Beruflich Dokumente

Kultur Dokumente

Michael Robinson Annulation

Hochgeladen von

Putramica WinartoCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Michael Robinson Annulation

Hochgeladen von

Putramica WinartoCopyright:

Verfügbare Formate

Solvent Free Synthesis of an ,-

Unsaturated Ketone

Authors Name

Putramica Winarto

putrahhh@gmail.com

ABSTRACT

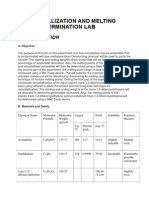

The formation of ethyl 2-oxo-4,6-dip-tolylcyclohex-3-enecarboxylate stemmed from the Microwave Irradiation of the

chalcone (E)-1,3-dip-tolylprop-2-en-1-one that resulted in a Robinson Annulation and the formation of the product

was not completely successful.

This experiment consisted of two parts, first among which

involved the creation of the chalcone by grinding

equimolar 4-methylbenzaldehyde and 4-

methylacetophenone in porcelain mortar with the use of

solid sodium hydroxide as the base catalyst.

1

After the

chalcone was created the melting point and the IR was

obtained. The melting point of the chalcone was 124C

and the literature melting point is 127C which indicates

that the product was relatively pure. IR of the chalcone

presented peaks at 1652.87

cm

-1

which is indicative that

the product has a conjugated ketone. There is also a peak

at 1591.09

cm

-1

which belongs to the aromatic rings and

at 809.36 cm

-1

there is a peak that suggests the benzene is

disubstituded and the groups are para to each other. Once

the chalcone product was verified, converting the

chalcone via Robinson Annulation could proceed. In the

second part of the experiment, the product was placed

into a microwave after being mixed with ethyl

acetoacetate and potassium carbonate.

2

After mixing the

reactents together, the solid was microwaved for 3

minutes on medium power which changed the color of the

solid to more a white color rather than a yellow color.

Robinson Annulation via microwave irradiation resulted

in a 33.33% product yield. IR of the product presented a

peak at 1738.73 cm

-1

which comes from the carbonyl of

an ester and one at 1653.91 cm

-1

from the conjugated

ketone carbonyl. At 1241.69 cm

-1

there is a carbon to

oxygen stretch that arises from the ester as well as a peak

that results from the aromatic rings at 1594.11 cm

-1

. The

IR of the crude procut was obtained and it offered a peak

at 1715.81 cm

-1

which indicates that the crude contains

unreacted ethyl acetoacateate. Because it was so,

recrystallization of the product in 95% ethanol was

necessary as ethanol-dioxane solvent was not readily

available. The crude was recrystallized using an ice bath,

cold ethanol, and a vacuum filtration and the IR obtained

lacked the 1715.81 cm

-1

peak which means

recrystallization of the crude was successful. Obtaining

the crude was a journey in and of its own because the

crude product melted in the oven after being filtered and

turned into a yellow, pasty, goopy liquid/solid mix. As a

result, the crude had to be dried through other means.

First the crude was dissolved completely in

dichloromethane and then it was dried with anhydrous

magnesium sulfate. After the crude was dried and

decanted, the remaining liquid was evaporated off in the

hood through the use of a stream of air until only solid

remained. The solid was then dissolved in hot ethanol and

recrystallized as stated above. The final solid was not

dried in the oven at first for fear that the end result would

mimic that of the crude, and the IR was taken after letting

it air dry. The IR showed an OH peak because of the

ethanol and an executive decision to put the final product

in the oven was made. After being in the oven for an

entire day the IR of the final product was taken once

again and it revealed a smaller OH peak which means the

ethanol has yet to dry completely. After the IR was taken,

the melting point followed suit. However, this proved to

be a problem as well.The final product did not melt at all,

instead it burned inside the melting point device; it

changed from a white-yellow color to a solid yellow color

before turning into a golden yellow color. The yellow got

darker and darker until eventually it turned black.

Because the first melting point was not successful another

melting point was taken and unfortunately the results

were the same. It can be deduced from the experiment

form that the melting point of the product should be in the

110s-120s as the form indicated a compound of similar

build (except it had OH instead of methyl for its R group)

and the melting point was 111-112C.

