Beruflich Dokumente

Kultur Dokumente

Table For Cements Shortcut)

Hochgeladen von

Rosette Go0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

234 Ansichten2 SeitenThis document compares and contrasts the classifications, components, dispensing forms, manipulation, pH, uses, and strengths of different dental cement types:

1) Zinc phosphate cement is a powder-liquid system composed primarily of zinc oxide and phosphoric acid. It has a low pH and is used as a cementing medium or base.

2) Copper cement is a modified zinc phosphate cement that contains copper oxide. It has a higher pH and compressive strength than zinc phosphate cement.

3) Zinc oxide eugenol is a two-paste system composed of zinc oxide powder and a eugenol liquid. It has an alkaline pH and is used as a temporary or permanent cementing medium.

4)

Originalbeschreibung:

Originaltitel

Table for Cements Shortcut)

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

DOC, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document compares and contrasts the classifications, components, dispensing forms, manipulation, pH, uses, and strengths of different dental cement types:

1) Zinc phosphate cement is a powder-liquid system composed primarily of zinc oxide and phosphoric acid. It has a low pH and is used as a cementing medium or base.

2) Copper cement is a modified zinc phosphate cement that contains copper oxide. It has a higher pH and compressive strength than zinc phosphate cement.

3) Zinc oxide eugenol is a two-paste system composed of zinc oxide powder and a eugenol liquid. It has an alkaline pH and is used as a temporary or permanent cementing medium.

4)

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

234 Ansichten2 SeitenTable For Cements Shortcut)

Hochgeladen von

Rosette GoThis document compares and contrasts the classifications, components, dispensing forms, manipulation, pH, uses, and strengths of different dental cement types:

1) Zinc phosphate cement is a powder-liquid system composed primarily of zinc oxide and phosphoric acid. It has a low pH and is used as a cementing medium or base.

2) Copper cement is a modified zinc phosphate cement that contains copper oxide. It has a higher pH and compressive strength than zinc phosphate cement.

3) Zinc oxide eugenol is a two-paste system composed of zinc oxide powder and a eugenol liquid. It has an alkaline pH and is used as a temporary or permanent cementing medium.

4)

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

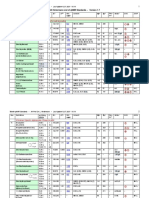

Classifications Zinc Phosphate Cement Copper Cement/ Zinc Oxide Eugenol Zinc Polycarboxylate/ Zinc Calcium

: Modified Zinc (ZOE) Polyacrylate Hydroxide

Phosphate Cement

Components: Powder Type I 25% Co oxide Comp o Powder •

onents: 6% Zinc oxide

65% Zn oxide

*powder- zinc oxide

Zinc oxide main •

Zinc oxide 90% component

(main component)

* liquid- eugenol 6% Calcium

25% Copper Magnesium oxide Hydroxide

oxide modifier •

Magnesium Oxide suspended in

Calcium hydroxide chloroform

modifier 10% Mg oxide modifier solution of

Liquid

Flouride anti resinous material

Bismuth

modifier

cariogenic agent •

85-88% Zn oxide o Liquid common solvent:

Liquid

Phosphoric acid aqueous solution of aqueous methyl

2-5% Copper oxide polyacrylic acid cellulose

Aluminum

phosphate

Magnesium 10% Mg oxide 50% by weight

phosphate WATER

water

+ Co-polymer

Dispensing Powder-liquid Powder-liquid 2 paste form powder-liquid single powder

form powder-liquid single powder 2 paste form

single paste

Manipulation o Mat o M o M o Mat Use: ball tip

erials: Glass Slab and aterials: Glass Slab aterials: Glass Slab erials: Glass Slab and spatula &

cement spatula and cement spatula and cement spatula cement spatula mixing pad

o Rati o R o 2 o Divi Mix till

o: 1.4 gm powder per 0.5 atio: 1.4 gm powder paste form- mix till de the powder into 2-3 homogenous

ml liquid per 0.5 ml liquid homogenous large increments and mix color

into the liquid one by one

Mixing time: 45-60

sec

pH 3.5 Type I- 0.8 7 1.7 11.5-13

Type II- 2.5

(after 28 days)pH

5.3

uses -cementing medium o - temporary cementing Luting agent Direct pulp

-base Temporary restorative medium Base capping agent

material -permanent cementing Liner

medium

- indirect pulp capping

-liner

-obtundent material in R.C

therapy

strength o com o c Type I conventional ZOE – o com o

pressive strength ompressive comp str= 800-1200 psi pressive strength compressive

