Beruflich Dokumente

Kultur Dokumente

Dental Materials 7

Hochgeladen von

Rosette GoOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Dental Materials 7

Hochgeladen von

Rosette GoCopyright:

Verfügbare Formate

DENTAL MATERIALS 7 *Dispose the modeling compound if it is not shiny when being

heated or manipulated because it means that the plastisizers

MODELING COMPOUND are already gone

• DENTAL/IMPRESSION COMPOUND

• Comes in cake or cone/stick form *Put in warm water bath before removing to soften or loosen

the cast from the impression

• CAKE FORM

o For full arch impression

*If you overheat during separation, modeling compound will

• CONE/STICK FORM stick to the cast

o For single tooth impression

o For tracing material to convert the defect of

cake

DRY HEAT

• Used for STICK or for small amounts

COMPONENTS OF MODELING COMPOUND

MOIST HEAT

• BEESWAX

• Used for CAKE or for large amounts

• THERMOPLASTIC RESIN

TOLERABLE TEMPERATURE BY THE PATIENT’S MOUTH

o Responsible for thermoplastic property

• 44°C - 45°C or 7°C - 8°C higher than normal body

temperature (37°C)

• GUTTA PERCHA, SHELLAC, STEARIC ACID

o PLASTISIZER

USES OF MODELING COMPOUNDS

To improve working property

• Making TYPE I

• FRENCH CHALK, TALC, DIATOMACEOUS EARTH

• Preliminary Impression Material

o Hardening agents/fillers

• Stock tray

• Coloring materials or pigments

o Remove from patient’s mouth by teasing

• no need for separating medium because they are

MANIPULATION OF MODELING COMPOUNDS

made of different materials

2 METHODS:

• produces Study Cast (Plaster of Paris)

• DRY HEAT

o open flame

PROPERTIES OF MODELING COMPOUND

alcohol lamp, torch, Bunsen burner

• POOR THERMAL CONDUCTIVITY

• MOIST HEAT

o Difficult to manipulate because it takes time

o Water bath

• GOOD FLOW PROPERTY

50°C - 70°C

o Can be a source of error or disadvantage

because it may lead to distortion

o Construct the cast immediately aftrer

*Overheating will remove the plastisizer

removing from patient’s mouth to prevent

distortion

o Dimensional change: shrinkage 0.3 – 0.4 %

o TYPE I – higher flow property

*Modeling compound must be RIGID

TYPE I

• 85% at 45°C

TYPE II

• 70% at 45°C

Rosette Go 120608

Das könnte Ihnen auch gefallen

- Go Smile Dental Clinic - Pcpi ProposalDokument4 SeitenGo Smile Dental Clinic - Pcpi ProposalRosette GoNoch keine Bewertungen

- Estimation Software For Presure VesselDokument36 SeitenEstimation Software For Presure VesselKarthikeyan Shanmugavel0% (1)

- Cinnabon ClassicDokument13 SeitenCinnabon Classicpaupaupaupaupaupau100% (2)

- Endodontics Final ReviewerDokument27 SeitenEndodontics Final ReviewerRosette Go100% (5)

- CoreJava Ratan CompleteMarerial PDFDokument398 SeitenCoreJava Ratan CompleteMarerial PDFSivaShankar100% (7)

- Troubleshooting Guides in Tissue ProcessingDokument3 SeitenTroubleshooting Guides in Tissue Processinggail_eunice12100% (1)

- Mushroom Grow Guide 8.21.links Yah50nDokument1 SeiteMushroom Grow Guide 8.21.links Yah50nIvan BaigorriaNoch keine Bewertungen

- Oral Diagnosis Prelims ReviewerDokument16 SeitenOral Diagnosis Prelims ReviewerRosette GoNoch keine Bewertungen

- Dental Jurisprudence Midterm Reviewer: Chapter 6: Powers, Duties and FunctionsDokument5 SeitenDental Jurisprudence Midterm Reviewer: Chapter 6: Powers, Duties and FunctionsRosette Go100% (1)

