Beruflich Dokumente

Kultur Dokumente

Operation HD785-7 Guidebook: Controls, Displays, and System Checks

Hochgeladen von

Sang Sang BaronganOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Operation HD785-7 Guidebook: Controls, Displays, and System Checks

Hochgeladen von

Sang Sang BaronganCopyright:

Verfügbare Formate

Operation HD785-7

Operation

HD785-7

Page 2/51 Operation HD785-7

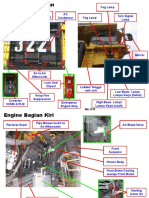

GENERAL VIEW

Page 3/51 Operation HD785-7

GENERAL VIEW OF CONTROLS AND GAUGES

Page 4/51 Operation HD785-7

CHARACTER DISPLAY

Page 5/51 Operation HD785-7

CHARACTER DISPLAY

SERVICE METER/ODOMETER

Even if the starting switch is at the OFF

position, the service meter will display as

long as the top part ( ) of machine monitor

mode selector switch 1 is being pressed.

USER MODE

REVERSE TRAVEL ODOMETER

RESET METHOD FOR FILTER, OIL

REPLACEMENT TIME

1. Press the ( ) of machine monitor mode

selector switch 1, and display the reverse

travel in odometer.

2. Press (>) or (<) of machine monitor mode

selector switch 2 and display

"MAINTENANCE MONITOR".

Page 6/51 Operation HD785-7

CHARACTER DISPLAY

3. Press the ( ) of machine monitor mode

selector switch 1.

4. Press (>) or (<) of machine monitor mode

selector switch 2 and display the item to be

reset.

5. Press the ( ) of machine monitor mode

selector switch 1.

6. When resetting the replacement time,

press (>) or (<) of machine monitor mode

selector switch 2, align the cursor with

YES, then press ( )

Page 7/51 Operation HD785-7

CHARACTER DISPLAY

METHOD FOR SELECTING LANGUAGE

1. Press the ( ) of machine monitor mode

selector switch 1 and display the reverse

travel odometer.

2. Press (>) or (<) of machine monitor mode

selector switch 2 and display "LANGUAGE".

3. Press the ( ) of machine monitor mode

selector switch 1. The presently selected

language is displayed.

4. Press (>) or (<) of machine monitor mode

selector switch 2 and select the language.

5. When the ( ) of machine monitor mode

selector switch 1 is pressed, the language is

set and the screen returns to the previous

screen.

Page 8/51 Operation HD785-7

CHARACTER DISPLAY

INPUT METHOD FOR TELEPHONE NUMBER

1. Press (>) or (<) of machine monitor mode

selector switch 2 and display "TEL".

2. Press ( ) of machine monitor mode selector

switch 1. It will change to the display in the

diagram on the right.

3. Up to 12 digits can be displayed for the

telephone number.

Input from the first digits.

The cursor is displayed at the input position.

Press (>) or (<) of machine monitor mode

selector switch 2 and display "0 - 9 ".

To leave a blank, select "*".

When the input value is decided, press ( ) of

machine monitor mode selector switch 1. The

cursor will move to the next position.

4. Repeat the procedure in Step 4 until the last

digit. At the last digit, press ( )

5. When completing the operation, press ( )

Page 9/51 Operation HD785-7

CHARACTER DISPLAY

METHOD OF SWITCHING BETWEEN RL AND RH

1. Press (>) or (<) of machine monitor mode

selector switch 2 to display "SELECT RL RH"

or "SELECT RH RL".

2. Press ( ) of machine monitor mode selector

switch 1. RL or RH is selected

3. When completing the operation, press ( )

ACTION CODE DISPLAY

-During Engine Running-

When action codes E02 or E03 occur, the alarm

buzzer sounds intermittently and the central

warning lamp lights up.

E03: When this code is displayed, stop the machine

immediately, check the failure code, and contact

your Komatsu distributor for repairs.

Page 10/51 Operation HD785-7

CHARACTER DISPLAY

E02: If overrun related information is displayed,

reduce the engine speed and the speed of the

machine while continuing operations.

E01: If maintenance location is displayed and

the maintenance caution lamp lights up, carry

out inspection and maintenance of the displayed

item after the completion of operations or when

the shift changes.

FILTER, OIL REPLACEMENT TIME DISPLAY

After completion of the system check, this

display (5) shows for 30 seconds the filters and

oil which are near the replacement interval.

The maintenance caution lamp also flashes or

lights up at the same time.

