sulaiman Mohsin AbdulAzizCopyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als XLS, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

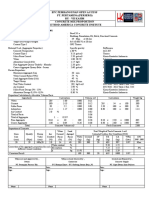

REINFORCEMENT STEEL SPECIFICATIONS BS4449/1997 & BS 4449/2005/ASTM A 615/A 615/M

Parameters BS 4449/1997 Grade 460B

Chemical Composition Chemical Composition Requirement C % 0.25 Max S % 0.05 Max P % 0.05 Max N % 0.012 Max CEV % 0.51 Max Yield Strength (min.) Tensile Strength (min) Mechanical Properties Elongation @ fracture (A5) Allowable deviation 0.02 0.005 0.005 0.001 0.03 460 N/mm

2

BS 4449/2005 Grade B500B

Chemical Composition C % 0.24 Max S % 0.055 Max P % 0.055 Max N % 0.014 Max Cu % 0.85 Max CEV % 0.50 Max Yield Strength(min.) Tensile Strength (min) Elongation @ maximum force (Agt) Allowable deviation 0.03

ASTM A 615/A 615M

Chemical Composition Allowable deviation

P % 0.06 Max

+25% Max

0.02 500 N/mm

2

Yield Strength(min.) Tensile Strength (min)

420 N/mm

1.08 x YS 14% (min)

1.08 x YS 5% (min)

Gauge Length = 5d Bar Size d 16mm d > 16mm 45 to 23 Weight Tolerance % 8mm - 10mm 6.5 % 12mm & above 4.5% Mandrel Size 5d 7d

Gauge Length = 100mm Bar Size d 16mm d > 16mm 90 to 20 8mm 6.0 % 10mm & above 4.5% Mandrel Size 4d 7d

620 N/mm2 10-18mm 9% Elongation 22-25mm 8% 32mm 7% Gauge Length = 200mm Mandrel Size 3.5d 5d 7d 180o

Rebend & Bend Test

Bar Size 10-16mm 18-25mm 32mm Bending Angle -6%

Das könnte Ihnen auch gefallen

- Rate+Analysis BW-PLATERDokument11 SeitenRate+Analysis BW-PLATERawasarevinayakNoch keine Bewertungen

- Perhitungan Settlement TanahDokument2 SeitenPerhitungan Settlement TanahSu NarkoNoch keine Bewertungen

- Materials Testing Manual Part 6: AggregatesDokument111 SeitenMaterials Testing Manual Part 6: AggregatesWaqas SadiqNoch keine Bewertungen

- TS10 Earthworks Drainage Bitument WorksDokument75 SeitenTS10 Earthworks Drainage Bitument WorksmojgfdNoch keine Bewertungen

- Test Report On The California Bearing Ratio AASHTO T 193 - 99Dokument1 SeiteTest Report On The California Bearing Ratio AASHTO T 193 - 99Dominto MicoNoch keine Bewertungen

- Skid Resistance For Paved Surfaces (Full Scale Tire)Dokument6 SeitenSkid Resistance For Paved Surfaces (Full Scale Tire)Kongsak AkkharawongwhatthanaNoch keine Bewertungen

- Epc Pembangunan Open Access Pt. Pertamina (Persero) Ru - Vii Kasim Concrete Mix Proportion Method America Concrete InsituteDokument4 SeitenEpc Pembangunan Open Access Pt. Pertamina (Persero) Ru - Vii Kasim Concrete Mix Proportion Method America Concrete InsituteBengkulu BetonNoch keine Bewertungen

- D5D5M-13 Standard Test Method For Penetration of Bituminous MaterialsDokument14 SeitenD5D5M-13 Standard Test Method For Penetration of Bituminous MaterialsAlabbas FadhelNoch keine Bewertungen

- Bharat Heavy Plate & Vessels Limited - VisakhapatnamDokument8 SeitenBharat Heavy Plate & Vessels Limited - VisakhapatnamRama Subramanyam ManepalliNoch keine Bewertungen

