Beruflich Dokumente

Kultur Dokumente

Design Distilasi Kelompok 3

Hochgeladen von

Arif Kartawana Shiddiq0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

55 Ansichten9 SeitenCopyright

© © All Rights Reserved

Verfügbare Formate

XLSX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als XLSX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

55 Ansichten9 SeitenDesign Distilasi Kelompok 3

Hochgeladen von

Arif Kartawana ShiddiqCopyright:

© All Rights Reserved

Verfügbare Formate

Als XLSX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 9

material carbon steel

number of tray 61 sieve trays plus reboiler and condenser

efficient trays 54%

condenser total

feed on tray 31

reflux ratio 1.24

tray spacing 12 inch 0.304801 m

weirs 1 inch 0.0254 m

column height 18.6 m

diameter 3 m

Aliran 16 17 18

Temperatur (C) 65 69.9 125

Pressure (Kpa) 65 45 65 Ethylbenzene

Mol Flow (kmol/h) 226.21 3.34 222.88 Styrene

Mass Flow (kg/h) 23709.6 289.5 23420 Benzene

Vapor density (kg/m3) Toluene

Liquid density (kg/m3)

Surface tension (dyne/cm)

Component flow (kmol/h)

Ethylbenzene 102.88 0.1 102.78

Styrene 120.09 0 0.06

Benzene 1.37 1.37 0

Toluene 1.86 1.86 0

T-401

Component

feed distilat bottom

C8H10 106.2 0.448706 0.024352 1680.740113

C8H8 104.2 0.53382 0 1

C6H6 78.11 0.008124 0.453593 0

C7H8 92.14 0.00935 0.522056 0

total 1 1 1681.740113

T-401

BM

(kg/kmol)

fraksi

formula

Mass Balance Overall

F = D + B

F = 226.21

D = 3.34

B = 222.88

Mass Balance 'Vapor Product'

V = D + L R = L/D = 1.5

Liquid flow above feed (L) = R x D dimana :

L = 5.01 L = Refluks rate

V = 8.35 V = Vapor Rate

Liquid flow below feed (Lm) = LD + F R = Reflux Ratio

Lm = 242.9434 Vm= 8.35

number of stages 61 stages

reboiler 1

Number of real stages =

= 61 stages

Pressure Drop = 9.81 x 10

-3

*ht*densitas liq

= 18581.84234 Pa 18.581

Distillate Product , T = 195 C Bottom Product , T = 330 C

vapor density (kg/m3) = 1.314 vapor density (kg/m3) =

liquid density (kg/m3) = 824.1 liquid density (kg/m3) =

surface Tension (N/m) =

22.54 x 10

-3

surface Tension (N/m) =

Flv Bottom = 1.438913578

Flv distillate = 1.161786579

tray spacing 0.3048

K1 distillate = 0.023

K1 bottom = 0.019

correction for surface tension

bottom K1 = 0.018845508 Vf = 0.380592305

distillate K1 = 0.023556601 Vf = 0.589465488

assume :

design for 85% flooding at maximum flow rate :

Un = %flooding x Uf

bottom Un = 0.323503459

distillate Un = 0.501045665

3. Column Diameter

1. Flow Rate

Number of stages / efficient stage

2. Physical Properties

maximum volumetrik flow rate : (mol x BM) / rho

bottom (m3/s) = 0.236554101

top (m3/s) = 0.487983574

Net area required : volume rate / Un

bottom (m2) = 0.731225879

distillate (m2) = 0.973930339

first trial = downcomer area as 12% of total

column cross-sectioned area :

bottom (m2) = 0.830938498

distillate (m2) = 1.106739021

column diameter :

bottom (m) = 1.028844196 tanyain bapak ini diameter apa ? Terus diameter tower itu yg mana

distillate (m) = 1.187374678

tinggi kolom = jumlah plate x tray spacing

tinggi kolom

Lm/Vm= 29.09502

Kpa

2.063

843.465

19.2 x 10

-3

3. Column Diameter

maximum volumetric liquid rate (m3/s) =

the column diameter is still unknown, but I assume that a double pass plate can be used