- Eramus Bridge PDFDokument10 SeitenEramus Bridge PDFBabaO.Riley100% (1)

- EMOC 208 Installation of VITT For N2 Cylinder FillingDokument12 SeitenEMOC 208 Installation of VITT For N2 Cylinder Fillingtejcd1234Noch keine Bewertungen

- VB Script ReferenceDokument27 SeitenVB Script ReferenceRajkumarNoch keine Bewertungen

- LAB Histopathologic-Technique EmbeddingInfiltration Finals 002Dokument3 SeitenLAB Histopathologic-Technique EmbeddingInfiltration Finals 002Jashmine May TadinaNoch keine Bewertungen

- Dental Materials m1Dokument2 SeitenDental Materials m1Rosette GoNoch keine Bewertungen

- Non Elastic ImpressionDokument65 SeitenNon Elastic ImpressionAbdelruhman SobhyNoch keine Bewertungen

- Impregnation & Embedding - SPC MLS 2B - Histopath LecDokument5 SeitenImpregnation & Embedding - SPC MLS 2B - Histopath Lecchristian Jay HorseradaNoch keine Bewertungen

- Sem 2-Non Elastic ImpDokument56 SeitenSem 2-Non Elastic ImpAswathi S KumarNoch keine Bewertungen

- Mls 410 Lec - Histopathologic and Cytologic Techniques: Infiltration, Embedding & SectioningDokument11 SeitenMls 410 Lec - Histopathologic and Cytologic Techniques: Infiltration, Embedding & Sectioningchristian Jay HorseradaNoch keine Bewertungen

- MLS 414 - Lab - Clinical Chem 1 PrelimsDokument11 SeitenMLS 414 - Lab - Clinical Chem 1 PrelimsKenneth Brayan B. CastilloNoch keine Bewertungen

- PSG College of Technology CoimbatoreDokument9 SeitenPSG College of Technology CoimbatoreMukesh KumarNoch keine Bewertungen

- PSG College of Technology CoimbatoreDokument9 SeitenPSG College of Technology Coimbatore18Y117 - MUKESHKUMAR M KNoch keine Bewertungen

- Casting DefectsDokument42 SeitenCasting DefectsNiharika SabharwalNoch keine Bewertungen

- Histologic Plant Tissue Preparation Techniques. 5 - Embedding StepDokument4 SeitenHistologic Plant Tissue Preparation Techniques. 5 - Embedding StepFrancis ValdezNoch keine Bewertungen

- Common Injection Moulding Defects, Causes, andDokument5 SeitenCommon Injection Moulding Defects, Causes, andsharuziNoch keine Bewertungen

- (Reversible) HydrocolloidDokument21 Seiten(Reversible) HydrocolloidVineela ChowdaryNoch keine Bewertungen

- 736 Heat Resistant Sealant-PDSDokument4 Seiten736 Heat Resistant Sealant-PDSRavindranath BellamkondaNoch keine Bewertungen

- HST NotesDokument19 SeitenHST NotesAngelaHernandezNoch keine Bewertungen

- Histopath Lec - Week 5 - Topic 7Dokument8 SeitenHistopath Lec - Week 5 - Topic 7Juren LasagaNoch keine Bewertungen

- Epilux 82: Product DescriptionDokument2 SeitenEpilux 82: Product DescriptionMoin AltafNoch keine Bewertungen

- Tech Topic Troubleshooting Tips For Injection Blow MoldingDokument3 SeitenTech Topic Troubleshooting Tips For Injection Blow MoldingHiếu Mai ĐứcNoch keine Bewertungen

- Laboratory ToolsDokument33 SeitenLaboratory Toolsmichameilromero13Noch keine Bewertungen

- Dental WaxesDokument82 SeitenDental WaxesVimalKumar100% (1)

- Pedrera Manuel III Chapter 17 ImpressionsDokument7 SeitenPedrera Manuel III Chapter 17 ImpressionsChloe DrilonNoch keine Bewertungen