- Data CPT TanahDokument18 SeitenData CPT TanahAndi Tenri MelaniNoch keine Bewertungen

- Footing DesignDokument272 SeitenFooting Designafifa kausar0% (1)

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Dokument4 SeitenF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Mohammed ElemamNoch keine Bewertungen

- Hilti Analysis For Shear Resistance: Detail CalculationDokument4 SeitenHilti Analysis For Shear Resistance: Detail Calculationinti lestariNoch keine Bewertungen

- Permeability Test-Double Packer Test - Template01Dokument1 SeitePermeability Test-Double Packer Test - Template01Mohammed AliNoch keine Bewertungen

- Sondir Cisumdawu STA 37+025 S1Dokument8 SeitenSondir Cisumdawu STA 37+025 S1Bambang WiNoch keine Bewertungen

- CAL PDF: Water TableDokument3 SeitenCAL PDF: Water TableSES DESIGNNoch keine Bewertungen

- Load TestDokument16 SeitenLoad TestMI ChoudharyNoch keine Bewertungen

- UntitledDokument6 SeitenUntitledmehrdad khoeiNoch keine Bewertungen

- ISI Load Test March 2014Dokument20 SeitenISI Load Test March 2014Projects CortexNoch keine Bewertungen

- California Bearing Ratio (CBR) TestDokument6 SeitenCalifornia Bearing Ratio (CBR) TestgimanuNoch keine Bewertungen

- V. Desain Pondasi: 5.1. Kapasitas Tiang Pancang Berdasarkan Nilai N - SPTDokument8 SeitenV. Desain Pondasi: 5.1. Kapasitas Tiang Pancang Berdasarkan Nilai N - SPTnugraha pierreNoch keine Bewertungen

- Laboratory Manual For Soil MechanicsDokument34 SeitenLaboratory Manual For Soil MechanicsChuckieNoch keine Bewertungen

- Determination of Point of Fixity As Per TomlinsonDokument3 SeitenDetermination of Point of Fixity As Per TomlinsonHanafiahHamzahNoch keine Bewertungen

- C - 15 Concrete Mix Design CementDokument6 SeitenC - 15 Concrete Mix Design CementEngineeri TadiyosNoch keine Bewertungen

- Review Actual BC7 (T1 T2)Dokument23 SeitenReview Actual BC7 (T1 T2)jampukNoch keine Bewertungen

- Construction JointDokument3 SeitenConstruction JointUttam Kumar GhoshNoch keine Bewertungen

- Cost EstimateDokument16 SeitenCost EstimateZerihun mulugetaNoch keine Bewertungen

- Reinforcement Steel SpecificationDokument1 SeiteReinforcement Steel SpecificationShammir Tabayag MangidaNoch keine Bewertungen

- Hiley b1vm4Dokument1 SeiteHiley b1vm4DipikaNoch keine Bewertungen

- Data: BH.01 Pile Size: Dia. 30 CM: Calculation SheetDokument4 SeitenData: BH.01 Pile Size: Dia. 30 CM: Calculation SheetRafaArdiSyahrezaNoch keine Bewertungen

- Pile DesignDokument6 SeitenPile DesignMUHAMMAD ALINoch keine Bewertungen

- Dwall Production Analysis-Based On STEC DWG D 920 NEW CS 4581 REV 0 25012010Dokument23 SeitenDwall Production Analysis-Based On STEC DWG D 920 NEW CS 4581 REV 0 25012010Tuntun TatNoch keine Bewertungen

- Non - Prestressed Beam (ACI 318-14 and SNI 2847-2013)Dokument6 SeitenNon - Prestressed Beam (ACI 318-14 and SNI 2847-2013)AndriSaputraGunawanNoch keine Bewertungen

- Labourer Histograms GraphDokument1 SeiteLabourer Histograms Graphcrk document JayanathNoch keine Bewertungen

- Unconsolidated-Undrained Triaxial Test: ASTM D-2850Dokument2 SeitenUnconsolidated-Undrained Triaxial Test: ASTM D-2850Rajinda BintangNoch keine Bewertungen

