Beruflich Dokumente

Kultur Dokumente

Laser Cut

Hochgeladen von

Anonymous QiMB2lBCJLOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Laser Cut

Hochgeladen von

Anonymous QiMB2lBCJLCopyright:

Verfügbare Formate

Diamond Laser cutting

Technology Effectively

Removes m- purity From

Rough Diamond-Visit Us!

www.ugam-india.com

Laser Cutting

AIternative

CNC Shape Cutting

Machines & Kits for

affordable prices. Free

catalog

www.torchmate.com

Advanced Laser

TechnoIogy

UPTECH, Professional

Maker of efficient,

productive Laser Systems

www.upitech.com

Laser Cutting Machines

ndustrial computer-

controlled, three-axis,

blade and laser cutters

BlackmanAndWhite.com

Ongoing Laser Jobs

Get ongoing short-run jobs

through online service

eMachineShop.com

www.emachineshop.com/par

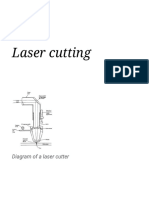

Laser Cutting Overview

Design for Manufacturing Menu [ Laser Cutting Services

Laser cuttingis a common manuIacturing process employed to cut many types

oI materials. Materials which may be laser cut include; Ierrous metals, non-

Ierrous metals, stone, plastics, rubber, and ceramics. Laser cutting works by

directing a high power pulsed laser at a speciIic location on the material to be

cut. The energy in the laser beam is absorbed into the surIace oI the material, and

the energy oI the laser is converted into heat, which melts or vaporizes the

material. Additionally, gas is Iocused or blown into the cutting region to expel or

blow away the molten metal and vapor Irom the cutting path.

There are several advantages oI laser cutting over mechanical cutting, since the

cut is perIormed by the laser beam, there is no physical contact with the material,

thereIore, contaminates cannot enter or embed into the material. Laser cutting

can produce high accuracy cuts, complex shapes, cut several parts

simultaneously, produce clean cutting edges which require minimal Iinishing, as

well as, low edge loads during cutting, which will reduce distortions.

The width oI laser cut or kerI, and quality oI the cut edges, are eIIected by power

oI the laser, laser beam pulses, and the motion oI the laser beam, and work-piece.

The Iollowing are typical cut or kerI widths resulting Irom laser cutting process:

Copyright 2000 - 2008, by Engineers Edge, All rights reserved. Disclaimer

Laser Cutting kerf Width vs. Material Thickness

Material Material Cut Thickness Material Removed (Kerf)

Aluminum .100 .010

Plastics .002 - .018 2 times the beam diameter

Steel and Iron

0.060

0.090

0.120

0.250

.002

.005

.008

.0012

Home

Products and Services

Engineering Forum

CAD Forum

Engineering Design Data

Engineering Drafting

Store

Engineering News

Engineering Calculators

Newsletter Register

Advertise

Feedback

Asme Y14.5M-1994

Geometric Dimensioning

and Tolerancing GD&T

Training

Copyright Notice

Screw Slide Chart Selector

$18.95

$16.95

Page 1 oI 1 Laser Cutting Overview - Engineers Edge

02/04/2008 http://www.engineersedge.com/manuIacturing/lasercutting.htm

Das könnte Ihnen auch gefallen

- CNC Fiber Laser Cutter For Cutting Plate and Tube 3015 1000WDokument16 SeitenCNC Fiber Laser Cutter For Cutting Plate and Tube 3015 1000WSot DesignNoch keine Bewertungen

- Metal LatheDokument25 SeitenMetal Lathebogesz68Noch keine Bewertungen

- 3D PrinterDokument10 Seiten3D PrinterHandy LeeNoch keine Bewertungen

- Advantages of Laser Cutting: WWW - Opticlabs.caDokument4 SeitenAdvantages of Laser Cutting: WWW - Opticlabs.caopticlabs laserkitNoch keine Bewertungen

