Beruflich Dokumente

Kultur Dokumente

C and W Data Hybird - 1027

Hochgeladen von

hassan.19860 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

39 Ansichten6 SeitenThis file contains the formulas to gain Heating Surface and Pressure of a Hybrid Boiler.

Very easy to understand.

Originaltitel

c and w Data Hybird_1027

Copyright

© © All Rights Reserved

Verfügbare Formate

DOC, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis file contains the formulas to gain Heating Surface and Pressure of a Hybrid Boiler.

Very easy to understand.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

39 Ansichten6 SeitenC and W Data Hybird - 1027

Hochgeladen von

hassan.1986This file contains the formulas to gain Heating Surface and Pressure of a Hybrid Boiler.

Very easy to understand.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 6

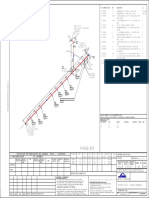

CONSTRUCTION AND WORKMANSHIP DATA

FOR BOLER NO: PIE 1027 HYBIRD

PAK INDUSTRIAL ENGINEERS (PVT) LTD

S/NO ITEM NAME DESCRIPTION SIZE MATERIAL

A SHELL Cylindrical, straight with 2 belt. ASTM A 516 GR 70

Outer Dia 54.12

Thickness 14mm

Inner Dia 5

T!tal "ength #.5 $t

"!ng, circum$erences seams 2

B TUBE PLATES !FRONT PLATE" ASTM A 516 GR70

Dia 5

Thickness 1# mm

%!de !$ attachment. &y weld 's detail in drawing.

(&"'C) *"'T+,

Dia 5

Thickness 1# mm

%!de !$ attachment. &y weld 's detail in drawing.

C TUBES # 2

$%

P&'' SEAMLESS ASTM A 106

Outer Dia -1mm

Thickness .5mm

"ength #.5$t

T!tal .! !$ Tubes 5-

*lain Tubes 44

/tay Tubes 12

/tay Tubes Thickness 5mm

D TUBES # (

)%

P&' SEAMLESS ASTM A 106

Outer Dia -1 mm

Thickness .5 mm

"ength #.5 $t

T!tal n! !$ Tubes 40

*lain Tubes 0

/tay Tubes 10

/tay Tubes Thickness 5 mm

E STAYS

LONG STAY

SA # 2* GIT

.!. !$ /tays 2

Thickness 1.25

/tay attachment with tube 1late &y weld

F MAIN HOLE Ty1e C!llar ring

O2al

"!cati!n /hell t!1

/i3e (Inner, 1241-4.#5

.!s. 1

G

INSPECTION HOLES

"!cati!n /hell side

/i3e (Inner, Id -61.5

.!s. 2

H BOILER MOUNTINGS I$$+) D,& N-'

/a$ety 7al2es 1.5 2

/t!1 7al2e 2 1

*ressure 8uage 0.5 6 # 1

8uage 8lass 9 2

&l!w D!wn 1 1 1 2 .O.

:eed Check 7al2e 1 1

%!brey C!nnecti!ns 1 1

'ir 7ent 7al2e 1 1

I FITTINGS

&urner 8'/ ;

<OOD

Chimney 15 6 0=

:eed *um1 %ulti stage

10)<

+c!n!mi3er -5 s>$t

'ir ?eater -5 s>$t

/u1er ?eater .I"

1. Certi$ied that 1articulars entered ab!2e by use are c!rrect and 1arts ; $ittings used in c!nstructi!n !$ the b!iler

are acc!rding t! entries made.

2. The design !$ the b!iler in secti!n and end 2iews with 1rinci1al 1arts $ully dimensi!ned are sh!wn in !ur drwg.

.! *I+ @ /T @ 002, steel maker=s certi$icates, results !$ 1late tests $!r tensile strength, el!ngati!n and bending

and ins1ecting auth!rity Certi$icates in $!rm II acc!m1any the data re1!rt.

. The &!iler has been designed and c!nstructed t! c!m1ly with the *akistan &!iler=s Ordinance 2002, &!iler

regulati!n and '/%+ &!iler and 1ressure 2essel C!de as ad!1ted by :ederal &!ilers &!ard !$ *akistan $!r a

w!rking 1ressure !$ 150*/I and satis$act!rily withst!!d a water test 1ressure !$ 255 */I at !ur w!rks !n

AAAAA04A2012 .

