Beruflich Dokumente

Kultur Dokumente

Structure of RCC Beam Design Task 01

Hochgeladen von

George GeorgianOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Structure of RCC Beam Design Task 01

Hochgeladen von

George GeorgianCopyright:

Verfügbare Formate

REFERENCE

Analysis

Length L 4.2

Width B 0.225

Dead load g 13.62 kN/m

Imposed load i 12 kN/m

Ultimate Design Load w 38.27 kN/m

Single span fixed end condition

BM @ fixed end M

A

56.25 kNm

BM @ mid span M

C

28.13

SF V 80.36 kN

Design Data

Material Properties

Concrete grade f

cu

20 N/mm

2

Characteristic steel strength f

y

460 N/mm

2

Youngs modulus of concrete E

C

26000 N/mm

2

Youngs modulus of steel E

S

200000 N/mm

2

Density of concrete p

ct

24 kN/m

3

Durabilty Requirements

Exposure condition - Severe

Beam

Design of Reinforcement

Sizes

Top r/f = 12 mm

Bottom r/f = 16 mm

Links = 6 mm

Cover = 25 mm

Width of the beam b

t

= 225 mm

overall depth of the beam h

b

= 350 mm

Design of Top Reinforcement

Effective depth d = 311 mm d = 311 mm

Design bending moment M = 56.25 kNm

Cl 3.4.4.4 K = M/[bd

2

f

cu

]

BS 8110; 1985 = 0.103 k = 0.103

Since K < 0.156 no compresiion r/f required

Z = [0.5+(0.25-K/0.9)

0.5

] * d

= 0.87 d

Take Z = 0.83d Z = 270.57 mm Z = 270.57 mm

Required area of steel to carry ultimate BM

A

s req,M

= M/[0.95*f

y

*Z]

= 476 mm

2

/m

Area of steel provided A

s prov

559 mm

2

/m

Provide T 16 2 Nos T 16 2 nos

and T 10 2 Nos T 10 1 nos

Design of Bottom Reinforcement

CALCULATION OUTPUT

Effective depth d = 311 mm d = 311 mm

Design bending moment M = 28.13 kNm

K = M/[bd

2

f

cu

]

= 0.052 k = 0.052

Since K < 0.156 no compresiion r/f required

Z = [0.5+(0.25-K/0.9)

0.5

] * d

= 0.94 d

Take Z = 0.92d Z = 292.34 mm Z = 292.34 mm

Required area of steel to carry ultimate BM

A

s req,M

= M/[0.95*f

y

*Z]

= 220 mm

2

/m

Area of steel provided A

s prov

270 mm

2

/m

Provide T 12 1 Nos T 12 2 nos

and T 10 2 Nos T 10 0 nos

Ckeck for Shear Resistance

Ultimate shear force at support V

u

= 80.36 kN

Shear stress = V

u

/[b

v

*d]

= 1.15 N/mm

2

= 1.15 N/mm

2

Maximum shear = 3.6 N/mm

2

100 A

s

/[b

v

*d] = 0.80

400/d = 1.29

c

= 0.62

c

+ 0.4 = 1.02

Since

c

+0.4 < < max shear, design links to be provided

Link size = 6 mm

Shear link spacing S

v

< 113.73

Max spacing < 0.75d < 233.25

Provide R6 @ 150 mm c/c upto 1.5 m from both ends

Middle area spacing shall be 200 mm c/c

Deflection Checking

SS condition assumed to check deflection

Table 3.10 BS

8110; 1985

Basic Span/Effective depth ratio = 20

Service stress in the tension r/f f

s

= 5*f

y

*A

s req

/(8*A

s prov

*

b

)

= 245 N/mm

2

Modification factor for tension r/f MF = 0.55+ [477-f

s

]/[120*(0.9+M/bd

2

)]

= 1.1 ( < 2.0 )

Hence allowable Span/Effective depth ratio = MF * Basic Span/Eff. Depth

= 22

Actual Span/Effective Depth ratio = 6.225/382

= 14.23

Since [Span/Eff.Depth]

actual

< [Span/Eff.Depth]

allowable

deflection is within the limit Deflection is within the limt

REFERENCE

Analysis

Length L 6

Width B 0.225

Dead load [slab+finishes+beam] g 15.29 kN/m

Imposed load i 12 kN/m

Ultimate Design Load w 40.61 kN/m

Single span fixed end condition

BM @ fixed end M

A

121.82 kNm

BM @ mid span M

C

60.91

SF V 121.82 kN

Design Data

Material Properties

Concrete grade f

cu

25 N/mm

2

Characteristic steel strength f

y

460 N/mm

2

Youngs modulus of concrete E

C

26000 N/mm

2

Youngs modulus of steel E

S

200000 N/mm

2

Density of concrete p

ct

24 kN/m

3

Durabilty Requirements

Exposure condition - Severe

Beam

Design of Reinforcement

Sizes

Top r/f = 20 mm

Bottom r/f = 16 mm

Links = 10 mm

Cover = 25 mm

Width of the beam b

t

= 225 mm

overall depth of the beam h

b

= 425 mm

Design of Top Reinforcement

Effective depth d = 382 mm d = 382 mm

Design bending moment M = 103.55 kNm

Cl 3.4.4.4 K = M/[bd

2

f

cu

]

