Beruflich Dokumente

Kultur Dokumente

Corrosion Lecture

Hochgeladen von

Fasil ParuvanathCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Corrosion Lecture

Hochgeladen von

Fasil ParuvanathCopyright:

Verfügbare Formate

SSCC : SULPHIDE STRESS CORROSION

CRACKING

IGC : INTERGRANULAR CORROSION

TWO IMPORTANT CORROSIONS TYPES

ENCOUNTERED BY US ARE COVERED:

BROADLY CLASSIFIED AS :

LOW TEMPERATURE CORROSION

---- CORROSION AT ROOM

TEMPERATURE AND BELOW

HIGH TEMPERATURE CORROSION

---- ELEVATED TEMPERATURE

CORROSION INCLUDING

THAT BY MOLTEN METALS

MEDIA

ONE OF THE MOST IMPORTANT

FACTORS.

PROCESS FLUIDS

CONTAMINANTS

SOLVENTS

CATALYSTS ETC.

HIC --

HYDROGEN INDUCED CRACKING

SSCC ---

A CRACKING PROCESS THAT

REQUIRES SIMULTANEOUS ACTION

OF A CORRODENT AND SUSTAINED

TENSILE STRESS.

WATER :

FUNCTIONS AS ELECTROLYTE

HYDROLYSES INORGANIC SALTS

COMBINATION OF AIR & WATER

IS DANGEROUS ---

AIR SUPPLIES O

2

WATER ACTS AS ELECTROLYTE

SOURCES :

ALMOST EVERY PART OF PROCESS

MEDIA :

EXCLUDED :

FAILURES DUE TO REDUCED SECTION AS A

RESULT OF CORROSION

FAILURES DUE TO INTER - CRYSTALLINE OR

TRANS - CRYSTALLINE CORROSION

H

2

S SOUR WATER

COMMON SOURCES :

CRUDE OIL

DECOMPOSITION OF ORGANIC

COMPOUNDS OF SULPHUR

PROCESS WATER CARRYING H

2

S

WITH NH

3

HCN ETC.

H

2

S REACTS WITH STEEL TO GIVE

A BLACK SULPHIDE FILM

C.S. HAS GOOD RESISTANCE TO

AQUEOUS SULPHIDE CORROSION

SOUR WATER

COMMON SOURCES

PROCESS WATER CARRYING H

2

S

WITH NH

3

HCN ETC

AQUEOUS H

2

S

C.S. AND LAS ARE USED

AQUEOUS H

2

S + NH

3

ETC

CONDITION MORE SEVERE

C.S. & LAS NOT USED

DEPENDING ON SEVERITY

S.S OR TITANIUM USED

HIC NACE STANDARD TM - 02 84

SSCC NACE STANDARD TM - 01 77

HIC TESTING :

SPECIMEN SIZE :

20 X 20 X 100 mm

SOLUTION :

A -- SODIUM CHLORIDE +

ACETIC ACID ( pH 2.7 )

SATURATED WITH H

2

S

B -- SYNTHETIC SEA WATER

( AS PER ASTM D 1141 )

pH 8.1 - 83

SATURATED WITH H

2

S

TEST DURATION :

96 HOURS ( 4 DAYS )

FINAL pH

SOLUTION A -- 4.0

SOLUTION B -- 4.8 - 5.4

TEST RESULT :

THREE SECTIONS OBSERVED

BLISTERS SHALL BE NIL

CSR , CLR AND CTR SHALL

BE WITHIN SPECIFIED

LIMITS

CSR =100 [ (a x b) / ( W x T) ]

CLR =100 [ a / ( W x T) ]

CTR =100 [ b / ( W x T) ]

a = CRACK LENGTH

b = CRACK AREA THICKNESS

W = SECTION WIDTH

T = TEST SPECIMEN THICKNESS

SSCC TESTING :

SPECIMEN SIZE :

ROUND BAR TENSILE SPECIMEN

GAUGE DIA. 6.35 mm

GAUGE LENGTH 25.4 mm

( OVERALL LENGTH 200 mm)

SOLUTION :

A -- SODIUM CHLORIDE +

ACETIC ACID ( pH 2.6 - 2.8 )

SATURATED WITH H

2

S

B -- SODIUM CHLORIDE +

SODIUM ACETATE +

ACETIC ACID ( pH 3.4 - 3.6 )

SATURATED WITH H

2

S

TEST DURATION :

720 HOURS ( 30 DAYS )

FINAL pH

SOLUTION A -- 4.0

SOLUTION B -- 4.0

TEST LOAD :

GENERALLY LOADED TO

72% OF STANDARD METAL

YIELD STRENGTH.

