Beruflich Dokumente

Kultur Dokumente

Pwps Aws Mks Aluminium

Hochgeladen von

Abu ZahidCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Pwps Aws Mks Aluminium

Hochgeladen von

Abu ZahidCopyright:

Verfügbare Formate

ANNEX F

AWS D1.2/D1.2M:2008

WELDING PROCEDURE SPECIFICATION (WPS)

Welding Procedure

MKS-S-AL-001

Specification No. _______________

25 June 2014

Date _________________________

Approved _______________________

Revisions _____________________

Date _________________________

Approved _______________________

Revisions _____________________

Date _________________________

Approved _______________________

Revisions _____________________

Date _________________________

Approved _______________________

Revisions _____________________

Date _________________________

Approved _______________________

Supporting PQR Numbers ________________

_______________

________________

________________

Supporting PQR Numbers ________________

_______________

________________

________________

_______________________________________________________________________________________________

Joints

Filler Metal

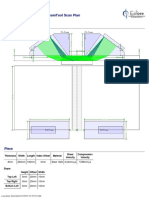

Groove Design Sketch

23

F-No. _________________

ER4043

AWS No. ____________

Class

1.6mm

Size of electrode _______________________________

OK Autorod 18.04 by ESAB

Type of electrode _______________________________

SuperGlaze 4043 by Lincoln

Other ________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

Shielding Gas

Argon

Shielding gas(es) _______________________________

99.99%

Percent composition_____________________________

15-25 liter/min

Flow rate______________________________________

Other ________________________________________

_____________________________________________

_____________________________________________

Backing

_____________________________________________

No Backing

Type ________________________________________

Position

Permanent ___________________________________

V, F, H

Position of groove_______________________________

Removed ____________________________________

Vertical Uphill

Welding progression_____________________________

Other _______________________________________

Other ________________________________________

____________________________________________

_____________________________________________

____________________________________________

_____________________________________________

____________________________________________

_____________________________________________

____________________________________________

_____________________________________________

Base Metals

Preheat

3mm

12mm

23

M No. ___________

Thickness ________

to _______

6061-T6

Alloy and Temper ______________________________

18C

Preheat temperature ____________________________

50C

Interpass temperature ___________________________

Form F(a)

152

AWS D1.2/D1.2M:2008

ANNEX F

WELDING PROCEDURE SPECIFICATION (WPS)

Cleaning

Brushing &/or Grinding

Initial cleaning oxide____________________________

Pass

No.

oil or chemical cleaning

Initial cleaning oil and dirt________________________

Brushing &/or Grinding

Interpass cleaning _____________________________

____________________________________________

Postweld Heat Treatment

Welding

Process

Amps

Volts

Travel

Speed

mm/s

GMAW 200-300

23-28

3.3-5.8

GMAW 200-300

23-28

3.3-5.8

GMAW 200-300

23-28

3.3-5.8

Not Applicable

Original temper ________________________________

F, H

Final temper __________________________________

GMAW 200-300

23-28

4.1-20

GMAW 200-300

23-28

4.1-20

GMAW 200-300

23-28

4.1-20

Temperature __________________________________

Time ________________________________________

Quench ______________________________________

____________________________________________

Process(es)

GMAW

Process _______________

Semi-Auto

Type*_______________

Process _______________

Type*_______________

Electrode (GTAW) _____________________________

____________________________________________

Technique

and/or

Stringer or weave bead _________________________

16mm

Orifice or gas cup size __________________________

yes

Oscillation ___________________________________

10-15mm

Contact tube to work distance ____________________

Single

Single pass or multipass ________________________

per side

Tungsten extension ____________________________

Method of backgouging _________________________

Other _______________________________________

- Current & Polarity: DCEP

____________________________________________

- Groove prep. : Mech. Cutting

____________________________________________

- GMAW mode: Short Arc

____________________________________________

____________________________________________

*Manual, automatic, polarity, pulse, etc.

