Beruflich Dokumente

Kultur Dokumente

Guide Lines For Tooling Design Before Taking For Design

Hochgeladen von

ramprakashchinniahOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Guide Lines For Tooling Design Before Taking For Design

Hochgeladen von

ramprakashchinniahCopyright:

Verfügbare Formate

Tooling Design Guide

GUIDE LINES FOR TOOLING DESIGN BEFORE TAKING FOR DESIGN

CHECK FOR Request for design Component drawing-suffix and date of the drawing should be same as in the request Process sheet tage drawing if an! Forging"Casting drawing #achine tool in which option to be carried out - detail and m"c capacit! chart Catalogues of tools to be used " equipment$ used during that option li%e chuc%& dial& 'aws etc$ (etails regarding wor% area con)e!or height etc$

WHILE DESIGNING *he component drawing and process sheets to be carefull! studied$ Components geometric tolerances"dimensional tolerances"specified dimensions - to be studied carefull!& with process and m"c tool " tooling used$ + rough s%etch of the 'ig " tooling to be prepared and discuss with process partner$ Chec% component drawing for pro'ection first angle"third angle$ Component )iews in 'ig"fixture to be corrected to third angle onl!$ Component"'ig"fixture"tooling"cutters are to be drawn to scale onl!$ tud! the capacit! of the machine tool& 'ig"fixture are to be in wor%ing range in between max"min$ Chec% for fouling of 'ig"fixture"tooling"tool with m"c tool$ Chec% cutter in min"max position& fouling with m"c tool& other tooling& 'ig"fixture$ Chec% - stro%e of the tool& remo)al of tool from holder in wor%ing position$ Chec%-remo)al of component from 'ig"fixture with tooling$ ,f more than one cutting tool is used ma%e a tool la!out to chec% the abo)e$ #ar% tool"toolings numbers that are used along with the 'ig"fixture for that opn$ -e)els are to be mar%ed for 'ig"fixture"tooling as well as for component .Ref process sheet or stage drawing for component dimensions at that stage/ Chec%-locations& butting and seating faces as specified in the process sheet$

Chec%-loading"unloading of component& easiness& hindrances& fouling while indexing& rotating& mo)ing& hand clearance& opening and closing of clamps etc$ +ss!$ fixtures"welding fixtures-chec% for remo)al of component from fixture after completion of operation$ *urning fixtures-chec% for balancing with component& loosening of elements while rotating$ Chec%-effecti)eness of clamping& )ibration& dampening$ Chec% - chip remo)al& chip flow$ 0hene)er necessar! introduce fool proof pins such that component can be loaded on one position onl!$ +fter drawing 1eneral +ss!$ get the appro)al of the concerned Process partner.$ Chec%-machining and ass!$ of elements$ +s far as possible std elements are to be used$ Chec%-'ig boring dimensions$ Chec%-dimensions to be shown in 1+& critical dimensions on ass!$ ,f more than one sheet is required to draw 1+ and elements use same si2e sheets onl! ne)er use different si2es of sheets for the same 'ig"tooling$ Chec%-ser)icing and replacement of elements$ Chec%-geometrical and dimensional tolerances$ Chec%-material and heat treatment notes for elements$ Ref enclosure for materials for elements$ Chec% slots for using with m"c tools& lifting hoo%s and handling pro)isions$ Component correct part number with issue number and date .as in design request/ is to be incorporated in the 'ig"fixture"tooling drawing$ 0rite the 'ig"fixture"tooling number in the process sheet in the appropriate place$ 0rite below the border line ref 'ig"tooling number if an!$ Rigid coupling de)ice must be pro)ided while designing -ift and turn o)er de)ices$ -ifting *ac%les must be fixed permanentl! fastened with components$ 3"4 GENERAL INSTRUCTIONS FOR STANDARDISATION +ll dimensions should be in mm onl!$ +s far as possible the locating bun%s and locating pins are to be standardi2ed in all 'igs of the same component as far as possible to be screwed with push fit and not to be press fitted$

1uide bushes& liner bushes-as far as possible should confirm to is standards$ -iner bushes with collar to be used as far as possible$ lip bushes-internal dia of bush for reamer 15 and for drill F6"16$ ,n inspection fixtures bushes are to be screwed with push fit .max clearance of 7$778 on dia with mating holes/$ +ll parts to be blac%ened$

GUIDELINES FOR MISTAKE PROOFING IN IG AND TOOL DESIGN tud! the component drawing for the particular operation$ Chec%-can the component be loaded in the 'ig"fixture in more than one position$ ,f so& chec% for fouling with an! part of 'ig"fixture& m"c tool& cutting tool& during operation& can cause damage to cutting tool& m"c tool& fixture during operation& will the component after completion of operation be incorrect requiring rewor% or to be scrapped when gets loaded in other than desired position in the fixture$ ,f so mista%e proofing is to be pro)ided in the form of pins"pro'ections"or an! other elements which will obstruct and pre)ent loading the component other than the desired orientation$