- Concrete Mix Design: Stage Item Reference or Values CalculationDokument8 SeitenConcrete Mix Design: Stage Item Reference or Values Calculationmanish100% (1)

- RC Specification Structural Steel Rev 0Dokument56 SeitenRC Specification Structural Steel Rev 0Waqas WaqasNoch keine Bewertungen

- Disain Stabilisasi TanahDokument32 SeitenDisain Stabilisasi TanahRaditiya PuteraNoch keine Bewertungen

- Report of Pile IGM-P-14 - Final - 06.05.2019Dokument64 SeitenReport of Pile IGM-P-14 - Final - 06.05.2019Dadi YashwantNoch keine Bewertungen

- Kolom - K2 - D.I.Dokument30 SeitenKolom - K2 - D.I.Mohamad HartadiNoch keine Bewertungen

- Geotechnical Scope of Work For ERL Unit-2Dokument75 SeitenGeotechnical Scope of Work For ERL Unit-2smjohirNoch keine Bewertungen

- Blow Count Calculation Hilleys FormulaDokument1 SeiteBlow Count Calculation Hilleys FormulaTin ZawNoch keine Bewertungen

- Punching CheckDokument2 SeitenPunching CheckJule LobresNoch keine Bewertungen

- M.sc. Concrete FormulaeDokument17 SeitenM.sc. Concrete FormulaeSana UllahNoch keine Bewertungen

- Bearing CapacityDokument4 SeitenBearing CapacityMohd Nizamuddin Mohamad NoorNoch keine Bewertungen

- Calibration Data Rebound Calibration Curve - 60 Mpa Flowable (ASTM C805)Dokument3 SeitenCalibration Data Rebound Calibration Curve - 60 Mpa Flowable (ASTM C805)balacadsNoch keine Bewertungen

- Info. Regarding Precast Pile DrivingDokument4 SeitenInfo. Regarding Precast Pile DrivingcivixxNoch keine Bewertungen

- IS 2911-Part-4Dokument17 SeitenIS 2911-Part-4Prabhakaran S100% (1)

- Data Cptu Utk TugasDokument447 SeitenData Cptu Utk Tugaserik azaryaNoch keine Bewertungen

- Lcet Lcet: ED How To Calculate Cement, Sand and Coarse Aggregate Quantity in Concrete? EDDokument4 SeitenLcet Lcet: ED How To Calculate Cement, Sand and Coarse Aggregate Quantity in Concrete? EDmanojNoch keine Bewertungen

- CUM (Monday, Dec 9, 2013)Dokument39 SeitenCUM (Monday, Dec 9, 2013)Catriona Cassandra SantosNoch keine Bewertungen

- Dowel Bars at Joints / Jacketing Requirement R4Dokument1 SeiteDowel Bars at Joints / Jacketing Requirement R4Kumy engineeringNoch keine Bewertungen

- Balok Persegi PrestressedDokument3 SeitenBalok Persegi PrestressedCholiz Cetia100% (1)

- SAJO-CT-1137 - QCT-GS010603 (2) N-18 - Rev.0 Monthly QC Test For April 2021Dokument138 SeitenSAJO-CT-1137 - QCT-GS010603 (2) N-18 - Rev.0 Monthly QC Test For April 2021dhan singhNoch keine Bewertungen

- Dynamics Spring Constant and Pile CapacityDokument124 SeitenDynamics Spring Constant and Pile CapacitykusumoajiNoch keine Bewertungen

- Civil Standard & Code No Area Code Standard AstmDokument10 SeitenCivil Standard & Code No Area Code Standard AstmTri SeptaNoch keine Bewertungen

- Zone 3 & Soil SD Input Zone 3 & Soil SD Input: Ca T 1.3 DBE MCEDokument3 SeitenZone 3 & Soil SD Input Zone 3 & Soil SD Input: Ca T 1.3 DBE MCEEngr Ghulam MustafaNoch keine Bewertungen

