Beruflich Dokumente

Kultur Dokumente

Welding Processes

Hochgeladen von

Jitendra UmaraliyaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Welding Processes

Hochgeladen von

Jitendra UmaraliyaCopyright:

Verfügbare Formate

1

ESSC - ADVANTAGES

SIMILAR EQPT. AS SAW

HIGHER DEPOSITION

VERY LOW DILUTION LEVEL

LESSER NO. OF LAYERS TO ACHIEVE

CHEMISTRY

STABLE PROCESS WITH LESS DEFECT

LOW FLUX CONSUMPTION (HALF OF WM)

2

I.D OVERLAY

FCAW GTAW PROCESS

OVERLAY ON SMALL DIAMETER

NO!!LE PIPES FORGINGS

DEVELOPED DOWN TO 2"## I.D

AFTER OVERLAY

MAX. LENGTH WELDED $ 2.% #&

'

PRODUCTIVITY

PROCESS MATERIAL DIA. AMP DEPOSITION NO. OF ELECTRODE

PER ARC-HR PER ARC-HR

(())

SMAW CS 2." *+ +., "-

'.2 1'+ 1.1 %%

%.+ 1*+ 1." '*

".+ 2%+ 2.% '%

SS 2." *+ +.- "2

'.2 1++ 1.+ ""

%.+ 1%+ 1.2 %2

FCAW CS 1.2 2++ '.'

SS 1.2 2++ '.%

%

PRODUCTIVITY

PROCESS MAT. DIA. AMP DEPOSITION PER

ARC-HR (Kg)

SAW CS 4.0 550 6.5

TWIN- CS 2.4X 2 550 6.6

WIRE SAW

TANDEM CS 4.0X 2 600 14

SAW

ESSC SS 60X0.5 1200 22

0X0.5 1!00 ""

120X0. 5 2200 42

"

-

FCAW

CONSUMABLE

C-Mn STEEL C- 1.6%Mn ER 70S-2 E 71T-1/ E70T-5 EH-14+TAPADA-!0/

"SA516 #R60/70$ S% + U&420TTR

C-M' LAS C- 0.5% M'/ E 701! A1 / ER !0S-D2 E70T-A1 / EA-% + OP41TT

"SA204-B$SA%02-B( C-Mn-M' E !01! D% E!1T1-A1 EA-4/EF-% + U&420TTR

1.25C)-0.5M' LAS 1*1.25C)-0.5M' E !01!B2 ER !0SB2 E !1T1-B2 EB2 + U&420TTR

"SA%!7#R11CL1/2(

2.25 C)-M' LAS 2.25C)-1M' E +01!B% ER +0SB% E+1T1-B% EB% + U&420TTR

"SA%!7 #R22CL2(

SS %04/ %04L 1!C) - !N, E %0!/ %0!L ER %0!/ %0!L E %0!LT-1 / E%0!LT0-1 ER%0!L + SS#R.1 / F--1

"SA240#R%04L(

SS %16/ %16L E %16/ %16L ER%16/ %16L E%16LT-1/ E%16LT0-1 ER%16L + SS#R.1 / F--1

"SA240#R%16L(

SS%21/ %47 E %47 ER%47 E%47T-1/ E%47T0-1 ER%47 + SS#R.1 / F--1

"SA240#R%21/ %21H(

SS-410S 1%%C)

E %0+LT-1/ E%0+LT0-

1

"SA240 T./0410S(

E %0+/ E%0+M'/

EN,C)F0%

ER%0+ / ER%0+M'/

ERN,CR%

BASE METAL - WELDN# CONSUMABLE SELECTON

SAW CONSUMABLE

E 701!/ 701!-1

1!C) - !N, -

2*%M'

1!C) - !N, -

N1+T2

MATERAL T3PE

NOMNAL

COMPOSTO

N

SMAW

CONSUMABLE

#TAW

CONSUMABLE

,

*

PREHEAT

ADVANTAGES

TO REMOVE OIL, MOISTURE ETC.

TO AVOID CRACKING

PREHEAT - MINIMUM 1 INCH. ON EITHER

SIDE OF JOINT.

USE ONLY LPG / ELECTRIC HEATING.

CARRY OUT UNIFORM PREHEAT

USE TEMPERATURE STICKS TO CHECK.