- Chess Pieces Manufacturing Description Part2Dokument10 SeitenChess Pieces Manufacturing Description Part2Chanel Méndez RamírezNoch keine Bewertungen

- Unit-I Theory of Metal CuttingDokument73 SeitenUnit-I Theory of Metal CuttingSarvesh Kumarasamy100% (1)

- Bending (Metalworking) : "Metal Bending" Redirects Here. For The Form of Stage Magic, SeeDokument10 SeitenBending (Metalworking) : "Metal Bending" Redirects Here. For The Form of Stage Magic, SeeJordan MosesNoch keine Bewertungen

- Type of ThreadsDokument1 SeiteType of ThreadsAnonymous QiMB2lBCJLNoch keine Bewertungen

- CNC-Cutting-Solutions CNC Controller For Cutting Machines WebDokument16 SeitenCNC-Cutting-Solutions CNC Controller For Cutting Machines Webismet hyseniNoch keine Bewertungen

- Laser Cutting - Wikipedia PDFDokument46 SeitenLaser Cutting - Wikipedia PDFSandeep KumarNoch keine Bewertungen

- Milling MachinesDokument48 SeitenMilling MachinesAliah IzzahNoch keine Bewertungen

- DCS-A-10C Flight Manual ENDokument663 SeitenDCS-A-10C Flight Manual ENTheGuilio100% (2)

- Design & Manufacturing of Components of Modified Bench Vise On Rapid Prototype MachineDokument13 SeitenDesign & Manufacturing of Components of Modified Bench Vise On Rapid Prototype MachineInternational Journal of Application or Innovation in Engineering & Management100% (1)

- Seminar Paper Laser Cutting: University of Maribor Faculty of Mechanical EngineeringDokument8 SeitenSeminar Paper Laser Cutting: University of Maribor Faculty of Mechanical EngineeringPrimož BrglezNoch keine Bewertungen

- LMT Onsrud Polaris Compression BrochureDokument2 SeitenLMT Onsrud Polaris Compression BrochureDaniel AustinNoch keine Bewertungen

- TaegoTech - PG BroshureDokument11 SeitenTaegoTech - PG Broshurealexl5892Noch keine Bewertungen

- Cubic Boron NitrideDokument15 SeitenCubic Boron Nitridekaran sahniNoch keine Bewertungen

- SUDA Fiber Laser Cutting Machine FC1530-1000W 2020.6.2Dokument15 SeitenSUDA Fiber Laser Cutting Machine FC1530-1000W 2020.6.2marceilinus devaluantoNoch keine Bewertungen

- E-Book - Cutting Tools For CNC RouterDokument11 SeitenE-Book - Cutting Tools For CNC RouterVictor ParvanNoch keine Bewertungen

- Laser Cutting: Navigation SearchDokument11 SeitenLaser Cutting: Navigation SearchIjie BladerzNoch keine Bewertungen

- Ultrasound ArtifactsDokument34 SeitenUltrasound ArtifactsPatricio Alejandro Montalvo Ramos100% (1)

- Unconventional Machining ProcessDokument27 SeitenUnconventional Machining ProcessNandam HarshithNoch keine Bewertungen

- Gambheer Singh Mecahnical 4 YearDokument23 SeitenGambheer Singh Mecahnical 4 YearMayank RawatNoch keine Bewertungen

- Solar Radiation Measuring InstrumentsDokument14 SeitenSolar Radiation Measuring InstrumentsadityapalsinghNoch keine Bewertungen

- Mopoke: Full Spectrum Cuas CapabilitiesDokument2 SeitenMopoke: Full Spectrum Cuas CapabilitiesCtayNoch keine Bewertungen

- Science: Quarter 2 - Module 2Dokument23 SeitenScience: Quarter 2 - Module 2MARIA LOURDES MENDOZA67% (3)

- Cutting Know HowDokument18 SeitenCutting Know Howlugarx100% (1)

- VersaDoc MP 4000 Sole Source SpecificationsDokument3 SeitenVersaDoc MP 4000 Sole Source SpecificationsdnajenNoch keine Bewertungen