THIS MAY BE CHANGED BY

CUSTOMER

TEST IS DEEMED PASSED IF

SPECIMEN DOES NOT BREAK

EXAMINATION AT 10 X DOES

NOT REVEAL CRACKS

SUSCEPTIBLE MATERIALS :

STAINLESS STEELS

PROCESS :

CORROSION RESISTANCE OF

STAINLESS STEELS IS DERIVED

FROM

Cr + O

2

--------> Cr

2

O

3

FROM

METAL

FROM

ATMOSPHERE

Cr

2

O

3

FORMS A TENACIOUS FILM

ON THE SURFACE.

MINIMUM 12 % Cr IS NEEDED

TO MAKE STEEL STAINLESS

WHEN S.S. PASSES THROUGH THE

TEMPERATURE RANGE OF 425

O

C

TO 850

O

C WE HAVE :

C + Cr -----> Cr

23

C

6

THE REACTION OCCURS AT

GRAIN BOUNDARIES

THUS THERE IS A BAND AT THE

GRAIN BOUNDARIES WHERE

Cr IS LESS THAN 12%

THIS AREA IS NO MORE

STAINLESS

THE PROCESS FLUIDS AND

CONTAMINANTS CAN ATTACK

IN THIS AREA.

THERE ARE A LOT OF PROCESSES

OF MANUFACTURING THAT TAKE

SS IN THIS RANGE

EG. WELDING ; CUTTING ; HOT/WARM

FORMING

SERVICE TEMPERATURE CAN ALSO

BE IN THIS RANGE

THUS THERE IS A NEED TO TEST

THE SUSCEPTABILITY TO IGC

THIS NEED IS GOVERNED BY

SERVICE CONDITIONS

APPLICABLE STD. ASTM A262

THERE ARE 5 PRACTICES

PRACTICE SOLUTION APPLICATION

A OXALIC ACID RAPID

ETCH TEST IDENTIFICATION

OF MATERIALS

WHICH WILL FAIL

B FERRIC SULPHATE DETECTS IGC BUT

+ SULPHURIC ACID NOT SIGMA PHASE

SUSCEPTABILITY

C 65 % NITRIC ACID DETECTS IGC BUT

AND SIGMA PHASE

SUSCEPTABILITY

E Cu +CuSO

4

+ DETECTS IGC BUT

16 % H

2

SO

4

NOT SIGMA PHASE

SUSCEPTABILITY

F Cu +CuSO

4

+ DETECTS IGC BUT

50 % H

2

SO

4

NOT SIGMA PHASE

SUSCEPTABILITY

PRACTICE TEST CONDITIONS

A ETCHING AND EXAMIN AT

250 x AND 500 x

B BOILING SOLUTION

120 HOURS

C BOILING SOLUTION

240 HOURS

E BOILING SOLUTION

24 HOURS

F BOILING SOLUTION

120 HOUR

NORMALLY PRACTICE B ; C AND E

ARE USED

IN PRACTICE B AND C WEIGHT

LOSS IS MEASURED.

THE CORROSION RATE IS GIVEN

BY THE WEIGHT LOSS

THIS IS NOT THE CORROSION

RATE IN ACTUAL SERVICE.

THE RESULT IS A RELATIVE

MEASURE

IN PRACTICE E SPECIMEN IS

BENT THROUGH 180

O

OVER A

FORMER OF 1T RADIUS.

THE BENT SURFACE IS EXAMINED

AT 100 x AND 250 x

TEST IS PASSED IF THERE ARE NO

CRACKS. CRACKS FROM EDGE ,

WRINKLES AND ORANGE PEEL

EFFECT ARE DISREGARDED.

PRACTICE B EVALUATION

Millimeter Per Month =

7290 x W

A x d x t

W = Weight Loss in gms.

A = Total Area of the Sample in cm

2

t = Time of Exposure in hours

d = Density of sample in gms / cc

Millimeter Per Month x 0.04 = Inches Per Month

Millimeter Per Month x 0.47 = Inches Per Year

Millimeter Per Month x 12 = Millimeter Per Year

Millimeter Per Month x 472 = mpy

Millimeter Per Month x Density / 3 =

Milligram Per Square Decimeter Per Day

PRACTICE C EVALUATION

3440880 (W)

( A ) ( d ) ( t )

MPY =

A= Total Specimen area (cm

2

)

W= Weight loss ( gms)

d= Density of sample ( gms / cm

3

)

t = Time of exposure ( hrs)

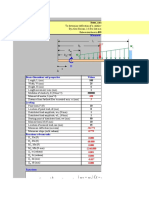

PRACTICE E

EVALUATION

FAILED MARGINAL

( DOUBTFUL )