Page 11/51 Operation HD785-7

CHARACTER DISPLAY

Items for display of filter, oil replacement time

Page 12/51 Operation HD785-7

CAUTION ITEMS

Page 13/51 Operation HD785-7

EMERGENCY STOP ITEM

Page 14/51 Operation HD785-7

EMERGENCY STOP ITEM

CENTRAL WARNING LAMP

ENGINE WATER TEMPERATURE CAUTION

LAMP

"E02 ENGINE OVERHEAT

TORQUE CONVERTER OIL TEMPERATURE

CAUTION LAMP

"E02 TC OVERHEAT"

RETARDER OIL TEMPERATURE CAUTION

LAMP

"E02 BRAKE OVERHEAT"

Page 15/51 Operation HD785-7

EMERGENCY STOP ITEM

BATTERY CHARGE CIRCUIT CAUTION LAMP

"E03 CHECK RIGHT NOW"

STEERING OIL TEMPERATURE CAUTION LAMP

"E02 STRG OVERHEAT

ENGINE OIL PRESSURE CAUTION LAMP

"E03 CHECK RIGHT NOW

BRAKE OIL PRESSURE CAUTION LAMP

"E03 CHECK RIGHT NOW"

Page 16/51 Operation HD785-7

EMERGENCY STOP ITEM

TILT CAUTION LAMP

This monitor (8) lights up if the dump body has

left its seat when the

rear frame of the machine has tilted beyond the

safety range to the

left or right.

MACHINE MONITOR, OPTION SYSTEM

CAUTION LAMP

"E03 CHECK RIGHT NOW"

ENGINE SYSTEM CAUTION LAMP

"E03 CHECK RIGHT NOW"

TRANSMISSION SYSTEM CAUTION LAMP

"E03 CHECK RIGHT NOW"

RETARDER SYSTEM CAUTION LAMP

"E03 CHECK RIGHT NOW"

Page 17/51 Operation HD785-7

PILOT DISPLAY PORTION

Page 18/51 Operation HD785-7

PILOT DISPLAY PORTION

ENGINE PRE-HEATING PILOT LAMP

When the starting switch is turned to the ON position

in cold weather.

RETARDER PILOT LAMP

Lights up when the retarder control lever is pulled and

the retarder is actuated.

LOCKUP PILOT LAMP

Lights up when the torque converter lockup is

engaged and the transmission is shifted to direct drive.

HEAD LAMP HIGH BEAM PILOT LAMP

lights up when the head lamps are set to high beam.

TURN SIGNAL PILOT LAMP

Flashes at the same time as the turn signal lamp

flashes.

Page 19/51 Operation HD785-7

PILOT DISPLAY PORTION

SHIFT INDICATOR

Shows the transmission shift range (speed range).

SHIFT LEVER POSITION PILOT LAMP

Displays the position of the shift lever.

The letter or number for the speed range selected

by the shift lever

lights up.

POWER MODE PILOT LAMP

Displays the power mode.

This monitor lights up when the high power mode is

used.

AUTO SUSPENSION MODE PILOT LAMP

(If equipped)

H : Hard mode

M : Medium mode

S : Soft mode

Page 20/51 Operation HD785-7

PILOT DISPLAY PORTION

AUTO RETARDER SET SPEED INDICATOR

Displays the set travel speed for the auto

retarder speed control (ARSC).

AUTO RETARDER READY PILOT LAMP

Shows that the auto retarder speed control can

be actuated at the set travel speed.

EXHAUST BRAKE PILOT LAMP

(If equipped)

Lights up when the exhaust brake is applied.

Page 21/51 Operation HD785-7

METERS

Page 22/51 Operation HD785-7

SWITCHES

Page 23/51 Operation HD785-7

SWITCHES

MACHINE MONITOR BULB CHECK SWITCH

Turn the starting switch ON, press this switch (3) and check for any

blown bulbs.

POWER MODE SELECTOR SWITCH

When the switch is pressed, the mode switches to high power

mode and the high power mode pilot lamp on the machine monitor

lights up.

If the switch is pressed again, the mode returns to the economy

mode and the power mode pilot lamp on the machine monitor goes

out.

When the engine is started, the economy mode is selected

automatically.

High power mode

Operates at maximum output.

Economy mode (general operations)

Use this for operations under general standard conditions.

Page 24/51 Operation HD785-7

SWITCHES

EMERGENCY STEERING SWITCH

When the switch is pressed, the emergency pump is actuated to

make it possible to operate the steering.

When the switch is ON, the pilot lamp (red) inside the switch and

the pilot lamp on the machine monitor light up.

The emergency steering pump can be used for a maximum of 90

seconds.

When the emergency steering is being used, keep the travel speed

to a maximum of 5 km/h (3.1 MPH).

On machines equipped with auto emergency steering, the auto

emergency steering is actuated automatically in the

following cases.