BS 8110; 1985 = 0.126 k = 0.126

Since K < 0.156 no compresiion r/f required

Z = [0.5+(0.25-K/0.9)

0.5

] * d

= 0.83 d

Take Z = 0.81d Z = 317.06 mm Z = 317.06 mm

Required area of steel to carry ultimate BM

A

s req,M

= M/[0.95*f

y

*Z]

= 747 mm

2

/m

Area of steel provided A

s prov

717 mm

2

/m

Provide T 20 1 Nos T 20 2 nos

and T 16 2 Nos T 16 1 nos

CALCULATION OUTPUT

Design of Bottom Reinforcement

Effective depth d = 382 mm d = 382 mm

Design bending moment M = 79.18 kNm

K = M/[bd

2

f

cu

]

= 0.096 k = 0.096

Since K < 0.156 no compresiion r/f required

Z = [0.5+(0.25-K/0.9)

0.5

] * d

= 0.88 d

Take Z = 0.89d Z = 336.16 mm Z = 336.16 mm

Required area of steel to carry ultimate BM

A

s req,M

= M/[0.95*f

y

*Z]

= 539 mm

2

/m

Area of steel provided A

s prov

629 mm

2

/m

Provide T 16 0 Nos T 16 0 nos

and T 20 2 Nos T 20 2 nos

Ckeck for Shear Resistance

Ultimate shear force at support V

u

= 121.82 kN

Shear stress = V

u

/[b

v

*d]

= 1.42 N/mm

2

= 1.42 N/mm

2

Maximum shear = 4.0 N/mm

2

100 A

s

/[b

v

*d] = 0.83

400/d = 1.05

c

= 0.60

c

+ 0.4 = 1.00

Since

c

+0.4 < < max shear, design links to be provided

Link size = 10 mm

Shear link spacing S

v

< 202.83

Max spacing < 0.75d < 286.5

Provide R10 @ 150 mm c/c upto 1.5 m from both ends

Middle area spacing shall be 200 mm c/c

Deflection Checking

SS condition assumed to check deflection

Table 3.10 BS

8110; 1985

Basic Span/Effective depth ratio = 20

Service stress in the tension r/f f

s

= 5*f

y

*A

s req

/(8*A

s prov

*

b

)

= 300 N/mm

2

Modification factor for tension r/f MF = 0.55+ [477-f

s

]/[120*(0.9+M/bd

2

)]

= 0.91 ( < 2.0 )

Hence allowable Span/Effective depth ratio = MF * Basic Span/Eff. Depth

= 18.2

Actual Span/Effective Depth ratio = 6.225/382

= 16.30

Since [Span/Eff.Depth]

actual

< [Span/Eff.Depth]

allowable

deflection is within the limit Deflection is within the limt

REFERENCE

Analysis SLAB THICK 150 MM

Length L 3

Width B 0.225

Dead load [slab+finishes] g 14.88 kN/m

Imposed load i 12 kN/m

Ultimate Design Load w 40.03 kN/m

Total Design Load F 120.10 kN

Single span fixed end condition

BM @ C M

C

39.63 kNm

BM @ B M

B

32.43

SF @ A V 54.04 kN

Design Data

Material Properties

Concrete grade f

cu

25 N/mm

2

Characteristic steel strength f

y

460 N/mm

2

Youngs modulus of concrete E

C

26000 N/mm

2

Youngs modulus of steel E

S

200000 N/mm

2

Density of concrete p

ct

24 kN/m

3

Durabilty Requirements

Exposure condition - Severe

Beam

Design of Reinforcement

Sizes

Top r/f = 12 mm

Bottom r/f = 12 mm

Links = 6 mm

Cover = 25 mm

Width of the beam b

t

= 225 mm

overall depth of the beam h

b

= 350 mm

Design of Top Reinforcement @ C

Effective depth d = 313 mm d = 313 mm

Design bending moment M = 39.63 kNm

Cl 3.4.4.4 K = M/[bd

2

f

cu

]