.

POSTHEATING

IF NOT DONE - CRACKS. FAILURE

IN

SERVICE.

HEATING AT 300 - 350 C FOR 3 /

HRS MIN. !EFORE ALLO"ING "ELD TO

COOL TO ROOM TEMPERATURE

FROM PREHEAT TEMPERATURE

AFTER POST HEATING COVER THE JOINT

"ITH AS!ESTOS FOR SLO" COOLING.

12

1'

CONSUMABLE PRICES

SMAW E#ECTRODE$ %TAW WIRE.)

TYPE COST() (R/)

E,+1* ""

E,+1*-1 -+

E*+1*B2 2,+

E'+*L %++

E'+.L "++

EN0C1F2' 12++

EN0C3, *++

1%

CONSUMABLE PRICES

SMAW E#ECTRODE$ %TAW WIRE(CONT.)

TYPE COST() (R/)

ER,+S-2 1.+

ER'+.L %*+

ER'+*L '"+

ERN0C1' 1+++

1"

CONSUMABLE PRICES

SAW$ &CAW WIRE

TYPE COSTSPOOL(R/)

S' 1*," (2" () SPOOL)

EH-1% 1'++ (2" () SPOOL)

ER'+*L '-2" (2" () SPOOL)

E,1T-1 1"++ (12." () SPOOL)

E'+.LT-1 "+++ (12." () SPOOL)

E'%,T-1 "+++ (12." () SPOOL)

E'+*LT-1 "+++ (12." () SPOOL)

1-

CONSUMABLE PRICES

&#UX

TYPE COST() (R/)

UV%2+TTR ,-

TAPADIA-*+ 2"

SS GR-1 1'+

F4-1 12"

', S 2++

1,

1*

In case fluxes are not used regularly,

oven temp. can be reduced to 100C.

However, the fluxes are to be baked at

00!"0C for # hrs m$n$mum pr$or to

$ssue.

% e.g.&'(#0))*, )apad$a +0 etc.,

00!"0C for # hrs

$mmed$ately before

use

SAW FLU4ES 00C m$n$mum.

-o t$me l$m$t

RE5UREMENTS FOR DR3N# OF WELDN# CONSUMABLES

# 1."!#00C for # hrs

m$n before use

100C m$n t$ll use

REMAR6S

/fter bak$ng the electrodes can be

stored $n hold$ng ovens % at 100C m$n t$ll

use ,

100C m$n t$ll use

BA6N# C3CLE

HOLDN# TME 7

TEMP.

SMAW

!do!

!0ow Hydrogen Carbon 1 0ow /lloy

2teel 3lectrodes % e.g. 3.01+,

3+01+ 4# etc. ,

#"0!00C for # hrs

m$n before use

SMAW

SL.

NO.

CONSUMABLES

!2ta$nless 2teel 3lectrodes,

! -on 5errous 3lectrodes

1

1.

2+

WE#DER '#&N. - ASME SEC.IX

ESSENTIA# VARIA(#ES

WELDING PROCESS

WELDING TYPE

BASE METAL (P N5.)

FILLER METAL N5. (F N5.)

WELD BASE METAL TH(. 6 DIAMETER LIMIT

BAC(ING

POSITIONS

21

WE#DIN% PROCESS

WE#DERS )

- SMAW

- GTAW

- FCAW GMAW

WE#DIN% OPERATORS )

- SAW

- ESSC

- MACHINE GTAW

WE#DER '#&N. - ASME SEC.IX

22

WE#DER '#&N. - ASME SEC.IX

WELDING TYPE

MANUAL SEMI-AUTOMATIC

MACHINE

AUTOMATIC

2'

WE#DER '#&N. - ASME SEC.IX

P N'.

P1

P%$4$5

P6$7

P!

