Beruflich Dokumente

Kultur Dokumente

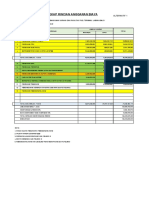

B0054833-4 Erection Arrangement DRB-XCL PC and Oil Fired Burner C.C.W

Hochgeladen von

Nanang Cesc UttaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

B0054833-4 Erection Arrangement DRB-XCL PC and Oil Fired Burner C.C.W

Hochgeladen von

Nanang Cesc UttaCopyright:

Verfügbare Formate

2

165

6 1/2"

2286 INSIDEWINDBOX

7'-6"

1

7

8

R

.

7

"

5

0

8

T

O

C

O

A

L

E

L

B

O

W

1

'-8

"

438 I.D.

1'-5 1/4"

533

1'-9"

127

5"

[21'-0"]

6401 ATOMIZERGUN REMOVAL SPACE

546 B.C.

1'-9 1/2"

686 REF TYP

2'-3"

4

2

5

R

E

F

T

Y

P

1

'-4

3

/

4

"

330

1'-1"

4

0

6

1

'-4

"

1

5

5

6

'

2

5

'

1

5

3

0

'

2

3

5

5

'

3642'

8

10

3

4

6

'

VIEWL

VIEWK

VIEWM

T

29

1'-9 1/2"B.C.

ON 76 [3"] CENTERS

NE3

NE3

2 1

7

8

NE14 18 16

SECTION A-A

5

G7. ELECTRICAL DATA FORATOMIZERAIRCYLINDERPROXIMITY SWITCH:

4

2327 RETRACTED

[7'-7 5/8"]

IN

W

IN

D

B

O

X

41

2 1/2"O.D. TUBES

IN

L

E

T

F

L

A

N

G

E

NE14 & NE28

FLANGE#2

NE14 & NE28

FLANGE#2

NE14 & NE28

LIFTING LUG

FLANGE#1

56

(16) 7/8"DIA THRU

CL STRADDLE

27

30

28

EQ SPC'D ON

8 [5/16]

NE9,

NE10

& NE27

4

'-7

"

D

IA

O

P

E

N

IN

G

9

1

4

3

'-0

"

I.D

. T

H

R

O

A

T

1/4"

6

1/4"

REF

4

'-5

"

IN

S

ID

E

1

3

4

6

1

3

9

7

6'-7 5/8"

INSERTED 2023

6

610 O.D.

2'-0"

457

1'-6"

1'-3"

381

1

'-4

1

/

2

"

I.D

.

4

1

9

368 REF

1'-2 1/2"

AB

AB

AC

AC

J

J

OPERATION, ANDFOR SOLICITING BIDS FOR THE ERECTION OF, THE EQUIPMENT DISCLOSEDHEREIN.

8 7 6 5 4 3 2 1

A

J

I

H

G

F

E

D

C

B

J

I

H

G

F

E

D

C

B

A

1 2 3 4 5 6 7 8

B 0 0 5 4 8 3 3

- DO NOTSCALE-

N O

D W G

J 44-Customer.slddrt

11/2"=1'-0"

NO

YES

YES

563-0060-39-53

REV

J

DWG NO COA PROJ ECTNO

DISTMFG

DISTEREC

DISTCUST

SCALE

DATE

CHKD

APPVD

DWN

USERDEFINED FIELD

B0054833.slddrw

DRB-XCL PC AND OIL FIRED

ERECTION ARRANGEMENT

C.C.W.

4 B0054833 AC5100 0635-212F

BURNER

USEDIMENSIONSONLY

ORIG CONTRACTNO

12/11/08

D.W.DOWDELL

D.A.SMITH

C.A.IAFANO

TYPE PROJ ECT

Babcock & Wilcox Power Generation Group, Inc.

2008 BABCOCK &WILCOX POWER GENERATION GROUP, INC. ALL RIGHTS RESERVED.

THIS DRAWING IS THE PROPERTY OF BABCOCK &WILCOX POWER GENERATION GROUP, INC. (B&WPGG) ANDITS USE IS

GOVERNEDBY THE TERMS ANDCONDITIONS OF THE CONTRACT FOR WHICH IT WAS CREATED. B&WPGG GRANTS A

NON-EXCLUSIVE LICENSE TO USE, REPRODUCE ANDDISTRIBUTE THIS DRAWING SOLELY FOR THE MAINTENANCE, REPAIR AND

20 SOUTH VAN BUREN AVENUE, BARBERTON, OHIO

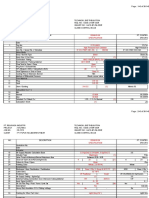

THERMOCOUPLE

J UNCTION BOX

27

W.P. W.P.