Sketch of Welding Sequence

Form F(a) (Continued)

153

Das könnte Ihnen auch gefallen

- MT Report FormDokument1 SeiteMT Report FormAmit HasanNoch keine Bewertungen

- Welder Qualification Test Log: Engineering Standards Manual OST220-03-01-ESM Chapter 13, WeldingDokument1 SeiteWelder Qualification Test Log: Engineering Standards Manual OST220-03-01-ESM Chapter 13, WeldingReza100% (1)

- F (D) Stud Welding WPS FormDokument1 SeiteF (D) Stud Welding WPS FormmivasaNoch keine Bewertungen

- F4-WPS PQR Stud WeldingDokument1 SeiteF4-WPS PQR Stud WeldingBernardo LeorNoch keine Bewertungen

- Industrial radiography A Complete Guide - 2019 EditionVon EverandIndustrial radiography A Complete Guide - 2019 EditionNoch keine Bewertungen

- B2.1 B2.1M 2014 Amd1 Procedure Qualification Record PQR PDFDokument2 SeitenB2.1 B2.1M 2014 Amd1 Procedure Qualification Record PQR PDFNavanitheeshwaran SivasubramaniyamNoch keine Bewertungen

- PT-MT-VT ReportDokument1 SeitePT-MT-VT ReportCarlos Nombela PalaciosNoch keine Bewertungen

- ASNTDokument5 SeitenASNTshifaNoch keine Bewertungen

- Ultrasonic Inspection Report: Item Specification Inspection SubjectDokument6 SeitenUltrasonic Inspection Report: Item Specification Inspection Subjectehsan.mNoch keine Bewertungen

- Phased Array Practical ExamDokument2 SeitenPhased Array Practical ExamMarcus AntoniusNoch keine Bewertungen

- 24 Practical Visual InspectionDokument5 Seiten24 Practical Visual InspectionMai Anh TaiNoch keine Bewertungen

- DNV OS C 401 (2001) Rules Fabrication and Testing of Offshore Structures PDFDokument44 SeitenDNV OS C 401 (2001) Rules Fabrication and Testing of Offshore Structures PDFrami ghorbelNoch keine Bewertungen

- MX2 Training Program 10G VerifyExitAngleDelay On IIWDokument21 SeitenMX2 Training Program 10G VerifyExitAngleDelay On IIWANH TAI MAINoch keine Bewertungen

- Se 797Dokument7 SeitenSe 797donaldoguerreroNoch keine Bewertungen

- IPBD Instruction Manual PDFDokument41 SeitenIPBD Instruction Manual PDFrobinknit2009Noch keine Bewertungen

- Visual InspectionDokument4 SeitenVisual InspectiondomsonengNoch keine Bewertungen

- Welding R1Dokument49 SeitenWelding R1proxywarNoch keine Bewertungen

- Hardox 450 Data SheetDokument2 SeitenHardox 450 Data SheetmatthewpincottNoch keine Bewertungen

- 096 SelDokument3 Seiten096 SelPiyush SrivastavaNoch keine Bewertungen

- Fir-001 - 10 03 18Dokument1 SeiteFir-001 - 10 03 18Kartik SolankiNoch keine Bewertungen

- Epoch 4 Operations ManualDokument164 SeitenEpoch 4 Operations ManualpjhollowNoch keine Bewertungen

- Rigaku Radioflex RF-EGM2 Series Brochure - VISCODokument4 SeitenRigaku Radioflex RF-EGM2 Series Brochure - VISCOrhinemineNoch keine Bewertungen

- Norma CWB Cambios en W47.1-2009Dokument6 SeitenNorma CWB Cambios en W47.1-2009Jose ManuelNoch keine Bewertungen

- Daytime Colorimetric Properties of Fluorescent Retroreflective Sheeting and Marking Materials For High Visibility Traffic Control and Personal Safety Applications Using 45°:normal GeometryDokument6 SeitenDaytime Colorimetric Properties of Fluorescent Retroreflective Sheeting and Marking Materials For High Visibility Traffic Control and Personal Safety Applications Using 45°:normal GeometryEnriqueVeNoch keine Bewertungen

- NDT Procedure BS EN 10307:2001 (Full Version Available From N-D-T.com)Dokument6 SeitenNDT Procedure BS EN 10307:2001 (Full Version Available From N-D-T.com)Mark BrailsfordNoch keine Bewertungen

- BS 2452 (1954)Dokument30 SeitenBS 2452 (1954)siswou100% (1)

- Adapting CSA W59 Ultrasonic Inspections For Use With Distance Amplitude Techniques Holloway Crawford Keay VaidyaDokument19 SeitenAdapting CSA W59 Ultrasonic Inspections For Use With Distance Amplitude Techniques Holloway Crawford Keay VaidyaTerfaia NadjatNoch keine Bewertungen