4. Liquid Flow Pattern 1. Flow Rate

2. Physical Properties

column diameter, Dc =

Column area, Ac=

Downcomer Area, Ad =

net area, An =

Active area, Aa = Ac-2Ad

Hole area, Ah (asumsi 10% dari Aa)

weir Length (fig.17.39) (mm)

Take weir height(mm)

hole diameter(mm)

6.Check Weeping

5. Provisional Plate Design

7. Plate Pressure Drop

8. Downcomer Liquid Backup

10.Trial Layout

tanyain bapak ini diameter apa ? Terus diameter tower itu yg mana

tinggi kolom = jumlah plate x tray spacing

tinggi kolom

11.Perforated area

12.Number Of Holes

13. Colum Height

9. check entrainment

0.016834

1.187374678

1.106739021

0.132808683 0.12

0.973930339

0.841121656

0.420560828

0.76

12

5

plate thickenes(mm) 5

Maximum liquid rate = 14.19869204

minimum liquid rate = 70%turndown 9.939084431

Maximum weir liquid crest, h ow (mm) 0.122652208

Minimum weir liquid crest, h ow (mm) 0.060099582

at minimum rate hw+h ow = 50.06009958

at.figure 11.32 , K2 = 30.3

Uh min 8.31294128

Dry Plate Drop

Maximum Vapor Velocity through holes :

Uh max (m/s) 0.562472978

from figure 17.42 for plate thickness/hole diameter=1 and Ah/Ap sebanding dengan Ah/Aa=0.1, Co=0,84

hd (mm liquid) = 0.055930293

Residual Head, hr (mm liquid) = 14.81982062

Total Plate Pressure Drop, ht (mm liquid) = 36.81483534

Downcomer Pressure Lose

Take hap = hw-10 = (mm) 40

area under apron, Aap (m2) 0.0304

As this is last than Ad, use Aap in equation 17.60

Hdc (mm) 50.90066643

Backup in downcomer, Hb (mm) 99.77560136 0.0997756

0,5 (Lt+Hw) 0.2124

0,16 m < 0,5 (Lt+Hw)

maximum volumetric liquid rate (m3/s) =

the column diameter is still unknown, but I assume that a double pass plate can be used

4. Liquid Flow Pattern

column diameter, Dc =

Column area, Ac=

Downcomer Area, Ad =

net area, An =

Active area, Aa = Ac-2Ad

Hole area, Ah (asumsi 10% dari Aa)

weir Length (fig.17.39) (mm)

Take weir height(mm)

hole diameter(mm)

6.Check Weeping

5. Provisional Plate Design

7. Plate Pressure Drop

8. Downcomer Liquid Backup

tray spacing is acceptable

Check Residence Time (second) 0.787171839

residence time kurang dari 3

uv (m/s) = 0.242886059

% flooding = uv/uf 75%

with Flv = 0,627 ; from fig 17.36,

fractional entrainment () =

0.75

at figure 11.34

lw/Dc = 0.6400675

c 82

angel subtended by the edge of the plate = 98

mean length,unperforated edge strips (m) 1.9444052

area of unperforated edge strips (m2) 0.0972203

mean length of calming zone , approx (m) 0.81

area of calming zone 0.081

total area for perforation Ap (m2) = (Aa-area of unperforated-area on calming) 0.6629014

Ah/Ap 0.6344244

From figure 11.35 lp/Dh 2.85

Area of One Hole (m2) 1.96E-05

Number of holes 2.14E+04

tinggi kolom = jumlah plate x tray spacing

18.59283719

11.Perforated area

12.Number Of Holes

13. Colum Height

9. check entrainment

7. Plate Pressure Drop

Das könnte Ihnen auch gefallen

- Presentation 2Dokument23 SeitenPresentation 2amandaNoch keine Bewertungen

- Komponen BM Kg/jam Kmol/jam Fraksi Mol: Umpan MasukDokument28 SeitenKomponen BM Kg/jam Kmol/jam Fraksi Mol: Umpan MasukBella Sherti VilesaNoch keine Bewertungen

- Horizontal SeparatorDokument64 SeitenHorizontal SeparatorKathleen RoldanNoch keine Bewertungen

- Composition of Feed, Top and Bottom and Relative Volatilities AreDokument20 SeitenComposition of Feed, Top and Bottom and Relative Volatilities AreGhazanfer AliNoch keine Bewertungen

