Beruflich Dokumente

Kultur Dokumente

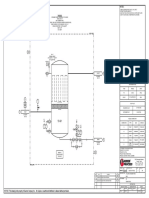

Datasheet Fuel Gas Scrubber (FGS-01)

Hochgeladen von

Andika Pratama0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

515 Ansichten4 SeitenThis document provides specifications for a fuel gas scrubber vessel (Tag No. FGS-01) being built for PT GASPRO SENTRACO in Subang, West Java. It outlines the vessel design requirements, materials, dimensions, estimated weights, nozzle listings and other construction details. The vessel will be an ASME Section VIII Division 1 stamped vertical vessel with a 30 inch inner diameter, 90 inch length, and maximum allowable working pressure of 260 psig. It will be built from SA 516 Grade 70 steel and coated/insulated for operating conditions of 100°F and 110 psig with hydrocarbon gas service.

Originalbeschreibung:

datasheet scrubber

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document provides specifications for a fuel gas scrubber vessel (Tag No. FGS-01) being built for PT GASPRO SENTRACO in Subang, West Java. It outlines the vessel design requirements, materials, dimensions, estimated weights, nozzle listings and other construction details. The vessel will be an ASME Section VIII Division 1 stamped vertical vessel with a 30 inch inner diameter, 90 inch length, and maximum allowable working pressure of 260 psig. It will be built from SA 516 Grade 70 steel and coated/insulated for operating conditions of 100°F and 110 psig with hydrocarbon gas service.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

515 Ansichten4 SeitenDatasheet Fuel Gas Scrubber (FGS-01)

Hochgeladen von

Andika PratamaThis document provides specifications for a fuel gas scrubber vessel (Tag No. FGS-01) being built for PT GASPRO SENTRACO in Subang, West Java. It outlines the vessel design requirements, materials, dimensions, estimated weights, nozzle listings and other construction details. The vessel will be an ASME Section VIII Division 1 stamped vertical vessel with a 30 inch inner diameter, 90 inch length, and maximum allowable working pressure of 260 psig. It will be built from SA 516 Grade 70 steel and coated/insulated for operating conditions of 100°F and 110 psig with hydrocarbon gas service.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

Revision 0

Customer : PT GASPRO SENTRACO

Plant Site : SUBANG, WEST JAVA

Item Name : FUEL GAS SCRUBBER

Tag No. : FGS-01

MFG Serial No. : MF-2080

Job No. : S-14049

Drawing No. : MF-S14049-FGS-01-001

Year Built :

Rev Date Checked

Doc. No : MF-DS-S14049-FGS01-001

ENGINEERING DEPARTMENT

Prepared Approved

20-May-14 Issued for Approval 0

MGY MJY

4

AP

S-14049

FGS-01

2014

PT MULTI FABRINDO GEMILANG

Description Page

ASME "U" STAMPED VESSEL

Client App'd

Per ASME Sect.VIII Div.1 2013 Code Application

DATA SHEET

Sheet 1

Job No.

Tag No.