- 1325 Portable CNC Cutting MachineDokument9 Seiten1325 Portable CNC Cutting MachineJorge Ligeti LandersNoch keine Bewertungen

- TFLW Series Water Chiller For Laser Operating Manual: Original Instruction E1201-2019-ENDokument36 SeitenTFLW Series Water Chiller For Laser Operating Manual: Original Instruction E1201-2019-ENali imron100% (2)

- Laser Metal Cutting MachineDokument2 SeitenLaser Metal Cutting Machineinalac2Noch keine Bewertungen

- Laser CuttingDokument8 SeitenLaser CuttingSharath KumarNoch keine Bewertungen

- Plasma CamDokument20 SeitenPlasma CamkairotdfNoch keine Bewertungen

- Edm Wire CutDokument2 SeitenEdm Wire CutRedza Rabani RosliNoch keine Bewertungen

- Laser Cutting PDFDokument43 SeitenLaser Cutting PDFManoj NehraNoch keine Bewertungen

- 09 Electric Tool Catalog 10 PDFDokument26 Seiten09 Electric Tool Catalog 10 PDFIndonesian ThuglifeNoch keine Bewertungen

- Mini Milling MachineDokument4 SeitenMini Milling Machinekrisbhaskar22Noch keine Bewertungen

- TRUMPF 2D Laser Cutting Machines Brochure enDokument48 SeitenTRUMPF 2D Laser Cutting Machines Brochure enAbhishek Y MNoch keine Bewertungen

- Incremental Sheet Metal Forming On CNC Milling Machine-ToolDokument4 SeitenIncremental Sheet Metal Forming On CNC Milling Machine-ToolDionysius WahyoeNoch keine Bewertungen

- Complete EDM Handbook - 12Dokument10 SeitenComplete EDM Handbook - 12ks2000n1Noch keine Bewertungen

- Water Jet CutterDokument16 SeitenWater Jet CutterRex Delon50% (2)

- MTM Lab PresentationDokument26 SeitenMTM Lab PresentationMuhammad WaseemNoch keine Bewertungen

- Wood Tooling CatalogDokument32 SeitenWood Tooling CatalogLam NguyenNoch keine Bewertungen

- Design of Mini Milling MachineDokument56 SeitenDesign of Mini Milling MachineSachin HolkarNoch keine Bewertungen

- CNC Wood Turning Lathe Cutters Bits Knife ToolsDokument5 SeitenCNC Wood Turning Lathe Cutters Bits Knife ToolsSalce SmithNoch keine Bewertungen

- U1Metal Cutting & Tool DesignDokument62 SeitenU1Metal Cutting & Tool DesignVansh puriNoch keine Bewertungen

- WWW Machinemfg Com Fiber Laser CuttingDokument20 SeitenWWW Machinemfg Com Fiber Laser CuttingPurushottam Kumar100% (1)

- Gs 3 MDokument316 SeitenGs 3 MNazielNoch keine Bewertungen

- End Mill Training Website PDFDokument64 SeitenEnd Mill Training Website PDFDejan Jovanovic100% (1)

- BroachingDokument22 SeitenBroachingvijchoudhary16Noch keine Bewertungen

- Theory of Metal CuttingDokument8 SeitenTheory of Metal CuttingAhmedNoch keine Bewertungen

- 16 Types of 3D Printer Filaments - Comparison & List of 3D MaterialsDokument1 Seite16 Types of 3D Printer Filaments - Comparison & List of 3D MaterialsCliqueLearn E-LearningNoch keine Bewertungen

- Recent Trends in ManufacturingDokument13 SeitenRecent Trends in ManufacturingAmbarish100% (2)

- H - Additional MachiningDokument51 SeitenH - Additional MachiningedsaregNoch keine Bewertungen

- For Wood Cutter MachineDokument19 SeitenFor Wood Cutter MachineRahul Rajput100% (1)