P+

P10$11

P24

P%4

P44

P54

P64

T./0 '8 M290),2:

C2)1'n S900:

L'; A::'. S900:

F0)),9,< 2n= M2)90n>,9,< S92,n:0>> S900:

A?>90n,9,< S92,n:0>> S900:

N,<@0: S900: ":0>> 9A2n 4.5% N,(

5?0n<A0= 2n= T0B/0)0= S900:

A:?B,n,?B 2n= A::'.>

C'//0) 2n= A::'.> "C?/)'n,<@0:(

N,<@0: 2n= N,<@0: B2>0 A::'.>

T,92n,?B 2n= T,92n,?B B2>0 A::'.>

C,)<'n,?B 2n= C,)<'n,?B B2>0 A::'.>

2%

WE#DER '#&N. - ASME SEC.IX

Base Metals for Welder Qualifcation

P N# 1 $%&#'(% P N#. 11 )*+ P

N#. 3

#& P N#. ,

P N#. -1 $%&#'(% P N#. -5

P N#. 5, #& P N#. .,

Qualifed Production Base Metals

P N# 1 $%&#'(% P N#. 11 , P N#. 3,

P N#. , )*+ '*)//0(*1+ 21$)3/ #4 /0203)&

5%1205)3 5#26#/0$0#*

P N#. -1 $%&#'(% P N#. -5

P N#. 5, )*+ P N#. .,

2"

F- NUMBERS

F% - LOW H2 TYPE CS LAS - E,+1*7 E *+1*B2

F" - AUSTENITIC SS - E'+.'+*'%,

F- - GTAWSAWFCAW CSLAS -ER,+S2S'E,1T-1

ER'+*E'+*LT-1

F'X-C3 6 C3 BASE ALLOYS - ERN0C3, EN0C3,

F%X-N0 6 N0 BASE ALLOYS - EN0C1F2'ERN0C1'

F"X-T0 6 T0 BASE ALLOYS - ERT0-1

F,X-HARD FACING CONS. -STELLITE-1-

2-

WE#DER '#&N. - ASME SEC.IX

5?2:,8,0= ;,9A

F N' 4

F N' 5

An. F N' 6

An. F N' 21 9A)'?DA F N' 25

An. F N' %1$ F N' %2$ F N' %%$

F N' %5$ F N' %6 ') F N' %7

F N' %4 ') 2n. F N' 41 9A)'?DAF N' 45

2n. F N' 51 9A)'?DA F N' 54

An. F N' 61

An. F N' 71 9A)'?DA F N' 72

5?2:,8,0= 8')

F N' 1$ 2$ %$ 4

F N' 5

A:: F N' 6

A:: F N' 21 9A)'?DA 25

On:. 9A0 >2B0 F N?B10) 2> ;2> ?>0=

=?),nD 9A0 E?2:,8,<29,'n 90>9

F N' %4 2n= 2:: F N' 41 9A)'?DA F N' 45

A:: F N' 51 9A)'?DA F N' 54

A:: F N' 61

On:. 9A0 >2B0 F N?B10) 2> ;2> ?>0=

=?),nD 9A0 E?2:,8,<29,'n 90>9

A:90)n290 F N' 8') W0:=0) P0)8')B2n<0 5?2:,8,<29,'n

2,

WE#DER '#&N. - ASME SEC.IX

Weld Thickness in Qualification Test

[t in inch (mm)]

FG%/4 "1+.05(

H%/4 "1+.05(

#ROO&E

Maximum Qualified Weld Thickness

[inch (mm)]

An. TA,<@n0>>

29

O&ERLA3

Qualification Test Thickness

[T in inch (mm)]

Thickness Qualified

[inch (mm)]

U/9' 1 "25.4( T 9' ?n:,B,90=

F 1 "25.4( 1 "25.4( 9' ?n:,B,90=

2*

WE#DER '#&N. - ASME SEC.IX

#ROO&E AND O&ERLA3 WELDS - LMTATONS ON PPE / TUBE DAMETERS

OD inch (mm) NB inch Minimum Maximum

H1 "25.4( H%/4 S,I0 W0:=0= Un:,B,90=

1 9' 2 "7/!( ') 25.4 BB

9' 7%.0% BB

%/4 9' 2"1/2( 1 "25.4( Un:,B,90=

FG 2"7/!( ') 7%.0%BB 2"1/2( 2"7/!( ') 7%.0% Un:,B,90=

2.

- SN#LE SDED WELD - WELD WTHOUT BAC6N#/

FBRE TAPE

- DOUBLE SDED WELD - WELD WTH CHP BAC6/

BAC6N#

!ACKING

WE#DER '#&N. - ASME SEC.IX

QUALIFICATION WITH QUALIFIE

FO!