ENGINEERING DEPARTMENT

Revision

NO. LOADING REQUIREMENT

1 INTERNAL DESIGN PRESSURE

2 EXTERNAL DESIGN PRESSURE

3

OPERATING INCLUDE THE ADDITIONAL PRESSURE DUE

TO STATIC HEAD OF LIQUID

4 WEIGHT OF THE VESSEL AND NORMAL CONTENTS UNDER

THE TEST CONDITIONS INCLUDE THE ADDITIONAL PRESSURE

DUE TO STATIC HEAD OF LIQUID

5 SUPERIMPOSED STATIC REACTIONS FROM WEIGHT OF MOTOR

6 SUPERIMPOSED STATIC REACTIONS FROM WEIGHT OF MACHINERY

7 SUPERIMPOSED STATIC REACTIONS FROM WEIGHT OF OTHER VESSEL

8 SUPERIMPOSED STATIC REACTIONS FROM WEIGHT OF PIPING

9 SUPERIMPOSED STATIC REACTIONS FROM WEIGHT OF LINING

10 SUPERIMPOSED STATIC REACTIONS FROM WEIGHT OF INSULATION

11 THE ATTACHMENT OF INTERNALS

12 THE ATTACHMENT OF VESSEL SUPPORT (SKIRT, LUGS, ETC)

13 CYCLIC AND DYNAMIC REACTIONS DUE TO PRESSURE

14 CYCLIC AND DYNAMIC REACTIONS DUE TO THERMAL VARIATIONS

15 CYCLIC AND DYNAMIC REACTIONS DUE TO EQUIPMENT MOUNTED

ON VESSEL

16 CYCLIC AND DYNAMIC REACTIONS DUE TO MECHANICAL LOADINGS

17 WIND REACTIONS

18 SNOW REACTIONS

19 SEISMIC REACTIONS

20 IMPACT REACTIONS SUCH AS THOSE DUE TO FLUID SHOCK

21 TEMPERATURE GRADIENTS AND DIFFERENTIAL THERMAL

EXPANSION

22 ABNORMAL PRESSURE, SUCH AS THOSE CAUSED BY DEFLAGRATION

WEIGHT OF THE VESSEL AND NORMAL CONTENTS UNDER

PT MULTI FABRINDO GEMILANG

Job No. S-14049 Vessel Loading Requirements

1

Tag No. FGS-01 ASME Sect. VIII Div. 1 2013 Ed. Sheet 2

ENGINEERING DEPARTMENT

1

1

2 ASME VIII Div 1, 2013 Ed MATERIAL SPEC.

3 Construction Category SA 516 Gr 70

4 SA 516 Gr 70/SA 105

5 SA 106 Gr B

6 Service HC Gas SA 516 Gr 70

7 Operating Condition SA 105

8 Temperature 100

O

F -

9 Pressure 110 Psig SA 36

10 Design Condition SA 36

11 Temperature 32 / 200

O

F Note 3

12 Pressure 200 Psig 316 SS

13 MAWP 260 Psig Not Required

14 H.T Press.( 1.3 x MAWP.) 338 Psig Not Required

15 Specific Gravity 0.55 Not Required

16 Capacity 39.94 ft

3

SS 316

17 ID Vessel 30 in - Nut SS 316

18 Length of Vessel (TL/WL) 90 in External Attachment SA 516 Gr 70/ SA 36

19 Shell Thickness 0.394 in External - Bolt SA 193 B7

20 Head Thick (min.) 0.315 in - Nut SA 194 2H

21 Corrosion Allowance 0.118 in Name Plate 304 SS

22 Weld Joint Efficiencies Foundation Bolt / Nut SA 307 Gr B

23 Shell Earthing Boss SA 36

24 Head Material Impact Testing Req'd Not Required

25 Non Destructive Testing

26 Radiography

27 Ultrasonic As per Code Type of Head 2 : 1 Ellipsoidal / Top Flange

28 Magnetic Particle Type of Support Leg

29 Dye Penetrant Platform / Ladder Not Required

30 Post Weld Heat Treatment Manway Davit Required

31 Insulation Earthing Boss Required

32 Fire Proofing Litfing Lug Required

33 External Painting Name Plate Required

34 Primer Coat

35 Intermediate Coat Empty 3387.4 lbs

36 Top Coat Operating 3497.6 lbs

37 Internal Painting Test 4518.4 lbs

38

39

40 NOTE :

41 1. Vendor shall confirm all data lat location marked with (*)

42 2. Vendor shall reponsible for detailed engineering of the vessel. Vendor to confirm that fabrication, inspection and testing

43 shall follow the Codes and Standards

44 3. Vendor shall provide weight information

45 4. Manway to be supplied c/w davit, gasket, cover, bolt & nut.

46 5. Part directly welded to shell / head

47

48

49

50

51

52

53

54

55

CONSTRUCTION

ESTIMATED WEIGHT

ASME Sect. VIII Div. 1 2013 Ed.