BS 8110; 1985 = 0.072 k = 0.072

Since K < 0.156 no compresiion r/f required

Z = [0.5+(0.25-K/0.9)

0.5

] * d

= 0.91 d

Take Z = 0.90d Z = 284.83 mm Z = 284.83 mm

Required area of steel to carry ultimate BM

A

s req,M

= M/[0.95*f

y

*Z]

= 318 mm

2

/m

Area of steel provided A

s prov

339 mm

2

/m

Provide T 12 3 Nos T 12 2 nos

CALCULATION OUTPUT

and T 16 0 Nos T 16 1 nos

Design of Bottom Reinforcement @ B

Effective depth d = 313 mm d = 313 mm

Design bending moment M = 32.43 kNm

K = M/[bd

2

f

cu

]

= 0.059 k = 0.059

Since K < 0.156 no compresiion r/f required

Z = [0.5+(0.25-K/0.9)

0.5

] * d

= 0.93 d

Take Z = 0.92d Z = 291.09 mm Z = 291.09 mm

Required area of steel to carry ultimate BM

A

s req,M

= M/[0.95*f

y

*Z]

= 255 mm

2

/m

Area of steel provided A

s prov

339 mm

2

/m

Provide T 12 3 Nos T 12 3 nos

and T 0 Nos T 0 0 nos

Ckeck for Shear Resistance

Ultimate shear force at support V

u

= 54.04 kN

Shear stress = V

u

/[b

v

*d]

= 0.77 N/mm

2

= 0.77 N/mm

2

Maximum shear = 4.0 N/mm

2

100 A

s

/[b

v

*d] = 0.48

400/d = 1.28

c

= 0.53

c

+ 0.4 = 0.93

Since

c

+0.4 > > 0.5 c max shear, minimum links required

Link size = 6 mm

Shear link spacing S

v

< 149.29

Max spacing < 0.75d < 234.75

Provide R6 @ 150 mm c/c upto 1.5 m throughout

Deflection Checking

SS condition assumed to check deflection

Table 3.10 BS

8110; 1985

Basic Span/Effective depth ratio = 20

Service stress in the tension r/f f

s

= 5*f

y

*A

s req

/(8*A

s prov

*

b

)

= 270 N/mm

2

Modification factor for tension r/f MF = 0.55+ [477-f

s

]/[120*(0.9+M/bd

2

)]

= 1.28 ( < 2.0 )

Hence allowable Span/Effective depth ratio = MF * Basic Span/Eff. Depth

= 25.6

Actual Span/Effective Depth ratio = 6.225/382

= 10.30

Since [Span/Eff.Depth]

actual

< [Span/Eff.Depth]

allowable

deflection is within the limit Deflection is within the limt

REFERENCE

Analysis SLAB THICK 150 MM

Length L 3

Width B 0.225

Dead load [slab+finishes] g 14.88 kN/m

Imposed load i 12 kN/m

Ultimate Design Load w 40.03 kN/m

Total Design Load F 120.10 kN

Single span fixed end condition

BM @ E M

E

28.82 kNm

BM @ D M

D

25.22 kNm

SF @ C V 66.05 kN

Design Data

Material Properties

Concrete grade f

cu

25 N/mm

2

Characteristic steel strength f

y

460 N/mm

2

Youngs modulus of concrete E

C

26000 N/mm

2

Youngs modulus of steel E

S

200000 N/mm

2

Density of concrete p

ct

24 kN/m

3

Durabilty Requirements

Exposure condition - Severe

Beam

Design of Reinforcement

Sizes

Top r/f = 12 mm

Bottom r/f = 12 mm

Links = 6 mm

Cover = 25 mm

Width of the beam b

t

= 225 mm

overall depth of the beam h

b

= 350 mm

Design of Top Reinforcement @ C

Effective depth d = 313 mm d = 313 mm

Design bending moment M = 28.82 kNm

Cl 3.4.4.4 K = M/[bd

2

f

cu

]

BS 8110; 1985 = 0.052 k = 0.052

Since K < 0.156 no compresiion r/f required

Z = [0.5+(0.25-K/0.9)

0.5

] * d

= 0.94 d

Take Z = 0.93d Z = 294.22 mm Z = 294.22 mm

Required area of steel to carry ultimate BM

A

s req,M

= M/[0.95*f

y

*Z]

= 224 mm

2

/m

Area of steel provided A

s prov

339 mm

2

/m

Provide T 12 3 Nos T 12 2 nos

CALCULATION OUTPUT

and T 16 0 Nos T 16 1 nos

Design of Bottom Reinforcement @ B

Effective depth d = 313 mm d = 313 mm

Design bending moment M = 25.22 kNm

K = M/[bd

2

f

cu

]