SINGLE SIDED SINGLE /

DOU!LE SIDED

DOU!LE SIDED DOU!LE SIDED

'+

PERFORMANCE 5UALFCATON- POSTON AND DAMETER

LMTATONS

NOTEJ

%1, 6$pe # o.d. and over. 7/8

17

#7

7

(7

7 and (7

#7,7,and (7

17

#7

"7

87

#7 and "7

P:290 2n= P,/0

OK0) 24 ,n.O.D.

P,/0

HG 24 ,n. O.D.

P:290 2n= P,/0

#)''K0 F,::09

P'>,9,'n 2n= T./0 W0:= 5?2:,8,0=

W0:= P'>,9,'n

6$pe!7roove

/00

/00

5

/00

/00

/00

5,H

5

5,H

5,H,'

5,H,9

/00

5,',9

5

5,H

/00

5

5,H

5 : -ote %1, ;

5,H : -ote %1, ;

5,',9

/00 /00

5 : -ote %1, ;

5 : -ote %1, ;

5 : -ote %1, ;

5,H : -ote %1, ;

5,9

5,',9

/00

5

5,H

5,'

5?2:,8,<29,'n T0>9

6late! 7roove

Das könnte Ihnen auch gefallen

- Pravilnik o Tehničkim Normativima Za Pokretne Zatvorene Sudove Za Komprimirane Tečne I Pod Pritiskom Rastvorene GasoveDokument13 SeitenPravilnik o Tehničkim Normativima Za Pokretne Zatvorene Sudove Za Komprimirane Tečne I Pod Pritiskom Rastvorene GasoveSrbislav GenicNoch keine Bewertungen

- RS 70 - Conexel - Relé de InterposiçãoDokument1 SeiteRS 70 - Conexel - Relé de InterposiçãoKim Nicolas SaikiNoch keine Bewertungen

- 8.1 - 5 MvaDokument4 Seiten8.1 - 5 MvafaharaNoch keine Bewertungen

- Interni Standard 37 Trajno Dozvoljene Struje Faznih Provodnika Nadzemnih VodovaDokument8 SeitenInterni Standard 37 Trajno Dozvoljene Struje Faznih Provodnika Nadzemnih Vodovacommunist88Noch keine Bewertungen

- BTB Network 2005-1 PDFDokument135 SeitenBTB Network 2005-1 PDFĐể Mai TắmNoch keine Bewertungen

- R5Sr&Ttug Gu% Vur Uw: Cap. 5,51,21 DRF 19,35,04 WMS 3,43,77Dokument2 SeitenR5Sr&Ttug Gu% Vur Uw: Cap. 5,51,21 DRF 19,35,04 WMS 3,43,77Ashish Kumar PandeyNoch keine Bewertungen

- UNIT Conversion FactorsDokument22 SeitenUNIT Conversion FactorsGuillermo Lopez-FloresNoch keine Bewertungen

- 8.01 Manufacturer'S Guaranteed Technical Data Schedule For 33/11 KV, 5/6.67 Mva Power TransformerDokument5 Seiten8.01 Manufacturer'S Guaranteed Technical Data Schedule For 33/11 KV, 5/6.67 Mva Power TransformerfaharaNoch keine Bewertungen

- NCSI HLT-BrochureDokument8 SeitenNCSI HLT-BrochureahmetNoch keine Bewertungen

- 36 มยผ.8116-52 มาตรฐานแผงควบคุมเครื่องสูบน้ำดับเพลิงDokument21 Seiten36 มยผ.8116-52 มาตรฐานแผงควบคุมเครื่องสูบน้ำดับเพลิงappril26Noch keine Bewertungen

- Nit 1987 2Dokument31 SeitenNit 1987 2kunaldeoraNoch keine Bewertungen

- TCP SpecDokument23 SeitenTCP SpecGiridharan GanesanNoch keine Bewertungen

- Transmission Line Design For IOE StudentsDokument20 SeitenTransmission Line Design For IOE StudentsKiran PanthaNoch keine Bewertungen

- Cuptoare Electr&Electromecanice GastronomieDokument23 SeitenCuptoare Electr&Electromecanice GastronomieEugen VasileNoch keine Bewertungen