3

This of course,

indicates that the product isnt pure at all and something

must have happened during the procedure, chief among

which, the microwave irradiation bit. The crude was set in

the 500-wat microwave for 3 minutes on medium and

resulted in little color change, however, when the crude

was set in the oven on high for 4-5 minutes, a massive

color change was observed. This lack of color chang e

indicates that perhaps the crude did not react completely

with the ethyl acetoacetate. Regarldess of the result, the

final product is at least, not the chalcone that was used as

a reactant in this experiment.

(1) Palleros, Daniel R. Solvent-free Synthesis of

Chalcones. PDF file.

(2) Priya V Frank, B'alakrishna Kalluraya, and

Shobhitha Shetty. Microwave Assisted

Robinsons Annulation: Synthesis of some novel

cyclohexanones under solvent free conditions.

PDF file.

(3) Casale, Kristin. Preparation of an ,-unsaturated

ketone via Michael and Aldol Condensation

Reactions. Chemistry 421 Lab Manual.

Chemistry Department, American River College.

Experimental Procedure. This experiment started off

with the addition of 0.00286 moles of ethyl acetoacetate

(0.360 mL) to .3362 grams (.00142 moles) compound 1.

0.00571 moles or .7897 grams of potassium carbonate

was also added. All three reactants were crushed by a

pestle in a mortar and then put inside a microwave under

medium heat for 3-4 minutes. Afterwards the crude

product was put under vacuum filtration and a small

amount of cold water was ran through it (<20 mL). After

letting the solid dry under suction for 3 minutes, place the

crystals in the oven to dry for 20-30 minutes. Chop up the

solid to ensure even drying. After 20-30 minutes have

passed, take the product out of the oven and let it cool to

room temperature before placing it inside a small beaker

or Erlenmeyer flask. As the product is cooling, acquire

20-30 mL of 95% ethanol and set some aside to put into a

centrifuge tube as cold ethanol will be needed. Prepare an

ice bath to put the centrifuge tube in. Place the remaining

ethanol on a hot plate and wait until it bubbles. Once the

solution is bubbling or near bubbling, use a Pasteur

pipette to transfer minute amounts of hot solvent to the

crude. Remember that the crude shold be dissolved in the

minimum amount of solvent to lessen yield loss. Once the

crude is completely dissolved by the hot ethanol, allow

the mixture to room to cool temperature. At this point you

may fill a beaker up with room temperature water and

place the beaker or Erlenmeyer flask inside for faster

cooling. After the product is cooled to room temperature,

place the beaker or flask inside the ice bath and swirl it

around. To aid in the recrystallization process, proceed to

scratch the inside of the beaker or flask with a glassrod to

induce crystallization. Repeat this process as many times

as necessary while swirling the beaker or flask when

required. You may also add in tiny tiny chunks of ice to

help. When the mixture has recrystallized completely,

pour the contents onto a Buchner funnel and vacuum

filtrate the solid. Wash the glassware with small portions

of cold ethanol and pour contents over the funnel. You

may also wash the solid inside the funnel with cold

ethanol. Allow solid to be under suction for at least 3

minutes. Place the solid in a preweighed beaker or watch

glass and place it inside the oven. Let it dry for 20-30

minutes again. Remove the product from the oven and

allow it to cool to room temperature before taking the

mass. Obtain the IR and melting point once the mass has

been taken. The IR and melting point should indicate that

compound 2 has been created.

Acknowledgment I would like to acknowledge

Michael Tomolillo who encountered the same unfortunate

fate as I when drying the crude product. Id also like to

thank Ariel, Beverly, Carol, and Don who were all more

than willing to share the vacuum filtration system that

they had set up. And to Kristin Casale who hath put up

with onslaughts of questions and is this ok?