MOUNT

SCANNER

HANDLE

VANEPULL

OUTERAIR

HANDLE

VANEPULL

RATCHETDRIVE

AIRZONEDISK

INNERAIR

MOUNT

10

SCANNER

IGNITOR

CFSOIL

DOOR

NE18

G1 &

9

EXCITER

CONNECTION

ENERGY

B&WHIGH

OBSERVATION

IGNITOR

UNIT#1F.W. - 1C-1, 1C-2, 1C-4, 1C-6

THISBURNERARRANGEMENTFORBURNERS:

(NE10 & NE12)

UNIT#2F.W. - 2C-1, 2C-2, 2C-4, 2C-6

CONNECTION

AIRMONITOR

LOWPRESSURE

FRONTVIEW

HIGHPRESSURE

AIRMONITOR

32

T

T

H

H

G

G

F

F

E E

D

D

C

C

B

B

A

A

1

UNIT#1 USERDEFINED FIELD UNIT#2

ORIG CONTRACTNO

PROJ ECTNO

563-0061-39-53

0635-212G

4

RETAINERSTRAP B0054912 6426486

57 2 ELBOW, 3/4"NPT3000#90 DEG SA105

1

3018110

58

17 1/4"CONICAL DIFFUSER(SILICON CARBIDE)

2 ASSEMBLY FLEXIBLEHOSE1"X59"LG 6254690

59 4 NIP TBE1"SCHXSX3"LG STL 3017884

60 2 TEETHRD 1"3000#SA105 3017949

61 2 BSHG HEXHD SCRD 1"X1/4"SA105 8004376

62 2 NIPPLE, 3/4"X4 1/2"XSTBENPTSA106BHF/CF 2316409

6421226

2 1 ASSEMBLY SLIP SEAL 2729173C 2729173

3 2 ASSEMBLY AND DETAIL RETAINERBAR 301556B 6403854

BY MANUFACTURING.

BY BURNERNUMBERAND NOZZLESROTATED TO THEIRAPPROXIMATELOCATIONS

BURNERNUMBERPERTHEGENERAL ARRANGEMENTS. BURNERSARESTENCILED

NE12. ERECTORMUSTINSERTBURNERSIN THEIRAPPROPRIATELOCATIONSBY

FILL HOLESIN COAL NOZZLEFORDEFLECTORRETAINERBARSWITHRTV SEALER.

NE11. APPLY RTV SEALERTO LEADING EDGEOF DEFLECTORAND COAL NOZZLE.

MATCHPAINTLINEOF COAL NOZZLEWITHMOUNTING PLATE.

SEEGENERAL ARRANGEMENTFORCORRECTORIENTATION. FORALIGNMENT

DIFFUSER(INSIDENOZZLE) IN LINEWITHCENTERLINEOF COAL ELBOWINLET.

IN COAL ELBOW. ERECTORTO ROTATECENTERLINEOF DEFLECTORAND

NE10. ERECTORTO ROTATENOZZLEIF NECESSARY TO LINEUP WITHBOLTHOLES

NE9. FORWELDING CERAMIC LINED COMPONENTS, SEEDRAWING 275065A.

ISCOMPLETE.

NE8. ERECTORTO INSUREPROPERDISK MOVEMENTAFTERBURNERINSTALLATION

THEERECTORUNLESSOTHERWISESPECIFIED.

NE7. THEFIELD INSTALLED INSULATION AND LAGGING ISTHERESPONSIBILITY OF

TO HOLD PACKING IN PLACE.

FRONTPLATE. INSTALL ROPEPACKING AND BEND SLIP SEAL TABSOVER

THEBURNER. THEN COMPLETETHEWELDING OF THESLIP SEAL TO THE

TOLERANCE. ALL SUPPORTBRACKETSMUSTBECARRYING THELOAD OF

POSSIBLEWITHOUTINFRINGING ON THE13 [1/2"] +6 [1/4"] -0"GAP

NE6. BURNERSARETO BEASLEVEL AND PERPENDICULARTO THEWALL TUBESAS

BURNERWEIGHTON SLIP SEAL.)

AIRSLEEVEWITHRESPECTTO THETHROATOPENING. (DO NOTSUPPORT

+/- 1/8". SLIP SEAL WILL SERVEASA GUIDEFORPOSITIONING THEBURNER

NE5. TACK WELD SLIP SEAL TO FRONTPLATECONCENTRIC WITHTHROATOPENING

DIMENSIONSATSUPPORTBRACKETS.

BEFOREWELDING SUPPORTCHANNELS, ERECTORTO INSURECLEARANCE

CENTERLINEOF BURNERAND RESTING ON SUPPORTCHANNELSIN WINDBOX.

NE4. SUPPORTCHANNELSTO BEPARALLEL TO TUBEWALL, PERPENDICULARTO

BY AIRSLEEVESUPPORTBARS.)

THREADS. (NO ADJ USTMENTSTO BEMADEBY TWISTING HOSE.)

NE20. TO PREVENTDAMAGETO HOSE, ALL ADJ USTMENTSMUSTBEMADEIN PIPE

TWISTING HOSEDURING INSTALLATION.

TWISTING. NO TORSIONAL FORCESMAY BEAPPLIED TO HOSEBY

PARALLEL TO THEVERTICAL CENTERLINEOF BURNERTO PREVENT

NE19. LOOP OF HOSETO BEINSTALLED IN A VERTICAL POSITION AND

MOUNTHIGHENERGY EXCITERON WINDBOXCASING.

NE18. LOCATEHIGHENERGY EXCITERWITHIN 3048 [10'-0"] OF LIGHTER. DO NOT

COVERPLATE.

TO INSURECLEARANCETHRUAIRVANES. THEN WELD LIGHTERPIPEAT

TUBEWALL. TACK WELD LIGHTERASSEMBLY THEN STROKEAIRCYLINDER

NE17. INSUREPROPERLOCATION FROM LIGHTERSHIELD TO CENTERLINEOF

REVERSETHISPROCEDURETO ATTAIN THEFULLY CLOSED POSITION

E) EXTEND RATCHETJ ACKBACK TO MECHANICALLY OPENED POSITION.

