Beruflich Dokumente

Kultur Dokumente

Modeling of Mass Transfer in Nonideal Multicomponent Mixture With Maxwell-Stefan

Hochgeladen von

Clausius ClapeyronOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Modeling of Mass Transfer in Nonideal Multicomponent Mixture With Maxwell-Stefan

Hochgeladen von

Clausius ClapeyronCopyright:

Verfügbare Formate

SEPARATION SCIENCE AND ENGINEERING

Chinese Journal of Chemical Engineering, 18(3) 362371 (2010)

Modeling of Mass Transfer in Nonideal Multicomponent Mixture

with Maxwell-Stefan Approach

*

SONG Yiming ()

1,2

, SONG Jinrong ()

1,2

, GONG Ming ()

1,2

, CAO Bin ()

1,2

,

YANG Yanhong ()

1,2

and MA Xiaoxun ()

1,2,

**

1

School of Chemical Engineering, Northwest University, Xian 710069, China

2

Chemical Engineering Research Center of the Ministry of Education for Advanced Use Technology of Shanbei

Energy, Xian 710069, China

Abstract The Intalox metal tower packing was used to simulate an industrial relevant extractive distillation col-

umn for purifying azeotropic multicomponent mixture. In order to explain the inconsistencies in the modeling of

transfer process in nonideal multicomponent distillation column, a method was developed with equilibrium stage

models (EQ) and non-equilibrium model (NEQ) incorporated with Maxwell-Stefan diffusion equations in the

framework of AspenONE

simulator. Dortmund Modified UNIFAC (UNIFAC-DMD) thermodynamic model was

employed to estimate activity coefficients. In addition, to understand the reason for the diffusion against driving

force and the different results by EQ and NEQ models, explicit investigations were made on diffusion coefficients,

component Murphree efficiency and mass transfer coefficients. The results provide valuable information for basic

design and applications associated with extractive distillation.

Keywords rate based model, equilibrium model, mass transfer coefficient, Murphree efficiency, extractive distil-

lation, simulation

1 INTRODUCTION

There is considerable industrial interest in design

and optimization of extractive distillation due to the

large number of industrial columns in operation and

the potential of developing improved separation

schemes so as to minimize energy consumption [1-3].

As a result, various extractive distillation systems

have been investigated, such as solvent selection

methods [4], development of new extractive distilla-

tion systems [5-7], and introduction of a salt to the

solvent to improve the separation [8]. However, there

are few publications [9-12] on modeling and simula-

tion of azeotropic multicomponent extractive distilla-

tion using non-equilibrium (NEQ) approach. In indus-

trial design, chemical engineers usually develop their

design procedures for separation equipment using

Ficks law of diffusion [13, 14], in which the flux J

i

is

linearly dependent on molar average mixture velocity

and composition gradient

i

x

( )

i i i i i i

J c v v c D x = (1)

This constitutive relation is strictly valid only under

the following conditions: (i) binary mixtures, (ii) dif-

fusion of dilute species in a multicomponent mixture,

and (iii) in the absence of electrostatic or centrifugal

force field. For practical purpose, we usually use

Murphree vapor efficiency (Ei

MV

) for a plate and the

height equivalent to a theoretical plate (HETP) for

packings. The concept works quite well for binary sepa-

ration [14, 15], based on the assumption that the effi-

ciencies of two components are equal and the physical

properties are constant along the column. However, it

is difficult to relate the concept to the construction and

performance of equipment, and to apply it to nonideal

multicomponent mixtures [16, 17]. In addition, some

bizarre behavior may appear, such as unbounded

component Murphree efficiencies [17], and the diffu-

sion in ternary mixture is much more complex than

that in binary mixture [18] because of coupling between

species concentration gradients. To avoid the am-

biguous component efficiencies and the limitation of

Ficks law for describing diffusion in multicomponent

mixture, a realistic model is needed. It is now gener-

ally accepted that the Maxwell-Stefan formulation

provides the most general and convenient approach

for describing transport process in multicomponent

mixture [11, 15, 19]. Lao and Taylor [20] first developed

a model based on the Maxwell-Stefan formulation for

multicomponent distillation for a single tray. In this

study, the NEQ approach incorporated with Maxwell-

Stefan diffusion theory is applied to simulate an in-

dustrial relevant extractive distillation column, and the

mass transfer process and associated influence factors,

such as mass transfer coefficients, Murphree effi-

ciency and diffusion coefficients, are investigated.

2 SIMULATION PROCESURE AND MODELING

2.1 Numerical set up and conditions

Figure 1 illustrates the schematic presentation of

an extractive distillation column. The column consists

of 27 stages, including the total condenser (stage 1)

Received 2009-12-24, accepted 2010-03-29.

* Supported by the National Natural Science Foundation of China (20776118), Science & Technology Bureau of Xian

[CXY09019 (1)], Innovation Foundation for Graduated Student of Northwest University (08YJC21), Shaanxi Research Center

of Engineering Technology for Clean Coal Conversion (2008ZDGC-13).

** To whom correspondence should be addressed. E-mail: maxym@nwu.edu.cn

Chin. J. Chem. Eng., Vol. 18, No. 3, June 2010 363

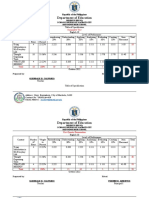

and partial reboiler (stage 27). Table 1 lists the principal

configuration data. In both EQ and NEQ approaches

the vapor phase is assumed to be thermodynamically

ideal. In addition, the test for the presence of the sec-

ond liquid phase is considered in EQ approach. To

determine the bulk properties in NEQ approach, which

is relative to the inlet and outlet properties for each

phase on each stage, mixed and countercurrent flow

are considered as flow patterns for bubble cap tray and

random packing respectively. The 25 mm Intalox

metal tower packing (IMTP) applied has a HETP

value of 0.42 m in the EQ simulation.

2.2 Mathematic modeling incorporated with

Maxwell-Stefan theory

2.2.1 Film model and Maxwell-Stefan theory

Simulation of distillation process is often carried

out with the equilibrium stage model [21]. However,

the equipment and flow pattern, which present the

hydrodynamic characteristics and influence the ther-

modynamic property, are beyond the scope of EQ ap-

proach. In most equipment, the flow of both phases is

highly turbulent [22-24], so on not-too large scales the

concentrations and temperatures in the bulk fluids can

be considered as uniform. Near the phase interface

turbulence dies out and eddies do not pass across it.