Das könnte Ihnen auch gefallen

- CHM557 Experiment 5 - The Robinson Annulation ReactionDokument9 SeitenCHM557 Experiment 5 - The Robinson Annulation ReactionMamamia0% (1)

- Oxidation of Benzoin To Benzil With Nitric AcidDokument1 SeiteOxidation of Benzoin To Benzil With Nitric AcidWan HafizaNoch keine Bewertungen

- Laboratory Report of Melting PointDokument5 SeitenLaboratory Report of Melting PointHanna Anne88% (8)

- Synthesis 7 Hydroxy 4 Methyl CoumarinDokument4 SeitenSynthesis 7 Hydroxy 4 Methyl CoumarinLam Khoa100% (1)

- Organic Chemistry Practical 3Dokument11 SeitenOrganic Chemistry Practical 3Kah Jun100% (2)

- Aldol CondensationDokument3 SeitenAldol CondensationDaniel McDermottNoch keine Bewertungen

- KokainDokument4 SeitenKokainAhmet RecepNoch keine Bewertungen

- CHM 556 Experiment 5Dokument12 SeitenCHM 556 Experiment 5Amar Safwan100% (1)

- Cocaine SynthDokument4 SeitenCocaine Synthjoepoker3785100% (2)

- Experiment 32Dokument14 SeitenExperiment 32Morgan Elizabeth Lepley100% (6)

- 2nd Experiment - Aldol CondensationDokument2 Seiten2nd Experiment - Aldol Condensationiluvm92Noch keine Bewertungen

- Production of 1 Phenyl 2 NitropropeneDokument2 SeitenProduction of 1 Phenyl 2 NitropropeneIgor Consoli Wandscheer100% (2)

- Robinson Annulation Reaction of 3-Nitrochalcone With Ethyl AcetoacetateDokument9 SeitenRobinson Annulation Reaction of 3-Nitrochalcone With Ethyl AcetoacetateAmirul Azhar100% (5)

- Multistep Synthesis of 2-Chloro-4-BromoanilineDokument9 SeitenMultistep Synthesis of 2-Chloro-4-Bromoanilinejcrider2100% (1)

- 11 Synthesis DibenzalacetoneDokument7 Seiten11 Synthesis DibenzalacetoneHyuReaper100% (1)

- 35 Exp 12Dokument4 Seiten35 Exp 12dubstepoNoch keine Bewertungen

- Preparation of Cyclohexene From CyclohexanolDokument7 SeitenPreparation of Cyclohexene From CyclohexanolDumile Nombasa100% (5)

- Experiment 4Dokument8 SeitenExperiment 4Botlhe Kgotla SamNoch keine Bewertungen

- Paper 3 ExperimentsDokument2 SeitenPaper 3 ExperimentsElena Arias AlfonsoNoch keine Bewertungen

- Hydrolysis of Methyl Salicylate TungDokument6 SeitenHydrolysis of Methyl Salicylate TungNguyen Son Tung100% (1)

- Aldol Condensation Reaction Lab ReportDokument4 SeitenAldol Condensation Reaction Lab ReportAvril Watson100% (3)

- Acetyl Chloride, Acetic Anhydride and Propionic AnhydrideDokument1 SeiteAcetyl Chloride, Acetic Anhydride and Propionic Anhydridede palo100% (1)

- Example Lab ReportDokument12 SeitenExample Lab ReportHung Dang QuangNoch keine Bewertungen

- Sample Questions Final Exam - Chem 2130 - Ochem LabDokument6 SeitenSample Questions Final Exam - Chem 2130 - Ochem LabSaadNoch keine Bewertungen

- Alrp 10 ADokument2 SeitenAlrp 10 Amahmood.mNoch keine Bewertungen

- Lab Report 1 Purifying Acetanilide Using The Process of RecrystallizationDokument10 SeitenLab Report 1 Purifying Acetanilide Using The Process of RecrystallizationZARGHAMNoch keine Bewertungen

- EXP 2 Advance Organic ChemistryDokument7 SeitenEXP 2 Advance Organic ChemistryMay Lee100% (1)

- Acetaminophen Lab - 2Dokument7 SeitenAcetaminophen Lab - 2Prithvi AwasthiNoch keine Bewertungen

- CyclohexeneDokument12 SeitenCyclohexenePatricia CruzNoch keine Bewertungen

- Orgo RecrystalizationDokument57 SeitenOrgo RecrystalizationRizza Mae SamalcaNoch keine Bewertungen

- The Ex 3Dokument3 SeitenThe Ex 3zFe 6Noch keine Bewertungen

- Recrystallization PDFDokument5 SeitenRecrystallization PDFMikee GutierrezNoch keine Bewertungen

- Figure 5.1 Preparation of CyclohexeneDokument5 SeitenFigure 5.1 Preparation of CyclohexeneMark Cliffton BadlonNoch keine Bewertungen