PASSED

STEP DUAL

DITCH

As Received

After exposure

After bending

PARENT METAL

100 x

100 x

100 x

HAZ

Before exposure

After exposure

WELD

Before exposure

After exposure

PASSED

FAILED

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Influence LinesDokument5 SeitenInfluence LinessushilkumarNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Beam Cantilever ComDokument15 SeitenBeam Cantilever ComHareesh GrNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- 7.1 Finite Element Simulation of Chassis DesignDokument5 Seiten7.1 Finite Element Simulation of Chassis DesignFasil ParuvanathNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Module 1 Lecture 3 FinalDokument12 SeitenModule 1 Lecture 3 Finaltejap314Noch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- NAFEMS BooksDokument4 SeitenNAFEMS Booksds_srinivas50% (2)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- 30.design and Analysis of A Automobile FrameDokument1 Seite30.design and Analysis of A Automobile FrameFasil ParuvanathNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Goforth Diathesis-Stress Model FinalDokument3 SeitenGoforth Diathesis-Stress Model FinalmaretadekaNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Are Structures Cheat Sheet 1Dokument5 SeitenAre Structures Cheat Sheet 1priodeep chowdhuryNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Environmental Product Declaration: Power Transformer Trafostar 63 MvaDokument4 SeitenEnvironmental Product Declaration: Power Transformer Trafostar 63 MvaFasil ParuvanathNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- BGR 270 MVA 1-PH GT short circuit strength calculationDokument3 SeitenBGR 270 MVA 1-PH GT short circuit strength calculationFasil ParuvanathNoch keine Bewertungen

- 16 - Chapter 6Dokument5 Seiten16 - Chapter 6Fasil ParuvanathNoch keine Bewertungen

- Genetic Algorithm Optimizes Chassis Section Modulus for Load, StressDokument1 SeiteGenetic Algorithm Optimizes Chassis Section Modulus for Load, StressFasil ParuvanathNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Graphics - Software OpengGLDokument2 SeitenGraphics - Software OpengGLFasil ParuvanathNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Ease of Doing Business in India: Factors & ImprovementsDokument4 SeitenEase of Doing Business in India: Factors & ImprovementsFasil ParuvanathNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Pass Format From Police StationDokument1 SeitePass Format From Police StationThe Indian Express83% (6)

- Climate Change Affect ChilldrenDokument5 SeitenClimate Change Affect ChilldrenFasil ParuvanathNoch keine Bewertungen

- Climate Change Affect ChilldrenDokument5 SeitenClimate Change Affect ChilldrenFasil ParuvanathNoch keine Bewertungen

- (BS ISO 128-40 - 2001) - Technical Drawings. General Principles of Presentation. Basic Conventions For Cuts and Sections PDFDokument14 Seiten(BS ISO 128-40 - 2001) - Technical Drawings. General Principles of Presentation. Basic Conventions For Cuts and Sections PDFFasil Paruvanath100% (1)

- Stress ManagementDokument10 SeitenStress ManagementRishabh MehtaNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- 7.1 Finite Element Simulation of Chassis DesignDokument5 Seiten7.1 Finite Element Simulation of Chassis DesignFasil ParuvanathNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Parameter Changes - ConfigDokument1 SeiteParameter Changes - ConfigFasil ParuvanathNoch keine Bewertungen

- Genetic Algorithm Optimizes Chassis Section Modulus for Load, StressDokument1 SeiteGenetic Algorithm Optimizes Chassis Section Modulus for Load, StressFasil ParuvanathNoch keine Bewertungen

- List of Tables: Table Title No. NoDokument2 SeitenList of Tables: Table Title No. NoFasil ParuvanathNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Vehicle Chassis Optimization Using Genetic AlgorithmDokument3 SeitenVehicle Chassis Optimization Using Genetic AlgorithmFasil ParuvanathNoch keine Bewertungen

- Pippin PDFDokument6 SeitenPippin PDFFasil ParuvanathNoch keine Bewertungen

- 13 ReferencesDokument9 Seiten13 ReferencesAbdelrahman MagdyNoch keine Bewertungen

- 03 AbstractsDokument3 Seiten03 AbstractsFasil ParuvanathNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Lenovo s30 Manual PDFDokument1 SeiteLenovo s30 Manual PDFFasil ParuvanathNoch keine Bewertungen

- Practitioners GuideDokument5 SeitenPractitioners GuideNarina Avi SeptiyantiNoch keine Bewertungen