D) RETIGHTEN U-BOLTS

C) RETRACTRATCHETJ ACK 102 [4"]

B) LOOSEN U-BOLTS

A) ASSURETHATRATCHETJ ACK ISMECHANICALLY OPEN

POSITION YOUMUST:

CLOSED TO 102 [4"] FROM FULLY OPENED. TO ACHIEVETHEFULLY OPENED

RATCHETJ ACK WILL ALLOWFOR203 [8"] OF TRAVEL: FROM FULLY

FULLY CLOSED POSITION. IN IT'SCURRENTPOSITION THE

NE16. BURNERSARESHIPPED WITHTHERATCHETJ ACK DRIVESIN THE

FORLIFTING BURNER.)

AFTERINSTALLATION ISCOMPLETE. (DO NOTUSETHESEMEMBERS

NE15. ERECTORTO REMOVEALL SUPPORTMEMBERSPAINTED YELLOW

ELBOWCOVER 3/4"DIA BOLTAND NUT 100 14.8

16 & 18 1"DIA BOLT& NUT 245 33.9

17 1/ 2"NUT 30 4.15

NE1. UNLESSOTHERWISENOTED: ALL NPP TO NPP WELDSSHALL CONFORM TO

FIND NO. DESCRIPTION FT-LBS KG/M

NE14. TORQUEREQUIREMENTS:

BURNERELEMENTASSEMBLY: 1590 KG [3503 LBS.]

NE13. ESTIMATED WEIGHTS:

(DO NOTLIFTBURNER IN LIFTING LUG ON COVERPLATEAND AIRSLEEVE.

NE3. TO AVOID DAMAGETO BURNERS, USE38 [1 1/2"] DIA HOLESPROVIDED

NE2. DISSIMILARWELD SST TO CARBON. SEEFIELD WELD SCHEDULEDRAWING.

GOOD INDUSTRY PRACTICE.

c) ALL REMAINING BOLTS.

OBJ ECTS, ANY IMPACTCAN DAMAGETHECERAMIC.

b) FOUR(4) CORNERBOLTSFORFLANGES#2.

a) FOUR(4) CORNERBOLTSFORFLANGES#1.

C) REBOLTFLANGESSEQUENTIALLY ASFOLLOWS:

B) CLEAN FLANGESAND APPLY HIGHTEMPERATURERTV.

A) UNBOLTAND REMOVECOVER.

NE28. FIELD PROCEDUREFORREMOVAL AND INSTALLATION OF COAL ELBOWCOVER:

NE27. TRIM VANESASNEEDED TO MAINTAIN TOLERANCES.

PRIORTO INSERTING THECOAL NOZZLEINTO THEBURNER.

THECOAL NOZZLETHERMOCOUPLESARETO BEINSTALLED ON THECOAL NOZZLE

SEEBURNERGENERAL ARRANGEMENTDRAWINGSFORCORRECTORIENTATIONS.

MOUNTING HOLESAREINLINEWITHTHECENTERLINEOF THECOAL ELBOWINLET.

NE26. ORIENTATECOAL NOZZLESO THECENTERLINEBETWEEN THEDEFLECTOR

6 & 9 O'CLOCK PATTERN TO FORM A COMPLETEWELD.

ELBOW. WELD PROCEDURETO BE16 [5/8"] LG. SEAL WELD IN A 12, 3,

REG. ROD SUPPORTPIPEAND REG. ROD SUPPORTPIPETO COAL

TO REG. ROD SUPPORTPIPE, ROD & PORTSEAL ASSEMBLY TO

TRAVEL OF REGULATING ROD, THEN WELD SUPPORTBRACKET

HOLESATEACHEND OF STROKEAND INSUREUNRESTRICTED

AND VERIFY ALIGNMENTBY CHECKING CONCENTRICITY OF

FIND NO. 43 AND AIRCYLINDERFIND NO. 44 TO THEBURNER

NO. 41, DRIVEBRACKETFIND NO. 42, MOUNTING BRACKET

NE25. ASSEMBLEEXISTING COAL ELBOW, ROD SUPPORTPIPEFIND

AWAY FROM AIRCYLINDERTO CONTROL TRAVEL SPEED.

NE24. ASSEMBLEFLOWCONTROL VALVESFIND NO. 55 WITHARROWPOINTING

NE23. INDEXREGULATING ROD ATNORMAL FIRING POSTITION, WITHSCRIBELINE.

BEFLUSHWITHCLAMPSWHEN PROBETIP ISFLUSHWITHOIL IGNITORSHIELD.

NE22. ERECTORTO FILEMARK SPARK TCD WITH(4) 6 [1/4"] INCREMENTS. FIRSTMARK TO

3 2

: .0025M

<10V @25 MA AC

INDICATESBURNERTERMINAL

SYMBOL:

5.6-7.0 KG/CM

80-100 PSIG: .089 CF PERSTROKE

G6. AIRREQUIREMENTSFORATOMIZERAIRCYLINDER:

VOLTAGERANGE. . . . . . 20-250 VAC/DC

T

VOLTAGEDROP . . . . . . . <8V @25 MA DC

2.5 MA @121-250 VAC/ DC

LEAKAGECURRENT. . . . .1.7 MA @120 VAC/DC

LOAC CURRENT. . . . . . . .2-25 MA

WELDING INSTRUCTIONSFORCERAMIC COMPONENTS. . . . . . . . 275065A

R

FIELD WELD SCHEDULE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B0054841

ERECTION ARRANGEMENTDIFFERENTIAL PRESSUREGAGE. . . . . .B0054842

ARRANGEMENTRECOMMENDED SPAREPARTS. . . . . . . . . . . . . . .B0054840

ERECTION ARRANGEMENTTHERMOCOUPLES. . . . . . . . . . . . . . . . .B0054839

ERECTION ARRANGEMENTSECTIONS& VIEWS3 . . . . . . . . . . . . . . B0054850

ERECTION ARRANGEMENTSECTIONS& VIEWS2 . . . . . . . . . . . . . . B0054838

ERECTION ARRANGEMENTSECTIONS& VIEWS1 . . . . . . . . . . . . . . B0054837

GENERAL ARRANGEMENTREARWALL . . . . . . . . . . . . . . . . . . . . . . B0054793

GENERAL ARRANGEMENTFRONTWALL . . . . . . . . . . . . . . . . . . . . . B0054792

REFERENCEDRAWINGS:

G5. ELECTRICAL DATA FOROIL IGNITORPROXIMITY SWITCH:

PERSTROKE

3

: .0025M

2

5.6-8.4 KG/CM

80-120 PSIG: .017 CF PERSTROKE

CYLINDER:

G4. AIRREQUIREMENTSFOROIL IGNITORPROBEDRIVE

PERSTROKE

3

: .0025M

2

5.6-8.4 KG/CM

80-120 PSIG: .087 CF PERSTROKE

G3. AIRREQUIREMENTSFOROIL IGNITORDRIVECYLINDER:

G2. SEAL AIRREQUIREMENTS:

85-250 VAC, 50-60 HZ, 1 PHASE, 100VA

G1. ELECTRICAL REQUIREMENTSFORHIGHENERGY SPARK IGNITOR:

GENERALNOTES:

D) CARESHOULD BETAKEN TO AVOID CONTACTWITHANY OTHER

CERAMIC PARTFORLIFTING.

C) DO NOTUSEA CABLEORCHAIN THROUGHORAROUND ANY

B) FORPARTSWITHOUTLIFTING LUGS, USENYLON SLING FORLIFTING.

A) ALWAYSUSELIFTING LUGS, IF PROVIDED, TO LIFTPART.

TO AVOID BREAKING, CRACKING AND CHIPPING:

CERAMIC ISA VERY BRITTLEPRODUCTAND REQUIRESSPECIAL HANDLING

NE21. GENERAL HANDLING FORCERAMIC COMPONENTS:

ERECTION NOTES:

B0054897 6420532

5 1 17 1/4"DEFLECTOR(SILICON CARBIDE) 6381785C 6381785

6 4 FLANGESEGMENT 2763817A 2763817

7 1 DIFFUSERMOUNTING BRACKET 299350B 2174414

8 1 GASKET 356104C 4688613

9 1 EXCITERHIGHENERGY 348822C 4688147

10 1 IGNITORCFSOIL R.H. "L =10'-0""LS"=8'-0 5/16" 2269078E 6419310

11 4 BURNERSUPPORTBRACKETRETAINER 162770A 4539895

12 4 C6 X10.5 X1'-4"LG. A36 4678009

13 .5 TUBE SEALER, RED SILICONERUBBER 0330146

14 31 FT PACKING ROUND ROPEFIBERFRAX2300 5/8" 4591668

15 2 WASHERPLN 1/2"TYPEBWIDEF844 6029947

16 16 NUTHEX1"A563B(GR5) 4685586

17 6 NUTHEX1/2"13UNC-2BA563A 4546572

18 16 BOLTHEX1"X3 1/4"LG. A449TP1 (GR5) 4695347

19 2 ASSEMBLY FLEXIBLEHOSE3/8"X50"LG 6253420

20 2 TEETHRD 1/2"3000#STL 3017087

21 2 BSHG HEXHD SCRD 1/2"X3/8"SA105 0350068

22 4 PLUG THRD SQ HD 1/4"3000#SA105 3026365

23 2 BSHG HEXHD SCRD 1/2"X1/4"STL 3014711

24

DESCRIPTION FLOW PRESSURE

a OIL IGNITORCONN.

5 SCFM

8.5NM

3

/ HR

2"WC ABOVEWINDBOX

5 CM WC ABOVEWINDBOX

b OIL IGNITORCONN.