When the steering hydraulic pump fails

When the engine has stopped during operation

When the emergency steering is actuated, stop the machine

promptly and perform inspection.

If the starting switch is at the ON position and the parking brake

switch is at the TRAVEL position when the machine is stopped, the

automatic emergency steering is actuated after 1 second, so set the

parking brake switch to the PARKING position.

Page 25/51 Operation HD785-7

SWITCHES

MACHINE MONITOR MODE SELECTOR SWITCH 1, 2

This switch (16) is used to operate the character display.

Page 26/51 Operation HD785-7

CONTROL LEVERS AND PEDALS

Page 27/51 Operation HD785-7

CONTROL LEVERS AND PEDALS

GEAR SHIFT LEVER

R position:

RL: Select this when high rimpull is needed.

RH: Select this when travel speed is needed.

Page 28/51 Operation HD785-7

CONTROL LEVERS AND PEDALS

DUMP LEVER

A) RAISE

B) HOLD: The dump body stops and is held in

position.

C) FLOAT: The dump body moves freely under

external force.

D) LOWER

RETARDER CONTROL LEVER

DUMP LEVER LOCK KNOB

SECONDARY BRAKE PEDAL

It is possible to apply the parking brake with

this pedal.

Use this brake pedal if the brake pedal is

damaged or there is any other problem and

the wheel brakes do not work.

As a emergency brake.

Page 29/51 Operation HD785-7

CHECK BEFORE STARTING

1. CHECK COOLANT LEVEL, ADD COOLANT

2. CHECK DUST INDICATOR

Page 30/51 Operation HD785-7

CHECK BEFORE STARTING

3. CHECK OIL LEVEL IN ENGINE OIL PAN, ADD OIL

4. CHECK OIL LEVEL IN TRANSMISSION CASE,

ADD OIL

5. CHECK OIL LEVEL IN STEERING AND HOIST OIL

TANK, ADD OIL

Page 31/51 Operation HD785-7

CHECK BEFORE STARTING

6. CHECK OIL LEVEL IN BRAKE SUB-TANK,

ADD OIL

7. CHECK FOR LEAKAGE OF OIL FROM

BRAKE OIL RECOVERY TANK

Front & Rear

8. DRAIN WATER, SEDIMENT FROM FUEL

TANK

Page 32/51 Operation HD785-7

CHECK BEFORE STARTING

9. DRAIN WATER FROM FUEL PRE-FILTER

10. CHECK WATER SEPARATOR, DRAIN

WATER AND SEDIMENT

Page 33/51 Operation HD785-7

CHECK BEFORE STARTING

11. CHECK FUEL LEVEL, ADD FUEL

Fuel tank capacity: 1300 liters (343.46 US gal)

12. CHECK WHEEL HUB NUTS, TIGHTEN

Tightening torque: 1519 to 1852 Nm

{155 to 189kgfm, 1121 to 1367 lbft}

13. CHECK CENTRAL WARNING LAMP, ALARM

BUZZER, MONITOR LAMPS AND METERS

Press machine monitor check switch (1)

Page 34/51 Operation HD785-7

CHECK BEFORE STARTING

14. CHECK BRAKING CAPACITY OF SECONDARY

BRAKE

Check the braking capacity of the secondary brake

as follows.

1. Stop the machine on flat ground, raise the oil

pressure to the maximum, set the parking brake to

TRAVEL, then depress secondary brake pedal (1).

( emergency brake )

2. Set gear shift lever (2) to the D position, gradually

raise the engine speed, and check that the machine

does not move even when the engine reaches full

speed. If the machine does not move, it is normal.

15. CHECK EMERGENCY STEERING

CHECK EMERGENCY STEERING

1. Turn starting switch key to the ON position.

2. Turn emergency steering switch (1) ON, and check

that the steering wheel can be operated.

If the steering wheel cannot be operated, please

contact your Komatsu distributor.

Page 35/51 Operation HD785-7

CHECK BEFORE STARTING

16. CHECK BACKUP ALARM

1. Turn the engine starting switch to the ON position.

2. Place the gear shift lever in the R position and check

that the backup alarm is working.

17. CHECK ELECTRIC WIRING

18. CHECK INFLATION PRESSURE OF TIRES

Measure the inflation pressure with a tire pressure

gauge, while the tires are cool, before starting work.

Check for damage or wear to the tires and the rims.

Check for loose wheel hub bolts.