Fig. 2 presents the simplest model, the film model, for

mass and heat transfer [17, 22, 24].

Figure 2 The simplest non-equilibrium model

In the film model, it is assumed that all the resis-

tance to mass transfer is concentrated in a thin film

adjacent to the interface [24-26], in which the transfer

occurs by steady state molecular diffusion. Outside this

film, in the bulk fluid, all composition gradients are

wiped out by turbulent eddy. A fully turbulent flow of

bulk phase is adjacent to the thin film in laminar flow

parallel to the interface. Mass transfer through this

film is in the direction normal to the interface, and any

constituent molecular diffusion or convection parallel

to the surface resulted from composition gradients along

the interface is negligible. To calculate the interphase

mass transfer fluxes in multicomponent mixtures, it is

now generally accepted that the Maxwell-Stefan diffu-

sion formulation is adopted for the fluid phases [27-32],

in which chemical potential gradients are used as the

driving forces for diffusion. A linear relation is postulated

Figure 1 Schematic presentation of extractive distillation

column

Table 1 Principal configuration data

Input data and specified parameters

Operating specifications

feed stage of entrainer above stage 6

feed stage of C

4

above stage 19

temperature of entrainer 50 C

pressure of entrainer 1 MPa

pressure of C

4

stream 0.51 MPa

reflux ratio 2

C

4

condition vapor

flow rate of C

4

10000 kgh

1

mass fraction of C

4

n-butane 50%

1-butene 3%

cis-2-butene 16%

trans-2-butene 31%

flow rate of entrainer 80000 kgh

1

entrainer condition liquid

mass fraction of water in entrainer 8.30%

Column parameters

number of stage 27

diameter of packing in the column 1.25 m

number of wash tray 5

diameter of wash tray 1.2 m

random packing IMTP, 25mm-metal

wash tray bubble cap tray

Chin. J. Chem. Eng., Vol. 18, No. 3, June 2010 364

between the driving forces and the fluxes:

1 1 1

n n N

j i i j j i i j

ij i

j j j i ij i ij

j i j i

x j x j x N x N

c c

= = =

= =

(2)

where x

i

represents the mole fraction in the fluid phase,

N

i

is the molar flux,

ij

is the Maxwell-Stefan diffu-

sivity, and

i

is the chemical potential gradient,

which is from the frictional drag of one group of mole-

cules moving through the others. It does not matter

whether the frictional drag arises purely from inter-

molecular collisions as in the simple kinetic theory of

gases or additionally from intermolecular forces be-

tween two groups of molecules. The Maxwell-Stefan

diffusivity is given by

( )

2 1 2

d

d

i

RT

x v v

z

= (3)

With this definition, the Maxwell-Stefan diffusivity

(m

2

s

1

) is related to the drag coefficient, and is easier

to interpret and predict than Ficks diffusivity. For an

ideal binary gas mixture it is equal to Ficks diffusivity.

Following the approach of Krishna and Taylor [24]

Eq. (2) can be recast in terms of the mass transfer

coefficients k

ij

1 1

1, 2, , 1

n n

j i i j

ij j

j j i ij

j i

x N x N

x i n

c k

= =

= =

(4)

where x

j

represents the difference in composition

between the bulk fluid and interface, and

ij

represents

thermodynamic correction factor related to the non-

ideal behavior. For a highly nonideal mixture, the ther-

modynamic factor is usually a strong function of the

mixture composition and vanishes in the region of the

critical point [17, 21]. The driving force contains con-

tributions due to mole fraction and activity coefficient

of species i, and the contribution of mole fraction gra-

dient is similar to that of concentration in Ficks equa-

tion. However, Ficks equation does not consider the

effect of nonideality via the activity coefficient [33, 34].

Thus the formulation is useful in relating the practical

coefficients to the molecular collision processes and

the intermolecular interactions in the mixture [24]. It

takes proper account of diffusional coupling between

the species transfer, i.e. the flux of any species de-

pends on the driving forces of all the species present

in the mixture.

2.2.2 Model formulation

For the system considered in the simulation as

shown in Fig. 2, our immediate task is to develop the

balances for describing the transport processes.

Material and energy balances for the bulk liquid

and vapor:

L F L L

1 , 1

0

j ij j i j ij ij j ij

F x L x N r L x

+ + + = (5)

V FV V V V V

1 1

0

j j j j j j j j

F H V H Q q V H

+ +

+ + + = (6)

V F V V

1 , 1

0

j ij j i j ij ij j ij

F y V y N r V y

+ +

+ + + = (7)

L FL L L L L

1 1

0

j j j j j j j j

F H L H Q q L H

+ + + = (8)

Material and energy balances for liquid and vapor film:

I fL L

0

ij ij ij

N r N + = (9)

V fV I

0

ij ij ij

N r N + = (10)

I L

0

j j

q q = (11)

V I

0

j j

q q = (12)

Phase equilibrium:

I I

0

ij ij ij

y K x = (13)

Mole fraction summation for bulk liquid and vapor:

1

1 0

n

ij

i

x

=

=

(14)

1

1 0

n

ij

i

y

=

=

(15)

Mole fraction summation for interface:

I

1

1 0

n

ij

i

x

=

=

(16)

I

1

1 0

n

ij

i

y

=

=

(17)

Mass flux for bulk liquid and vapor:

( ) ( )

( )

E L I

L L L

0

j j j j j j

j j t j

x z

x x

R N N x

+

=

(18)

( ) ( )

I I V V V

0

j j j j j t j

y y R N N y

+ =

(19)

where is the matrix of thermodynamical factors:

L

L

L

, , ,

, ,

ln

j j

ij

i k j i k ij

kj

T P

x

x

= +

(20)

V

V

V

, , ,

, ,

ln

j j

ij

i k j i k ij

kj

T P

y

y

= +

(21)

The symbol means fixing the mole fractions of all

other components except for the n-th component while

evaluating the differentiation. The inverse matrixes of

mass transfer coefficients R are

L

, ,

L I L L I L

1 , , , ,

1, , 1

n

ij mj

i i j

m j j i n j j j i m j

m i

x x

R

a k a k

i n

=

= +

=

(22)

L

L L L L L L , ,

, , , ,

1 1

1, , 1,

i k j ij

j j i k j j j i n j

R x

a k a k

i n i k

=

= (23)

Chin. J. Chem. Eng., Vol. 18, No. 3, June 2010 365

V

, ,

V I L V I V

1 , , , ,

1, , 1

n

ij mj

i i j

m j j i n j j j i m j

m i

y y

R

a k a k

i n

=

= +

=

(24)

V

V I V V I V , ,

, , , ,

1 1

1, , 1,

i k j ij

j j i k j j j i n j

R y

a k a k

i n i k

=

= (25)

The heat stream for the bulk liquid and vapor phase is

given by

( )

I L L L L I L

1

0

n

j j j ij ij j j

i

a h q N H T T

=

+ =

(26)

( )

I V V V V V I

1

0

n

j j j ij ij j j

i

a h q N H T T

=

+ =

(27)

To reduce the size of Jacobian elements, the mass

transfer coefficients are written as

o

, , , ,

j

i k j j i k j

k k D

= (28)

where

o

j

k is a function of flow, temperature, composi-

tion and other properties but independent of compo-

nents i and k.