"U" Stamp

Vertical

Job No. S-14049 Vessel Loading Requirements

Revision

Tag No. FGS-01 Sheet 3

PART

Shell

Head

Nozzle Neck (pipe / plate)

Reinforcing Pad

Orientation

Design Code

CONSTRUCTION MATERIAL

DESIGN DATA

Flange

Fitting

Support

Base Plate

Gasket

Demister

Vortex Breaker

Inlet Device

Internal Attachment

Internal - Bolt

N/A

N/A

N/A

Yes

N/A

1.00

RT1

PT MULTI FABRINDO GEMILANG

N/A

Polyurethane

Epoxy

Zinc Silicate

1.00

PT MULTI FABRINDO GEMILANG ENGINEERING DEPARTMENT

1

Sheet 4

QTY SIZE (in) RATING

1 2" 150# Gas Inlet

1 2" 150# Gas Outlet

1 2" 150# Drain

1 8" 150# Handhole c/w cover, gasket, bolt & nut

Job No. S-14049 Vessel Loading Requirements

Revision

Tag No. FGS-01 ASME Sect. VIII Div. 1 2013 Ed.

REMARKS SERVICE

NOZZLE LIST

WNRF

WNRF

WNRF

MARK

N1

N2

N3

H1

TYPE

WNRF

Das könnte Ihnen auch gefallen

- C:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchDokument1 SeiteC:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchFadhila Ahmad AnindriaNoch keine Bewertungen

- Api 618 4th Ed Si DatasheetsDokument17 SeitenApi 618 4th Ed Si Datasheetshmshawki100% (5)

- CPF-010 Utility Line Sizing Attachment - 0Dokument31 SeitenCPF-010 Utility Line Sizing Attachment - 0goodspeed_phNoch keine Bewertungen

- Body Flange Design-Appx-2Dokument4 SeitenBody Flange Design-Appx-2Matthieu100% (1)

- Pipe Line SizingDokument2 SeitenPipe Line SizingNaveen PeteNoch keine Bewertungen

- FEA-Inlet Separator & Scrubber Process Data Sheet ADA Rev. B0Dokument14 SeitenFEA-Inlet Separator & Scrubber Process Data Sheet ADA Rev. B0ddaalayamoct313024Noch keine Bewertungen

- TBE Inlet Separator V 2100 FLNG2Dokument6 SeitenTBE Inlet Separator V 2100 FLNG2halipzramlyzNoch keine Bewertungen

- MEP-R-ES-007-Flare Stack, Flare Tip and Flame Front GeneratorDokument10 SeitenMEP-R-ES-007-Flare Stack, Flare Tip and Flame Front GeneratorimyourscinNoch keine Bewertungen

- TEMA Sheet Heat Exchanger Specification SheetDokument3 SeitenTEMA Sheet Heat Exchanger Specification SheetSonNguyenNoch keine Bewertungen

- Cpe 12016 Ped 1903Dokument97 SeitenCpe 12016 Ped 1903ImmanuelNoch keine Bewertungen

- Reciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)Dokument17 SeitenReciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)tutuionutNoch keine Bewertungen

- Flat To Steep Curve - Orifice Plate at Pump DischargeDokument1 SeiteFlat To Steep Curve - Orifice Plate at Pump Dischargeorchids28Noch keine Bewertungen

- API 650 Datasheet 1Dokument16 SeitenAPI 650 Datasheet 1alwacsNoch keine Bewertungen

- Compress Report For Pressure VesselDokument394 SeitenCompress Report For Pressure VesselgaurangNoch keine Bewertungen

- CN5191 - L2 - A1-Centrifugal Pump Process Data SheetDokument1 SeiteCN5191 - L2 - A1-Centrifugal Pump Process Data SheetMochi CumilinaNoch keine Bewertungen