- Rebar in Coil Qualities and CertificationsDokument4 SeitenRebar in Coil Qualities and CertificationsKhairil Fajri IndragaNoch keine Bewertungen

- Chemical CompositionDokument13 SeitenChemical Compositionssharma3474Noch keine Bewertungen

- Steel Grade Indian StandardsDokument5 SeitenSteel Grade Indian StandardsPriyanathan ThayalanNoch keine Bewertungen

- Calculus For BeginnersDokument21 SeitenCalculus For BeginnersJay LawsonNoch keine Bewertungen

- Curing ConcreteDokument10 SeitenCuring ConcreteShariq KhanNoch keine Bewertungen

- Chapter One: 1.1 GeneralDokument1 SeiteChapter One: 1.1 GeneralSulaiman Mohsin AbdulAzizNoch keine Bewertungen

- Structuro W437-Formerly RXDokument2 SeitenStructuro W437-Formerly RXSulaiman Mohsin AbdulAziz0% (1)

- Calculation of Stresses in Footings Subjected To Uniaxial or Biaxial MomentsDokument6 SeitenCalculation of Stresses in Footings Subjected To Uniaxial or Biaxial MomentsSulaiman Mohsin AbdulAziz100% (1)

- Design For Torsion and Shear According To ACI-318-99Dokument1 SeiteDesign For Torsion and Shear According To ACI-318-99Sulaiman Mohsin AbdulAzizNoch keine Bewertungen

- All Sheets ConcreteDokument72 SeitenAll Sheets ConcreteSulaiman Mohsin AbdulAziz100% (1)

- Design of Monolithic Corbels and Brackets According To Aci 318 - 99Dokument1 SeiteDesign of Monolithic Corbels and Brackets According To Aci 318 - 99Sulaiman Mohsin AbdulAzizNoch keine Bewertungen

- Decentralized Wastewater Treatment Highlights BrochureDokument20 SeitenDecentralized Wastewater Treatment Highlights BrochureSulaiman Mohsin AbdulAzizNoch keine Bewertungen

- ETABSDokument5 SeitenETABSSulaiman Mohsin AbdulAzizNoch keine Bewertungen

- About A-PDF WatermarkDokument1 SeiteAbout A-PDF WatermarkSulaiman Mohsin AbdulAzizNoch keine Bewertungen

- 39 TransportationDokument7 Seiten39 Transportationmpe1Noch keine Bewertungen

- Shear Strength Prediction of Crushed Stone Reinforced Concrete Deep Beams Without StirrupsDokument2 SeitenShear Strength Prediction of Crushed Stone Reinforced Concrete Deep Beams Without StirrupsSulaiman Mohsin AbdulAziz100% (1)

- Influence LinesDokument6 SeitenInfluence LinesClorinda Astete ChuquichaicoNoch keine Bewertungen

- CM A Hollow Core SlabsDokument36 SeitenCM A Hollow Core SlabsSulaiman Mohsin AbdulAziz100% (1)

- 129-044 - Boring Big HolesDokument4 Seiten129-044 - Boring Big HolesSulaiman Mohsin AbdulAzizNoch keine Bewertungen

- Hollow Core Sales PresentationDokument29 SeitenHollow Core Sales PresentationSulaiman Mohsin AbdulAzizNoch keine Bewertungen

- Different CFRP Strengthening Techniques For Prestressed Hollow Core Concrete Slabs Experimental Study and Analytical Investigation - Copy (211434589)Dokument11 SeitenDifferent CFRP Strengthening Techniques For Prestressed Hollow Core Concrete Slabs Experimental Study and Analytical Investigation - Copy (211434589)Sulaiman Mohsin AbdulAzizNoch keine Bewertungen

- RC Hollow Members Confined With FRP Experimental Behavior and Numerical ModelingDokument339 SeitenRC Hollow Members Confined With FRP Experimental Behavior and Numerical ModelingSulaiman Mohsin AbdulAziz100% (1)