- Ahmad Zakwan Bin Kassim - Lab 3 - CHM557Dokument15 SeitenAhmad Zakwan Bin Kassim - Lab 3 - CHM557Ahmad ZakwanNoch keine Bewertungen

- Katch UmbelliferoneffrDokument9 SeitenKatch Umbelliferoneffrapi-456902531Noch keine Bewertungen

- Experiment 1: Crystallization of Impure Acetanilide ObjectiveDokument4 SeitenExperiment 1: Crystallization of Impure Acetanilide ObjectiveEZLYEN AZLINNoch keine Bewertungen

- DibenzalacetoneDokument3 SeitenDibenzalacetoneDrGajanan VaishnavNoch keine Bewertungen

- Friedel CraftsDokument6 SeitenFriedel CraftsKhoa Dang Nguyen100% (9)

- Preparation of Meta DinitrobenzeneDokument3 SeitenPreparation of Meta DinitrobenzeneGaneshParajuliNoch keine Bewertungen

- Chem Unit 3 NotesDokument12 SeitenChem Unit 3 NotesMena Hashem100% (3)

- Exer 2 ContDokument6 SeitenExer 2 ContJames Aaron SantiagoNoch keine Bewertungen

- Recrystallization Is One of The Many Techniques Used To Purify OrganicDokument8 SeitenRecrystallization Is One of The Many Techniques Used To Purify OrganicVanessaOlgaJ.DagondonNoch keine Bewertungen

- Como Hacer CocainaDokument7 SeitenComo Hacer CocainaDiego Mares Buendia100% (2)

- Drugs - How To Make Cocaine Synthetically)Dokument4 SeitenDrugs - How To Make Cocaine Synthetically)api-2618198977% (22)

- Acetylation Ferrocene 2012Dokument3 SeitenAcetylation Ferrocene 2012VargasArn50% (2)

- Lab CHM 457 Exp 2Dokument10 SeitenLab CHM 457 Exp 2JohanNoch keine Bewertungen

- Drugs - How To Make Cocaine (Synthetically)Dokument5 SeitenDrugs - How To Make Cocaine (Synthetically)jsssh80% (5)

- Experiment 12 Preparation of Adipic Acid From CyclohexeneDokument6 SeitenExperiment 12 Preparation of Adipic Acid From Cyclohexenesaransh1994Noch keine Bewertungen

- Miscellaneous ChemicalsDokument8 SeitenMiscellaneous Chemicalsgbonger100% (8)

- Kitchen Improvised ExplosivesDokument19 SeitenKitchen Improvised Explosivessf_pet100% (2)

- Synthesis of CyclohexeneDokument4 SeitenSynthesis of CyclohexeneMinsa ChoudryNoch keine Bewertungen

- Super Cool Science and Engineering Activities: with Max Axiom Super ScientistVon EverandSuper Cool Science and Engineering Activities: with Max Axiom Super ScientistNoch keine Bewertungen

- Plant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterVon EverandPlant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterNoch keine Bewertungen

- Chemistry at Home - A Collection of Experiments and Formulas for the Chemistry EnthusiastVon EverandChemistry at Home - A Collection of Experiments and Formulas for the Chemistry EnthusiastNoch keine Bewertungen

- Home Brewing Beer And Other Juicing Recipes: How to Brew Beer Explained in Simple Steps: How to Brew Beer Explained in Simple StepsVon EverandHome Brewing Beer And Other Juicing Recipes: How to Brew Beer Explained in Simple Steps: How to Brew Beer Explained in Simple StepsNoch keine Bewertungen

- Catamaran AnalysisDokument83 SeitenCatamaran AnalysisbhukthaNoch keine Bewertungen

- Chapter 9 and 10Dokument18 SeitenChapter 9 and 10billNoch keine Bewertungen

- Silvaco ATHENA Description 1 PDFDokument18 SeitenSilvaco ATHENA Description 1 PDFRahul JaiswalNoch keine Bewertungen

- User Manual of Egov 11.0 Implementation of It Solution For RVNL D3799 Document Version / DetailsDokument64 SeitenUser Manual of Egov 11.0 Implementation of It Solution For RVNL D3799 Document Version / DetailsRVNLPKG6B VBL-GTLMNoch keine Bewertungen