- Article 16 Magnetic Flux Leakage (MFL) ExaminationDokument4 SeitenArticle 16 Magnetic Flux Leakage (MFL) ExaminationAnonymous ihanyMJNoch keine Bewertungen

- Calibrating Pressure GaugesDokument4 SeitenCalibrating Pressure GaugesRonny AndalasNoch keine Bewertungen

- As 1816.1-2007 Metallic Materials - Brinell Hardness Test Test Method (ISO 6506-1-2005 MOD)Dokument3 SeitenAs 1816.1-2007 Metallic Materials - Brinell Hardness Test Test Method (ISO 6506-1-2005 MOD)SAI Global - APACNoch keine Bewertungen

- Welding Gauges PDFDokument4 SeitenWelding Gauges PDFsopan kharcheNoch keine Bewertungen

- Beamtool Scan Plan: Inspection LayoutDokument4 SeitenBeamtool Scan Plan: Inspection LayoutMohan RajNoch keine Bewertungen

- W14-661 (0 To 40 Bar) PDFDokument3 SeitenW14-661 (0 To 40 Bar) PDFBalaji BobadeNoch keine Bewertungen

- E1936-97 Evaluating Digitization SystemsDokument4 SeitenE1936-97 Evaluating Digitization SystemsNDT Div, MedequipNoch keine Bewertungen

- Method of Shearing Test For Fillet Weld Joint: Nissan Engineering StandardDokument5 SeitenMethod of Shearing Test For Fillet Weld Joint: Nissan Engineering StandardRicardo F.A.Noch keine Bewertungen

- Spark Test For Iron SteelDokument3 SeitenSpark Test For Iron SteelTegar Kukuh Ahmad JulfikarNoch keine Bewertungen

- Norsok M101 Structural Steel FabricationDokument67 SeitenNorsok M101 Structural Steel FabricationbreeeeezzzzzeNoch keine Bewertungen

- E428Dokument6 SeitenE428valentinNoch keine Bewertungen

- General Level-II QuestionsDokument4 SeitenGeneral Level-II QuestionsGomathi SankarNoch keine Bewertungen

- Shadesofgrey by Dr. KolblDokument1 SeiteShadesofgrey by Dr. KolblAnonymous JLrzWCNoch keine Bewertungen

- Asme NDT MethodDokument1 SeiteAsme NDT Methodkinglordofato100% (1)

- Attachment D (SAEP 316)Dokument1 SeiteAttachment D (SAEP 316)imtiazNoch keine Bewertungen

- Penetrants TESTINGDokument86 SeitenPenetrants TESTINGsankaran_muthukumarNoch keine Bewertungen

- Quiz 1Dokument1 SeiteQuiz 1shabbir626Noch keine Bewertungen

- B31.3 InterpretationsDokument338 SeitenB31.3 InterpretationsRamdasNoch keine Bewertungen

- ASME P NumbersDokument6 SeitenASME P NumbersAbdul KharisNoch keine Bewertungen

- Iso18563 1 2022Dokument54 SeitenIso18563 1 2022baurzhannNoch keine Bewertungen

- API 1104 ComplateDokument24 SeitenAPI 1104 ComplateAwale UdinNoch keine Bewertungen

- Application Form For CSWIP 5 Year Renewal (Overseas) - v3 1Dokument7 SeitenApplication Form For CSWIP 5 Year Renewal (Overseas) - v3 1Bamarasan ArasanNoch keine Bewertungen

- Mini-Wheel Encoder: Standard InclusionsDokument2 SeitenMini-Wheel Encoder: Standard InclusionsGhaithNoch keine Bewertungen

- MTC Er70s 2Dokument1 SeiteMTC Er70s 2Mirza BaigNoch keine Bewertungen

- Pws Convention PresentationDokument93 SeitenPws Convention Presentationbenj100% (1)

- RTDokument14 SeitenRTaravindanNoch keine Bewertungen

- Ultrasonic Examination Austenitic and Dissimilar WeldsDokument6 SeitenUltrasonic Examination Austenitic and Dissimilar WeldshocimtmNoch keine Bewertungen

- DFT Measurement Worksheet: Paint InspectionDokument1 SeiteDFT Measurement Worksheet: Paint Inspectionjay nathNoch keine Bewertungen

- F (A) - WPS FormDokument2 SeitenF (A) - WPS FormSuhaina SulimanNoch keine Bewertungen

- F (E) Stud Welding PQR FormDokument1 SeiteF (E) Stud Welding PQR FormmivasaNoch keine Bewertungen