2.3 Correlation methods

Accurate transfer efficiency and knowledge of the

maximum hydraulic capacity [35] and pressure drop [36]

of a packing are essential for design and operation of

packed columns. The transfer process in packed col-

umns is dependent on many factors, such as flow rates

of vapor and liquid, physical properties, and vapor-liquid

equilibrium [37-42], which change from location to

location along the column. Most of the existing mod-

els for prediction of height of a transfer unit (HTU)

are inappropriate if the factors stated above change

along the column significantly, especially for nonideal

and chemical reaction systems.

2.3.1 Correlations for interfacial area and mass trans-

fer coefficients

For bubble cap tray, the correlation of Gerster et

al. [43] is used to estimate the interfacial area and

mass transfer coefficients, which is as follows.

Binary mass transfer coefficient for the liquid

and vapor:

( ) ( )

0.5

8 L

s L ,

L

,

L I

0.21313 0.15 4.127 10

i k

i k

F Lt D

k

a

+

= (29)

V L

w s ,

w

0.5 V

V, , b

I

104.85

0.776 4.567 0.2377

i k

i k s

Q

h F k

l

Sc A v

a

+ + =

(30)

Interfacial area:

I 0.375 0.247 0.515

b V L w

0.27 a A Re Re h = (31)

Superficial F-factor:

( )

0.5

V V

s s t

F u

= (32)

Average residence time for liquid:

L L w L

0.9998 / t h Zl Q = (33)

Liquid height:

L w L w s

0.04191 0.19 2.4545 / 0.0135 h h Q l F = + + (34)

Average volumetric flow rate per pass for liquid:

L L p

/ Q Q N = (35)

For IMTP packing, the correlation of Onda et al.

[44] is used to predict the interfacial area and mass

transfer coefficients.

Binary mass transfer coefficient for the liquid

and vapor:

( ) ( )

0.333

L

0.4 0.667

L 0.5

p p , L, , L

L

0.0051

i k i k

g

a d k Sc Re

=

(36)

( )

2

V 0.7 0.333 V

p p , V V, , p ,

5.23

i k i k i k

a d k Re Sc a D

= (37)

Effective interfacial area for mass transfer:

I

w t p

a a A h = (38)

Wetted surface area per unit volume:

0.75

0.1 0.05 0.2

c

w p L L L

1 exp

1.45

a a Re Fr We

=

(39)

2.3.2 Correlations for heat transfer coefficients

The Chilton and Colburn method is based on the

relationship of Chilton-Colburn analogy and calcu-

lates heat transfer coefficients from the binary mass

transfer coefficients. It is probably the most successful

and widely used analogy and proved to be the most

accurate [45-50].

Heat transfer coefficients for vapor and liquid:

2/ 3

L

L L L L

L L L

P

P

k C

C D

=

(40)

2/ 3

V

V V V V

V V V

P

P

k C

C D

=

(41)

Average diffusivity and mass transfer coefficient:

( )( )

( )( )

c c

c c

1

1 1

1

1 1

n n

ij kj ikj

i k i

j

n n

ij kj

i k i

x x D

D

x x

= = +

= = +

+ +

=

+ +

(42)

Chin. J. Chem. Eng., Vol. 18, No. 3, June 2010 366

( )( )

( )( )

c c

c c

1

1 1

1

1 1

n n

ij kj ikj

i k i

j

n n

ij kj

i k i

x x D

K

x x

= = +

= = +

+ +

=

+ +

(43)

where n

c

is the number of components. The Chilton-

Colburn averaging parameter has the default value

of 10

4

. Eqs. (5)-(43) describe the transport process

for the investigated system and the numerical solution

represents the behavior in the column. The set of equa-

tions is solved using Newtons method. Property moni-

tors are configured to verify the convergence. How-

ever, for some properties, such as diffusivities, partial

molar enthalpies and activity coefficients, the deriva-

tives are not available for the property monitors as they

involve derivatives of matrices or derivatives of deriva-

tives. The next section gives the results of the simulation.

2.4 Thermodynamic property

In the nonequilibrium model, we assume that

equilibrium exists at the interface. Thermodynamic

model is needed to describe the equilibrium for the

mixture. Due to the highly nonideal behavior in extrac-

tive distillation, it is necessary to apply relative com-

plex thermodynamic method for accurate prediction of

the corresponding phase equilibria. The choice of spe-

cific thermodynamic model has a great effect on the

results of simulation [8, 27, 46]. Two models are usually

used in multicomponent distillation: multicomponent

equations of state and Gibbs excess energy models.

The latter are useful for strongly nonideal mixtures at

not-too-high pressures [27, 33]. In this study it is found

that the predictions, especially the temperature profiles,

by NRTL, UNIQUAC and ASOG are quite different. The

estimated profiles by UNIFAC and UNIFAC-DMD

with parameters regressed from VLE data are similar.

To regress the UNIFAC-DMD parameters, the values

provided by Detherm V2.0 are used in this work. Ta-

bles 2 and 3 show the definition of UNIFAC group

parameter and UNIFAC group vector, respectively.

Fig. 3 shows that the prediction results are in good

agreement with experimental data selected from

Detherm V2.0.

Table 2 Definition of UNIFAC groups

Group ID Group number Molecular structure

G1005 1005

G1010 1010

G1015 1015

G1060 1060

G1065 1065

G1070 1070

G1300 1300 H

2

O

G3450 3450 C

5

H

9

NO

Table 3 UNIFAC-DMD group vector containing the

UNIFAC group number and the number of

occurrence of each group

No. a

1 1010 1010 1015 1015 1300 3450

2 2 1 2 2 1 1

3 1015 1015 1065 1060

4 2 1 1 1

5 1070

6 1

Components: a, n-butane; b, 1-butene; c, cis-2-butene; d,

trans-2-butene; e, water; f, N-methylpyrrolidone.