Das könnte Ihnen auch gefallen

- Manufacturing EngineeringDokument70 SeitenManufacturing EngineeringPRINCE RAJNoch keine Bewertungen

- Elementary Tech Skills MatrixDokument2 SeitenElementary Tech Skills MatrixMary Beth Hertz100% (1)

- Arish Kumar - ResumeDokument5 SeitenArish Kumar - ResumevcdheenaNoch keine Bewertungen

- IE 443 Lesson 4 Maintainability and Availability AnalysisDokument46 SeitenIE 443 Lesson 4 Maintainability and Availability Analysishamidu athumaniNoch keine Bewertungen

- Manufacturing and Operations ManagementDokument52 SeitenManufacturing and Operations ManagementRohit DhawareNoch keine Bewertungen

- Presentation On QFD and VOCDokument12 SeitenPresentation On QFD and VOCvundavilliravindraNoch keine Bewertungen

- Part Approval File Checklist Mandatory Documents For All PartsDokument2 SeitenPart Approval File Checklist Mandatory Documents For All Partssumit_saraf_5Noch keine Bewertungen

- Employee Attendance SheetDokument1 SeiteEmployee Attendance SheetRG Nawin KrishnaNoch keine Bewertungen

- Training Feedback FormDokument2 SeitenTraining Feedback FormKathy McSheaNoch keine Bewertungen

- JigDokument13 SeitenJigJunaid YNoch keine Bewertungen

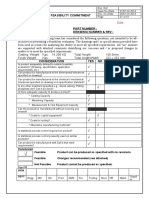

- 02-Team Feasibility CommittmentDokument1 Seite02-Team Feasibility CommittmentVinod SaleNoch keine Bewertungen

- A Review On Springback Effect in Sheet Metal Forming ProcessDokument7 SeitenA Review On Springback Effect in Sheet Metal Forming ProcessantonytechnoNoch keine Bewertungen

- Dis 6 W 2 HDokument14 SeitenDis 6 W 2 HBalachandar SathananthanNoch keine Bewertungen

- Process Planning Guide for ManufacturingDokument12 SeitenProcess Planning Guide for Manufacturingselva_raj215414Noch keine Bewertungen

- Personnel Competence MatrixDokument2 SeitenPersonnel Competence MatrixTRISHULA INDIANoch keine Bewertungen

- Manufacturing Engineering IDokument4 SeitenManufacturing Engineering Iahmish kabbaxe100% (1)

- Routing and Route SheetsDokument4 SeitenRouting and Route SheetsAvilash Sharma100% (1)

- Design Mee2008 VusDokument42 SeitenDesign Mee2008 VusRajesh RJNoch keine Bewertungen

- Green Manufacturing TechniquesDokument18 SeitenGreen Manufacturing TechniquesFiroz KhanNoch keine Bewertungen

- AE 2253 Production Technology Lesson Plan for Aeronautical Engineering Sem IVDokument2 SeitenAE 2253 Production Technology Lesson Plan for Aeronautical Engineering Sem IVGiridharan SharmaNoch keine Bewertungen

- Supplier Cost Increase1Dokument3 SeitenSupplier Cost Increase1prasad_kcpNoch keine Bewertungen

- Unit Ii: Process PlanningDokument17 SeitenUnit Ii: Process PlanningVijaya Prabhu KumarasamyNoch keine Bewertungen

- Tool and Die Maker PDFDokument9 SeitenTool and Die Maker PDFArun PrasathNoch keine Bewertungen

- GD&T Dimensioning and Tolerancing GuideDokument3 SeitenGD&T Dimensioning and Tolerancing Guidedesign12Noch keine Bewertungen

- Cipc-Pro-L2-002 - Control of Tool and Customer Property Procedure Rev 05 2Dokument8 SeitenCipc-Pro-L2-002 - Control of Tool and Customer Property Procedure Rev 05 2Marvin CubeNoch keine Bewertungen

- Statistical Quality Control (SQC) : Tazia HossainDokument17 SeitenStatistical Quality Control (SQC) : Tazia HossainNazmul hassan LimonNoch keine Bewertungen

- Mould Manufacturing Technology: Checklist For Mould AssemblyDokument8 SeitenMould Manufacturing Technology: Checklist For Mould AssemblyThe Pure ConsciousnessNoch keine Bewertungen

- Project: NO. Module (S) Aps Task Description CURRENT (As of Nov-18) 1 System MaintenanceDokument18 SeitenProject: NO. Module (S) Aps Task Description CURRENT (As of Nov-18) 1 System MaintenanceElvera GeorgeNoch keine Bewertungen