- Distillation Column Design GuideDokument49 SeitenDistillation Column Design GuideMercy John71% (7)

- Distillation Column1Dokument49 SeitenDistillation Column1chaitanyavura0% (1)

- Drainage Design For Soroako - Port ChannelDokument13 SeitenDrainage Design For Soroako - Port ChannelEngDbt100% (2)

- DISTILLATION 2bDokument24 SeitenDISTILLATION 2bhusseinNoch keine Bewertungen

- Horizontal SeparatorDokument16 SeitenHorizontal SeparatorMaryJane Ayisha Sado-Obah100% (1)

- Distillation Column1Dokument49 SeitenDistillation Column1Nagwa MansyNoch keine Bewertungen

- Distillation ColumnDokument49 SeitenDistillation ColumnHardik SampatNoch keine Bewertungen

- Distillation Column1Dokument49 SeitenDistillation Column1prafulla1983100% (1)

- Distillation ColumnDokument49 SeitenDistillation ColumngenergiaNoch keine Bewertungen

- Annex 30 Tool - Design - Waste Stabilization PondsDokument8 SeitenAnnex 30 Tool - Design - Waste Stabilization Pondsmurkeking100% (1)

- Distillation Tower - Rectification SectionDokument4 SeitenDistillation Tower - Rectification SectionKvspavan KumarNoch keine Bewertungen

- Distillation Column 2 Final RevisedDokument27 SeitenDistillation Column 2 Final RevisedfjdmejiaNoch keine Bewertungen

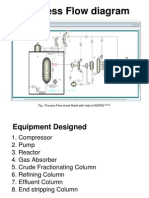

- Process Flow Diagram: Fig: Process Flow Sheet Made With Help of ASPENDokument42 SeitenProcess Flow Diagram: Fig: Process Flow Sheet Made With Help of ASPENSwarnim RajNoch keine Bewertungen

- Design Calculations of Distillation ColuDokument25 SeitenDesign Calculations of Distillation ColuDHEERESH KUMARNoch keine Bewertungen

- Dist Col Cal.Dokument9 SeitenDist Col Cal.MayurShindeNoch keine Bewertungen

- Chlorobenzene Design 2520of 2520equipmentsDokument44 SeitenChlorobenzene Design 2520of 2520equipmentsElizabeth Patrick100% (2)

- Distillation ColumnDokument16 SeitenDistillation ColumnSatya Narayan SharmaNoch keine Bewertungen

- Domestic Water Booster Pump CalculationsDokument26 SeitenDomestic Water Booster Pump CalculationsAnonymous BJ9omO100% (10)

- HCL Scrubber DesignDokument5 SeitenHCL Scrubber DesignManish0301198375% (4)

- Distillation Column DesignDokument67 SeitenDistillation Column Designrajindo1Noch keine Bewertungen

- HX Design v1Dokument12 SeitenHX Design v1mansourotaibiNoch keine Bewertungen

- Cumene Design 2520of 2520equipmentsDokument72 SeitenCumene Design 2520of 2520equipmentsG Vamsee KrishnaNoch keine Bewertungen

- Ethyleneglycol Design 2520of 2520equipmentsDokument41 SeitenEthyleneglycol Design 2520of 2520equipmentsHardik Gandhi100% (1)

- Calculation and Design of Packed Column For AcidDokument14 SeitenCalculation and Design of Packed Column For AcidDavid LambertNoch keine Bewertungen

- Calculation of Air Duct Pressure Loss (Rectangular)Dokument15 SeitenCalculation of Air Duct Pressure Loss (Rectangular)Phyu Mar Thein KyawNoch keine Bewertungen

- Stair Case Pressurization Calculation - Class ADokument8 SeitenStair Case Pressurization Calculation - Class ALarry Bea100% (4)

- Bell Method Example 7 5Dokument9 SeitenBell Method Example 7 5Amin FarukiNoch keine Bewertungen

- Divinylbenzene Equipment DesignDokument20 SeitenDivinylbenzene Equipment DesignMehul DeshpandeNoch keine Bewertungen

- From Table We KnowDokument5 SeitenFrom Table We KnowTaha ZakiNoch keine Bewertungen

- Siphon Sizing 2 PDFDokument6 SeitenSiphon Sizing 2 PDFNugrahaNoch keine Bewertungen