- PDFDokument514 SeitenPDFRizki PrasetyoNoch keine Bewertungen

- Complete EDM Handbook - 10Dokument8 SeitenComplete EDM Handbook - 10peroz_ak47Noch keine Bewertungen

- Cartridge Type Boring BarDokument4 SeitenCartridge Type Boring BarvishalNoch keine Bewertungen

- Metal Cutting (F) SDokument62 SeitenMetal Cutting (F) SBrijesh VermaNoch keine Bewertungen

- K40 Laser Cutter Rebuild 12x24in Cutting AreaDokument13 SeitenK40 Laser Cutter Rebuild 12x24in Cutting AreaMarcos Leonardo Dagnino AvilaNoch keine Bewertungen

- Edm Wire Cut LabDokument6 SeitenEdm Wire Cut LabJieMan BahRom100% (1)

- Edm ReportDokument25 SeitenEdm ReportPablo Contreras100% (1)

- 4 Axis 500KHz Linkage Offline Motion Controller System PLC Control G Code+100 Pulse Handwheel MPG With Emergency Stop For CNC Router Engraving Milling Lathe Machine RMHV3.1Dokument11 Seiten4 Axis 500KHz Linkage Offline Motion Controller System PLC Control G Code+100 Pulse Handwheel MPG With Emergency Stop For CNC Router Engraving Milling Lathe Machine RMHV3.1jonNoch keine Bewertungen

- Theory of Metal CuttingDokument162 SeitenTheory of Metal CuttingShrikrushna MaliNoch keine Bewertungen

- (##) Non Conventional Air Compressor (Compressed Air Production From Speed SDokument73 Seiten(##) Non Conventional Air Compressor (Compressed Air Production From Speed SSakthiVelMNoch keine Bewertungen

- Lazer Cutting: Dr. Öğr. Üyesi Cevat ÖZARPADokument30 SeitenLazer Cutting: Dr. Öğr. Üyesi Cevat ÖZARPAMetin AYDINNoch keine Bewertungen

- 14264A Construction Mechanic Basic Chapters 11 PDFDokument44 Seiten14264A Construction Mechanic Basic Chapters 11 PDFAnonymous QiMB2lBCJLNoch keine Bewertungen

- Antennas Inside An Automobile: Gps/Glonass Digital Audio Digital TV Sirius RadioDokument2 SeitenAntennas Inside An Automobile: Gps/Glonass Digital Audio Digital TV Sirius RadioAnonymous QiMB2lBCJLNoch keine Bewertungen

- BND Ts Tire Envelope Swept VolumeDokument21 SeitenBND Ts Tire Envelope Swept VolumeAnonymous QiMB2lBCJLNoch keine Bewertungen

- The Nikon Guide To Landscape Photography - 2014 UKDokument162 SeitenThe Nikon Guide To Landscape Photography - 2014 UKAnonymous QiMB2lBCJLNoch keine Bewertungen

- BND TechSource - Tire Data CalculatorDokument7 SeitenBND TechSource - Tire Data Calculatorrojillo88Noch keine Bewertungen

- CNC CodeDokument6 SeitenCNC CodeAnonymous QiMB2lBCJLNoch keine Bewertungen

- Daily Expense TrackerDokument4 SeitenDaily Expense TrackerAnonymous QiMB2lBCJLNoch keine Bewertungen

- Mathematical Tools: Math Guide - 34.1Dokument103 SeitenMathematical Tools: Math Guide - 34.1Anonymous QiMB2lBCJLNoch keine Bewertungen

- Indian Girl Baby NameDokument30 SeitenIndian Girl Baby NameAnonymous QiMB2lBCJLNoch keine Bewertungen

- Hot & Cold ProcessDokument1 SeiteHot & Cold ProcessAnonymous QiMB2lBCJLNoch keine Bewertungen

- Ferrous ProductDokument4 SeitenFerrous ProductAnonymous QiMB2lBCJLNoch keine Bewertungen

- Manufacturing ProcessesDokument32 SeitenManufacturing ProcessesSandesh PawarNoch keine Bewertungen