- Biogen Rope Dressing - GBDokument2 SeitenBiogen Rope Dressing - GBMassimiliano VolaNoch keine Bewertungen

- Gel TroubleshootingDokument57 SeitenGel TroubleshootingSid sidNoch keine Bewertungen

- MicroPara LAB - M2Dokument2 SeitenMicroPara LAB - M2Gianna LingadNoch keine Bewertungen

- Impression in FPDDokument50 SeitenImpression in FPDSayooj Prabhakar PmNoch keine Bewertungen

- Gypsum ProductsDokument4 SeitenGypsum ProductsJEANASHLEY PUNZALANNoch keine Bewertungen

- Hydro Colloid (Agar & Alginate)Dokument26 SeitenHydro Colloid (Agar & Alginate)Muhammad Ibrahim Nujid0% (1)

- SCWS - Water, Sand & Stimulation Service June'22Dokument23 SeitenSCWS - Water, Sand & Stimulation Service June'22Kamal Edlin HusinNoch keine Bewertungen

- IMPRESSION MATERIALS - NotesDokument13 SeitenIMPRESSION MATERIALS - NotesJEANASHLEY PUNZALANNoch keine Bewertungen

- Unit 3 GlassDokument22 SeitenUnit 3 Glasspranilpatil1319Noch keine Bewertungen

- Clinchem 1 Handouts 2Dokument4 SeitenClinchem 1 Handouts 2Future TrekingNoch keine Bewertungen

- PyrogripDokument1 SeitePyrogripManoj ChitreNoch keine Bewertungen

- Foodlube Multipaste - GBDokument2 SeitenFoodlube Multipaste - GBtKc1234Noch keine Bewertungen

- Day 2 Tissue Processing123Dokument4 SeitenDay 2 Tissue Processing123Naomi NicoleNoch keine Bewertungen

- Technical Data Sheet Permatex General Purpose Epoxy ProductsDokument2 SeitenTechnical Data Sheet Permatex General Purpose Epoxy ProductsΧρήστος πορηςNoch keine Bewertungen

- HTMLE RecallsDokument3 SeitenHTMLE Recallsninaalteres123Noch keine Bewertungen

- Refresher Training On RM Test MethodsDokument25 SeitenRefresher Training On RM Test MethodsJohn WickNoch keine Bewertungen

- OD1995R08013ADokument2 SeitenOD1995R08013AMaría BermúdezNoch keine Bewertungen

- SCWS - HESS Water, Sand & Stimulation Service June'22Dokument23 SeitenSCWS - HESS Water, Sand & Stimulation Service June'22Kamal Edlin HusinNoch keine Bewertungen

- Basic Lost Wax Kilncasting: What This Tipsheet CoversDokument8 SeitenBasic Lost Wax Kilncasting: What This Tipsheet CoversAli AhmadNoch keine Bewertungen

- Technical Data Sheet Permatex Optimum Grey RTV Silicone GasketDokument2 SeitenTechnical Data Sheet Permatex Optimum Grey RTV Silicone GasketKhalifa-Assil BaoucheNoch keine Bewertungen

- PHAYG062 Preformula2on: Amorphous MaterialsDokument27 SeitenPHAYG062 Preformula2on: Amorphous Materialschegu BusinessNoch keine Bewertungen

- Apcoline 4100Dokument2 SeitenApcoline 4100Moin AltafNoch keine Bewertungen

- Introduction of HistologyDokument3 SeitenIntroduction of HistologySiti Hajar RevillaNoch keine Bewertungen

- Mushroom Grow Guide 9.21.linksDokument1 SeiteMushroom Grow Guide 9.21.linksThomas MartiNoch keine Bewertungen

- Rules and Guidelines For Laboratory Procedures IN Fabrication of Complete DentureDokument144 SeitenRules and Guidelines For Laboratory Procedures IN Fabrication of Complete Denturevikki100% (1)