Front wheel and rear wheel

19. DOES BODY POSITIONER OPERATE NORMALLY?

Page 36/51 Operation HD785-7

ARCS (Automatic Retarder Speed Controller)

Page 37/51 Operation HD785-7

TROUBLESHOOTING

AFTER RUNNING OUT OF FUEL

1. Fill the fuel tank with fuel.

2. Loosen air bleeding plug (2) at the fuel main

filter head.

3. Loosen wing bolt (4) which is fixing lever (5)

of priming pump (3). Move lever (5) up and

down to let fuel flow out of air bleeding plug

(2) until bubbles do not come out any more.

4. Tighten air bleeding plug (1) and then tighten

wing bolt (3) of priming pump (2) securely to

lock lever (4).

Page 38/51 Operation HD785-7

TROUBLESHOOTING

Emergency Disposal

IF TRANSMISSION HAS TROUBLE

1. Decelerate the machine with the brake and

stop it on a safe place.

2. Set the shift lever to the N position, then set

the parking brake switch to the PARKING

position.

3. In some trouble modes, the gear is not

shifted even if the shift lever is operated.

In this case, perform the following procedure.

1) Remove emergency escape connector (1)

(No. A-1F, A-M, white 1-pin connector), then

insert it again.

2) Set the parking brake switch to the TRAVEL

position.

3) Operate the shift lever to move the machine

to a safe place without depressing the

accelerator pedal.

Page 39/51 Operation HD785-7

TROUBLESHOOTING

Emergency Disposal

METHOD OF LOWERING DUMP BODY IN

EMERGENCY

1. Remove hydraulic tank cap (F) and release

the remaining pressure in the hoist circuit

2. Loosen locknut (2) of manual lower valve (1).

3. Turn grip (3) of valve (1) counterclockwise.

The oil in the hoist cylinder is drained into the

hydraulic tank and the dump body lowers.

4. Tighten grip (3) and locknut (2).

Page 40/51 Operation HD785-7

TROUBLESHOOTING

Emergency Disposal

WHEN PARKING BRAKE HAS BEEN ACTUATED IN EMERGENCY

If the pressure in the hydraulic circuit goes down abnormally because of oil

leakage or some other cause, the parking brake is automatically applied.

It is necessary to tow or move the machine, the parking brake must be

released. Release the parking brake as follows.

METHOD OF RELEASING PARKING BRAKE IN EMERGENCY

1. When releasing the parking brake manually, prepare 34 M16 (80-95mm (3.2 -

3.7 in) below head, pitch 2.0mm (0.079 in) (flat)) bolts and M16 washers each.

2. Prepare a container to catch the oil.

3. Stop the engine.

4. Put blocks under the wheels.

5. Set the container to catch the oil under

the brake portion.

6. Remove plug (1) from the rear axle brake portion.

Remove plug (2) from the axle brake portion.

There are 9 plugs on the right side and 9 plugs

on the left side.

REAR

FRONT

Page 41/51 Operation HD785-7

WHEN PARKING BRAKE HAS BEEN ACTUATED IN

EMERGENCY [No.1]

Rear

18M16 bolts (distance under head:85 to 95 mmthread pitch:2 mm

18M16 washers

Front

16M16 bolts (distance under head:80 to 90 mmthread pitch:2 mm

16M16 washers

REMARK

There are 9 plugs on the right and left side. (Rear)

There are 8 plugs on the right and left side. (Front)

REAR FRONT

Releasing of Parking Brake Manually

Page 42/51 Operation HD785-7

WHEN PARKING BRAKE HAS BEEN ACTUATED IN

EMERGENCY [No.2]

Rear Pull up parking brake piston

Parking Brake Piston

Service Brake Piston

Front Pull up parking brake piston

Service Brake Piston

Parking Brake Piston

(ref.HD465-7)Pull up

Foot brake piston

Service brake piston Parking brake piston

Page 43/51 Operation HD785-7

EXPLANATION OF COMPONENTS

SPECIFICATIONS

Page 44/51 Operation HD785-7

HANDLING AUTOMATIC SPIN REGULATOR (ASR) (OPTION)

ASR is a function to prevent slipping of the drive wheels caused by excessive

torque. Accordingly, the machine can

start and travel normally even on a bad or frozen road surface.

EXPLANATION OF COMPONENTS

ASR SWITCH

This switch (1) turn to the ASR system ON/OFF.

(A): ASR system ON

(B): ASR system OFF

Page 45/51 Operation HD785-7

HD785-7 Main Different & Cautioning Points of

Maintenance compared with HD785-5

1. Initial 250H Engine Oil Change become no need

2. Suspention Oil : More heat resistance type [ HO-MVK ]

3. Initial 250H Service Additiononal Items when replacing T/M, Brake Oil Sub tank at

Initial 250H

3-1: Bleed Air from Front and Rear Brake and Parking Brake,

Every 250H

1. Check Brake Accumulator Function

Check the drop of accumulator Pressure of Service Brake, Emergency Brake,

Retarder Brake Procedure

A: Start the Engine and run it at midium Speed for 1 (one) minute, and then Stop it.