Figure 3 Temperature predicted by UNIFAC-DMD with

parameters regressed by vapor liquid equilibrium data

cis-2-butene & n-butane; cis-2-butene & NMP; cis-2-butene

& I-butene

3 SIMULATION RESULTS

We have developed equations to describe the

thermo- and hydrodynamic behavior in the region ad-

jacent to the interface with the appropriate boundary

conditions at the interface, and considered the trans-

port process across the interface. Both EQ and NEQ

simulations are carried out in the framework of As-

penONE

. Fig. 4 shows column composition profiles

predicted by EQ and NEQ models and experimental

values, in which only the profiles of n-butane and

trans-2-butene in vapor phase are plotted for a better

Figure 4 Composition profiles predicted by EQ and NEQ

models

n-butane (NEQ); n-butane (EQ); experiment (n-butane);

trans-2-butene (NEQ); trans-2-butane (EQ)

Chin. J. Chem. Eng., Vol. 18, No. 3, June 2010 367

view of the profiles without the loss of generality. The

composition profiles predicted by EQ and NEQ mod-

els differ significantly. The composition profile of

n-butane predicted by NEQ model shows an excellent

agreement with experimental data, while that by EQ

model differs significantly from the experimental val-

ues. In order to understand the reason, Murphree effi-

ciency, diffusion coefficients and mass transfer coeffi-

cients are investigated.

3.1 Murphree vapor efficiency and diffusion co-

efficients

In this section, we present information on com-

ponent Murphree vapor efficiencies and binary diffu-

sion coefficients. The NEQ approach does not use the

efficiency, but the efficiencies of each component on

each tray can be calculated from its results. Fig. 5 pre-

sents component Murphree vapor efficiencies calcu-

lated from the results of NEQ simulation. The differ-

ences in Ei

MV

are from the differences in the diffusivities

of binary pair vapor in the mixture, and Maxwell-Stefan

diffusion takes proper account of diffusional coupling

between the species. Moreover, the efficiencies vary

greatly from stage to stage and some are abnormal. Some

of the components have extreme values of 2400%

and +800%. In particular, the efficiencies of n-butane

are negative on some stages. Such odd behavior as

negative efficiency was observed experimentally for

acetone, methanol and water mixture in a sieve tray

column [51]. The main reasons are as follows. On the

one hand, the entrainer acts as a selective semiperme-

able filter, which lets those more soluble components,

1-butene, cis-2-butene and trans-2-butene, pass pref-

erentially. These components in the vapor phase enter

the liquid region through the interface and release its

latent heat. n-butane in the liquid absorbs the energy

released at the interface and moves from its low con-

centration region into n-butane rich vapor phase,

leading reverse diffusion of n-butane. On the other

hand, because of the poor solubility the equilibrium of

n-butane does not exist at the interface, so that the

driving force y

i

of n-butane in vapor boundary layer

vanishes, i.e. y

i

0. Its flux is resulted from the

movement of other components in the mixture, mainly

by 1-butene, cis-2-butene and trans-2-butene, so the

component efficiencies are greater than 100% and

may be positive or negative. At the same time, com-

ponent efficiency changes along the column signifi-

cantly. As a result, the mole fraction of component

(Fig. 4) on any stage with the NEQ approach is dif-

ferent from that by the EQ approach. In Fig. 5 with

increasing vapor loading from top to bottom, the effi-

ciencies for trans-2-butene, 1-butene and cis-2-butene

increase slightly. The situation is changed dramatically

when vaporous C

4

mixture is introduced. The sudden

jump discontinuity in the efficiencies appears from

stage 19 (feed stage of vaporous C

4

mixture) to stages

18 and 17, with the largest positive values (220% for

1-butene and 150% for cis-2-butene). The negative

efficiencies of n-butane appear from stage 11 to stage

23, which drive n-butane from the low concentration

liquid region into the rich vapor region. Tables 4 and 5

show the binary diffusion coefficients in vapor phase

on stages 8 and 22 respectively. The binary diffusion

coefficients of NMP have the smallest values and

those of n-butane are the next, which indicates that the

flux of n-butane is resulted from the movement of

other components. Table 6 shows the corresponding

mole fraction on stages 8 and 22, on which the driving

force of n-butane is much greater than that of others

and the mole fractions of n-butane in vapor phase are

much greater than that in liquid phase. n-butane moves

into vapor phase from liquid phase against the driving

Figure 5 Component Murphree vapor efficiencies along column

n-butane; trans-2-butene; cis-2-butene; 1-butene; NMP; water

Table 4 Binary diffusion coefficients in vapor

phase on stage 8 (10

6

m

2

s

1

)

a

0 1.0284 1.0216 1.0226 2.3961 0.7522

b

1.0284 0 1.0640 1.0651 2.5320 0.7880

c

1.0216 1.0640 0 1.0570 2.4994 0.7841

d

1.0226 1.0651 1.0570 0 2.4846 0.7831

e

2.3961 2.5320 2.4994 2.4846 0 1.7884

f

0.7522 0.7880 0.7841 0.7831 1.7884 0

Components: a, n-butane; b, 1-butene; c, cis-2-butene; d,

trans-2-butene; e, water; f, N-methylpyrrolidone.

Chin. J. Chem. Eng., Vol. 18, No. 3, June 2010 368

force. The component Murphree efficiency in Fig. 5

indicates that the values of HETP or HTU are different

from stage to stage, so the application of classical HTU-

NTU approach and constant Ei

MV

for packed-column

design will lead to poor results compared with the

more rigorous approach with the Maxwell-Stefan model.

Olano et al. [52] also obtained similar conclusion for

other process. In addition, EQ model offers no explicit

information about diffusion and transfer across the

interface, so that the variation of Murphree vapor effi-

ciency along column is not considered. As a result,

process design based on EQ concept involves uncer-

tainties of Murphree efficiency and limitation of

Ficks diffusion theory. On the contrary, NEQ ap-

proach gives us quite a detailed understanding of what

is going on in the equipment.