= 0.046 k = 0.046

Since K < 0.156 no compresiion r/f required

Z = [0.5+(0.25-K/0.9)

0.5

] * d

= 0.95 d

Take Z = 0.94d Z = 297.35 mm Z = 297.35 mm

Required area of steel to carry ultimate BM

A

s req,M

= M/[0.95*f

y

*Z]

= 194 mm

2

/m

Area of steel provided A

s prov

226 mm

2

/m

Provide T 12 2 Nos T 12 2 nos

and T 0 Nos T 0 0 nos

Ckeck for Shear Resistance

Ultimate shear force at support V

u

= 66.05 kN

Shear stress = V

u

/[b

v

*d]

= 0.94 N/mm

2

= 0.94 N/mm

2

Maximum shear = 4.0 N/mm

2

100 A

s

/[b

v

*d] = 0.48

400/d = 1.28

c

= 0.53

c

+ 0.4 = 0.93

Since

c

+0.4 < < max shear, design links to be provided

Link size = 6 mm

Shear link spacing S

v

< 144.91

Max spacing < 0.75d < 234.75

Provide R6 @ 125 mm c/c upto 1.5 m from support

Deflection Checking

SS condition assumed to check deflection

Table 3.10 BS

8110; 1985

Basic Span/Effective depth ratio = 20

Service stress in the tension r/f f

s

= 5*f

y

*A

s req

/(8*A

s prov

*

b

)

= 190 N/mm

2

Modification factor for tension r/f MF = 0.55+ [477-f

s

]/[120*(0.9+M/bd

2

)]

= 1.72 ( < 2.0 )

Hence allowable Span/Effective depth ratio = MF * Basic Span/Eff. Depth

= 34.4

Actual Span/Effective Depth ratio = 6.225/382

= 10.30

Since [Span/Eff.Depth]

actual

< [Span/Eff.Depth]

allowable

deflection is within the limit Deflection is within the limt

REFERENCE

Analysis SLAB THICK 125 MM

Length L 3

Width B 1

Dead load g 4.6 kN/m

Imposed load i 4 kN/m

Ultimate Design Load w 12.84 kN/m

Single span fixed end condition

BM @ fixed end M

A

10.60 kNm

BM @ mid span M

C

8.70 kNm

SF V 19.26 kN

Design Data

Material Properties

Concrete grade f

cu

25 N/mm

2

Characteristic steel strength f

y

460 N/mm

2

Youngs modulus of concrete E

C

26000 N/mm

2

Youngs modulus of steel E

S

200000 N/mm

2

Density of concrete p

ct

24 kN/m

3

Durabilty Requirements

Exposure condition - Severe

Beam

Design of Reinforcement

Sizes

Top r/f = 0 mm

Bottom r/f = 10 mm

Links = mm

Cover = 25 mm

Width of the strip b

t

= 1000 mm

overall depth of the slab h

b

= 125 mm

Design of Top Reinforcement

Effective depth d = 95 mm d = 95 mm

Design bending moment M = 10.60 kNm

Cl 3.4.4.4 K = M/[bd

2

f

cu

]

BS 8110; 1985 = 0.047 k = 0.047

Since K < 0.156 no compresiion r/f required

Z = [0.5+(0.25-K/0.9)

0.5

] * d

= 0.94 d

Take Z = 0.83d Z = 89.3 mm Z = 89.3 mm

Required area of steel to carry ultimate BM

A

s req,M

= M/[0.95*f

y

*Z]

= 272 mm

2

/m

Area of steel provided A

s prov

314 mm

2

/m

Provide T 10 4 Nos T 10 5 nos

and T 10 0 Nos T 10

T10 @ 250 mm spacing

CALCULATION OUTPUT

Design of Bottom Reinforcement

Effective depth d = 95 mm d = 95 mm

Design bending moment M = 8.70 kNm

K = M/[bd

2

f

cu

]

= 0.039 k = 0.039

Since K < 0.156 no compresiion r/f required

Z = [0.5+(0.25-K/0.9)

0.5

] * d

= 0.95 d

Take Z = 0.92d Z = 90.25 mm Z = 90.25 mm

Required area of steel to carry ultimate BM

A

s req,M

= M/[0.95*f

y

*Z]

= 221 mm

2

/m

Area of steel provided A

s prov

314 mm

2

/m

Provide T 10 4 Nos T 10 5 nos

T10 @ 250 mm spacing

Ckeck for Shear Resistance

Ultimate shear force at support V

u

= 19.26 kN

Shear stress = V

u

/[b

v

*d]