12,000-16,000psi strength 12,000- Tensile str= 200psi 8000psi strength

o tens 16,000psi Type II EBA-Allumina o tens <1200psi

o t comp str= 9320 psi

ile strength 700psi Tensile str= 1030psi ile strength 1030-2250psi

ensile strength Type III Polymer-Modified

700psi comp str= 7308 psi

Tensile str=603 psi

Type IV ZOE Liner

comp str= 798 psi

Tensile str= 62.3psi

Das könnte Ihnen auch gefallen

- Go Smile Dental Clinic - Pcpi ProposalDokument4 SeitenGo Smile Dental Clinic - Pcpi ProposalRosette GoNoch keine Bewertungen

- Endodontics Final ReviewerDokument27 SeitenEndodontics Final ReviewerRosette Go100% (5)

- Cementation Guide: Tooth Surface: FeldspathicDokument1 SeiteCementation Guide: Tooth Surface: FeldspathicPinky TolaniNoch keine Bewertungen

- Oral Diagnosis Prelims ReviewerDokument16 SeitenOral Diagnosis Prelims ReviewerRosette GoNoch keine Bewertungen

- Dental Jurisprudence Midterm Reviewer: Chapter 6: Powers, Duties and FunctionsDokument5 SeitenDental Jurisprudence Midterm Reviewer: Chapter 6: Powers, Duties and FunctionsRosette Go100% (1)

- Pedodontics MidtermsDokument4 SeitenPedodontics MidtermsRosette GoNoch keine Bewertungen

- Minimally Invasive Dentistry: PracticalDokument9 SeitenMinimally Invasive Dentistry: PracticalChristie Maria ThomasNoch keine Bewertungen

- CAD-CAM Endocrown FinalDokument22 SeitenCAD-CAM Endocrown Finalrfl2012Noch keine Bewertungen

- Instruments & MaterialsDokument1 SeiteInstruments & MaterialsRosette GoNoch keine Bewertungen

- Oral and Dental HistologyDokument6 SeitenOral and Dental HistologyCésar HelenoNoch keine Bewertungen

- Periodontium (4) : Periodontal LigamentsDokument6 SeitenPeriodontium (4) : Periodontal Ligamentsمحمد محمود القحيفNoch keine Bewertungen

- Retention and StabilityDokument31 SeitenRetention and Stabilityمحمد محمود القحيفNoch keine Bewertungen

- Lab 5 Cementum and Periodontal LigamentDokument13 SeitenLab 5 Cementum and Periodontal Ligamentdr.naseer100% (1)

- Oral MucosaDokument4 SeitenOral MucosaKathleen Cay Medrano PanopioNoch keine Bewertungen

- Anterior Teeth Ndbe McqsDokument5 SeitenAnterior Teeth Ndbe McqsParneetNoch keine Bewertungen

- Eme 1Dokument8 SeitenEme 1Tara LingatingNoch keine Bewertungen

- 32: Periodontal Development IIDokument11 Seiten32: Periodontal Development IINYUCD17Noch keine Bewertungen

- Ivoclar Vivadent All-Ceramics: N-CementsDokument2 SeitenIvoclar Vivadent All-Ceramics: N-CementsThaer Saad Al DeenNoch keine Bewertungen

- Compiledendo PerioDokument112 SeitenCompiledendo PerioAvner TolentinoNoch keine Bewertungen

- Surgical Drainage of Deep Neck AbscessesDokument27 SeitenSurgical Drainage of Deep Neck AbscessesIrma DamayantiNoch keine Bewertungen

- CeramicsDokument8 SeitenCeramicsMostafa Hamdy AhmedNoch keine Bewertungen

- Icdas Ii PDFDokument30 SeitenIcdas Ii PDFFarah ShazwanaNoch keine Bewertungen

- CROWNS For Final Year Class 2023Dokument119 SeitenCROWNS For Final Year Class 2023ARNOLD OBINoch keine Bewertungen

- 3-Access Cavity Preparation PDFDokument60 Seiten3-Access Cavity Preparation PDFAllisyia MalauNoch keine Bewertungen