3.2 Mass transfer rate and mass transfer coeffi-

cients of component

Since NEQ approach presents quite detailed be-

havior in the column, it is possible to investigate the

mass transfer rate of component across the interface,

diffusion coefficients and mass transfer coefficients on

each stage. Fig. 6 illustrates the transfer rate of com-

ponent across the interface along the column. The flux

of n-butane across the interface is from liquid phase to

vapor phase, and the fluxes of other components such

as 1-butene, cis-2-butene, trans-2-butene, water and

NMP are from vapor phase to liquid region. On the

Table 5 Binary diffusion coefficients in vapor

phase on stage 22 (10

6

m

2

s

1

)

a

0 1.0842 1.0773 1.0793 2.5292 0.7930

b

1.0842 0 1.1199 1.1215 2.6564 0.8312

c

1.0773 1.1199 0 1.1131 2.6230 0.8270

d

1.0793 1.1215 1.1131 0 2.6142 0.8255

e

2.5292 2.6564 2.6230 2.6142 0 1.8792

f

0.7930 0.8312 0.8270 0.8255 1.8792 0

Components: a, n-butane; b, 1-butene; c, cis-2-butene; d,

trans-2-butene; e, water; f, N-methylpyrrolidone.

Table 6 Mole fraction in vapor and liquid phase on stage 8 and 22

Mole fraction/molmol

1

Stage Phase

a

8 vapor 0.800337 0.017297 0.047475 0.126164 0.008403 0.000324

liquid 0.142389 0.004061 0.012969 0.032672 0.269374 0.538535

22 vapor 0.396424 0.040453 0.175672 0.374683 0.012286 0.000482

liquid 0.062889 0.009248 0.047499 0.095076 0.261728 0.523560

Components: a, n-butane; b, 1-butene; c, cis-2-butene; d, trans-2-butene; e, water; f, N-methylpyrrolidone.

Figure 6 Mass transfer rates of component across the interface predicted by NEQ models

(Positive values refer to transfer from vapor to liquid)

Chin. J. Chem. Eng., Vol. 18, No. 3, June 2010 369

feed stages (6 and 19), the fluxes for C

4

components

change dramatically, mainly because the introduction

of fresh feed stream increases the driving force for

transfer and intensity of turbulence. The mass transfer

rate reduces from stage 6 to stage 19 but increases

from stage 20 to the bottom with the increase of vapor

loading. To investigate the mass transfer, it is custom-

ary to determine mass transfer coefficients [38, 45, 53, 54].

Eqs. (42) and (43) are used to calculate the average

diffusion and mass transfer coefficients of stage from

binary pair diffusion and mass transfer coefficients,

which are estimated with Eqs. (29), (30), (36) and (37).

Figs. 7-9 illustrate the average diffusion and mass

transfer coefficients in liquid and vapor phases along

the column. Both diffusion coefficients and mass

transfer coefficients in vapor phase are much greater

than those in liquid phase, mainly due to the differ-

ences in viscosity and density of the phases. In NEQ

approach, the movement of molecule or a group of

molecules depends on the driving forces of all the

species present in the mixture, while in EQ approach

the driving forces are merely the forces between the

key component and other species. Moreover, the in-

terfacial area is reduced as the deformation of fluid

surface is hindered due to the increase of inner friction

in the fluid, leading a decrease in mass transfer rate.

Figure 7 Average diffusion and mass transfer coefficients in liquid phase along column

D

L

; k

L

Figure 8 Average mass transfer coefficients in vapor phase and vapor Reynolds number along column

Re

V

; k

V

Figure 9 Kinematic viscosity and average diffusion coefficients of vapor

V

; D

V

Chin. J. Chem. Eng., Vol. 18, No. 3, June 2010 370

In addition, the mass transfer coefficient in vapor

phase is sensitive to the vapor loading, so it changes

dramatically on the feed stage. The diffusion coeffi-

cients for both phases and mass transfer coefficients in

liquid phase increase from the top to the bottom of the

column. This can be explained as follows. On the one

hand, the selective semipermeable filter lets the more

soluble components cross the interface preferentially

and release their condensation heat freely, leading an

enrichment of n-butane in the vapor film adjacent to

the interface. On the other hand, liquid n-butane ab-

sorbs the energy released and vaporizes, which also

enriches n-butane in the vapor film adjacent to the

interface. Consequently, n-butane diffuses from the

interface to the bulk vapor phase and carries away

those components diffusing towards the interface. The

resistance for diffusion and mass transfer is hence re-

duced, increasing the mass transfer and diffusion co-

efficients and leading the movement of n-butane from

its low concentration liquid region to n-butane rich

vapor phase. For other components, the mechanism is

the same in the liquid phase. On stage 6, where fresh

entrainer is introduced into the column, the diffusion

and mass transfer coefficients in liquid phase take the

smallest values (Fig. 7), but the flux of n-butane from

liquid phase to vapor region has the highest value (Fig.

6) due to the largest driving forces for extraction. On

the contrary, the mass transfer coefficient in vapor

phase takes relative large value, though the diffusion

coefficient on this stage has the smallest value. This is

mainly due to the relative large kinematic viscosity,

which can be traced back to vapor density.

4 CONCLUSIONS

The limitations of Ficks law for describing dif-

fusion in nonideal multicomponent mixture are dis-

cussed. The Maxwell-Stefan diffusion theory is used

to describe transfer processes and associated influence

factors are investigated on the basis of EQ and NEQ

simulations. The major conclusions are as follows.

(1) The flux of n-butane, which has the smallest

solubility, is resulted from the movement of all the

species present in the C

4

mixture. Diffusion against

driving force is explained by NEQ approach.

(2) The Murphree efficiencies of components in

C

4

mixture differ from each other and vary greatly

from stage to stage. The unbounded and negative effi-

ciencies are the results of diffusional coupling.

(3) The differences in the results with NEQ and

EQ are from the difference in the Murphree efficiencies

of components, which can be traced back to the differ-

ence in diffusivities D

y,ij

of the binary pair vapor phase.

(4) The NEQ approach takes proper account of

diffusional coupling between the species transfer, which

helps understanding of what is going on in the extrac-

tive distillation column, and avoids the uncertainties

of tray efficiency or HETP concept. The effects of

design parameter and equipment geometry are in-

cluded. This is an important extension of the classical

analysis using equilibrium stages.

Thus for the simulation of extractive distillation

column to separate n-butane from 1-butene, cis-2-butene

and trans-2-butene mixture, the rigorous NEQ ap-

proach is more appropriate.