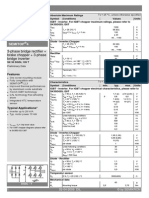

HEATING SURFACE CALCULATION

FOR BOILER NO PIE 1027

DRAWING NO PIE # ST # 002

2

$%

PASS

OD I. I.C?+/ 2.5

"+.8T? I. :++T #.5

.O O: TB&+/ 5-

:OC%B"' D OD 4 22E5 4 "8T? I. :T 4 .O/ O: TB&+/

2.5 E12 4 22E5 4 #.5 4 5-

(11 S. FT

(

)%

PASS

OD I. I.C?+/ 2.5

"+.8T? I. :++T #.5

.O O: TB&+/ 40

:OC%B"' D OD 4 22E5 4 "8T? I. :T 4 .O/ O: TB&+/

2.5 E12 4 22E5 4 #.5 4 40

222 S.FT

TOT'" ?+'TI.8 /BC:'C+ D

2

.D

*'// TB&/ F

CD

*'// TB&+/

TOT'" ?+'TI.8 /BC:'C+ D 11F 222 F 115

TOTAL HEATING SURFACE / 5(( S. FT

STRENGTH CALCULATION FOR BOILERS UNDER PAKISTAN

BOILERS REGULATION

BOILER NO PIE 1027

DRAWING NO PIE # ST # 002

SHELL

+>uati!n .! 251

<*

OD D OBT+C DI' O: /?+"" I. I.C?+/

ID D I..+C DI' O: /?+"" I. I.C?+/

: D *+C%I//I&"+ <OC)I.8 /TC+// I. "&E/G. I.C?+/

+ D +::I+CI+.CH O: <+"DI.8 IOI.T

OD 5

T?IC).+// 0.5

ID 54

: 14000

+ 100J

/O"BTIO.. 1. (OD K OD @ ID K ID, D 2L2#.L5 @ 2#0LD 11L.L5

2. (OD K OD F ID K ID, D F D 555.L5

<.* D

97 . 5737

97 . 119 1 14000 X X

WP / 2*271 PSI

WATER WALLS HEADER

+>uati!n .! 251 +D *AD

*

<* +D 4A2.5

4

OD D OBT+C DI' O: /?+"" I. I.C?+/

ID D I..+C DI' O: /?+"" I. I.C?+/

: D *+C%I//I&"+ <OC)I.8 /TC+// I. "&E/G. I.C?+/

+ D +::I+CI+.CH O: <+"DI.8 IOI.T

OD -.55

T?IC).+// 0.5

ID -

: 14000

+ .55J

/O"BTIO.. 1. (OD K OD @ ID K ID, D 45.5 @ - D L.5

2. (OD K OD F ID K ID, D 45.5F - D #1.5

<.* D

5 . 81

5 . 9 375 . 14000 X X

WP / 611*0 PSI

SMOKE TUBES FOR 2

ND

PASS (

)%

PASS

E12&3,-$ N- 1**

FORMULA /

OD D !uter dia !$ tubes in inches

T D thickness !$ tubes in 100

th

!$ an inch.

C D c!nstant

OD 2.5

T .25 TE25 D 0.12#

C2 100 TK100 D 12.5L5

C -

C4 25.4

SOLUTION:

T @ - D -.5L5

100 (TA-, D -5L.52#

WP / ((*76 PSI

15 15 GUEST STAY

124510451666

10 NOS ASTM A 516 GR

70

17 17 MUD HOLE 64 PADE ( NOS ASTM A 516 GR

70

1( 1( MAIN HOLE 1245164

WITH RING 14574

1 NO ASTM A 516 GR

70

12 12 GAUGE GLASS COCK

SET 5/04

2 NO MS FORGED

11 11 MAIN STOP 8AL8E

ANGLE TYPE 154

1 NO MILD STEEL

10 10 BLOW DOWN 8AL8E

GEAR TYPE 154 9 14

( NOS MILD STEEL

* * FEED CHECK 9NON

RETURN 8AL8E 154

1 NO MILD STEEL

0 0 AIR 8ENT 8ALE 14 1 NO MILD STEEL

7 7 SAFETY 8AL8E SPRING

15

MILD STEEL

6 6 (

RD

PASS STAY TUBES

6166 566

10 NOS ASTM A 106

5 5 (

RD

PASS PLAIN TUBES

6166 566

(0 NOS ASTM A 106

7 7 2

ND

PASS STAY TUBES

6166 (566

12 NOS ASTM A 106

( ( 2

ND

PASS PLAIN TUBES

6166 (566

77 NOS ASTM A 106

2 2 TUBE PLATE 574 DIA

1066 T:

2 NOS ASTM A 516 GR

70

1 1 SHELL 574 OD 05 ;3 L

<4 T:

1 NO ASTM A 516 GR

70

S= DRG= DESCRIPTION .TY TYPE

BOILER NO PIE 1027 APPRO8AL NO

PIE ST002

DP>160 PSI WP 150 PSI TP 150 PSI HEATING SURFACE

5(( S.FT

PAK INDUSTRIAL ENGINEERS

218- C, OPP. BADAR PURA,MULTAN ROAD, LAHORE

Tel: !2-"2-#$"!$%!$-!8 &'(: !2-"2-#$"!$%!!