- KU-TWK-10-ME-DTS-0304 Rev 2 Data Sheet For Common Electrostatic Coalescer Package PDFDokument7 SeitenKU-TWK-10-ME-DTS-0304 Rev 2 Data Sheet For Common Electrostatic Coalescer Package PDFRexx Mexx100% (1)

- Sample8 DrawingDokument1 SeiteSample8 DrawingRam Kumar NNoch keine Bewertungen

- HSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterDokument2 SeitenHSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterThanh Phuc Nguyen100% (1)

- Quick Opening ClosuresDokument4 SeitenQuick Opening ClosureseduinNoch keine Bewertungen

- ACFrOgBo1iGqwe3hPVDeso7MlgDOoxXORvOyEPoZX7JH5P r8f w5kQHxIeABvtbWmHyzF8fls6khF BW 5H54Qnr8eSv2XIP8cFF1tq7Bcevn9Kl6UNUgaqVsIwYNgDokument2 SeitenACFrOgBo1iGqwe3hPVDeso7MlgDOoxXORvOyEPoZX7JH5P r8f w5kQHxIeABvtbWmHyzF8fls6khF BW 5H54Qnr8eSv2XIP8cFF1tq7Bcevn9Kl6UNUgaqVsIwYNgbaccour bilelNoch keine Bewertungen

- PVV Cal Sheet LabixDokument45 SeitenPVV Cal Sheet LabixPranpath Narupantawart50% (2)

- API 610 Data Sheet 1 PDFDokument6 SeitenAPI 610 Data Sheet 1 PDFSuresh Kumar MittapalliNoch keine Bewertungen

- Table-1 Scope of Work Supply (MR For ACHE)Dokument6 SeitenTable-1 Scope of Work Supply (MR For ACHE)Avinash ShuklaNoch keine Bewertungen

- (P&id1) PDFDokument1 Seite(P&id1) PDFHatem FaroukNoch keine Bewertungen

- Mechanical Data Sheet For Fuel Gas FiltersDokument4 SeitenMechanical Data Sheet For Fuel Gas FilterssudjonoNoch keine Bewertungen

- SVSW 004110 G8 0001 Rev.a Datasheet For Chemical Storage TankDokument4 SeitenSVSW 004110 G8 0001 Rev.a Datasheet For Chemical Storage Tanknguyenquoc1988100% (1)

- SCR Mean - Metal - Temps For Heat Exchanger TubeDokument2 SeitenSCR Mean - Metal - Temps For Heat Exchanger TubescranderiNoch keine Bewertungen

- Gas Liquid Separator V 2001 DatasheetDokument1 SeiteGas Liquid Separator V 2001 DatasheetMathias OnosemuodeNoch keine Bewertungen

- Data Sheet For PSVDokument9 SeitenData Sheet For PSVashams492Noch keine Bewertungen

- Degassing Boot SizingDokument31 SeitenDegassing Boot SizingRexx Mexx50% (2)

- Condensate Tank - For 250Dokument3 SeitenCondensate Tank - For 250Sakthi VelNoch keine Bewertungen

- Vessel Data SheetDokument1 SeiteVessel Data SheetMichael HaiseNoch keine Bewertungen

- Gear Pump Datasheets 1Dokument12 SeitenGear Pump Datasheets 1MauliNoch keine Bewertungen

- TQ - Air Fin Cooler (CS) - ModificationDokument6 SeitenTQ - Air Fin Cooler (CS) - ModificationAvinash ShuklaNoch keine Bewertungen

- Model 75 Gas Filter Separator LTR PDFDokument4 SeitenModel 75 Gas Filter Separator LTR PDFИльяс ГабдуловNoch keine Bewertungen

- 001.17056.000028-AK007-01 Cartridge FilterDokument5 Seiten001.17056.000028-AK007-01 Cartridge FilterQuy RomNoch keine Bewertungen

- Equipment Data Sheet: Type: Doc No: Mds-Pv-01Dokument3 SeitenEquipment Data Sheet: Type: Doc No: Mds-Pv-01Waqas WaqasNoch keine Bewertungen