NOMENCLATURE

A

b

active bubbling area on the tray, m

2

A

t

cross-sectional area of the column, m

2

a

p

specific surface of packing, m

2

m

3

a

w

wetted area, m

2

c molar concentration, molm

3

D diffusions coefficient, m

2

s

1

Maxwell-Stefan diffusions coefficient, m

2

s

1

d diameter, m

d

h

hydraulic diameter, m

d

p

nominal packing size, m

F feed stream, kgh

1

g gravitational acceleration, ms

2

H enthalpy, kJ

h specific enthalpy, kJkmol

1

h

L

liquid height, m

h

p

height of the packed section, m

h

w

average weir length per liquid pass, m

K equilibrium coefficient

k mass transfer coefficients, ms

1

L mass stream of liquid, kgh

1

M mole mass, kgkmol

1

N

p

number of liquid flow passes

n

c

number of component

Q heat input to stage, Js

1

Q

L

, Q

V

volumetric flow rate for liquid and vapor, m

3

s

1

q heat transfer rate, Js

1

R gas constant, JK

1

mol

1

r reaction rate, kmols

1

T absolute temperature, K

t

L

average residence time for liquid, s

u inner energy, kJkmol

1

V vapor stream, kgh

1

v velocity, ms

1

x mole fraction in liquid , molmol

1

y mole fraction in vapor , molmol

1

z height of package, m

heat transfer coefficient, Wm

2

K

1

thermodynamic correction factor

film thickness, m

heat conductivity, Wm

1

K

1

dynamic viscosity, Pas

kinematic viscosity, m

2

s

1

density, kgm

3

surface tension, Nm

1

to

surface tension of liquid to the stage

fugacity, Pa

fugacity coefficient

E

driving force caused by electric potential

Superscripts

F feed

f film

I interface

L liquid phase

V vapor phase

Subscripts

i index of component

j index of stage

Chin. J. Chem. Eng., Vol. 18, No. 3, June 2010 371

k bulk of phase

L liquid

m component

n last component

p packing

s surface

t total

V vapor

w wetted area

REFERENCES

1 Billet, R., Industrielle Destillation, Chemie Verlag, Weinheim (1995).

(in German)

2 Dssel, R., Stichlmair, J., Separation of azeotropic mixtures by batch

distillation using an entrainer, Comput. Chem. Eng., 19, 113-118 (1995).

3 Castillo, F.J.L., Towler, G.P., Influence of mlulticomponent mass

transfer on homogeneous azeotropic distillation, Chem. Eng. Sci.,

53 (5), 963-976 (1999).

4 Langston, P., Hilal, N., Shingfield, S., Webb, S., Simulation and op-

timization of extractive distillation with water as solvent, Chem.

Eng. Process, 44, 345-351 (2005).

5 Jimnez, L., Wanhschafft, O.M., Julka, V., Analysis of residue curve

maps of reactive and extractive distillation units, Comput. Chem.

Eng., 25, 635-642 (2001).

6 Lei, Z.G., Zhou, R.Q., Duan, Z.T., Process improvement on sepa-

rating C

4

by extractive distillation, Chem. Eng. J., 85, 379-386 (2002).

7 Repke, J.U., Ausner, I., Paschke, S., Hoffmann, A., Wozny, G., On

the track to understanding three phases in one tower, Trans IChemE,

Part A, Chem. Eng. R. & D., 85 (A1), 50-58 (2007).

8 Thomsen, K., Iliuta, M.C., Rasmussen, P., Extended UNIQUAC

model for correlation and prediction of vapor-liquid-liquid-solid

equilibria in aqueous salt systems containing non-electrolytes. Part b:

alcohol (ethanol, propanols, butanols)-water-salt systems, Chem.

Eng. Sci., 59, 3631-3647 (2004).

9 Eckert, E., Vank, T., Some aspects of rate-based modeling and

simulation of three-phase distillation columns, Comput. Chem. Eng.,

25, 603-612 (2001).

10 Kewis, W.K., Seader, J.D., The rate-based approach for modeling

staged separations, Chem. Eng. Prog., 85, 41-49 (1989).

11 Higler, A., Chande, R., Taylor, R., Baur, R., Krishna, R., Nonequi-

librium modeling of three-phase distillation, Comput. Chem. Eng.,

28, 2021-2036 (2004).

12 Yang, X.J., Yin, X., Ouyang, P.K., Simulation of 1,3-butadiene

production process by dimethylfomamide extractive distillation,

Chin. J. Chem. Eng., 17 (1), 27-35 (2009).

13 Eckert, J.S., Trays and packings: Selecting the proper distillation

column packing, Chem. Eng. Prog., 66, 39-44 (1970).

14 Fullarton, D., Selektivitt und bertragungsleitstung, Chem. Eng.

Proc., 20, 255-263 (1986). (in German)

15 Higler, A., Krishna, R., Taylor, R., Nonequilibrium cell model for

multicomponent (reactive) separation processes, AIChE J., 45 (11),

2357-2370 (1999).

16 Kooijman, H.A., Taylor, R., Modeling mass transfer in multicom-

ponent distillation, Chem. Eng. J., 57, 177-188 (1995).

17 Krishna, R., Wesselingh, J.A., The Maxwell-Stefan approach to

mass transfer, Chem. Eng. Sci., 52 (6), 861-911 (1997).

18 Toor, H.L., Diffusion in three-component gas mixtures, AIChE J.,

3, 198-207 (1957).

19 Zimmerman, A., Joulia, X., Gourdon, C., Gorak, A., Maxwell-Stefan

approach in extractor design, Chem. Eng. J., 57, 229-236 (1995).

20 Lao, M., Taylor, R., Modeling mass transfer in three-phase distilla-

tion, Ind. Eng. Chem. Res., 33, 2637-2650 (1994).

21 Wesselingh, J.A., Non-equilibrium modeling of distillation, Trans

IChemE., 75 (A), 529-538 (1997).

22 Krishna, R., Standart, G.L., A multicomponent film model incorpo-

rating an exact matrix method of solution to the Maxwell-Stefan

equations, AIChE J., 22, 383-389 (1976).

23 Krishna, R., Martinez, H.F., Sreedhar, R., Standart, G.L., Murphree

point efficiencies in multicomponent mixtures, Trans. Inst. Chem.

Eng., 55, 178-186 (1977).

24 Krishna, R., Taylor, R., Multicomponent Mass Transfer, John Wiley

& Sons, New York (1993).

25 Walter, G.W., The two-film theory of gas absorption, Chemical

and Metallurgical Engineering, 29 (4), 146-148 (1923).