B: Turn the startion switch to the ON position and depress Brake Pedal 4 (four times),

If the Brake pressure caution lamp lights up, the Gas pressure may be low.

Page 46/51 Operation HD785-7

HD785-7 Main Different & Cautioning Points of

Maintenance compared with HD785-5

Every 500H Service

1. Fuel Pre Filter Cartridge Replacement

Every 1000H Service

1. Change oil in Brake Sub Tank

2. Replace Fuel Main Filter Cartridge - It is prohibited to fill

in Fuel in Main Fuel Filter with Hands (Use Priming

Pump)

Every 2000H Service

1. Check Accumulator Gas Check (Cut In and Cut Out

Pressure Check)

Every 8000H

1. Replace Fuel Spray Prevention Cap

Every 15000H Service

Check Replace Steering A Arm Mounting Bolts and Lock

Plate

Check, replace steering a

arm mounting bolt

Page 47/51 Operation HD785-7

HANDLING ABS (OPTION)

The ABS (anti-skid brake system) is a brake system that ensures the steering ability

and stable machine posture.

It works by automatically suppressing the skidding caused by the wheels locking

when the brakes are applied

suddenly or are applied on snow-covered roads or other slippery road surfaces.

EXPLANATION OF COMPONENTS

ABS MAIN SWITCH

The switch (1) is used to turn the ABS system ON/OFF.

(A): ABS system ON

(B): ABS system OFF

Page 48/51 Operation HD785-7

HANDLING PAYLOAD METER (VHMS BUILT-IN TYPE)

(OPTION)

Payload display

External display lamps

There is display lamps at Left side also.

Download connector inside cab

(end marked PLM)

Download connector outside cab

(end marked PLM)

Page 49/51 Operation HD785-7

EXTERNAL DISPLAY LAMPS (OPTION)

The external lamps display the payload as follows.

Page 50/51 Operation HD785-7

PERFORMING CALIBRATION (OPTION)

Carry out calibration at the following occasions.

When the machine or payload meter are

received

Once every month

When the suspension cylinder gas pressure

and oil amount have been adjusted (when the

suspension has been adjusted)

When the suspension pressure sensor has

been replaced

When the machine has been modified and the

weight of the machine when empty has changed

more than 100kg (221 lb)

Drive the machine at a speed of 10 km/h (6.2

MPH). When the travel speed becomes stable,

press the ( ) of machine monitor selector

switch 1 (1) and display CALIBRATION. The

word CALIBRATION flashes two or three times,

and then the display on the right is given.

(1) ( )

(2) ( > )

Page 51/51 Operation HD785-7

END OF

Operation

Das könnte Ihnen auch gefallen

- John Titor TIME MACHINEDokument21 SeitenJohn Titor TIME MACHINEKevin Carey100% (1)

- Komatsu Hd785-7 Rigid Dump TrucksDokument20 SeitenKomatsu Hd785-7 Rigid Dump Truckswahyu100510Noch keine Bewertungen

- Basic Trouble Shooting KomatsuDokument40 SeitenBasic Trouble Shooting Komatsuphankhoa83Noch keine Bewertungen

- 02 d155 Monitoring ModeDokument51 Seiten02 d155 Monitoring Modeghitacrainic100% (7)

- HITACHI - EX1200-6 - Technical Manual Operational - TO18J-E-00Dokument314 SeitenHITACHI - EX1200-6 - Technical Manual Operational - TO18J-E-00George Zormpas75% (12)

- 785-5 Instrument Familiarization & AssessmentDokument61 Seiten785-5 Instrument Familiarization & AssessmentCrispin Cris Nspm100% (1)

- Cat EngineDokument94 SeitenCat Enginejoshuadelapava100% (1)

- QRF HD785-7Dokument2 SeitenQRF HD785-7Ralf MaurerNoch keine Bewertungen

- 14m16m Motor GraderDokument139 Seiten14m16m Motor GraderClaudia Marques100% (8)

- 785 - 789Dokument75 Seiten785 - 789MACHINERY101GEAR100% (3)

- CAT Dump 777EDokument4 SeitenCAT Dump 777Edunglx100% (3)

- Manual Power Train Caterpillar 777d Off Highway Truck ComponentsDokument46 SeitenManual Power Train Caterpillar 777d Off Highway Truck ComponentsDarmawan Putranto88% (25)