- Lenovo Diagnostics - LOG: 9/3/2022 1:17:56 PM - PassedDokument12 SeitenLenovo Diagnostics - LOG: 9/3/2022 1:17:56 PM - Passedlorena chavestaNoch keine Bewertungen

- Lesson 7:: Concept in Integrated Arts ProductionDokument36 SeitenLesson 7:: Concept in Integrated Arts Productionmaria genio50% (2)

- Department of Education Schools Division of Ilocos Sur Nagbukel National High SchoolDokument3 SeitenDepartment of Education Schools Division of Ilocos Sur Nagbukel National High Schoolperlita galla100% (1)

- Bombardier Global5000 Factsheet ENDokument2 SeitenBombardier Global5000 Factsheet ENpeterNoch keine Bewertungen

- 1 eDokument14 Seiten1 eamloNoch keine Bewertungen

- 1 - Camera - Operations - How To Maintain A Camera and Roles of A Camera OperatorDokument22 Seiten1 - Camera - Operations - How To Maintain A Camera and Roles of A Camera Operator18bumby JohnNoch keine Bewertungen

- BoholanerssDokument37 SeitenBoholanerssAndres Rafael TomaganNoch keine Bewertungen

- 1893 Dardistan in 1866, 1886 and 1893 by Leitner SDokument288 Seiten1893 Dardistan in 1866, 1886 and 1893 by Leitner SBilal Afridi100% (1)

- Primary Cheats: Vehicles VehiclesDokument1 SeitePrimary Cheats: Vehicles VehiclesAizuddin Airis KarimanNoch keine Bewertungen

- Furniture - Crossword PuzzleDokument3 SeitenFurniture - Crossword PuzzleannaNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Submitted To: Sir Hassan Submitted By: Syeda Mahwish Sajid (THM Evening 29)Dokument15 SeitenSubmitted To: Sir Hassan Submitted By: Syeda Mahwish Sajid (THM Evening 29)Maniya GillaniNoch keine Bewertungen

- Daftar Game DVD Yang TersediaDokument5 SeitenDaftar Game DVD Yang Tersediasaptagames100% (1)

- Hydraulic & Mechanical PullersDokument9 SeitenHydraulic & Mechanical PullersMeilvy Rahmadani PaneNoch keine Bewertungen

- List of Selected Candidates Against Advertisement No 105 2022Dokument4 SeitenList of Selected Candidates Against Advertisement No 105 2022Awadhesh MalviyaNoch keine Bewertungen

- Petrang Kabayo Cast and CrewDokument8 SeitenPetrang Kabayo Cast and CrewAlexis Beatriz PeretNoch keine Bewertungen

- Notorious ScreenplayDokument88 SeitenNotorious Screenplaysagarrajaneni100% (1)

- Murphy Essential Grammar in Use Intermediate 2015 17Dokument1 SeiteMurphy Essential Grammar in Use Intermediate 2015 17Alper GülNoch keine Bewertungen

- Mass Media and Arts in The UKDokument10 SeitenMass Media and Arts in The UKJose RojoNoch keine Bewertungen

- 10 Week MMADokument6 Seiten10 Week MMAFilip VelickovicNoch keine Bewertungen

- Saturn's RingDokument2 SeitenSaturn's RingRobin GunawanNoch keine Bewertungen

- Executive+Committee+Roster+ +february+2014Dokument6 SeitenExecutive+Committee+Roster+ +february+2014George SkinnerNoch keine Bewertungen

- Fontes EspeciaisDokument5 SeitenFontes EspeciaisCaricarob By Carlos RobaertNoch keine Bewertungen

- A+ Guide To Hardware, 4eDokument62 SeitenA+ Guide To Hardware, 4eepriyaa100% (4)

- Tle 6 Q1 Las 3-4Dokument4 SeitenTle 6 Q1 Las 3-4Shel TamNoch keine Bewertungen

- MT20Dokument2 SeitenMT20groovey9040Noch keine Bewertungen

- Communication Strategy of VodafoneDokument35 SeitenCommunication Strategy of VodafoneArgha Gupta100% (2)

- BMS Sem VI Exam Results 2022Dokument3 SeitenBMS Sem VI Exam Results 2022HATKE SOCIETYNoch keine Bewertungen

- Drill and MarchingDokument34 SeitenDrill and Marchingsharonmangundu036Noch keine Bewertungen

- Cultural Experience ReflectionDokument2 SeitenCultural Experience Reflectionapi-458033330Noch keine Bewertungen

- Module 1 - 1st Quarter (CPAR)Dokument12 SeitenModule 1 - 1st Quarter (CPAR)maria alexalinda salcedoNoch keine Bewertungen