- Oral Microbiology Periodontitis PDFDokument85 SeitenOral Microbiology Periodontitis PDFSIDNEY SumnerNoch keine Bewertungen

- Tangy Cleaned Up 2015Dokument41 SeitenTangy Cleaned Up 2015Pass Boards100% (10)

- Chapter 2: Operative Dentistry and Prosthodontics: AnswersDokument13 SeitenChapter 2: Operative Dentistry and Prosthodontics: AnswersBinayak UpadhyayaNoch keine Bewertungen

- E-1-Osteoporosis and Periodontitis 2016Dokument14 SeitenE-1-Osteoporosis and Periodontitis 2016Yessid Baltazar Arango100% (1)

- Study Place Resto Comm Dent 3Dokument17 SeitenStudy Place Resto Comm Dent 3Zean TrainNoch keine Bewertungen

- Anesthesiology (Review Center)Dokument9 SeitenAnesthesiology (Review Center)yellow rangerNoch keine Bewertungen

- Classification of Periodontal Diseases and Conditions 2018Dokument15 SeitenClassification of Periodontal Diseases and Conditions 2018Jean DatorNoch keine Bewertungen

- 2015Dokument45 Seiten2015jimmyNoch keine Bewertungen

- Lecture 5 3rd Class PDFDokument6 SeitenLecture 5 3rd Class PDFBrandon AviciiNoch keine Bewertungen

- 2016 Nbe Based Mock Paper Key PDFDokument7 Seiten2016 Nbe Based Mock Paper Key PDFSanNoch keine Bewertungen

- Oral Tuberculosi S: Dr. Ishita Singhal Mds First YearDokument31 SeitenOral Tuberculosi S: Dr. Ishita Singhal Mds First YearDR. ISHITA SINGHALNoch keine Bewertungen

- Embryology: Odontogenesis Odontogenesis - Origin and Tissue Formation of TeethDokument2 SeitenEmbryology: Odontogenesis Odontogenesis - Origin and Tissue Formation of TeethRosette GoNoch keine Bewertungen

- Failures in Periodontal Therapy: Review ArticleDokument6 SeitenFailures in Periodontal Therapy: Review ArticlezinniaNoch keine Bewertungen

- Satish PERIO PDFDokument134 SeitenSatish PERIO PDFIpshita NNoch keine Bewertungen

- All Ceramic Restorations PDFDokument6 SeitenAll Ceramic Restorations PDFMahdy AlShammariNoch keine Bewertungen

- Dendritic Cells (Most Numerous Immune Cells)Dokument13 SeitenDendritic Cells (Most Numerous Immune Cells)Emma RanNoch keine Bewertungen

- 2010 AnsDokument37 Seiten2010 AnsArjun NarangNoch keine Bewertungen

- 2.dental CeramicsDokument320 Seiten2.dental CeramicsNamitha AP100% (1)

- A Review of Root Fractures - Final PrintDokument9 SeitenA Review of Root Fractures - Final Printemchen11Noch keine Bewertungen

- Partial Veneer 78Dokument133 SeitenPartial Veneer 78Sorabh JainNoch keine Bewertungen

- B9051 PDFDokument31 SeitenB9051 PDFGonçalo Cunha-Coutinho0% (1)

- Dentosphere - World of Dentistry - MCQs in Endodontics - Disinfection and ObturationDokument14 SeitenDentosphere - World of Dentistry - MCQs in Endodontics - Disinfection and Obturationbadr abdelkaderNoch keine Bewertungen

- Fellowship in Maxillofacial Trauma: GoalsDokument6 SeitenFellowship in Maxillofacial Trauma: GoalsMax FaxNoch keine Bewertungen

- Krok 2 Stomatology: Test Items For Licensing ExaminationDokument30 SeitenKrok 2 Stomatology: Test Items For Licensing ExaminationjimmyNoch keine Bewertungen

- Luting CementsDokument13 SeitenLuting CementsPanah SalahiNoch keine Bewertungen

- Pedo 721 2001 Final PDFDokument12 SeitenPedo 721 2001 Final PDFyalahopaNoch keine Bewertungen

- Soffit and PCD PDFDokument4 SeitenSoffit and PCD PDFKalpanaNoch keine Bewertungen

- Pom F3Dokument1 SeitePom F3Rosette GoNoch keine Bewertungen

- MCQs On Oral Histology - Dental Pulp - 1-5Dokument5 SeitenMCQs On Oral Histology - Dental Pulp - 1-5Karizma TravelNoch keine Bewertungen