- Employee Operator Competence Training AssessmentDokument3 SeitenEmployee Operator Competence Training AssessmentWinnie EldamaNoch keine Bewertungen

- GD & TDokument43 SeitenGD & TMahender Kumar100% (1)

- Metric ThreadsDokument35 SeitenMetric ThreadsmihaidelianNoch keine Bewertungen

- Manufacturing and Production - Human Factors - KPI LibraryDokument4 SeitenManufacturing and Production - Human Factors - KPI Librarytaghavi1347Noch keine Bewertungen

- Standards ManagementDokument3 SeitenStandards ManagementGourav SainiNoch keine Bewertungen

- Quality Management and Performance A ReviewDokument19 SeitenQuality Management and Performance A ReviewIAEME PublicationNoch keine Bewertungen

- Die Casting Machine OperatorDokument1 SeiteDie Casting Machine OperatorChristine BairdNoch keine Bewertungen

- Z & t Tests: Hypothesis Testing ExamplesDokument20 SeitenZ & t Tests: Hypothesis Testing ExamplesRushin Mehta100% (1)

- F.disp.01 Schedule V-S Dispatch PlanDokument6 SeitenF.disp.01 Schedule V-S Dispatch PlanSaurabhNoch keine Bewertungen

- NCR Supplier Scorecard ProcessDokument11 SeitenNCR Supplier Scorecard ProcesssamcbsivNoch keine Bewertungen

- 6 Machines and Machine Processs 1aDokument28 Seiten6 Machines and Machine Processs 1aAlfred KuwodzaNoch keine Bewertungen

- Engineering Management Course Code: EMG: Instructor: Engr. Cesar Amante TingDokument63 SeitenEngineering Management Course Code: EMG: Instructor: Engr. Cesar Amante TingCesar Amante TingNoch keine Bewertungen

- Ch-24 Limit, Tolerance & FitsDokument104 SeitenCh-24 Limit, Tolerance & FitsK Pavan KumarNoch keine Bewertungen

- Process Flow ChartDokument11 SeitenProcess Flow Chartsudar1477Noch keine Bewertungen

- Policy and Procedure of Employee SatisfactionDokument8 SeitenPolicy and Procedure of Employee SatisfactionAbdur Rashid KhanNoch keine Bewertungen

- Team 4 Ansoff Matrix PresentationDokument20 SeitenTeam 4 Ansoff Matrix Presentationramyab115Noch keine Bewertungen

- CONTROL CHARTS GUIDEDokument26 SeitenCONTROL CHARTS GUIDEAnurag KushwahaNoch keine Bewertungen

- 7 QC ToolsDokument8 Seiten7 QC ToolspremNoch keine Bewertungen

- Machine ToolsDokument92 SeitenMachine ToolsraghavNoch keine Bewertungen

- ISO TS 16949 2009 Audit ChecklistDokument27 SeitenISO TS 16949 2009 Audit ChecklistKhaled HaddadNoch keine Bewertungen

- ComparatorsDokument23 SeitenComparatorsShashwat RaiNoch keine Bewertungen

- Bench MarkingDokument21 SeitenBench MarkingRajiv DalelaNoch keine Bewertungen

- Routing - PPT by Gopal K. DixitDokument38 SeitenRouting - PPT by Gopal K. DixitkaashniNoch keine Bewertungen

- Design and Validation of A Low-Cost MicroscopeDokument3 SeitenDesign and Validation of A Low-Cost Microscopeyousrazeidan1979Noch keine Bewertungen

- Competency MapDokument1 SeiteCompetency Mappatrick mesaNoch keine Bewertungen

- Supplier-QUAL TM 0027-01 PPAP PackageDokument67 SeitenSupplier-QUAL TM 0027-01 PPAP PackageMahe RonaldoNoch keine Bewertungen

- CHAPTER 1 Measurement and InstrumentationDokument38 SeitenCHAPTER 1 Measurement and InstrumentationAsif Bin SyedNoch keine Bewertungen

- Gauges: Inspection Tools for Checking Manufacturing TolerancesDokument33 SeitenGauges: Inspection Tools for Checking Manufacturing TolerancesUsman ansarNoch keine Bewertungen

- Machine Tools and Machining: Grinding Machine GuideDokument38 SeitenMachine Tools and Machining: Grinding Machine GuideFaisal MaqsoodNoch keine Bewertungen

- Emp Warning NoteDokument1 SeiteEmp Warning NoteJohn A MerlinoNoch keine Bewertungen

- Training and DevelopmentDokument25 SeitenTraining and Developmentp2chitra540Noch keine Bewertungen

- Piping Shop Fabrication SpecificationDokument20 SeitenPiping Shop Fabrication SpecificationAnonymous NIICRJNoch keine Bewertungen