- SM HD785-7 Sen01274-14Dokument1.815 SeitenSM HD785-7 Sen01274-14Lucio Valderrama100% (2)

- Catalogo 2 777DDokument79 SeitenCatalogo 2 777DEdith RiosNoch keine Bewertungen

- 777F - Serv1828 - TXTDokument272 Seiten777F - Serv1828 - TXTalexander_198575% (4)

- 777F OEM Off-Highway Truck-Maintenance IntervalsDokument91 Seiten777F OEM Off-Highway Truck-Maintenance IntervalsJoel Rodríguez100% (1)

- Cat 797BDokument28 SeitenCat 797BForomaquinas100% (7)

- HD785 7 2007nov18 Compacted 51902Dokument118 SeitenHD785 7 2007nov18 Compacted 51902Jheison Valencia100% (2)

- Global Service Learning: 777F (JRP) Off-Highway TrucksDokument79 SeitenGlobal Service Learning: 777F (JRP) Off-Highway TrucksManuel Pompa Flores100% (2)

- Caterpillar Monitoring System DashboardDokument41 SeitenCaterpillar Monitoring System DashboardAlejandro Alberto Robalino Mendez100% (1)

- 06 HoistDokument15 Seiten06 HoistBorishnicob100% (4)

- Cat 16M Motor Grader PDFDokument28 SeitenCat 16M Motor Grader PDFAzizul Kamarudin100% (1)

- 16M Motor Grader-Maintenance IntervalsDokument62 Seiten16M Motor Grader-Maintenance IntervalsJuan Amanqui Garcia100% (3)

- Shop Manual HD 785-7 SEN01274-03 PDFDokument1.437 SeitenShop Manual HD 785-7 SEN01274-03 PDFLuisAlbertoVerdejoTapia80% (10)

- 773EDokument31 Seiten773EWilliams ArayaNoch keine Bewertungen

- Shop Manual HD 785-7Dokument1.821 SeitenShop Manual HD 785-7munh100% (7)

- Control Elements of the ShredderDokument18 SeitenControl Elements of the Shredderpurushmicro100% (1)

- HD1500-7 Introduction & General Service PDFDokument122 SeitenHD1500-7 Introduction & General Service PDFanggie100% (2)

- KOMPONEN - HD785-7 SippDokument23 SeitenKOMPONEN - HD785-7 Sippziky dun100% (1)

- HD785-5 Shop Manual PDFDokument1.332 SeitenHD785-5 Shop Manual PDFSON100% (2)

- Shop Manual HD785-7 (Japones)Dokument1.491 SeitenShop Manual HD785-7 (Japones)Antonio Hernández Mendieta91% (11)

- HD785 Sensor Limitations and Fault CodeDokument53 SeitenHD785 Sensor Limitations and Fault CodeMohan Preeth100% (4)

- 777d PDFDokument24 Seiten777d PDFrodizianoNoch keine Bewertungen

- 02 HD785-7 Presentation For Pama All 06may15Dokument20 Seiten02 HD785-7 Presentation For Pama All 06may15Bima Dwi Utomo83% (6)

- COH Hoist System Component Location and OperationDokument21 SeitenCOH Hoist System Component Location and OperationFata AlbanaNoch keine Bewertungen

- 777D Off Highway Truck: Service Training MalagaDokument46 Seiten777D Off Highway Truck: Service Training Malagajose10001100% (4)

- D155a-6 Omm Pen00319-00Dokument343 SeitenD155a-6 Omm Pen00319-00Sang Sang Barongan88% (17)

- D155a-6 Omm Pen00319-00Dokument343 SeitenD155a-6 Omm Pen00319-00Sang Sang Barongan88% (17)

- D155a-6 Omm Pen00319-00Dokument343 SeitenD155a-6 Omm Pen00319-00Sang Sang Barongan88% (17)

- 773 e Part BookDokument912 Seiten773 e Part Bookeko sunaryo100% (3)

- 3508 Valve Setting Task SheetDokument4 Seiten3508 Valve Setting Task Sheetrizqi mubarak50% (2)

- 777 2 PDFDokument280 Seiten777 2 PDFAlif Yunis S100% (2)

- Komatsu HD785-7Dokument20 SeitenKomatsu HD785-7Muhammad FattahNoch keine Bewertungen

- Fiat Spider 2000 Owners ManualDokument68 SeitenFiat Spider 2000 Owners ManualWilliam Rios80% (5)

- Product Bulletin: Cat 777D Off-Highway TrucksDokument36 SeitenProduct Bulletin: Cat 777D Off-Highway TrucksDipendra BhattacharyaNoch keine Bewertungen