- Certification To Iso 9001 - 2008 StandardDokument2 SeitenCertification To Iso 9001 - 2008 StandardSam SchzNoch keine Bewertungen

- Sample Welding Procedure Specification (WPS) FormDokument1 SeiteSample Welding Procedure Specification (WPS) Formfallalovaldes50% (4)

- Ba Transmitterm 300cond2channele521213180507Dokument64 SeitenBa Transmitterm 300cond2channele521213180507Leo PastinNoch keine Bewertungen

- Tata Steel Bulb Flats BroDokument11 SeitenTata Steel Bulb Flats BroMd. Rafique HassanNoch keine Bewertungen

- Material Purchase Matl Qty Weight (KG) Cost (SGD) Unit Total Unit TotalDokument2 SeitenMaterial Purchase Matl Qty Weight (KG) Cost (SGD) Unit Total Unit TotalAbu ZahidNoch keine Bewertungen

- Orrcon Steel PFCDokument1 SeiteOrrcon Steel PFCmjscarNoch keine Bewertungen

- AWI Heat Input CalculatorDokument2 SeitenAWI Heat Input CalculatorAhmed Abd ElmegeedNoch keine Bewertungen

- BOM Phosphate TankDokument1 SeiteBOM Phosphate TankAbu ZahidNoch keine Bewertungen

- Risk Assessment FormDokument9 SeitenRisk Assessment FormAbu ZahidNoch keine Bewertungen

- Pipe Thread NPT and BSPT Fittings CompatibilityDokument5 SeitenPipe Thread NPT and BSPT Fittings CompatibilityEduardoNoch keine Bewertungen

- BOM Phosphate TankDokument1 SeiteBOM Phosphate TankAbu ZahidNoch keine Bewertungen

- Steel MachinabilityDokument1 SeiteSteel MachinabilityAbu ZahidNoch keine Bewertungen

- High Temp Fabric Expansion JointDokument1 SeiteHigh Temp Fabric Expansion JointAbu ZahidNoch keine Bewertungen

- Beam Press BendingDokument1 SeiteBeam Press BendingAbu ZahidNoch keine Bewertungen

- AluminiumDokument47 SeitenAluminiumTeik Yong FooNoch keine Bewertungen

- Air Pipe Line ProgressDokument1 SeiteAir Pipe Line ProgressAbu ZahidNoch keine Bewertungen

- Webforge Alum GratingDokument2 SeitenWebforge Alum GratingAbu ZahidNoch keine Bewertungen

- AWS - Welding SymbolsDokument1 SeiteAWS - Welding SymbolsAli Saifullizan IsmailNoch keine Bewertungen

- Pipe Profile TemplateDokument3 SeitenPipe Profile TemplateAbu ZahidNoch keine Bewertungen

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Mild Cert PFC200x75Dokument1 SeiteMild Cert PFC200x75Abu ZahidNoch keine Bewertungen

- Simplify Proof Load TestDokument1 SeiteSimplify Proof Load TestAbu ZahidNoch keine Bewertungen

- Alum 6xxx PwpsDokument1 SeiteAlum 6xxx PwpsAbu Zahid100% (1)

- F (A) - WPS FormDokument2 SeitenF (A) - WPS FormSuhaina SulimanNoch keine Bewertungen

- PlasticsDokument161 SeitenPlasticsAbu ZahidNoch keine Bewertungen

- Lexan XL10Dokument1 SeiteLexan XL10Abu ZahidNoch keine Bewertungen

- Cost Estimation - MachiningDokument12 SeitenCost Estimation - MachiningAbu Zahid100% (2)

- SSHBrochure FinalDokument9 SeitenSSHBrochure FinalAbu ZahidNoch keine Bewertungen

- ITP (Inspection and Test Plans) - NSW, AUSDokument14 SeitenITP (Inspection and Test Plans) - NSW, AUSJaques Brice Lo Nascimento50% (2)

- 004 Form Itp - Format NewDokument6 Seiten004 Form Itp - Format NewmanktxdNoch keine Bewertungen

- Aalco Metals LTD Aluminium Alloy Cleaning Aluminium 52Dokument2 SeitenAalco Metals LTD Aluminium Alloy Cleaning Aluminium 52Abu ZahidNoch keine Bewertungen

- AH36Dokument3 SeitenAH36Abu ZahidNoch keine Bewertungen