- TMJ Part 3Dokument25 SeitenTMJ Part 3api-324160601Noch keine Bewertungen

- Dentalplaque Part1 161112155549Dokument54 SeitenDentalplaque Part1 161112155549Alankrita Singh100% (1)

- Catherine A. Hebert, D.D.S .: Internal Vs External ResorptionDokument2 SeitenCatherine A. Hebert, D.D.S .: Internal Vs External ResorptionJames OnealNoch keine Bewertungen

- Evidence Based EndodonticsDokument114 SeitenEvidence Based EndodonticsSanket PandeyNoch keine Bewertungen

- NBDE 2 Last Week Imp RevDokument9 SeitenNBDE 2 Last Week Imp RevMirza Hammad Ul-HaqNoch keine Bewertungen

- Mucogingival Surgery (Mucogingival Problems and Management)Dokument46 SeitenMucogingival Surgery (Mucogingival Problems and Management)Dr.Arshad SayedNoch keine Bewertungen

- The ADA Practical Guide to Patients with Medical ConditionsVon EverandThe ADA Practical Guide to Patients with Medical ConditionsNoch keine Bewertungen

- Flow Uerdingen KrefeldDokument1 SeiteFlow Uerdingen KrefeldtotpityiNoch keine Bewertungen

- 278 AltichemDokument2 Seiten278 AltichemChun HuangNoch keine Bewertungen

- Guest Ice Breaker SampleDokument1 SeiteGuest Ice Breaker SampleRosette GoNoch keine Bewertungen

- Anesthesiology Midterm ReviewerDokument4 SeitenAnesthesiology Midterm ReviewerRosette Go100% (1)

- Know The Systemic Diseases Suffered by The PatientsDokument2 SeitenKnow The Systemic Diseases Suffered by The PatientsRosette GoNoch keine Bewertungen

- Pom F7Dokument2 SeitenPom F7Rosette GoNoch keine Bewertungen

- Presence of Fever InfectionDokument1 SeitePresence of Fever InfectionRosette GoNoch keine Bewertungen

- Pom F3Dokument1 SeitePom F3Rosette GoNoch keine Bewertungen

- Practice Management Prelim ReviewerDokument4 SeitenPractice Management Prelim ReviewerRosette GoNoch keine Bewertungen

- Oral MucosaDokument3 SeitenOral MucosaRosette Go100% (2)

- Forensic Dentistry MidtermsDokument3 SeitenForensic Dentistry MidtermsRosette GoNoch keine Bewertungen

- NeoplasmsDokument2 SeitenNeoplasmsRosette GoNoch keine Bewertungen

- Embryology: Odontogenesis Odontogenesis - Origin and Tissue Formation of TeethDokument2 SeitenEmbryology: Odontogenesis Odontogenesis - Origin and Tissue Formation of TeethRosette GoNoch keine Bewertungen

- Energy Transfer in The Body: Presented By: Sneha Shah MPT 1 Year (Neuro)Dokument32 SeitenEnergy Transfer in The Body: Presented By: Sneha Shah MPT 1 Year (Neuro)Vijay ChithraNoch keine Bewertungen

- Disha Challenger Chemistry For JEE Main and Advanced@StudyAffinityDokument831 SeitenDisha Challenger Chemistry For JEE Main and Advanced@StudyAffinityThe Joker M ANoch keine Bewertungen

- Mercaptans As Chain Transfer Agents - ArkemaDokument11 SeitenMercaptans As Chain Transfer Agents - Arkemaichsan hakimNoch keine Bewertungen

- CarbonatoDokument2 SeitenCarbonatoFlávio ViníciusNoch keine Bewertungen

- Epv PDFDokument2 SeitenEpv PDFMuhammad Fikri PratamaNoch keine Bewertungen

- Chemical Method of Sterilization - Pharmaceutics IVDokument6 SeitenChemical Method of Sterilization - Pharmaceutics IV03365985198Noch keine Bewertungen

- Role of Zirconium Conversion Coating in Corrosion Performance of Aluminum AlloysDokument27 SeitenRole of Zirconium Conversion Coating in Corrosion Performance of Aluminum Alloysbmalki68Noch keine Bewertungen