= 0.2 N/mm

2

= 0.2 N/mm

2

Maximum shear = 4.0 N/mm

2

100 A

s

/[b

v

*d] = 0.33

400/d = 4.21

c

= 0.63

c

+ 0.4 = 1.03

Since < 0.5 c

Deflection Checking

Continous condition assumed to check deflection

Table 3.10 BS

8110; 1985

Basic Span/Effective depth ratio = 27

Service stress in the tension r/f f

s

= 5*f

y

*A

s req

/(8*A

s prov

*

b

)

= 202 N/mm

2

Modification factor for tension r/f MF = 0.55+ [477-f

s

]/[120*(0.9+M/bd

2

)]

= 1.78 ( < 2.0 )

Hence allowable Span/Effective depth ratio = MF * Basic Span/Eff. Depth

= 48.06

Actual Span/Effective Depth ratio = 3000/85

= 31.58

Since [Span/Eff.Depth]

actual

< [Span/Eff.Depth]

allowable

deflection is within the limit Deflection is within the limt

REFERENCE

Analysis SLAB THICK 125 MM

Length L 6

Width B 1

Dead load g 4.6 kN/m

Imposed load i 4 kN/m

Ultimate Design Load w 12.84 kN/m

Single span fixed end condition

BM @ fixed end M

A

3.46 kNm

BM @ mid span M

C

4.76 kNm

SF V 38.52 kN

Design Data

Material Properties

Concrete grade f

cu

25 N/mm

2

Characteristic steel strength f

y

460 N/mm

2

Youngs modulus of concrete E

C

26000 N/mm

2

Youngs modulus of steel E

S

200000 N/mm

2

Density of concrete p

ct

24 kN/m

3

Durabilty Requirements

Exposure condition - Severe

Beam

Design of Reinforcement

Sizes

Top r/f = 0 mm

Bottom r/f = 10 mm

Links = 10 mm

Cover = 25 mm

Width of the strip b

t

= 1000 mm

overall depth of the slab h

b

= 125 mm

Design of Top Reinforcement

Effective depth d = 85 mm d = 85 mm

Design bending moment M = 3.46 kNm

Cl 3.4.4.4 K = M/[bd

2

f

cu

]

BS 8110; 1985 = 0.019 k = 0.019

Since K < 0.156 no compresiion r/f required

Z = [0.5+(0.25-K/0.9)

0.5

] * d

= 0.98 d

Take Z = 0.83d Z = 80.75 mm Z = 80.75 mm

Required area of steel to carry ultimate BM

A

s req,M

= M/[0.95*f

y

*Z]

= 98 mm

2

/m

Area of steel provided A

s prov

314 mm

2

/m

Provide T 10 4 Nos T 10 2 nos

CALCULATION OUTPUT

Design of Bottom Reinforcement

Effective depth d = 85 mm d = 85 mm

Design bending moment M = 4.76 kNm

K = M/[bd

2

f

cu

]

= 0.026 k = 0.026

Since K < 0.156 no compresiion r/f required

Z = [0.5+(0.25-K/0.9)

0.5

] * d

= 0.97 d

Take Z = 0.92d Z = 82.45 mm Z = 82.45 mm

Required area of steel to carry ultimate BM

A

s req,M

= M/[0.95*f

y

*Z]

= 132 mm

2

/m

Area of steel provided A

s prov

314 mm

2

/m

Provide T 10 4 Nos T 10 5 nos

T10 @ 250 mm spacing

Ckeck for Shear Resistance

Ultimate shear force at support V

u

= 38.52 kN

Shear stress = V

u

/[b

v

*d]

= 0.45 N/mm

2

= 0.45 N/mm

2

Maximum shear = 4.0 N/mm

2

100 A

s

/[b

v

*d] = 0.37

400/d = 4.71

c

= 0.67

c

+ 0.4 = 1.07

Since < 0.5 c

Deflection Checking [Not necessary in long span direction]

SS condition assumed to check deflection

Table 3.10 BS

8110; 1985

Basic Span/Effective depth ratio = 20

Service stress in the tension r/f f

s

= 5*f

y

*A

s req

/(8*A

s prov

*

b

)

= 121 N/mm

2

Modification factor for tension r/f MF = 0.55+ [477-f

s

]/[120*(0.9+M/bd

2

)]

= 2.45 ( < 2.0 )