- Waxes: by DR Samreen Ahmed Dept of Dental MaterialsDokument8 SeitenWaxes: by DR Samreen Ahmed Dept of Dental MaterialsHamza NadeemNoch keine Bewertungen

- Ernesto Pekač Liveni AlumnijumDokument28 SeitenErnesto Pekač Liveni AlumnijumSasa RadicNoch keine Bewertungen

- Steel Shield 1200Dokument2 SeitenSteel Shield 1200Moin AltafNoch keine Bewertungen

- Gel Content & Peel Test: Benjamin Lippke, Romain PénidonDokument14 SeitenGel Content & Peel Test: Benjamin Lippke, Romain PénidonKarthikeyanKarthikNoch keine Bewertungen

- Chem Part 2Dokument11 SeitenChem Part 2Hersheen MagaddatuNoch keine Bewertungen

- Resin-Coated Sand: Troubleshooting GuideDokument2 SeitenResin-Coated Sand: Troubleshooting GuideKhanguyen MaiNoch keine Bewertungen

- Wa0004.Dokument32 SeitenWa0004.Aisha samreenNoch keine Bewertungen

- Ingeo™ Biopolymer 8052D Technical Data Sheet Foam GradeDokument3 SeitenIngeo™ Biopolymer 8052D Technical Data Sheet Foam Grademajid mehrabiNoch keine Bewertungen

- Histopathologic TechniquesDokument10 SeitenHistopathologic TechniquesM C0% (1)

- 2 0bracketplacementguideforspeed2ndedition 110403201913 Phpapp01Dokument91 Seiten2 0bracketplacementguideforspeed2ndedition 110403201913 Phpapp01Golam MortuzaNoch keine Bewertungen

- The Nail technician’s Career Guide - The blueprint to a successful nail salon businessVon EverandThe Nail technician’s Career Guide - The blueprint to a successful nail salon businessNoch keine Bewertungen

- Anesthesiology Midterm ReviewerDokument4 SeitenAnesthesiology Midterm ReviewerRosette Go100% (1)

- Guest Ice Breaker SampleDokument1 SeiteGuest Ice Breaker SampleRosette GoNoch keine Bewertungen

- Presence of Fever InfectionDokument1 SeitePresence of Fever InfectionRosette GoNoch keine Bewertungen

- Pom F3Dokument1 SeitePom F3Rosette GoNoch keine Bewertungen

- Know The Systemic Diseases Suffered by The PatientsDokument2 SeitenKnow The Systemic Diseases Suffered by The PatientsRosette GoNoch keine Bewertungen

- Pom F7Dokument2 SeitenPom F7Rosette GoNoch keine Bewertungen

- Practice Management Prelim ReviewerDokument4 SeitenPractice Management Prelim ReviewerRosette GoNoch keine Bewertungen

- Instruments & MaterialsDokument1 SeiteInstruments & MaterialsRosette GoNoch keine Bewertungen

- Pedodontics MidtermsDokument4 SeitenPedodontics MidtermsRosette GoNoch keine Bewertungen

- NeoplasmsDokument2 SeitenNeoplasmsRosette GoNoch keine Bewertungen

- Forensic Dentistry MidtermsDokument3 SeitenForensic Dentistry MidtermsRosette GoNoch keine Bewertungen

- Embryology: Odontogenesis Odontogenesis - Origin and Tissue Formation of TeethDokument2 SeitenEmbryology: Odontogenesis Odontogenesis - Origin and Tissue Formation of TeethRosette GoNoch keine Bewertungen

- Oral MucosaDokument3 SeitenOral MucosaRosette Go100% (2)

- Table For Cements Shortcut)Dokument2 SeitenTable For Cements Shortcut)Rosette GoNoch keine Bewertungen

- Zaroulas Mies Fullpaper 2020 05 21Dokument9 SeitenZaroulas Mies Fullpaper 2020 05 21sidgonzoNoch keine Bewertungen