- LaserGas II SP CompactDokument2 SeitenLaserGas II SP CompactualassefernandoNoch keine Bewertungen

- Red 670Dokument28 SeitenRed 670Mahmoud Shafie100% (1)

- Data Sheet BDokument22 SeitenData Sheet BtceterexNoch keine Bewertungen

- Noi Hap Tiet Trung Sa 500aDokument19 SeitenNoi Hap Tiet Trung Sa 500aBIOMED HCCNoch keine Bewertungen

- Activity: Power HouseDokument6 SeitenActivity: Power HousePrakash MuthukrishnanNoch keine Bewertungen

- GE3139-03 Ung Suat Trong DaDokument100 SeitenGE3139-03 Ung Suat Trong DaBùi Mạnh SangNoch keine Bewertungen

- GTG 1690gr Brushgen 50hzDokument3 SeitenGTG 1690gr Brushgen 50hzAntonio DsfvsdcNoch keine Bewertungen

- Operator'S Manual 72633-D: 35 LB DrumDokument4 SeitenOperator'S Manual 72633-D: 35 LB DrumSaul PerezNoch keine Bewertungen

- June 7 & 8 - MOVED To Rockin' A ArenaDokument1 SeiteJune 7 & 8 - MOVED To Rockin' A ArenaKathy766Noch keine Bewertungen

- Labour Productivity Chart 1Dokument12 SeitenLabour Productivity Chart 1Mc Rolly RombaoaNoch keine Bewertungen

- Rfi Checklist NokiaDokument6 SeitenRfi Checklist NokiaBaba HimanathNoch keine Bewertungen

- Lm3886-Egizmo DesignDokument7 SeitenLm3886-Egizmo DesignKarloff AutencioNoch keine Bewertungen

- Nuclear CostDokument2 SeitenNuclear CostSouthern Alliance for Clean Energy100% (1)

- Ejercicios Tema FuncionesDokument2 SeitenEjercicios Tema Funcionesguille.camib06Noch keine Bewertungen

- Isolated Footing Design (IS 456-2000)Dokument12 SeitenIsolated Footing Design (IS 456-2000)Divya TadepalliNoch keine Bewertungen

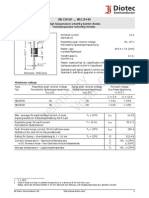

- SB12H30 ... SB12H40: High Temperature Schottky Barrier Diodes Hochtemperatur-Schottky-DiodenDokument2 SeitenSB12H30 ... SB12H40: High Temperature Schottky Barrier Diodes Hochtemperatur-Schottky-DiodenselocaNoch keine Bewertungen

- Buy Emerson 0.65-168 (KVA-VAH) Interactive UPS Online - GeMDokument4 SeitenBuy Emerson 0.65-168 (KVA-VAH) Interactive UPS Online - GeMArun Chand C VNoch keine Bewertungen

- Dokumen - Tips Atr 72 500 Pilot HandbookDokument27 SeitenDokumen - Tips Atr 72 500 Pilot HandbookRokas JankauskasNoch keine Bewertungen

- Datasheet Search Site - WWW - AlldatasheetDokument3 SeitenDatasheet Search Site - WWW - Alldatasheetpanagosp66Noch keine Bewertungen

- Service Manual 3781-84 KVG - 98 Supplied 2008 - 2014Dokument326 SeitenService Manual 3781-84 KVG - 98 Supplied 2008 - 2014Miguel LopezNoch keine Bewertungen

- The Deputy Manager 220kv GIS G/S Ravi LahoreDokument9 SeitenThe Deputy Manager 220kv GIS G/S Ravi LahoreJavaid IqbalNoch keine Bewertungen

- Procedure For Fab, Erec & Testing of Abovegroud PipingDokument16 SeitenProcedure For Fab, Erec & Testing of Abovegroud Pipingvpsimbu86Noch keine Bewertungen

- Change Request - 8.4.0: 25.306 CR 0200 RevDokument3 SeitenChange Request - 8.4.0: 25.306 CR 0200 Revtech_geekNoch keine Bewertungen

- Iec 439-1 Iec 947-2Dokument13 SeitenIec 439-1 Iec 947-2zuma zaiamNoch keine Bewertungen