10 SCFM

17 NM

AC VOLTS AMPS

4688667 BALL VALVE1"SHARPE54574N 2 31

6423304 B0054895 COAL NOZZLEMOUNTING PLATE 1 30

6425088 B0054905 ASSEMBLY MOUNTING PLATE 1 29

6423294 B0054892 ASSEMBLY 16 1/2"CERAMIC LINED COAL NOZZLE 1 28

6436076 B0054932 ASSEMBLY 17 1/4"I.D. CERAMIC LINED COAL ELBOW 1 27

6441549 GO SWITCHLIMITSWITCH73-13527DCA 1 26

2233574 NIPPLE1/2"X3"LG TBENPTSA106B 2 25

4688127 BALL VALVE1/2"SHARPE54574N 2

10 CM WC ABOVEFURNACE

4"WC ABOVEFURNACE

/HR

3

7.8 NM

4 SCFM

ROD & PORTSEAL d

5 CM WC ABOVEFURNACE

2"WC ABOVEFURNACE

/ HR

3

17NM

10 SCFM

ATOMIZERASPIRATOR c

5 CM WC ABOVEFURNACE

2"WC ABOVEFURNACE

/ HR

3

5 250 -- --

5 125 5 480

1 48 2 240

2 24 4 120

AMPS DC VOLTS

ITEM

NO

QTY. DESCRIPTION DRAWING NUMBER PARTNUMBER

1 1 ASSEMBLY BURNERELEMENTC.C.W. B0054852

ITEM

NO

QTY. DESCRIPTION DRAWING NUMBER PARTNUMBER

32 1 ASSEMBLY CABLE15'-0" 4688148

33 1 HIGHENERGY SPARK ROD PL-12"=9'-11 9/16" 188723B 2226783

34 1 HIGHENERGY SPARK PROBETIP 188722B 8804376

35

36

37 1 TARGETMAGNET 6441550

38 1 SWITCHPLATE B0055213 6441512

39 1 SWITCHPLATE B0055214 6441532

40 1 ASSEMBLY ATOMIZERMF "L"=13'-9" 146577D 6420663

41 1 ASSEMBLY SUPPORTPIPE B0054845 6420534

42 1 ASSEMBLY DRIVEBRACKET 6255238B 6255238

43 1 ASSEMBLY MOUNTING BRACKET 2324955B 2324955

44 1 AIRCYLINDERYATESW/PROXY SWITCHES4"BOREMODEL NO. L4-N-B4.0V12.00N1.00V4S11 4703920

45 1 ROD EYEYATES#13-MSRE-0750 2324916

46 1 CLEVISPIN YATES#12-YP-9004-3-G-CBS-A 2324917

47 1 CLEVISBRACKETYATES#14-YCB-133-05-CBS-A 2324914

48 2 U-BOLT3/8"X2"W/ 4 NUTSCARBON STEEL 4677637

49 2 PROXIMITY SWITCHCABLE30'-0"LG. 6441548

50 4 BOLTHEX1/2"-13UNC-2A X2"LG A563A 4661082

51 4 NUTHVY HEX3/8"24UNF-2B 4700049

52 4 WASHERSPRING LOCK 1/2"STL 0493478

53 4 WASHERLOCK 3/8"STL 0493475

54 2 NIP HEXRED CAJ ON B-8-HRN-6 6041159

55 2 VALVEFLOWCONTROL 3/8"N.P.T. PNEU-TROL F-25BK 3087733

56

REVISIONS

REV DESCRIPTION DATE APPROVED

1

ADDED CUSTOMERTITLEBLOCK. QTY FORITEM NO. 54 WAS

2. CAI/ DAS

2/ 3/ 2009 DWD

2

CHG'D DESC. OF ITEM NO. 26, 27, 28, 29, 30, 38, 39, 49 AND

56. ADDED ITEM NO. 37. UPDATED GRAPHICSIN FRONTVIEW

AND SECTION A-A. ADDED SECTIONSAB-ABAND AC-AC.

REVISED NE14. ADDED NE26-28. REVISED CUSTOMERTITLE

BLOCK FROM YYY TO BNR. CAI/ DAS

6/ 2/ 2009 DWD

3

REVISED DRAWING REVISION NUBMERSIN TITLE BLOCK.

DAS

6/ 16/ 2009 DWD

4

CHG'D DESC AND P/ N FORITEM NO. 9. ADDED ITEM

NOs. 32-34. REVISED CUSTOMERTITLE BLOCK. CAI/ DAS

3/ 1/ 2010 DWD

EMPLOYERS DOCUMENT REVIEWANDSTATUS

LOG

IN

DATE 08/09/09 REVIEW BY REVISION STATUS DISTRIBUTION 1

COMM NO : 0316 MECHANICA

L

A : ACCEPTED X CONTRACTOR X

LOG

OUT

DATE: 16/10/09 ELECTRICAL B : ACCEPTED AS NOTED RECORD 1

COMM NO: 0231 I &C C : NOT ACCEPTED PIKITRING J BN 1

RELEASEDBY : DATE: 16/10/09 SUPPORT I : INFORMATION ONLY PROJ ECT 1

Owner :

PT. PLN (PERSERO)

SURALAYA STEAM POWER PLANT UNIT 1- 4 ( 4 X 400 MW)

LOT 1 : BOILER UNIT 1 & 2

REHABILITATION PROJECT Contract No. 255.PJ/041/DIR/2008

PT PLN (PERSERO) JASA ENJINIRING

DRAWING TITLE :

PLN DRAWINGNo. REV

0 1 0 4 1 L 1 - 0 2 - M - 5 1 - H J A - 0 1 0

Contractor :

MARUBENI CORPORATION

Revision History

Rev. Rev. Date Created by Checked

by

Approved by Description

01 2/03/2009 C.A. IAFANO D. SMITH D.W. DOWDELL ADDEDCUSTOMER TITLE BLOCK.

02 6/02/2009 C.A. IAFANO D. SMITH D.W. DOWDELL ADDEDCOAL NOZZLE ANDRELATEDPARTS.

03 6/16/2009 D.SMITH D.SMITH D.W.DOWDELL REVISEDDRAWINGREVISION NUMBERS

04 3/1/2010 C.A.IAFANO D.SMITH D.W.DOWDELL CHGDDESC ANDP/NFOR ITEM9. ADDEDITEMS

32-34. REVISEDCUSTOMER TITLE BLOCK.

Contractors (Partner, Subcontractor)

Babcock&WilcoxPower GenerationGroup

Scale

1 1/2"=1-0

Contractors Document/ Drawing No

SRLSPP12-1-255-BNR-A-008-04

Responsible dept.

ISP

Created by

C.A. IAFANO

Checkedby

D.A. SMITH

Approvedby

D.W. DOWDELL

Size

J

Originator

B&W

Document Title (Subtitle)

ERECTION ARRANGEMENT

DRB-XCL AND OIL FIRED

BURNER

C.C.W.