Das könnte Ihnen auch gefallen

- Caterpillar 3208 Diesel Engine SM Manual Copy OneDokument350 SeitenCaterpillar 3208 Diesel Engine SM Manual Copy Oneswoods71588% (25)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsVon EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Pipe Schedule and Thickness RevisedDokument4 SeitenPipe Schedule and Thickness Revisedrajaram100% (1)

- Shinwa Cooling TowersDokument71 SeitenShinwa Cooling TowersFREDIELABRADOR67% (3)

- Rigging PracticesDokument58 SeitenRigging Practicesravi00098Noch keine Bewertungen

- Pocket Guide to Flanges, Fittings, and Piping DataVon EverandPocket Guide to Flanges, Fittings, and Piping DataBewertung: 3.5 von 5 Sternen3.5/5 (22)

- HCR 910-DSDokument720 SeitenHCR 910-DSElizabeth Octagon100% (1)

- Duct Static Pressure Loss CalculationDokument8 SeitenDuct Static Pressure Loss CalculationYe Thiha Min100% (2)

- IsometricsDokument4 SeitenIsometricsMuhammedHafisNoch keine Bewertungen

- easyFIXS Canon Service Tools and Supported Printers PDFDokument1 SeiteeasyFIXS Canon Service Tools and Supported Printers PDFComputer AppsNoch keine Bewertungen

- E-Hydro Trip Sub Technical DatasheetDokument4 SeitenE-Hydro Trip Sub Technical DatasheetEvolution Oil ToolsNoch keine Bewertungen

- 13 - Copes-Vulcan ValvesDokument7 Seiten13 - Copes-Vulcan ValvesshalegpNoch keine Bewertungen

- PmsDokument94 SeitenPmssdk1978100% (1)

- PBM Sanitary Ball ValvesDokument40 SeitenPBM Sanitary Ball ValvesAnonymous bTvqZMftNoch keine Bewertungen

- Sample8 DrawingDokument1 SeiteSample8 DrawingRam Kumar NNoch keine Bewertungen

- 06 632Dokument12 Seiten06 632Fernando Sabino100% (1)

- 185-170-5-300-M44-0058 RevDDokument1 Seite185-170-5-300-M44-0058 RevDVashish RamrechaNoch keine Bewertungen

- Butterfly ValveDokument1 SeiteButterfly ValveDnyaneshwar0% (1)

- MD PV ASME v0.1Dokument35 SeitenMD PV ASME v0.1rizalramaNoch keine Bewertungen

- Sample13 DrawingDokument2 SeitenSample13 DrawingSourav HaitNoch keine Bewertungen

- FAULT CODES Toshiba Studio 160Dokument7 SeitenFAULT CODES Toshiba Studio 160Bansi KhetwaniNoch keine Bewertungen

- Model E & Pe RegulatorsDokument5 SeitenModel E & Pe RegulatorsMiguel Angel NajeraNoch keine Bewertungen

- Equipment Erection ProcedureDokument6 SeitenEquipment Erection Procedureคุณพ่อน้อง บิ๊กบอส100% (1)

- Butterfly ValveDokument14 SeitenButterfly ValveSingSareblakKanaManahNoch keine Bewertungen

- AES Type Heat ExchangerDokument8 SeitenAES Type Heat ExchangerSudhanshu67100% (1)

- 250 PSI CWP Iron Body Gate Valve: 250 PSI/17.2 Bar Non-Shock Cold Working PressureDokument1 Seite250 PSI CWP Iron Body Gate Valve: 250 PSI/17.2 Bar Non-Shock Cold Working PressureStephanie AdkinsNoch keine Bewertungen

- Caractéristiques Des Joints Gaskets Characteristics: Gray Cells Shall Leave Empty, Yellow Cells Are OptionalDokument14 SeitenCaractéristiques Des Joints Gaskets Characteristics: Gray Cells Shall Leave Empty, Yellow Cells Are OptionalNikki RobertsNoch keine Bewertungen

- DK-Lok Tube Fittings - Tube To SAE O-Ring SealDokument6 SeitenDK-Lok Tube Fittings - Tube To SAE O-Ring SealHLHDungNoch keine Bewertungen