- A Cat.740 ArticDokument20 SeitenA Cat.740 ArticSang Sang BaronganNoch keine Bewertungen

- A Cat.740 ArticDokument20 SeitenA Cat.740 ArticSang Sang BaronganNoch keine Bewertungen

- A Cat.740 ArticDokument20 SeitenA Cat.740 ArticSang Sang BaronganNoch keine Bewertungen

- Formation R984C enDokument120 SeitenFormation R984C enSang Sang Barongan67% (3)

- SANY SRT95C Rigid Dump TruckDokument4 SeitenSANY SRT95C Rigid Dump TruckTLK Channel100% (1)

- Hd465 7r OmmDokument395 SeitenHd465 7r OmmSang Sang Barongan100% (5)

- HD1500-7 Field Assembly Manual PDFDokument224 SeitenHD1500-7 Field Assembly Manual PDFanggie100% (1)

- GD825A-2 transmission operation, components and testing guideDokument28 SeitenGD825A-2 transmission operation, components and testing guideLucyan Ionescu100% (4)

- Of F-Highway Truck: FeaturesDokument8 SeitenOf F-Highway Truck: Featuresmario palondonganNoch keine Bewertungen

- HD465-7E0 Shop Manual PDFDokument1.640 SeitenHD465-7E0 Shop Manual PDFRodrigo Milla Irarrazabal67% (3)

- SM - HD785-5 LCDokument976 SeitenSM - HD785-5 LCnurdinzai100% (1)

- SCA ALKO Case Study ReportDokument4 SeitenSCA ALKO Case Study ReportRavidas KRNoch keine Bewertungen

- PM PPM OHT 777D CaterpillarDokument83 SeitenPM PPM OHT 777D CaterpillarDiki Abu MeshalNoch keine Bewertungen

- 773E Introduction MasterDokument46 Seiten773E Introduction MasterRicardo Manríquez100% (1)

- HPCR FuelManagement (E)Dokument28 SeitenHPCR FuelManagement (E)Hartono Exca100% (1)

- HD785-7 - OMM - (Operation Manual and Maintenance)Dokument335 SeitenHD785-7 - OMM - (Operation Manual and Maintenance)Yustisi Lazuardi80% (10)

- HD465-7RDokument6 SeitenHD465-7RDanu PratamaNoch keine Bewertungen

- Small Catalog OHT CAT 773E PDFDokument4 SeitenSmall Catalog OHT CAT 773E PDFSupriyono Abdullah100% (1)

- PC1250-8 Eess018304 1011Dokument20 SeitenPC1250-8 Eess018304 1011Ioannis Zorzos100% (2)

- Side Instrument Bezel and ControlsDokument2 SeitenSide Instrument Bezel and ControlsAngel RosasNoch keine Bewertungen

- Group 3 Monitoring System: 1. ClusterDokument19 SeitenGroup 3 Monitoring System: 1. ClusterPriscila RodriguesNoch keine Bewertungen

- MN 00505-QRG09-CAM Printed in The USA 1/08Dokument17 SeitenMN 00505-QRG09-CAM Printed in The USA 1/08Andrew GoncharNoch keine Bewertungen

- Precor 9.27 ServiceManualDokument58 SeitenPrecor 9.27 ServiceManualAdrian Garcia FrancoNoch keine Bewertungen

- 4 - Monitor HuyndaiDokument10 Seiten4 - Monitor Huyndaigiapy0000Noch keine Bewertungen

- TENDLLOD0001Dokument35 SeitenTENDLLOD0001Miguel ViegasNoch keine Bewertungen

- Windows PDFDokument43 SeitenWindows PDFCatalin BuleandraNoch keine Bewertungen

- Upload Sign in Join Books Audiobooks Comics Sheet Music DownloadDokument4 SeitenUpload Sign in Join Books Audiobooks Comics Sheet Music DownloadSang Sang BaronganNoch keine Bewertungen

- New Cat Prod LineDokument72 SeitenNew Cat Prod LineSang Sang Barongan0% (1)

- CGB45ADokument37 SeitenCGB45ASang Sang BaronganNoch keine Bewertungen

- Seam 056601 PDokument308 SeitenSeam 056601 PSang Sang BaronganNoch keine Bewertungen

- Contoh Surat Lamaran KerjaDokument8 SeitenContoh Surat Lamaran KerjaSang Sang BaronganNoch keine Bewertungen

- Electronics Ecommerce Website: 1) Background/ Problem StatementDokument7 SeitenElectronics Ecommerce Website: 1) Background/ Problem StatementdesalegnNoch keine Bewertungen

- Experiences from OJT ImmersionDokument3 SeitenExperiences from OJT ImmersionTrisha Camille OrtegaNoch keine Bewertungen