- 001-MBA-SPSS Applications - 10-06-2023Dokument74 Seiten001-MBA-SPSS Applications - 10-06-2023seyon sithamparanathanNoch keine Bewertungen

- Oracle Process Manufacturing Master SetupsDokument42 SeitenOracle Process Manufacturing Master SetupsMadhuri Uppala100% (2)

- Calibration of The Continuous Surface Cap Model For ConcreteDokument19 SeitenCalibration of The Continuous Surface Cap Model For ConcreteAbhijit KulkarniNoch keine Bewertungen

- MDM Heiana Nadia Hamzah: Prepared byDokument50 SeitenMDM Heiana Nadia Hamzah: Prepared bySyarfa FurzanneNoch keine Bewertungen

- HAARPDokument230 SeitenHAARPMartin hume100% (2)

- 4 A Short History of Islamic Science From Genesis To Decline ShortversionDokument24 Seiten4 A Short History of Islamic Science From Genesis To Decline ShortversionKateryna KuslyvaNoch keine Bewertungen

- EE TermsDokument25 SeitenEE TermsKerr AgotNoch keine Bewertungen

- Webinar HPLC PT GeneCraft LabsDokument44 SeitenWebinar HPLC PT GeneCraft LabsBayu Indra Permana100% (1)

- EX - NO:1a Data Definition Languages (DDL) Commands of Base Tables and ViewsDokument44 SeitenEX - NO:1a Data Definition Languages (DDL) Commands of Base Tables and Viewslalit thakur100% (1)

- Ekg 8Dokument2 SeitenEkg 8Arun SNoch keine Bewertungen

- 2-Way Doherty Amplifier With BLF888ADokument27 Seiten2-Way Doherty Amplifier With BLF888AerdemsecenNoch keine Bewertungen

- West Knits Book 3Dokument56 SeitenWest Knits Book 3Alexandr Maxiuta100% (17)

- Javascript Date ObjectDokument5 SeitenJavascript Date Objectshivi08Noch keine Bewertungen

- Builders' Metalwork: Ci/Sfb 21.9 Xt6Dokument32 SeitenBuilders' Metalwork: Ci/Sfb 21.9 Xt6JC TsuiNoch keine Bewertungen

- Atma Ram Sanatan Dharma College: PresentationDokument6 SeitenAtma Ram Sanatan Dharma College: PresentationRishikeshav RaviNoch keine Bewertungen

- Sarvani ProfileDokument12 SeitenSarvani Profiledox4print100% (1)

- Wa Wa40-3 Komatsu s3d84Dokument2 SeitenWa Wa40-3 Komatsu s3d84james foxNoch keine Bewertungen

- Abstract of Talk by Dr. Nitin Oke For National Conference RLTDokument2 SeitenAbstract of Talk by Dr. Nitin Oke For National Conference RLTnitinNoch keine Bewertungen

- L011375 - MT4434TE Spec SheetDokument2 SeitenL011375 - MT4434TE Spec SheetJunior BautistaNoch keine Bewertungen

- Allen-Bradley RSLogix 500 PDFDokument6 SeitenAllen-Bradley RSLogix 500 PDFGanda PutraNoch keine Bewertungen

- Asco Series 042 Gas Shutoff CatalogDokument4 SeitenAsco Series 042 Gas Shutoff CatalogRoqueNetNoch keine Bewertungen

- About The MS Regression ModelsDokument17 SeitenAbout The MS Regression ModelsLars LarsonNoch keine Bewertungen

- Sony - HST 211 - Sen 211 SMDokument30 SeitenSony - HST 211 - Sen 211 SMOswaldo CamposNoch keine Bewertungen

- 50 Circular 2022Dokument1 Seite50 Circular 2022Shaurya BansalNoch keine Bewertungen

- Roasting Matte To Nickel Oxide and MetalDokument7 SeitenRoasting Matte To Nickel Oxide and MetalDavid SanchezNoch keine Bewertungen

- Arid Agriculture University, Rawalpindi: Final Exam / Fall 2020 (Paper Duration 24 Hours) To Be Filled by TeacherDokument3 SeitenArid Agriculture University, Rawalpindi: Final Exam / Fall 2020 (Paper Duration 24 Hours) To Be Filled by TeacherUmair KhanNoch keine Bewertungen