- Sheet Metal Forgintuve MFGDokument41 SeitenSheet Metal Forgintuve MFGAnonymous QiMB2lBCJLNoch keine Bewertungen

- Hot Forge UpsetDokument13 SeitenHot Forge UpsetAnonymous QiMB2lBCJLNoch keine Bewertungen

- Energy Conversion 1.1 - Demo Version: Engineering SoftwareDokument36 SeitenEnergy Conversion 1.1 - Demo Version: Engineering SoftwareAnonymous QiMB2lBCJLNoch keine Bewertungen

- CNC CodeDokument6 SeitenCNC CodeAnonymous QiMB2lBCJLNoch keine Bewertungen

- Unit - V LasersDokument14 SeitenUnit - V LasersSitaramaraju VengalarajuNoch keine Bewertungen

- Lexmark E450dn Service Manual PDFDokument158 SeitenLexmark E450dn Service Manual PDFNergal CostiNoch keine Bewertungen

- Velocity of SoundDokument9 SeitenVelocity of SoundYcarta SleumasNoch keine Bewertungen

- Optical Communication Question BankDokument24 SeitenOptical Communication Question BankdhivyakrishnaNoch keine Bewertungen

- Stainless SteelDokument2 SeitenStainless Steeltablo1234Noch keine Bewertungen

- Group 3: Capalaran, Joshua Espuerta, Erjohn Limba, David Orhalo, Felix Jr. Tradio, BernadetteDokument14 SeitenGroup 3: Capalaran, Joshua Espuerta, Erjohn Limba, David Orhalo, Felix Jr. Tradio, BernadetteANNAMARSNoch keine Bewertungen

- Hologram: Produced by A Split Coherent Beam of RadiationDokument9 SeitenHologram: Produced by A Split Coherent Beam of RadiationsidharthNoch keine Bewertungen

- G-PM Lab 1Dokument11 SeitenG-PM Lab 1Sohail AhmedNoch keine Bewertungen

- Weld Properties of AISI 303 Free-Machining Stainless SteelDokument9 SeitenWeld Properties of AISI 303 Free-Machining Stainless SteeltazzorroNoch keine Bewertungen

- STANLEY - Asia Laser Range Catalogue (Low Res) - Oct 16Dokument52 SeitenSTANLEY - Asia Laser Range Catalogue (Low Res) - Oct 16bejanNoch keine Bewertungen

- On PN Junction DiodeDokument12 SeitenOn PN Junction DiodeAditya Singh Maurya100% (1)

- Analog ElectronicsDokument47 SeitenAnalog ElectronicsAditya AgrawalNoch keine Bewertungen

- Zro 2Dokument2 SeitenZro 2Phương NguyễnNoch keine Bewertungen

- IMA QuestionsDokument2 SeitenIMA QuestionsRevthi SankerNoch keine Bewertungen

- Explosion-Proof Smoke Detector: GeneralDokument2 SeitenExplosion-Proof Smoke Detector: GeneralBambang Sigit PriyantoNoch keine Bewertungen

- GBIC S CiscoDokument4 SeitenGBIC S Ciscopaulo_an7381Noch keine Bewertungen

- Dehp 4050 UbxsesDokument71 SeitenDehp 4050 UbxsesjavierNoch keine Bewertungen

- Thermal Problems in HEMT PDFDokument96 SeitenThermal Problems in HEMT PDFATman VaghamshiNoch keine Bewertungen

- Types of PrintersDokument5 SeitenTypes of PrintersDanna ZabatNoch keine Bewertungen

- J.S. Wurtele - X-Ray Free Electron LasersDokument25 SeitenJ.S. Wurtele - X-Ray Free Electron LasersDublin000Noch keine Bewertungen

- TS9566 Extending Machine Vision in LabVIEW To 3D ApplicationsDokument29 SeitenTS9566 Extending Machine Vision in LabVIEW To 3D ApplicationsNilesh VaidyaNoch keine Bewertungen