- Ex 9, Punching ShearDokument4 SeitenEx 9, Punching ShearMohafisto SofistoNoch keine Bewertungen

- The Contents of The Presentation Are ©EPC-UKDokument24 SeitenThe Contents of The Presentation Are ©EPC-UKMILIAPUTRINoch keine Bewertungen

- 1453126373ps pgs011816 PDFDokument8 Seiten1453126373ps pgs011816 PDFCoolerAdsNoch keine Bewertungen

- Final Teaching Scheme & Syllbus ME Electrical SplitDokument21 SeitenFinal Teaching Scheme & Syllbus ME Electrical SplitvagoliyoNoch keine Bewertungen

- Node Voltage and Current AIM: Write A Program To Find The Node Voltage and CurrentDokument40 SeitenNode Voltage and Current AIM: Write A Program To Find The Node Voltage and Currentirenezach88Noch keine Bewertungen

- Nordøytrål: Imo No.: 9219771 Fishing Id: M-HØ359 SP Shipbase No.: K115606 Last UpdateDokument7 SeitenNordøytrål: Imo No.: 9219771 Fishing Id: M-HØ359 SP Shipbase No.: K115606 Last UpdateWahyuNoch keine Bewertungen

- DM74LS138 - DM74LS139 Decoder/Demultiplexer: General Description FeaturesDokument6 SeitenDM74LS138 - DM74LS139 Decoder/Demultiplexer: General Description FeaturesSetiawan Bima Adi SaputraNoch keine Bewertungen

- KEEMYAADokument406 SeitenKEEMYAAkhNoch keine Bewertungen

- Calculate Cable Size and VoltageDokument5 SeitenCalculate Cable Size and Voltageechiechi28082011Noch keine Bewertungen

- Bai6 2Dokument27 SeitenBai6 2Trịnh HòaNoch keine Bewertungen

- Cx. Vel. 16S 2221 ToDokument85 SeitenCx. Vel. 16S 2221 ToClaudemiro CostaNoch keine Bewertungen

- Engineering Info CompleteDokument14 SeitenEngineering Info CompleteIvanNoch keine Bewertungen

- PHYS 352 Energy Loss by ElectronsDokument8 SeitenPHYS 352 Energy Loss by Electronssamuel_07Noch keine Bewertungen

- Differential and Comparative Cost AnalysisDokument41 SeitenDifferential and Comparative Cost AnalysisjungvoltNoch keine Bewertungen

- Exp No: Usage of Cursor Date:: Branch Name, House No (PK), AmountDokument6 SeitenExp No: Usage of Cursor Date:: Branch Name, House No (PK), AmountaaanathanNoch keine Bewertungen

- 1202 Detail SheetsDokument61 Seiten1202 Detail SheetsUcok DedyNoch keine Bewertungen

- Olaplex SephoraDokument1 SeiteOlaplex SephoraAlessiaNoch keine Bewertungen

- Innovative Mechanical Final Projects List 2013 SooxmaDokument6 SeitenInnovative Mechanical Final Projects List 2013 SooxmaRajKumawatNoch keine Bewertungen

- Datasheet SKHI 22A PDFDokument12 SeitenDatasheet SKHI 22A PDFGlauber GoncalvesNoch keine Bewertungen

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- Divided States: Strategic Divisions in EU-Russia RelationsVon EverandDivided States: Strategic Divisions in EU-Russia RelationsNoch keine Bewertungen

- Creativity and Change in Nigerian ChristianityVon EverandCreativity and Change in Nigerian ChristianityNoch keine Bewertungen

- Stonco Illustrated Price Guide LP-11 1972Dokument100 SeitenStonco Illustrated Price Guide LP-11 1972Alan MastersNoch keine Bewertungen

- DLP ScienceDokument5 SeitenDLP ScienceRochelle Ann Ramilo GonzalesNoch keine Bewertungen

- Garcia Welding: Filler Metal Selection GuideDokument8 SeitenGarcia Welding: Filler Metal Selection GuideGustavo MorilloNoch keine Bewertungen