Hence allowable Span/Effective depth ratio = MF * Basic Span/Eff. Depth

= 49

Actual Span/Effective Depth ratio = 3000/120

= 35.29

Since [Span/Eff.Depth]

actual

< [Span/Eff.Depth]

allowable

deflection is within the limit Deflection is within the limt

REFERENCE

Analysis SLAB THICK 150 MM

Length L 7

Width B 0.225

Dead load [slab+finishes] g 15.42 kN/m

Imposed load i 12 kN/m

Ultimate Design Load w 40.79 kN/m

Single span fixed end condition

BM @ fixed end M

A

166.55 kNm

BM @ mid span M

C

83.28

SF V 142.76 kN

Design Data

Material Properties

Concrete grade f

cu

25 N/mm

2

Characteristic steel strength f

y

460 N/mm

2

Youngs modulus of concrete E

C

26000 N/mm

2

Youngs modulus of steel E

S

200000 N/mm

2

Density of concrete p

ct

24 kN/m

3

Durabilty Requirements

Exposure condition - Severe

Beam

Design of Reinforcement

Sizes

Top r/f = 20 mm

Bottom r/f = 16 mm

Links = 10 mm

Cover = 25 mm

Width of the beam b

t

= 225 mm

overall depth of the beam h

b

= 475 mm

Design of Top Reinforcement

Effective depth d = 432 mm d = 432 mm

Design bending moment M = 149.90 kNm

Cl 3.4.4.4 K = M/[bd

2

f

cu

]

BS 8110; 1985 = 0.143 k = 0.143

Since K < 0.156 no compresiion r/f required

Z = [0.5+(0.25-K/0.9)

0.5

] * d

= 0.8 d

Take Z = 0.81d Z = 345.6 mm Z = 345.6 mm

Required area of steel to carry ultimate BM

A

s req,M

= M/[0.95*f

y

*Z]

= 993 mm

2

/m

Area of steel provided A

s prov

943 mm

2

/m

Provide T 20 3 Nos T 20 2 nos

and T 16 0 Nos T 16 2 nos

CALCULATION OUTPUT

Design of Bottom Reinforcement

Effective depth d = 432 mm d = 432 mm

Design bending moment M = 104.09 kNm

K = M/[bd

2

f

cu

]

= 0.099 k = 0.099

Since K < 0.156 no compresiion r/f required

Z = [0.5+(0.25-K/0.9)

0.5

] * d

= 0.87 d

Take Z = 0.89d Z = 375.84 mm Z = 375.84 mm

Required area of steel to carry ultimate BM

A

s req,M

= M/[0.95*f

y

*Z]

= 634 mm

2

/m

Area of steel provided A

s prov

742 mm

2

/m

Provide T 12 1 Nos T 12 0 nos

and T 20 2 Nos T 20 2 nos

Ckeck for Shear Resistance

Ultimate shear force at support V

u

= 142.76 kN

Shear stress = V

u

/[b

v

*d]

= 1.47 N/mm

2

= 1.47 N/mm

2

Maximum shear = 4.0 N/mm

2

100 A

s

/[b

v

*d] = 0.97

400/d = 0.93

c

= 0.61

c

+ 0.4 = 1.01

Since

c

+0.4 < < max shear, design links to be provided

Link size = 10 mm

Shear link spacing S

v

< 193.73

Max spacing < 0.75d < 324

Provide R10 @ 150 mm c/c upto 1.5 m from both ends

Middle area spacing shall be 200 mm c/c

Deflection Checking

SS condition assumed to check deflection

Table 3.10 BS

8110; 1985

Basic Span/Effective depth ratio = 20

Service stress in the tension r/f f

s

= 5*f

y

*A

s req

/(8*A

s prov

*

b

)

= 303 N/mm

2

Modification factor for tension r/f MF = 0.55+ [477-f

s

]/[120*(0.9+M/bd

2

)]

= 0.87 ( < 2.0 )

Hence allowable Span/Effective depth ratio = MF * Basic Span/Eff. Depth

= 17.4

Actual Span/Effective Depth ratio = 6.225/382

= 16.72

Since [Span/Eff.Depth]

actual

< [Span/Eff.Depth]

allowable

deflection is within the limit Deflection is within the limt

REFERENCE

Analysis SLAB THICK 150 MM

Length L 3

Width B 0.225

Dead load [slab+finishes] g 17.18 kN/m

Imposed load i 14 kN/m

Ultimate Design Load w 46.45 kN/m

Total Design Load F 139.36 kN

Single span fixed end condition

BM @ C M

C

45.99 kNm

BM @ B M

B

37.63

SF @ A V 62.71 kN

Design Data

Material Properties

Concrete grade f

cu

25 N/mm

2

Characteristic steel strength f

y

460 N/mm

2

Youngs modulus of concrete E

C

26000 N/mm

2

Youngs modulus of steel E

S

200000 N/mm

2

Density of concrete p

ct

24 kN/m

3

Durabilty Requirements

Exposure condition - Severe

Beam

Design of Reinforcement

Sizes

Top r/f = 12 mm

Bottom r/f = 12 mm

Links = 6 mm

Cover = 25 mm

Width of the beam b

t

= 225 mm

overall depth of the beam h

b

= 350 mm

Design of Top Reinforcement @ C

Effective depth d = 313 mm d = 313 mm

Design bending moment M = 45.99 kNm

Cl 3.4.4.4 K = M/[bd

2

f

cu

]