DocumentType

For FINAL

Identification number

B0054833

Rev.

04

Date

3/1/2010

Sheet

1/1

Das könnte Ihnen auch gefallen

- B0054827-4 Erection Arrangement DRB-XCL PC Fired Burner C.WDokument1 SeiteB0054827-4 Erection Arrangement DRB-XCL PC Fired Burner C.WNanang Cesc UttaNoch keine Bewertungen

- B0054832-4 Erection Arrangement DRB-XCL PC Fired Burner C.C.WDokument1 SeiteB0054832-4 Erection Arrangement DRB-XCL PC Fired Burner C.C.WNanang Cesc UttaNoch keine Bewertungen

- Corporate Proposal For Vertical Flare Stack InstallationiDokument13 SeitenCorporate Proposal For Vertical Flare Stack InstallationiJude EdohorNoch keine Bewertungen

- TECOtubeexpanders BROCHUREDokument56 SeitenTECOtubeexpanders BROCHUREMontajes Industriales EOS, MIESANoch keine Bewertungen

- BOQ Fire SystemDokument90 SeitenBOQ Fire SystemDSAKNoch keine Bewertungen

- 1 - Transmittal No. R0051734-CTCDokument7 Seiten1 - Transmittal No. R0051734-CTCNanang Cesc UttaNoch keine Bewertungen

- Gatut 1617 8403Dokument6 SeitenGatut 1617 8403Chy IdNoch keine Bewertungen

- Daftar Harga Fire Hydrant AppronDokument2 SeitenDaftar Harga Fire Hydrant AppronWeri IsvebriantiNoch keine Bewertungen

- Term of Reference Assessment Study of Unbalance Liquid Level of Central Separator of Ulubelu Unit 3&4Dokument7 SeitenTerm of Reference Assessment Study of Unbalance Liquid Level of Central Separator of Ulubelu Unit 3&4tiantaufik100% (1)

- Amendment TOR Proyek EPC Terminal Regasifikasi LNG Cilacap RevDokument8 SeitenAmendment TOR Proyek EPC Terminal Regasifikasi LNG Cilacap RevFahri AdrianNoch keine Bewertungen

- Data PipaDokument9 SeitenData PipaediabcNoch keine Bewertungen

- ICSS For Gathering Station Jatiasri (Common Safety)Dokument7 SeitenICSS For Gathering Station Jatiasri (Common Safety)Dwiayu LastaryNoch keine Bewertungen

- Mto N2Dokument13 SeitenMto N2dimas prasetyoNoch keine Bewertungen

- EIMGP-I-ME-DTS-01-001 - R1 Mechanical Data Sheet CPO Tank TK-120 TK-121Dokument7 SeitenEIMGP-I-ME-DTS-01-001 - R1 Mechanical Data Sheet CPO Tank TK-120 TK-121Teguh IndrawanNoch keine Bewertungen

- General Method Statement R1.Dokument21 SeitenGeneral Method Statement R1.Ganjar Dreadlocks NugrahaNoch keine Bewertungen

- Instalasi Pipa SteamDokument140 SeitenInstalasi Pipa SteamYudi KurniawanNoch keine Bewertungen

- Request Form JaimonDokument306 SeitenRequest Form JaimonjaimonjoyNoch keine Bewertungen

- Kabel MetalDokument2 SeitenKabel Metalsri haryadiNoch keine Bewertungen

- Form Welding SchematicDokument1 SeiteForm Welding SchematicZainudinNoch keine Bewertungen

- 3.2 Big Block Assembly 3.2.1 Work Shop Assembly Pre-RequisitionsDokument14 Seiten3.2 Big Block Assembly 3.2.1 Work Shop Assembly Pre-RequisitionsEur-Ing Nicola GalluzziNoch keine Bewertungen

- Murphy Offshore Inspection and Maintenance ReportDokument20 SeitenMurphy Offshore Inspection and Maintenance ReportJaowad DabielNoch keine Bewertungen

- B 84567 SB MM1 SPC ST 00 0301 - 1 - AOC - Seal Gas Mercury Guard BedDokument7 SeitenB 84567 SB MM1 SPC ST 00 0301 - 1 - AOC - Seal Gas Mercury Guard BedpragatheeskNoch keine Bewertungen

- SUR - Erection BOQ - ST & Geno - Rev ADokument5 SeitenSUR - Erection BOQ - ST & Geno - Rev Ashaikhsajid242Noch keine Bewertungen

- Estimasi Biaya Jasa Pekerjaan ElectricalDokument19 SeitenEstimasi Biaya Jasa Pekerjaan ElectricalHarry Priyulanda RukkaNoch keine Bewertungen

- SVDN CPP I 0023 D01 0002 Rev.04 General Arrangement Drawing in Signaler ReplaceDokument8 SeitenSVDN CPP I 0023 D01 0002 Rev.04 General Arrangement Drawing in Signaler ReplacejfdlksaNoch keine Bewertungen

- Quotation For Industrial Pipling MaterialsDokument6 SeitenQuotation For Industrial Pipling MaterialsKingsley MNoch keine Bewertungen

- Tube Removal Catalog Web ELLIOTDokument24 SeitenTube Removal Catalog Web ELLIOTJose Luis RattiaNoch keine Bewertungen

- Perhitungan Pressure Vessel LengkapDokument70 SeitenPerhitungan Pressure Vessel LengkapReo Aditya MahesaNoch keine Bewertungen