- Dogging Guide 2003 - WorkCover NSWDokument76 SeitenDogging Guide 2003 - WorkCover NSWtadeumatas100% (1)

- Hot Wire Anemometry HandoutDokument4 SeitenHot Wire Anemometry HandoutZ-BNoch keine Bewertungen

- Apqp - DR SHFTDokument60 SeitenApqp - DR SHFTrajesh5000100% (2)

- 2019 All PDFDokument27 Seiten2019 All PDFvishesh bhatiaNoch keine Bewertungen

- Quality ControlDokument10 SeitenQuality ControlSabbir AhmedNoch keine Bewertungen

- Sewer Connection Application Guidance PDFDokument7 SeitenSewer Connection Application Guidance PDFSamuel FuentesNoch keine Bewertungen

- Parallel Port Programming (PART 1) With CDokument13 SeitenParallel Port Programming (PART 1) With ChertzoliNoch keine Bewertungen

- Bazele Matematice Ale Calculatoarelor - Florian Mircea BoianDokument132 SeitenBazele Matematice Ale Calculatoarelor - Florian Mircea BoiannimsocNoch keine Bewertungen

- Kinematics-03-Subjective SolvedDokument11 SeitenKinematics-03-Subjective SolvedRaju SinghNoch keine Bewertungen

- Wireless Intelligent Network (WIN)Dokument24 SeitenWireless Intelligent Network (WIN)Nakul Gawande100% (1)

- Electronic Dice Using LEDs Electrical Engineering ProjectDokument16 SeitenElectronic Dice Using LEDs Electrical Engineering Projectprakhar agarwal33% (3)

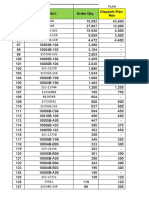

- Order Qty Vs Dispatch Plan - 04 11 20Dokument13 SeitenOrder Qty Vs Dispatch Plan - 04 11 20NPD1 JAKAPNoch keine Bewertungen

- Nuevo CvuDokument1 SeiteNuevo CvuJesús GonzálezNoch keine Bewertungen

- Calibration. of Storage Tanks Class # 2070 Srini Sivaraman SK JapanDokument4 SeitenCalibration. of Storage Tanks Class # 2070 Srini Sivaraman SK JapanJose Rafael Mora CasalNoch keine Bewertungen

- Topic 6 ESD & EMI Considerations Electrostatic Sensitive Devices (M4.2, 5.12 &5.14) - 1Dokument49 SeitenTopic 6 ESD & EMI Considerations Electrostatic Sensitive Devices (M4.2, 5.12 &5.14) - 1BeaglelalahahaNoch keine Bewertungen

- HARGA REFERENSI B2S PapuaDokument6 SeitenHARGA REFERENSI B2S PapuaAbiyoga AdhityaNoch keine Bewertungen

- Ibr CalculationsDokument9 SeitenIbr Calculationsaroonchelikani67% (3)

- HighpuritysealsDokument6 SeitenHighpuritysealstuannhocutNoch keine Bewertungen

- Cache MemoryDokument20 SeitenCache MemoryKeshav Bharadwaj RNoch keine Bewertungen

- Tube Well Design Project SolutionDokument5 SeitenTube Well Design Project SolutionEng Ahmed abdilahi IsmailNoch keine Bewertungen

- Sewerage & Sewage Treatment PlantDokument26 SeitenSewerage & Sewage Treatment PlantSyed ZamanNoch keine Bewertungen

- MILL Series GB-1007 01Dokument20 SeitenMILL Series GB-1007 01Ady IonutNoch keine Bewertungen

- PT14 Engine Monitor 1Dokument2 SeitenPT14 Engine Monitor 1BJ DixNoch keine Bewertungen

- Fast, Accurate Data Management Across The Enterprise: Fact Sheet: File-Aid / MvsDokument4 SeitenFast, Accurate Data Management Across The Enterprise: Fact Sheet: File-Aid / MvsLuis RamirezNoch keine Bewertungen