BS 8110; 1985 = 0.083 k = 0.083

Since K < 0.156 no compresiion r/f required

Z = [0.5+(0.25-K/0.9)

0.5

] * d

= 0.9 d

Take Z = 0.90d Z = 281.7 mm Z = 281.7 mm

Required area of steel to carry ultimate BM

A

s req,M

= M/[0.95*f

y

*Z]

= 374 mm

2

/m

Area of steel provided A

s prov

402 mm

2

/m

Provide T 12 0 Nos T 12

CALCULATION OUTPUT

and T 16 2 Nos T 16 2 nos

Design of Bottom Reinforcement @ B

Effective depth d = 313 mm d = 313 mm

Design bending moment M = 37.63 kNm

K = M/[bd

2

f

cu

]

= 0.068 k = 0.068

Since K < 0.156 no compresiion r/f required

Z = [0.5+(0.25-K/0.9)

0.5

] * d

= 0.92 d

Take Z = 0.92d Z = 287.96 mm Z = 287.96 mm

Required area of steel to carry ultimate BM

A

s req,M

= M/[0.95*f

y

*Z]

= 299 mm

2

/m

Area of steel provided A

s prov

339 mm

2

/m

Provide T 12 3 Nos T 12 3 nos

and T 0 Nos T 0 0 nos

Ckeck for Shear Resistance

Ultimate shear force at support V

u

= 62.71 kN

Shear stress = V

u

/[b

v

*d]

= 0.89 N/mm

2

= 0.89 N/mm

2

Maximum shear = 4.0 N/mm

2

100 A

s

/[b

v

*d] = 0.57

400/d = 1.28

c

= 0.56

c

+ 0.4 = 0.96

Since

c

+0.4 > > 0.5 c max shear, minimum links required

Link size = 6 mm

Shear link spacing S

v

< 149.29

Max spacing < 0.75d < 234.75

Provide R6 @ 150 mm c/c upto 1.5 m throughout

Deflection Checking

SS condition assumed to check deflection

Table 3.10 BS

8110; 1985

Basic Span/Effective depth ratio = 20

Service stress in the tension r/f f

s

= 5*f

y

*A

s req

/(8*A

s prov

*

b

)

= 267 N/mm

2

Modification factor for tension r/f MF = 0.55+ [477-f

s

]/[120*(0.9+M/bd

2

)]

= 1.22 ( < 2.0 )

Hence allowable Span/Effective depth ratio = MF * Basic Span/Eff. Depth

= 24.4

Actual Span/Effective Depth ratio = 6.225/382

= 10.30

Since [Span/Eff.Depth]

actual

< [Span/Eff.Depth]

allowable

deflection is within the limit Deflection is within the limt

REFERENCE

Analysis SLAB THICK 150 MM

Length L 3

Width B 0.225

Dead load [slab+finishes] g 17.18 kN/m

Imposed load i 14 kN/m

Ultimate Design Load w 46.45 kN/m

Total Design Load F 139.36 kN

Single span fixed end condition

BM @ E M

E

33.45 kNm

BM @ D M

D

29.26 kNm

SF @ C V 76.65 kN

Design Data

Material Properties

Concrete grade f

cu

25 N/mm

2

Characteristic steel strength f

y

460 N/mm

2

Youngs modulus of concrete E

C

26000 N/mm

2

Youngs modulus of steel E

S

200000 N/mm

2

Density of concrete p

ct

24 kN/m

3

Durabilty Requirements

Exposure condition - Severe

Beam

Design of Reinforcement

Sizes

Top r/f = 12 mm

Bottom r/f = 12 mm

Links = 6 mm

Cover = 25 mm

Width of the beam b

t

= 225 mm

overall depth of the beam h

b

= 350 mm

Design of Top Reinforcement @ C

Effective depth d = 313 mm d = 313 mm

Design bending moment M = 33.45 kNm

Cl 3.4.4.4 K = M/[bd

2

f

cu

]

BS 8110; 1985 = 0.061 k = 0.061

Since K < 0.156 no compresiion r/f required

Z = [0.5+(0.25-K/0.9)

0.5

] * d

= 0.93 d

Take Z = 0.93d Z = 291.09 mm Z = 291.09 mm

Required area of steel to carry ultimate BM

A

s req,M

= M/[0.95*f

y

*Z]