- GA Drawing Deluge Valve System - R2Dokument4 SeitenGA Drawing Deluge Valve System - R2Keannu Radhika Putra WibowoNoch keine Bewertungen

- PT Rapid Infrastruktur Indonesia Compro General 20220210Dokument52 SeitenPT Rapid Infrastruktur Indonesia Compro General 20220210Andhika Permana SutantoNoch keine Bewertungen

- Procedure: Technical Bid Evaluation For Catodic ProtectionDokument6 SeitenProcedure: Technical Bid Evaluation For Catodic ProtectionPer Bagus HandokoNoch keine Bewertungen

- Kast O Lite 30 Li GDokument2 SeitenKast O Lite 30 Li GaamirsaddiqNoch keine Bewertungen

- Taijune Fire Tube Steam BoilerDokument8 SeitenTaijune Fire Tube Steam BoilerAjay GoswamiNoch keine Bewertungen

- Bill of Material For Mechnical & Structure For Hot Water Skid Rev.0 - 3Dokument5 SeitenBill of Material For Mechnical & Structure For Hot Water Skid Rev.0 - 3Vu TranNoch keine Bewertungen

- 72 Europac BrochureDokument2 Seiten72 Europac BrochureAntyox Stark100% (1)

- 020-Tbe Gas FilterDokument6 Seiten020-Tbe Gas FilterSilpa Asti Nura100% (1)

- Struktur Organisasi Office & ProyekDokument17 SeitenStruktur Organisasi Office & ProyekfitraNoch keine Bewertungen

- Procedure: Technical Bid Evaluation For Catodic ProtectionDokument6 SeitenProcedure: Technical Bid Evaluation For Catodic ProtectionPer Bagus Handoko100% (1)

- 0203 KSS Marker StripDokument1 Seite0203 KSS Marker StripAgus Heri TulasnoNoch keine Bewertungen

- Price List Kabel SutradoDokument6 SeitenPrice List Kabel SutradoNauval SetyawanNoch keine Bewertungen

- MTO ValveDokument2 SeitenMTO ValveAgus MarpaungNoch keine Bewertungen

- API Standard Storage Tank Data Sheet Rev 0Dokument3 SeitenAPI Standard Storage Tank Data Sheet Rev 0Nasi GorengNoch keine Bewertungen

- Notes: PT Unilever Oleochemical Indonesia Sunshine Project Piping, Insulation & Mecahnical Tender - Osbl & IsblDokument14 SeitenNotes: PT Unilever Oleochemical Indonesia Sunshine Project Piping, Insulation & Mecahnical Tender - Osbl & Isblrizky youlandaNoch keine Bewertungen

- BOQ Tanjung Uban MekanikalDokument21 SeitenBOQ Tanjung Uban MekanikalRemmo S ArdiansyahNoch keine Bewertungen

- JssDokument288 SeitenJssagungNoch keine Bewertungen

- Carbon Steel Pipe Price ListDokument2 SeitenCarbon Steel Pipe Price ListJoel Ivan Lopez Munachi100% (1)

- Scope of SupplyDokument12 SeitenScope of Supplyreza39Noch keine Bewertungen

- STF HRSGDokument20 SeitenSTF HRSGDaniellzhangNoch keine Bewertungen

- Spring Datasheeet PauDokument4 SeitenSpring Datasheeet PauFeri KaruanaNoch keine Bewertungen

- Boq Pekerjaan Pondasi 500 KV Lot 1.: Foundation For 500 KV Two Circuit TowersDokument8 SeitenBoq Pekerjaan Pondasi 500 KV Lot 1.: Foundation For 500 KV Two Circuit TowersErick SavrinaldoNoch keine Bewertungen

- AnnexureDokument391 SeitenAnnexureTommy ArjanggiNoch keine Bewertungen

- AAF Diesel Engine Clean Air Solutions - EN PDFDokument4 SeitenAAF Diesel Engine Clean Air Solutions - EN PDFsundarNoch keine Bewertungen

- ZA0-2 35,0ae-03 00Dokument15 SeitenZA0-2 35,0ae-03 00Marcos Dos Santos VieiraNoch keine Bewertungen

- 61 - Tank 933 Fabrication & ErectionDokument3 Seiten61 - Tank 933 Fabrication & ErectionDarius Frane MarasiganNoch keine Bewertungen

- Model 10 10fb 11 Carbon HousingsDokument4 SeitenModel 10 10fb 11 Carbon HousingsrezNoch keine Bewertungen

- F5063a-K-003-00 NDT Procedure PDFDokument11 SeitenF5063a-K-003-00 NDT Procedure PDFJatmika Budi SantosaNoch keine Bewertungen

- Punch List: 1798-PL-FCB-27 Fabcon Industrial Services FZ LLC ITT-1798 Daelim 19441-1798-2-R0 19441-1798-2-R0Dokument3 SeitenPunch List: 1798-PL-FCB-27 Fabcon Industrial Services FZ LLC ITT-1798 Daelim 19441-1798-2-R0 19441-1798-2-R0Brain AliveNoch keine Bewertungen

- Filtro y StrainerDokument2 SeitenFiltro y StrainerJose HuguetNoch keine Bewertungen

- PTWDokument3 SeitenPTWAngel Silva VicenteNoch keine Bewertungen

- 05000Dokument4 Seiten05000José O TelloNoch keine Bewertungen

- Application of A High-Order Asymptotic Expansion Scheme To Long-Term Currency OptionsDokument14 SeitenApplication of A High-Order Asymptotic Expansion Scheme To Long-Term Currency OptionsNanang Cesc UttaNoch keine Bewertungen