- India Today 11-02-2019 PDFDokument85 SeitenIndia Today 11-02-2019 PDFGNoch keine Bewertungen

- Journal Entries & Ledgers ExplainedDokument14 SeitenJournal Entries & Ledgers ExplainedColleen GuimbalNoch keine Bewertungen

- To Introduce BgjgjgmyselfDokument2 SeitenTo Introduce Bgjgjgmyselflikith333Noch keine Bewertungen

- Exercises 6 Workshops 9001 - WBP1Dokument1 SeiteExercises 6 Workshops 9001 - WBP1rameshqcNoch keine Bewertungen

- Evaluating Sources IB Style: Social 20ib Opvl NotesDokument7 SeitenEvaluating Sources IB Style: Social 20ib Opvl NotesRobert ZhangNoch keine Bewertungen

- Math5 Q4 Mod10 DescribingAndComparingPropertiesOfRegularAndIrregularPolygons v1Dokument19 SeitenMath5 Q4 Mod10 DescribingAndComparingPropertiesOfRegularAndIrregularPolygons v1ronaldNoch keine Bewertungen

- Nokia MMS Java Library v1.1Dokument14 SeitenNokia MMS Java Library v1.1nadrian1153848Noch keine Bewertungen

- Motor Master 20000 SeriesDokument56 SeitenMotor Master 20000 SeriesArnulfo Lavares100% (1)

- Account Statement From 30 Jul 2018 To 30 Jan 2019Dokument8 SeitenAccount Statement From 30 Jul 2018 To 30 Jan 2019Bojpuri OfficialNoch keine Bewertungen

- Sarvali On DigbalaDokument14 SeitenSarvali On DigbalapiyushNoch keine Bewertungen

- WSP Global EnvironmentDokument20 SeitenWSP Global EnvironmentOrcunNoch keine Bewertungen

- Bluetooth TutorialDokument349 SeitenBluetooth Tutorialjohn bougsNoch keine Bewertungen

- Software Requirements Specification: Chaitanya Bharathi Institute of TechnologyDokument20 SeitenSoftware Requirements Specification: Chaitanya Bharathi Institute of TechnologyHima Bindhu BusireddyNoch keine Bewertungen

- Axe Case Study - Call Me NowDokument6 SeitenAxe Case Study - Call Me NowvirgoashishNoch keine Bewertungen

- Decision Maths 1 AlgorithmsDokument7 SeitenDecision Maths 1 AlgorithmsNurul HafiqahNoch keine Bewertungen

- MODULE+4+ +Continuous+Probability+Distributions+2022+Dokument41 SeitenMODULE+4+ +Continuous+Probability+Distributions+2022+Hemis ResdNoch keine Bewertungen

- Phys101 CS Mid Sem 16 - 17Dokument1 SeitePhys101 CS Mid Sem 16 - 17Nicole EchezonaNoch keine Bewertungen

- Steam Turbine Theory and Practice by Kearton PDF 35Dokument4 SeitenSteam Turbine Theory and Practice by Kearton PDF 35KKDhNoch keine Bewertungen

- PRODUCTDokument82 SeitenPRODUCTSrishti AggarwalNoch keine Bewertungen

- Marketing Plan for Monuro Clothing Store Expansion into CroatiaDokument35 SeitenMarketing Plan for Monuro Clothing Store Expansion into CroatiaMuamer ĆimićNoch keine Bewertungen

- QuickTransit SSLI Release Notes 1.1Dokument12 SeitenQuickTransit SSLI Release Notes 1.1subhrajitm47Noch keine Bewertungen

- Hyper-Threading Technology Architecture and Microarchitecture - SummaryDokument4 SeitenHyper-Threading Technology Architecture and Microarchitecture - SummaryMuhammad UsmanNoch keine Bewertungen

- Log File Records Startup Sequence and Rendering CallsDokument334 SeitenLog File Records Startup Sequence and Rendering CallsKossay BelkhammarNoch keine Bewertungen

- Multiple Choice: CH142 Sample Exam 2 QuestionsDokument12 SeitenMultiple Choice: CH142 Sample Exam 2 QuestionsRiky GunawanNoch keine Bewertungen

- NewspaperDokument11 SeitenNewspaperКристина ОрёлNoch keine Bewertungen

- GIS Multi-Criteria Analysis by Ordered Weighted Averaging (OWA) : Toward An Integrated Citrus Management StrategyDokument17 SeitenGIS Multi-Criteria Analysis by Ordered Weighted Averaging (OWA) : Toward An Integrated Citrus Management StrategyJames DeanNoch keine Bewertungen