- PVH Sight Glass Data SheetDokument11 SeitenPVH Sight Glass Data SheetANIKET PATILNoch keine Bewertungen

- uPVC Pipes According to DIN StandardsDokument7 SeitenuPVC Pipes According to DIN Standardsしんちゃん ナカリンNoch keine Bewertungen

- BallValues PDFDokument12 SeitenBallValues PDFDevdatt WaghuleNoch keine Bewertungen

- Parafusos PT SemblexDokument10 SeitenParafusos PT SemblexSBonderNoch keine Bewertungen

- PB TW10 GBDokument6 SeitenPB TW10 GBfebri_bontangNoch keine Bewertungen

- PRV TDSDokument2 SeitenPRV TDSIskandar HasibuanNoch keine Bewertungen

- Butterfly Valve, Grooved End, Globe, Model GLR300GDokument9 SeitenButterfly Valve, Grooved End, Globe, Model GLR300Grahu2260Noch keine Bewertungen

- Min1244a12 - Tag 130-Pu-029Dokument7 SeitenMin1244a12 - Tag 130-Pu-029Monty MathewsNoch keine Bewertungen

- TS 6p-200Dokument2 SeitenTS 6p-200Arnold Abalos VersozaNoch keine Bewertungen

- TYCO Keystone F14.Lined - Butterfly.valve enDokument4 SeitenTYCO Keystone F14.Lined - Butterfly.valve enIrina CretuNoch keine Bewertungen

- Aloyco Stainess Steel ValvesDokument26 SeitenAloyco Stainess Steel Valvescristi_molins100% (1)

- Re 500Dokument15 SeitenRe 500mazmamrefNoch keine Bewertungen

- Catalog Valve KSBDokument58 SeitenCatalog Valve KSByoboo100% (1)

- TAD-Datasheet 6L6GC-STR Version1.3 08.07.11Dokument1 SeiteTAD-Datasheet 6L6GC-STR Version1.3 08.07.11Ludwig_ANoch keine Bewertungen

- Handwheels: Product Details Order / Inquiry CAD DataDokument1 SeiteHandwheels: Product Details Order / Inquiry CAD DataDaniel MikicNoch keine Bewertungen

- Bombas Dosificadoras Milton Roy Lmi CDokument2 SeitenBombas Dosificadoras Milton Roy Lmi CErikLjNoch keine Bewertungen

- Pneumatically Operated Diaphragm ValveDokument8 SeitenPneumatically Operated Diaphragm ValveRavi ChaurasiaNoch keine Bewertungen

- DB 658 688 GBDokument6 SeitenDB 658 688 GBDenial BasanovicNoch keine Bewertungen

- Do All Parts BookModel ML - 3801 - 5418353Dokument64 SeitenDo All Parts BookModel ML - 3801 - 5418353bubbaglass4u2100% (1)

- SRTDokument3 SeitenSRTDaniel SamokovliaNoch keine Bewertungen

- Excess Flow Valves Bleed Valves and Purge ValvesDokument6 SeitenExcess Flow Valves Bleed Valves and Purge ValvesNilesh MistryNoch keine Bewertungen

- SK 50 DGDL 126 T: Converter, Inverter, BrakeDokument4 SeitenSK 50 DGDL 126 T: Converter, Inverter, Brakemurugan_parvathyNoch keine Bewertungen

- Report of Supply ChainDokument22 SeitenReport of Supply ChainkhanimmadNoch keine Bewertungen

- Metric Section BDokument26 SeitenMetric Section BniladriprasadrNoch keine Bewertungen

- Flareless Bite Type Fittings GuideDokument24 SeitenFlareless Bite Type Fittings GuideRickson Viahul Rayan CNoch keine Bewertungen

- 3C - 101295 R-0Dokument1 Seite3C - 101295 R-0kasturisunilkumarNoch keine Bewertungen

- 10 SEER air conditioner specsDokument4 Seiten10 SEER air conditioner specsOscar Sanchez Velasquez0% (1)

- Jal International Company LTDDokument3 SeitenJal International Company LTDsrinivasaphanikiranNoch keine Bewertungen

- Pressfit 316 Stainless Steel Pipe SystemDokument12 SeitenPressfit 316 Stainless Steel Pipe SystemFaull JackmanNoch keine Bewertungen

- Automatic Valve Gemue DB - 512 - GBDokument6 SeitenAutomatic Valve Gemue DB - 512 - GBTaher Yusuf100% (1)

- Fluidic Components and Equipment 1968–9: Pergamon Electronics Data SeriesVon EverandFluidic Components and Equipment 1968–9: Pergamon Electronics Data SeriesNoch keine Bewertungen