- 068 - ME8351, ME6302 Manufacturing Technology I - 2 Mark Important QuestionsDokument5 Seiten068 - ME8351, ME6302 Manufacturing Technology I - 2 Mark Important QuestionsMr. T. Anjaneyulu Mr. T. AnjaneyuluNoch keine Bewertungen

- Apparel Cost Sheet SampleDokument3 SeitenApparel Cost Sheet SampleAbhinav Verma85% (13)

- Embroidery Stitches An Illustrated Guide - Anne ButlerDokument136 SeitenEmbroidery Stitches An Illustrated Guide - Anne ButlerChakgonzalo100% (1)

- Mori Seiki ZT 1000 y enDokument16 SeitenMori Seiki ZT 1000 y enOswald muñoz100% (1)

- Power Sharpening System - Woodworking Techniques - American WoodworkerDokument8 SeitenPower Sharpening System - Woodworking Techniques - American WoodworkerAnonymous xEKsRmtjONoch keine Bewertungen

- No 4 Plane TotesDokument3 SeitenNo 4 Plane TotesBranZzZzZNoch keine Bewertungen

- AISC Sculpture J STPDokument178 SeitenAISC Sculpture J STPPrashant DalviNoch keine Bewertungen

- Project On Making A CNC Machine in EthiopiaDokument10 SeitenProject On Making A CNC Machine in EthiopiaSolomon BefrduNoch keine Bewertungen

- Manual Industrial Overlock JackDokument54 SeitenManual Industrial Overlock JackMario DM67% (3)

- Medium Cover Medium Lining: Bottom BottomDokument7 SeitenMedium Cover Medium Lining: Bottom Bottom童钰Noch keine Bewertungen

- Ballscrew nuts for rolled ballscrewsDokument2 SeitenBallscrew nuts for rolled ballscrewsRafael HenriquesNoch keine Bewertungen

- General Metal Fabrication and AssemblyDokument9 SeitenGeneral Metal Fabrication and Assemblysola sidoNoch keine Bewertungen

- Crochet Sock Monkey Hat PatternDokument10 SeitenCrochet Sock Monkey Hat PatternCrochet Free100% (1)

- Carpentry DemoDokument56 SeitenCarpentry DemoJaymel PurgatorioNoch keine Bewertungen

- Heat Treatment Types for Improving Metal PropertiesDokument29 SeitenHeat Treatment Types for Improving Metal PropertiesPratheep AddrinNoch keine Bewertungen

- Sunflower Doll M N Ature Pattern (Engl SH)Dokument13 SeitenSunflower Doll M N Ature Pattern (Engl SH)Alex Castairs100% (5)

- Engineering Drawing Dimensioning GuideDokument43 SeitenEngineering Drawing Dimensioning GuideajayNoch keine Bewertungen

- Stiches Part 2Dokument21 SeitenStiches Part 2Simran Pahwa100% (1)

- KashidaDokument24 SeitenKashidaharleenkaur05Noch keine Bewertungen

- Everything about high-speed steelDokument2 SeitenEverything about high-speed steeljerfmosNoch keine Bewertungen

- Woodturning Workshop S3 Episode GuideDokument3 SeitenWoodturning Workshop S3 Episode GuideScott OldfieldNoch keine Bewertungen

- List of Needed MachinesDokument6 SeitenList of Needed MachinesAyech NabilNoch keine Bewertungen

- Interweave Knits 2009 FallDokument76 SeitenInterweave Knits 2009 FallMelissaBenini100% (11)

- Subject: Fabric Studies Unit 4: Knitted Fabrics Quadrant 1 - E-TextDokument20 SeitenSubject: Fabric Studies Unit 4: Knitted Fabrics Quadrant 1 - E-TextashrafbookNoch keine Bewertungen

- Mr. A. Panchariya Dept. of Mech. Engg. MNIT JaipurDokument143 SeitenMr. A. Panchariya Dept. of Mech. Engg. MNIT JaipurAnand KumarNoch keine Bewertungen

- Easter Bunnies GnomesDokument10 SeitenEaster Bunnies Gnomeslyubomirat100% (10)

- Manufacturing Processes (Machining Processes & Machine Tools) (Beng) (Handout)Dokument82 SeitenManufacturing Processes (Machining Processes & Machine Tools) (Beng) (Handout)bananaNoch keine Bewertungen

- MC-45 Price List 2018Dokument36 SeitenMC-45 Price List 2018Sahili SalveNoch keine Bewertungen

- 003 MillingDokument59 Seiten003 MillingKalikene MwambeloNoch keine Bewertungen

- Report by Mary Grace I. ValilaDokument37 SeitenReport by Mary Grace I. ValilaJocelyn GaniaNoch keine Bewertungen