- Siphon - Sizing 6 PDokument6 SeitenSiphon - Sizing 6 PJaber Osmani100% (1)

- Design A Distillation Column With A Total Condenser and Partial Re Boiler For The Following SeparationDokument41 SeitenDesign A Distillation Column With A Total Condenser and Partial Re Boiler For The Following SeparationSihanu Subasingha100% (1)

- Distillation DesignDokument18 SeitenDistillation DesignViswanath KapavarapuNoch keine Bewertungen

- Air Exchanger TDDokument9 SeitenAir Exchanger TDRajput PratiksinghNoch keine Bewertungen

- Distillation Column DesignDokument27 SeitenDistillation Column DesignManisha DeenaNoch keine Bewertungen

- 1) Flow: 239869283.xls - Ms - Office Piping Pressure Drop and Pump Design Calculation SheetDokument4 Seiten1) Flow: 239869283.xls - Ms - Office Piping Pressure Drop and Pump Design Calculation SheetHemantk8731100% (1)

- CalculationDokument8 SeitenCalculationmahaveenNoch keine Bewertungen

- Water Supply Scheme DesignDokument19 SeitenWater Supply Scheme DesignOladunni Afolabi100% (1)

- Primary TreatmentDokument22 SeitenPrimary TreatmentEmil AbdoNoch keine Bewertungen

- Zentiva DataDokument19 SeitenZentiva DataJay Sheth9Noch keine Bewertungen

- Grit Removal DesignDokument5 SeitenGrit Removal Designnassif75Noch keine Bewertungen

- Preliminiary TreatmentDokument22 SeitenPreliminiary TreatmentIsmail toro100% (1)

- Scrubber Design SheetDokument11 SeitenScrubber Design Sheetganeshdhage100% (1)

- Perancangan Plate Adn Frame HEDokument36 SeitenPerancangan Plate Adn Frame HEDavid LambertNoch keine Bewertungen

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportVon EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNoch keine Bewertungen

- Dictionary of Textile Finishing: Deutsch/Englisch, English/GermanVon EverandDictionary of Textile Finishing: Deutsch/Englisch, English/GermanBewertung: 1.5 von 5 Sternen1.5/5 (3)

- Numerical Methods for Simulation and Optimization of Piecewise Deterministic Markov Processes: Application to ReliabilityVon EverandNumerical Methods for Simulation and Optimization of Piecewise Deterministic Markov Processes: Application to ReliabilityNoch keine Bewertungen

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsVon EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNoch keine Bewertungen

- Understanding Process Equipment for Operators and EngineersVon EverandUnderstanding Process Equipment for Operators and EngineersBewertung: 4.5 von 5 Sternen4.5/5 (3)

- O level Physics Questions And Answer Practice Papers 3Von EverandO level Physics Questions And Answer Practice Papers 3Bewertung: 3 von 5 Sternen3/5 (1)

- Koleksi KnifeDokument22 SeitenKoleksi KnifeArif Kartawana ShiddiqNoch keine Bewertungen

- 471 Energy Balance 10-05Dokument13 Seiten471 Energy Balance 10-05Emanoel FrazãoNoch keine Bewertungen

- Determine The Time Required For 80% ConversionDokument3 SeitenDetermine The Time Required For 80% ConversionArif Kartawana ShiddiqNoch keine Bewertungen

- Pengendalian Proses PDFDokument2 SeitenPengendalian Proses PDFArif Kartawana ShiddiqNoch keine Bewertungen

- Lesson 2 - Fractional DistillationDokument5 SeitenLesson 2 - Fractional DistillationAditya ShyamsunderNoch keine Bewertungen

- Raghavan Calculation NewDokument143 SeitenRaghavan Calculation NewDHAVALESH AMNoch keine Bewertungen

- An Industrial and Academic Perspective On Plantwide Control: James J. Downs . Sigurd SkogestadDokument12 SeitenAn Industrial and Academic Perspective On Plantwide Control: James J. Downs . Sigurd SkogestadFaris HartonoNoch keine Bewertungen

- Distillation Non IdealDokument11 SeitenDistillation Non IdealKashif RiazNoch keine Bewertungen