- Kixx Atf Dx-Iii: GM Dexron - Iii, Mercon, Allison C-4Dokument1 SeiteKixx Atf Dx-Iii: GM Dexron - Iii, Mercon, Allison C-4jack sliverNoch keine Bewertungen

- Installation Manual for CS Instruments Spot Drilling CollarDokument13 SeitenInstallation Manual for CS Instruments Spot Drilling CollarArmando SixtoNoch keine Bewertungen

- Service Manual: EPSON Stylus Pro 7600/9600Dokument322 SeitenService Manual: EPSON Stylus Pro 7600/9600Luis Miguel Martinez PerezNoch keine Bewertungen

- Hydraulic PM Procedure ExampleDokument3 SeitenHydraulic PM Procedure Exampleahmed mohamedNoch keine Bewertungen

- VEH MB ML320 EFI Throttle Valve Actuator FunctionDokument1 SeiteVEH MB ML320 EFI Throttle Valve Actuator Functiond9dNoch keine Bewertungen

- Hyc 610Dokument2 SeitenHyc 610saneesh v.simonNoch keine Bewertungen

- RLC 1st ManualDokument141 SeitenRLC 1st Manualjaved shaikh chaandNoch keine Bewertungen

- Electrovalva E6-E11 SeriesDokument3 SeitenElectrovalva E6-E11 SeriesMonica GrecuNoch keine Bewertungen

- 2 WaydistributorDokument53 Seiten2 WaydistributormbhaditNoch keine Bewertungen

- M.V Arabian Sea Electrical Repairs For Lay Up 2017: RS No. Work Specification QTY RemarksDokument3 SeitenM.V Arabian Sea Electrical Repairs For Lay Up 2017: RS No. Work Specification QTY RemarksMariyath Muraleedharan KiranNoch keine Bewertungen

- Charger CatalogueDokument16 SeitenCharger CatalogueNguyen Quang Sang0% (1)

- Tutorials For STM32F103RB: Nicolas BarbotDokument13 SeitenTutorials For STM32F103RB: Nicolas BarbotcarNoch keine Bewertungen

- K3214Dokument8 SeitenK3214Bharath ErNoch keine Bewertungen

- Echometer Acoustic Wellhead Parts List: Part Number Part Name PictureDokument4 SeitenEchometer Acoustic Wellhead Parts List: Part Number Part Name PictureBoyke SaptaNoch keine Bewertungen

- EE 402 Special Electric Machines SyllabusDokument65 SeitenEE 402 Special Electric Machines SyllabusharithaNoch keine Bewertungen

- LG Therma V Split Rukovodstvo PolzovatelyaDokument30 SeitenLG Therma V Split Rukovodstvo Polzovatelyagheorghe tabaraNoch keine Bewertungen

- SSSC (Phasor Model) - MATLAB & Simulink ExampleDokument2 SeitenSSSC (Phasor Model) - MATLAB & Simulink ExampleRahmadi SetiawanNoch keine Bewertungen

- Coa Unit-3Dokument35 SeitenCoa Unit-3Revanth RavikantiNoch keine Bewertungen

- Hydraulic Gear Shift (HGS) Systems: Made by Kongsberg AutomotiveDokument4 SeitenHydraulic Gear Shift (HGS) Systems: Made by Kongsberg AutomotiveFrancis QuarshieNoch keine Bewertungen

- Rfid Door Lock SystemDokument13 SeitenRfid Door Lock SystemOlumoyin Tolulope100% (1)

- SMC8508T Ug R01Dokument27 SeitenSMC8508T Ug R01Epure LiviuNoch keine Bewertungen

- Features 10N65 650V N-Channel MOSFET: TO-220F PackageDokument7 SeitenFeatures 10N65 650V N-Channel MOSFET: TO-220F PackageMindSet MarcosNoch keine Bewertungen

- Mercedes-Benz C-Class Sedan 2014 4d Hybrid EN 205.14v2.0Dokument2 SeitenMercedes-Benz C-Class Sedan 2014 4d Hybrid EN 205.14v2.0Ricardo Santo AntonioNoch keine Bewertungen

- Power Planer ManualDokument8 SeitenPower Planer ManualCataNoch keine Bewertungen

- Reduce RsDokument73 SeitenReduce RsbangpaiNoch keine Bewertungen

- sn75hvd12 PDFDokument37 Seitensn75hvd12 PDFAnonymous mYNls8PNoch keine Bewertungen

- AT400T41T M.Y. 2013 Cursor 13 Euro ViDokument16 SeitenAT400T41T M.Y. 2013 Cursor 13 Euro ViCesar MartinezNoch keine Bewertungen