26 Krishnamurthy, R., Taylor, R., A nonequilibrium stage model of

multicomponent separation processes. Part I: model, AIChE J., 3,

449-461 (1985).

27 Baehr, H.D., Thermodynamik 11. Auflage, Springer-Verlag, Berlin

(2002). (in German)

28 Seader, J.D., The rate-based approach for modeling staged separa-

tions, Chem. Eng. Prog., 85, 41-49 (1989).

29 Springer, P.A.M., Krishna, R., Crossing of boundaries in ternary

azeotropic distillation: influence of interphase mass transfer, Int.

Comm. Heat & Mass Transfer, 28 (3), 347-356 (2001).

30 Springer, P.A.M., van der Molen, S., Krishna, R., The need for us-

ing rigorous rate-based models for simulations of ternary azeotropic

distillation, Comput. Chem. Eng., 26, 1265-1279 (2002).

31 Springer, P.A.M., van der Molen, S., Baur, R., Krishna, R., Ex-

perimental verification of the Maxwell-Stefan formulation in de-

scribing composition trajectories during azeotropic distillation,

Trans IChemE., 80 (A), 654-666 (2002).

32 Springer, P.A.M., Baur, R., Krishna, R., Composition trajectories

for heterogeneous azeotropic distillation in a bubble-cap tray col-

umn, Trans IChemE., 81(A), 413-426 (2003).

33 Mersmann, A., Thermische Verfahrenstechnik, Springer Verlag,

Berlin (1980). (in German)

34 Ojeda Nava, J.A., Krishna, R., Influence of unequal component ef-

ficiencies on trajectories during distillation of a homogeneous

azeotropic mixture, Chem. Eng. Process, 43, 305-316 (2004).

35 Oluji, ., Development of a complete simulation model for pre-

dicting the hydraulic and separation performance of distillation

columns equipped with structured packings, Chem. Biochem. Eng.,

11 (1), 31-46 (1997).

36 Stichlmair, J., Bravo, J.L., Fair, J.R., General model for prediction

of pressure drop and capacity of countercurrent gas: liquid packed

columns, Gas Sep. Purif., 3, 19-28 (1989).

37 Rehfeldt, S., Stichlmair, J., Measurement and calculation of multi-

component diffusion coefficients in liquids, Fluid Phase Equilibria,

256, 99-104 (2007).

38 Billet, R., Schultes, M., Prediction of mass transfer columns with dumped

and arranged packings, Trans IChemE., 77 (A), 498-504 (1999).

39 Baur, R., Taylor, R., Krishna, R., Copati, J.A., Influence of mass

transfer in distillation of mixtures with a distillation boundary,

Trans IChemE., 77 (A), 561-565 (1999).

40 Antonio Rocha, J., Bravo, J.L., Fair, J.R., Distillation columns con-

taining structured packings: a comprehensive model for their per-

formance (II) mass-transfer model, Ind. Eng. Chem. Res., 35 (5),

1660-1667 (1996).

41 Zeck, S., Einflu von thermophysikalischen soffdaten auf die

auslegung und den betrieb von destillationskolonnen, Chem. Ing.

Teck., 62 (9), 707-717 (1990).(in German)

42 Xu, Z.P., Afacan, A., Chuang, K.T., Predicting mass transfer in

packed columns containing structured packings, Trans IChemE., 78

(A), 91-98 (2000).

43 Aspen Technology, AspenONE

2006 Reference Manual, Aspen

Technology Inc., Cambridge, MA (2008).

44 Onda, K., Akeuchi, H.T., Okumoto, Y., Mass transfer coefficients

between gas and liquid phases in packed columns, J. Chem. Eng.

Jpn., 1 (1), 56-61 (1968).

45 Billet, R., Schultes, M., Predicting mass transfer in packed col-

umns, Chem. Eng. Technol., 16, 1-9 (1993).

46 Gorak, A., Simulation thermischer trennverfahren fluider

vielkomponentengemische, Prozesssimulation, Schuler, H., eds.,

Wiley-VCH, Germany, 349-408 (2002). (in German)

47 Lucia, A., Amale, A., Taylor, R., Distillation pinch points and more,

Comput. Chem. Eng., 32, 1342-1364 (2008).

48 Rao, D.P., Prem Kumar, R.S., Pandit, P., Das, T.C.T., Multicomponent

tray efficiencies accounting for entrainment, Chem. Eng. J., 57,

237-246 (1995).

49 Strigle, R. F. Jr., Rukovena, F., Packed distillation column design,

Chem. Eng. Progr., 75 (3), 86-91 (1979).

50 Strigle, R.F., Jr, Random Packing and Packed Towers, Design and

Applications, GPC, Houston (1988).

51 Vogelpohl, A., Murphree efficiencies in multicomponent systems,

Ins. Chem. Eng. Symp. Ser., 56, 25-31(1979).

52 Olano, S., Nagura, S., Kosuge. H., Asano, K., Mass transfer in bi-

nary and ternary distillation by a packed column with structured

packing, J. Chem. Eng. Jpn., 28, 750-757 (1995).

53 Gao, X.Q., Ma, Y.G., Zhu, C.Y., Yu, G.C., Towards the mechanism

of mass transfer of a single bubble, Chin. J. Chem. Eng., 14 (2),

158-163 (2006).

54 Yuan, X.G., Yu, G.C., Computational mass transfer method for chemi-

cal process simulation, Chin. J. Chem. Eng., 16 (4), 497-502 (2008).

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- RSC Advances - 2014-4-25257Dokument11 SeitenRSC Advances - 2014-4-25257Clausius ClapeyronNoch keine Bewertungen

- Is Iso 1066 1975Dokument9 SeitenIs Iso 1066 1975Clausius ClapeyronNoch keine Bewertungen

- Selecting Thermodynamic Models For Process Simulation of Organic VLE and LLE SystemsDokument5 SeitenSelecting Thermodynamic Models For Process Simulation of Organic VLE and LLE SystemsoscarmaumarNoch keine Bewertungen

- 2 SO2-Air Cyanide OxydationDokument8 Seiten2 SO2-Air Cyanide OxydationbazanvlNoch keine Bewertungen

- Process Equipment Cost EstimationDokument80 SeitenProcess Equipment Cost EstimationKSSri100% (3)

- 2 SO2-Air Cyanide OxydationDokument8 Seiten2 SO2-Air Cyanide OxydationbazanvlNoch keine Bewertungen