- B 84567 SB Mm2 DSR ST 60 0020 - 1 - Aoc - GTG Fuel Gas Filter CoalescerDokument11 SeitenB 84567 SB Mm2 DSR ST 60 0020 - 1 - Aoc - GTG Fuel Gas Filter CoalescerpragatheeskNoch keine Bewertungen

- Air Blowe DatasheetDokument1 SeiteAir Blowe DatasheetMoein PNoch keine Bewertungen

- For Information: GE OfficialDokument6 SeitenFor Information: GE OfficialMaulik Dave50% (2)

- Basket Strainer PDC 350NBDokument1 SeiteBasket Strainer PDC 350NBKailas Nimbalkar0% (1)

- 1 TPH For 10.54P Boiler IBR Design Calculations - R2-6-2-13Dokument21 Seiten1 TPH For 10.54P Boiler IBR Design Calculations - R2-6-2-13Vishal KandNoch keine Bewertungen

- Revised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedDokument10 SeitenRevised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedAnonymous bHh1L1Noch keine Bewertungen

- Indirect Fired HeaterDokument2 SeitenIndirect Fired HeaterJoshua CollierNoch keine Bewertungen

- Validated SheetDokument12 SeitenValidated SheetrohitkushNoch keine Bewertungen

- Strainer Screen & Mesh Selection GuideDokument4 SeitenStrainer Screen & Mesh Selection Guidelenasko0% (1)

- TBDP A M DS 0007 2Dokument7 SeitenTBDP A M DS 0007 2Bùi Văn HợpNoch keine Bewertungen

- Flare Data SheetDokument3 SeitenFlare Data Sheetandy131078Noch keine Bewertungen

- Vessel Spec SheetDokument1 SeiteVessel Spec SheetValiNoch keine Bewertungen

- Flare Stack Data SheetDokument4 SeitenFlare Stack Data SheetAnonymous QSfDsVxjZ100% (1)

- Vertical Two-Phase Separator Sizing (SI Units) : Client Proj No Project Calc No Subject Sheet OFDokument4 SeitenVertical Two-Phase Separator Sizing (SI Units) : Client Proj No Project Calc No Subject Sheet OFJhonnatan Fredy Gomez DominguezNoch keine Bewertungen

- B 84547 DY MM2 DSR ST 20 0001 - Rev.1A.MDS Inlet - Separator.IFUDokument10 SeitenB 84547 DY MM2 DSR ST 20 0001 - Rev.1A.MDS Inlet - Separator.IFUYusri FakhrizalNoch keine Bewertungen

- C29732-01-Pid-02.0 - P&id Scrubber TT-006Dokument1 SeiteC29732-01-Pid-02.0 - P&id Scrubber TT-006omarNoch keine Bewertungen

- Electric Heater Datasheet: Case 1A Case 1B Case 2 Case 3 Case 4 Case 5Dokument3 SeitenElectric Heater Datasheet: Case 1A Case 1B Case 2 Case 3 Case 4 Case 5Tuấn VũNoch keine Bewertungen

- 25nb y StrainerDokument1 Seite25nb y StrainerKailas NimbalkarNoch keine Bewertungen

- De MisterDokument2 SeitenDe MisterLaxman G GalipelliNoch keine Bewertungen

- Data Sheet: Document NoDokument3 SeitenData Sheet: Document Nobagus handokoNoch keine Bewertungen

- 18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Dokument5 Seiten18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Avinash ShuklaNoch keine Bewertungen

- Sizing Separators and Accumulators PDFDokument4 SeitenSizing Separators and Accumulators PDFjt_breakdanceNoch keine Bewertungen

- B 84567 SB Mm1 DSR ST 60 0021 1 Aoc GTG Fuel Gas HeaterDokument7 SeitenB 84567 SB Mm1 DSR ST 60 0021 1 Aoc GTG Fuel Gas HeaterpragatheeskNoch keine Bewertungen