- Lecture 1aDokument23 SeitenLecture 1aSaritaNoch keine Bewertungen

- A Practical Guide For EN 61000-4-6: Test & Measurement TechniquesDokument29 SeitenA Practical Guide For EN 61000-4-6: Test & Measurement TechniquesRanganokNoch keine Bewertungen

- How Solar Flares Affect Communication - SciencingDokument2 SeitenHow Solar Flares Affect Communication - SciencingchelseyNoch keine Bewertungen

- Lightning Is A Naturally OccurringDokument1 SeiteLightning Is A Naturally OccurringenergyNoch keine Bewertungen

- SunspotsDokument9 SeitenSunspotsThe Physics SocietyNoch keine Bewertungen

- Welding ProcessesDokument28 SeitenWelding ProcessesJitendra UmaraliyaNoch keine Bewertungen

- Holophane Bantam Prismpack Series Brochure 3-75Dokument4 SeitenHolophane Bantam Prismpack Series Brochure 3-75Alan MastersNoch keine Bewertungen

- PlasmaDokument2 SeitenPlasmaMurthy ChavaliNoch keine Bewertungen

- Gas Tungsten Arc WeldingDokument1 SeiteGas Tungsten Arc WeldingabhibawaNoch keine Bewertungen

- Form Request OvertimeDokument21 SeitenForm Request OvertimeAndika ArdaNoch keine Bewertungen

- Curriculum Vitae Hans-Stephan Bosch: EducationDokument2 SeitenCurriculum Vitae Hans-Stephan Bosch: EducationDNoch keine Bewertungen

- Presto Predictability of The Variable Solar-Terrestrial CouplingDokument25 SeitenPresto Predictability of The Variable Solar-Terrestrial CouplinghassanNoch keine Bewertungen

- Precios Dogo Labor Rapifix - 14fDokument111 SeitenPrecios Dogo Labor Rapifix - 14fgustavoNoch keine Bewertungen

- The SunDokument40 SeitenThe SunKaren Vanessa Magada MendozaNoch keine Bewertungen

- Stellarator Fusion Rectors OverviewDokument7 SeitenStellarator Fusion Rectors OverviewroberoayonNoch keine Bewertungen

- Dielectric BreakdownDokument8 SeitenDielectric BreakdownPranjal RathoreNoch keine Bewertungen

- (For PKG2 Only Applicable) : Uop Lines Applicable Post Heat RequirementDokument1 Seite(For PKG2 Only Applicable) : Uop Lines Applicable Post Heat RequirementMuhammad SawadNoch keine Bewertungen

- Annex 4Dokument36 SeitenAnnex 4Ann Matinong Dela Cruz100% (1)

- Plasma (Physics)Dokument14 SeitenPlasma (Physics)Shubham BansalNoch keine Bewertungen

- New 01. Price List VS Online Welding Mechine Professional 290123Dokument4 SeitenNew 01. Price List VS Online Welding Mechine Professional 290123Deta PutraNoch keine Bewertungen

- Sample Welding Map Project Kecil PDFDokument1 SeiteSample Welding Map Project Kecil PDFMuhammad Fitransyah Syamsuar Putra100% (1)

- V.E. Lukash and R.R. Khayrutdinov - Model of Real Time ITER Plasma Position, Shape and Current Control On Base of DINA CodeDokument4 SeitenV.E. Lukash and R.R. Khayrutdinov - Model of Real Time ITER Plasma Position, Shape and Current Control On Base of DINA CodeMsdsxNoch keine Bewertungen

- 6.2.5 Understanding The Physics of The Moon's WakeDokument7 Seiten6.2.5 Understanding The Physics of The Moon's WakeWaleedSubhanNoch keine Bewertungen

- 6118 19036 1 PBDokument9 Seiten6118 19036 1 PBmuhamad bastianNoch keine Bewertungen

- Coronal Heating and EnergeticsDokument55 SeitenCoronal Heating and EnergeticsAjay TiwaryNoch keine Bewertungen

- The Layers of The Sun Cheat Sheet: by ViaDokument1 SeiteThe Layers of The Sun Cheat Sheet: by ViaSteve DonaldsonNoch keine Bewertungen

- 4.co - DMB 2243 Welding Process 2Dokument6 Seiten4.co - DMB 2243 Welding Process 2azmi yusofNoch keine Bewertungen