- Conversion IsopropanolDokument8 SeitenConversion IsopropanolClausius ClapeyronNoch keine Bewertungen

- Comparison MS CND Cyanide DestructionDokument7 SeitenComparison MS CND Cyanide DestructionClausius ClapeyronNoch keine Bewertungen

- Submitted To PublisherDokument13 SeitenSubmitted To PublisherClausius ClapeyronNoch keine Bewertungen

- Selecting Thermodynamic Models For Process Simulation of Organic VLE and LLE SystemsDokument5 SeitenSelecting Thermodynamic Models For Process Simulation of Organic VLE and LLE SystemsoscarmaumarNoch keine Bewertungen

- Process Control - Marlin - 2nd Edition, Cap 1 and 2Dokument0 SeitenProcess Control - Marlin - 2nd Edition, Cap 1 and 2Clausius ClapeyronNoch keine Bewertungen

- AllAboutColor EbookDokument157 SeitenAllAboutColor EbookCésar Zamora0% (1)

- Packed Column ThreeDokument12 SeitenPacked Column ThreeClausius ClapeyronNoch keine Bewertungen

- Distillation Monitoring and Control Using LabVIEW and SIMULINK ToolsDokument4 SeitenDistillation Monitoring and Control Using LabVIEW and SIMULINK ToolsClausius ClapeyronNoch keine Bewertungen

- Selecting Thermodynamic Models For Process Simulation of Organic VLE and LLE SystemsDokument5 SeitenSelecting Thermodynamic Models For Process Simulation of Organic VLE and LLE SystemsoscarmaumarNoch keine Bewertungen

- The Basics of Hacking and Pen TestingDokument30 SeitenThe Basics of Hacking and Pen TestingAnonNoch keine Bewertungen

- Sprite Graphics For The Commodore 64Dokument200 SeitenSprite Graphics For The Commodore 64scottmac67Noch keine Bewertungen

- User Manual: Swift S3Dokument97 SeitenUser Manual: Swift S3smnguyenNoch keine Bewertungen

- 0418 w08 QP 1Dokument17 Seiten0418 w08 QP 1pmvarshaNoch keine Bewertungen

- Introduction to Corporate Communication ObjectivesDokument26 SeitenIntroduction to Corporate Communication ObjectivesKali MuthuNoch keine Bewertungen

- Dasha TransitDokument43 SeitenDasha Transitvishwanath100% (2)

- Failure Reporting, Analysis, and Corrective Action SystemDokument46 SeitenFailure Reporting, Analysis, and Corrective Action Systemjwpaprk1100% (1)

- Process Validation Statistical ConfidenceDokument31 SeitenProcess Validation Statistical ConfidenceSally PujaNoch keine Bewertungen

- Laser Plasma Accelerators PDFDokument12 SeitenLaser Plasma Accelerators PDFAjit UpadhyayNoch keine Bewertungen

- حقيبة تعليمية لمادة التحليلات الهندسية والعدديةDokument28 Seitenحقيبة تعليمية لمادة التحليلات الهندسية والعدديةAnjam RasulNoch keine Bewertungen

- Embedded Systems - RTOSDokument23 SeitenEmbedded Systems - RTOSCheril MehtaNoch keine Bewertungen

- Configuring Nagios On Client For OSSIMDokument10 SeitenConfiguring Nagios On Client For OSSIMMaixender NganareNoch keine Bewertungen

- Laxmi Thakur (17BIT0384) Anamika Guha (18BIT0483) : Submitted byDokument6 SeitenLaxmi Thakur (17BIT0384) Anamika Guha (18BIT0483) : Submitted byLaxmi ThakurNoch keine Bewertungen

- Platon Si Academia Veche de ZellerDokument680 SeitenPlaton Si Academia Veche de ZellerDan BrizaNoch keine Bewertungen

- Watershed Management A Case Study of Madgyal Village IJERTV2IS70558Dokument5 SeitenWatershed Management A Case Study of Madgyal Village IJERTV2IS70558SharadNoch keine Bewertungen

- Key Note Units 3-4Dokument4 SeitenKey Note Units 3-4Javier BahenaNoch keine Bewertungen

- Rhodium Catalyzed Hydroformylation - CH 07Dokument14 SeitenRhodium Catalyzed Hydroformylation - CH 07maildesantiagoNoch keine Bewertungen

- Users GuideDokument34 SeitenUsers GuideZaratustra NietzcheNoch keine Bewertungen

- Shaft design exercisesDokument8 SeitenShaft design exercisesIvanRosellAgustíNoch keine Bewertungen

- Lenovo IdeaPad U350 UserGuide V1.0Dokument138 SeitenLenovo IdeaPad U350 UserGuide V1.0Marc BengtssonNoch keine Bewertungen

- Light Body ActivationsDokument2 SeitenLight Body ActivationsNaresh Muttavarapu100% (4)

- Saline Water Intrusion in Coastal Aquifers: A Case Study From BangladeshDokument6 SeitenSaline Water Intrusion in Coastal Aquifers: A Case Study From BangladeshIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNoch keine Bewertungen

- Charny - Mathematical Models of Bioheat TransferDokument137 SeitenCharny - Mathematical Models of Bioheat TransferMadalena PanNoch keine Bewertungen

- HAU Theology 103 Group Goal Commitment ReportDokument6 SeitenHAU Theology 103 Group Goal Commitment ReportEM SagunNoch keine Bewertungen

- Hum-Axis of Resistance A Study of Despair, Melancholy and Dis-Heartedness in Shahnaz Bashir's Novel The Half MotherDokument8 SeitenHum-Axis of Resistance A Study of Despair, Melancholy and Dis-Heartedness in Shahnaz Bashir's Novel The Half MotherImpact JournalsNoch keine Bewertungen

- Table of Specification ENGLISHDokument2 SeitenTable of Specification ENGLISHDonn Abel Aguilar IsturisNoch keine Bewertungen

- Advance Control Systems LabDokument2 SeitenAdvance Control Systems Labpadmajasiva100% (1)

- Fluorescent sensors for detection of heavy metalsDokument36 SeitenFluorescent sensors for detection of heavy metalskawtherahmedNoch keine Bewertungen

- Nektar Impact LX25 (En)Dokument32 SeitenNektar Impact LX25 (En)Camila Gonzalez PiatNoch keine Bewertungen

- Es E100091 Pi PDFDokument1 SeiteEs E100091 Pi PDFCarlos Humbeto Portillo MendezNoch keine Bewertungen