- Astm Specifications For Weld Fittings and FlangesDokument1 SeiteAstm Specifications For Weld Fittings and FlangesamitkumarkarmakarNoch keine Bewertungen

- 1 - Transmittal No. R0051734-CTCDokument7 Seiten1 - Transmittal No. R0051734-CTCNanang Cesc UttaNoch keine Bewertungen

- Coating ProcedureDokument10 SeitenCoating ProcedureNanang Cesc Utta100% (1)

- Welding Defects Part 4Dokument56 SeitenWelding Defects Part 4Nanang Cesc UttaNoch keine Bewertungen

- Item Rate For GMCTH Jajpur Rate Acceptance For Sub Structure - Concrete, Shuttering, Reinforcement Work & Pile Chipping WorkDokument3 SeitenItem Rate For GMCTH Jajpur Rate Acceptance For Sub Structure - Concrete, Shuttering, Reinforcement Work & Pile Chipping WorkBittudubey officialNoch keine Bewertungen

- CST 336 Final Project Computown DocumentationDokument12 SeitenCST 336 Final Project Computown Documentationapi-461214598Noch keine Bewertungen

- CatalogDokument76 SeitenCatalogmkpasha55mpNoch keine Bewertungen

- RCJ&Y - Jubail Industrial City 2: Phase 3 and 4 Sea Water Cooling StationDokument5 SeitenRCJ&Y - Jubail Industrial City 2: Phase 3 and 4 Sea Water Cooling Stationsalman KhanNoch keine Bewertungen

- Isuzu 4hk1x Sheet HRDokument4 SeitenIsuzu 4hk1x Sheet HRMuhammad Haqi Priyono100% (1)

- Excel 2016: Large Data 1 : Sorting and FilteringDokument19 SeitenExcel 2016: Large Data 1 : Sorting and FilteringSapna JoshiNoch keine Bewertungen

- F4 Search Help To Select More Than One Column ValueDokument4 SeitenF4 Search Help To Select More Than One Column ValueRicky DasNoch keine Bewertungen

- Practice Exam 1Dokument7 SeitenPractice Exam 1425Noch keine Bewertungen

- Molinos VerticalesDokument172 SeitenMolinos VerticalesLeonardo RodriguezNoch keine Bewertungen

- Rev2 Service Manual Apollo PDFDokument370 SeitenRev2 Service Manual Apollo PDFJordi Vaquero RamirezNoch keine Bewertungen

- TabulationDokument13 SeitenTabulationWildan PushNoch keine Bewertungen

- ISO - 3601-2 O-Rings HousingDokument56 SeitenISO - 3601-2 O-Rings HousingAlexey FlidliderNoch keine Bewertungen

- Conjoint SpssDokument28 SeitenConjoint SpssstatsoumyaNoch keine Bewertungen

- NanoDokument10 SeitenNanoRavi TejaNoch keine Bewertungen

- Form WorkDokument12 SeitenForm Workdharul khairNoch keine Bewertungen

- ZXComputingDokument100 SeitenZXComputingozzy75Noch keine Bewertungen

- (TDB) VRF ODU DVM S (R410A, 230V, 60Hz, CO) For LA - Ver.2.0 - 190529Dokument109 Seiten(TDB) VRF ODU DVM S (R410A, 230V, 60Hz, CO) For LA - Ver.2.0 - 190529jeffersonNoch keine Bewertungen

- Metric DIN 434 Square Taper Washers: Visit Our For Product AvailabilityDokument4 SeitenMetric DIN 434 Square Taper Washers: Visit Our For Product AvailabilityRodrigoNoch keine Bewertungen

- L18 PDFDokument8 SeitenL18 PDFrashmi sahooNoch keine Bewertungen

- Book - Adams Tutorial Ex17 W PDFDokument121 SeitenBook - Adams Tutorial Ex17 W PDFKamran ShahidNoch keine Bewertungen

- Interfacing Seven Segment Display With LPC1769Dokument18 SeitenInterfacing Seven Segment Display With LPC1769Gurudatta Palankar0% (1)

- DVMDokument197 SeitenDVMLeonardLapatratNoch keine Bewertungen

- Nuendo 4 Remote Control Devices EsDokument24 SeitenNuendo 4 Remote Control Devices EsRamon RuizNoch keine Bewertungen

- LN3 Geng2340Dokument61 SeitenLN3 Geng2340Seth VineetNoch keine Bewertungen

- Activa NewDokument160 SeitenActiva NewSiddharth Jain100% (1)

- Activation and Deactivation of CatalystsDokument16 SeitenActivation and Deactivation of Catalystsshan0214Noch keine Bewertungen

- Oil and Wildlife Conservation in UgandaDokument40 SeitenOil and Wildlife Conservation in UgandaAfrican Centre for Media ExcellenceNoch keine Bewertungen

- 2 Strokes 4 Strokes: 1 CylinderDokument2 Seiten2 Strokes 4 Strokes: 1 CylinderariffNoch keine Bewertungen

- Ecg Signal Thesis1Dokument74 SeitenEcg Signal Thesis1McSudul HasanNoch keine Bewertungen

- CHE 322 - Gaseous Fuel ProblemsDokument26 SeitenCHE 322 - Gaseous Fuel ProblemsDanice LunaNoch keine Bewertungen