- Science 8G Metals and Their UsesDokument2 SeitenScience 8G Metals and Their UsesHeba AwadNoch keine Bewertungen

- Contact MetamorphismDokument5 SeitenContact MetamorphismBangtan AmiiNoch keine Bewertungen

- High-Pour-Point and Asphaltic Crude Oils and CondensatesDokument5 SeitenHigh-Pour-Point and Asphaltic Crude Oils and CondensatesarispriyatmonoNoch keine Bewertungen

- J Cej 2020 125418Dokument95 SeitenJ Cej 2020 125418n v goodNoch keine Bewertungen

- Alkyne AllDokument28 SeitenAlkyne Allsushantkadam75100% (3)

- ZnFe2O4 Preparation by Sol-Gel MethodDokument11 SeitenZnFe2O4 Preparation by Sol-Gel MethodHosamNoch keine Bewertungen

- Gunj Glass Works. LTD Visit ReportDokument26 SeitenGunj Glass Works. LTD Visit ReportHM Bhatti100% (1)

- Chemical Effects of Electric Current Class 8 Extra Questions Science Chapter 14 - Learn CBSEDokument1 SeiteChemical Effects of Electric Current Class 8 Extra Questions Science Chapter 14 - Learn CBSEDivyansh GargNoch keine Bewertungen

- Rates of Reaction FlashcardsDokument5 SeitenRates of Reaction FlashcardsRayan KassamNoch keine Bewertungen

- Chapter 2: Threats To The Marine Environment: Pollution and Physical DamageDokument15 SeitenChapter 2: Threats To The Marine Environment: Pollution and Physical DamagePablo E Bravo SNoch keine Bewertungen

- Synthesis Characterization and Applications of Microencapsulated Phase Change Materials in Thermal Energy Storage A Review 2017 Energy and BuildingsDokument19 SeitenSynthesis Characterization and Applications of Microencapsulated Phase Change Materials in Thermal Energy Storage A Review 2017 Energy and BuildingsSusi SusilowatiNoch keine Bewertungen

- Method of Obtaining Anatural HydroxytyrosolDokument13 SeitenMethod of Obtaining Anatural Hydroxytyrosolsalvatore raffaNoch keine Bewertungen

- Electrode and Its TypesDokument10 SeitenElectrode and Its TypesPratheep AddrinNoch keine Bewertungen

- AK Hintermann - List of QNMR Standards - Last Update 12.07.2021Dokument7 SeitenAK Hintermann - List of QNMR Standards - Last Update 12.07.2021RAMONA RICLEANoch keine Bewertungen

- Final Design Report Group 6 (Latest) PDFDokument385 SeitenFinal Design Report Group 6 (Latest) PDFManishaa Varatha RajuNoch keine Bewertungen

- Section 7 Nitrogenous Fertilizer: CE: Section 7 MC P.1Dokument3 SeitenSection 7 Nitrogenous Fertilizer: CE: Section 7 MC P.1Kai Keung ChiuNoch keine Bewertungen

- Bowens Reaction Series ExplanationDokument3 SeitenBowens Reaction Series ExplanationsuhantoroNoch keine Bewertungen

- SC5a Ionic-Bonding-Worksheet AnswersDokument2 SeitenSC5a Ionic-Bonding-Worksheet AnswersSri THIRUGNANA SAMBANDAMNoch keine Bewertungen

- DLL Science 7 Week 1 Q1Dokument31 SeitenDLL Science 7 Week 1 Q1Arjay MolanoNoch keine Bewertungen

- Lab Report-1Dokument5 SeitenLab Report-1Raza AliNoch keine Bewertungen

- Activated Carbon Nanofibers Derived From Coconut Shell - 2020 - Advanced PowderDokument7 SeitenActivated Carbon Nanofibers Derived From Coconut Shell - 2020 - Advanced PowderHarshit BhatiNoch keine Bewertungen

- Patent Application Publication (10) Pub. No.: US 2009/0192234 A1Dokument26 SeitenPatent Application Publication (10) Pub. No.: US 2009/0192234 A1Deva DrillTechNoch keine Bewertungen

- Chemical Compatibility Plastic Material Chart For PA66, PEEK, PPS, PVDF and POMDokument9 SeitenChemical Compatibility Plastic Material Chart For PA66, PEEK, PPS, PVDF and POMDeepak patilNoch keine Bewertungen