- Jasmine Beckles - Lab#10 Food TestDokument4 SeitenJasmine Beckles - Lab#10 Food Testjasmine becklesNoch keine Bewertungen

- BiodieselDokument76 SeitenBiodieselprash_13Noch keine Bewertungen

- Astm D396Dokument6 SeitenAstm D396dennise8100% (2)

- Construction and Evaluation of Composite Boards Made From High Density Polyethylene and Corn (Dokument51 SeitenConstruction and Evaluation of Composite Boards Made From High Density Polyethylene and Corn (Kristine Erica BaculodNoch keine Bewertungen

- Guidelines For SCP For Animal Feed IupacDokument23 SeitenGuidelines For SCP For Animal Feed IupacWambaNoch keine Bewertungen

- Gen Chem 1 Q1Mod1Dokument23 SeitenGen Chem 1 Q1Mod1Joselito UbaldoNoch keine Bewertungen

- United States Patent (10) Patent No.: US 8.481.295 B2Dokument37 SeitenUnited States Patent (10) Patent No.: US 8.481.295 B2Reva DeddyNoch keine Bewertungen

- Ransom & Randolph - Jewelry Casting - Investing FAQsDokument2 SeitenRansom & Randolph - Jewelry Casting - Investing FAQsGabrielNoch keine Bewertungen

- Sipawards 2019 ResultsDokument81 SeitenSipawards 2019 Resultsadrian fotacheNoch keine Bewertungen

- Sparkling Cocktails Martini Cocktails: With Lime and MintDokument2 SeitenSparkling Cocktails Martini Cocktails: With Lime and MintKnotsNoch keine Bewertungen

- Santa Monica College Chem 22 Lab ManualDokument59 SeitenSanta Monica College Chem 22 Lab ManualMide Ogundipe100% (1)

- Production Internship Project Report On Multifeed Distillery Plant Based On Rice/Grains As Raw MaterialDokument21 SeitenProduction Internship Project Report On Multifeed Distillery Plant Based On Rice/Grains As Raw MaterialMeghana SNoch keine Bewertungen

- Response Surface Modeling and Optimization of Direct Contact Membrane Distillation For Water DesalinationDokument15 SeitenResponse Surface Modeling and Optimization of Direct Contact Membrane Distillation For Water DesalinationYesid Tapiero MartínezNoch keine Bewertungen

- Secrets of Manufacturer SAFROLEDokument46 SeitenSecrets of Manufacturer SAFROLEcourtzp100100% (9)

- Key - 1157854 - 2023-10-11 10 - 56 - 19 +0000Dokument19 SeitenKey - 1157854 - 2023-10-11 10 - 56 - 19 +0000paaryan2624Noch keine Bewertungen

- ASPEN Tutorial - Chemical ReactorsDokument4 SeitenASPEN Tutorial - Chemical ReactorsShah MhNoch keine Bewertungen

- Elements, Compounds and Mixtures PowerpointDokument13 SeitenElements, Compounds and Mixtures PowerpointMaxime Van ElslanderNoch keine Bewertungen

- Engeniero Methanol Task 1&2Dokument61 SeitenEngeniero Methanol Task 1&2sasi100% (1)

- HULtdDokument23 SeitenHULtdDeepanjali KushwahaNoch keine Bewertungen

- Chemical Process Design and Optimization: Chapter 3a - Separation Train SynthesisDokument26 SeitenChemical Process Design and Optimization: Chapter 3a - Separation Train SynthesisLam DesmondNoch keine Bewertungen

- Moisture and Total Solids Analysis: Importance of Moisture AssayDokument7 SeitenMoisture and Total Solids Analysis: Importance of Moisture AssayNaveed Ul HasanNoch keine Bewertungen

- BarSmarts Workbook Final 1540824237528Dokument126 SeitenBarSmarts Workbook Final 1540824237528Shubham bisht67% (6)

- Abc VaDokument58 SeitenAbc VaParth PatelNoch keine Bewertungen

- HR Interview QuestionsDokument23 SeitenHR Interview QuestionsJay Maradiya100% (4)

- AcetamideDokument4 SeitenAcetamidejolouisNoch keine Bewertungen

- Praj Sweet SorghumDokument17 SeitenPraj Sweet SorghumRajeshMorghe100% (1)