= 263 mm

2

/m

Area of steel provided A

s prov

339 mm

2

/m

Provide T 12 3 Nos T 12 2 nos

CALCULATION OUTPUT

and T 16 0 Nos T 16 1 nos

Design of Bottom Reinforcement @ B

Effective depth d = 313 mm d = 313 mm

Design bending moment M = 29.26 kNm

K = M/[bd

2

f

cu

]

= 0.053 k = 0.053

Since K < 0.156 no compresiion r/f required

Z = [0.5+(0.25-K/0.9)

0.5

] * d

= 0.94 d

Take Z = 0.94d Z = 294.22 mm Z = 294.22 mm

Required area of steel to carry ultimate BM

A

s req,M

= M/[0.95*f

y

*Z]

= 228 mm

2

/m

Area of steel provided A

s prov

226 mm

2

/m

Provide T 12 2 Nos T 12 2 nos

and T 0 Nos T 0 0 nos

Ckeck for Shear Resistance

Ultimate shear force at support V

u

= 76.65 kN

Shear stress = V

u

/[b

v

*d]

= 1.09 N/mm

2

= 1.09 N/mm

2

Maximum shear = 4.0 N/mm

2

100 A

s

/[b

v

*d] = 0.48

400/d = 1.28

c

= 0.53

c

+ 0.4 = 0.93

Since

c

+0.4 < < max shear, design links to be provided

Link size = 6 mm

Shear link spacing S

v

< 106.24

Max spacing < 0.75d < 234.75

Provide R6 @ 125 mm c/c upto 1.5 m from support

Deflection Checking

SS condition assumed to check deflection

Table 3.10 BS

8110; 1985

Basic Span/Effective depth ratio = 20

Service stress in the tension r/f f

s

= 5*f

y

*A

s req

/(8*A

s prov

*

b

)

= 223 N/mm

2

Modification factor for tension r/f MF = 0.55+ [477-f

s

]/[120*(0.9+M/bd

2

)]

= 1.5 ( < 2.0 )

Hence allowable Span/Effective depth ratio = MF * Basic Span/Eff. Depth

= 30

Actual Span/Effective Depth ratio = 6.225/382

= 10.30

Since [Span/Eff.Depth]

actual

< [Span/Eff.Depth]

allowable

deflection is within the limit Deflection is within the limt

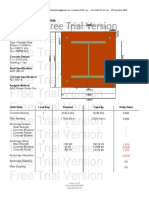

Design of Pad Footing TO BE EDITED

F2 - 600mm x 300mm plate resting on footing

Load F 193

Weight of footing 18.432

Service load P

ser

211.432

Ultimate load P

ult

317.148

Bearing capacity of soil 125 kN/m

2

Footing area 1.69

Say, Length 1.6

Width 1.6

Actual area 2.56 > 1.69 m

2

Overall depth "h" 300 mm > 178.09 mm

Design for Bending

Ultimate bearing pressure 123.89 < 125.00 kN/m

2

Critical BM at colum face BM 41.873 kNm

Bar diameter assumed 12 mm

Cover 50 mm

Effective depth 232

Average depth 238

M/bd

2

0.486

100A

s

/bd 0.1

Reinforcement required A

s

371.2

mm

2

Minimum r/f required 624 mm

2

Provide T12 @ 300 c/c

r/f provided 678.24 mm

2

> 624.00 mm

2

Check for Punching Shear

Max shear v 1.110 N/mm

2

< 4.00 N/mm

2

Critical perimeter 4056 mm

Area outside the perimeter 1.532 m

2

Punching shear V 189.77 kN

Stress v 0.197 N/mm

2

< 4.00 N/mm

2

Shear r/f not required

Detail

Foundation depth (to bottom of footing) : 1200 mm

Size : 1600 x 1600 mm

Footing thickness : 300 mm

Reinforcement : T12 @ 300 c/c both direction

Das könnte Ihnen auch gefallen

- Foundation DesignsDokument137 SeitenFoundation DesignssitehabNoch keine Bewertungen

- Manual Beam DesignDokument14 SeitenManual Beam DesignRonald Kaaku50% (2)

- Column Base PlateDokument3 SeitenColumn Base PlatePurnima ArkalgudNoch keine Bewertungen

- Axially Loaded FTNG DSNDokument12 SeitenAxially Loaded FTNG DSNKanaiyalal N. ShethNoch keine Bewertungen

- SteelDokument80 SeitenSteelAnonymous HJ7hmihhNoch keine Bewertungen

- Design of Isolated FoundationDokument27 SeitenDesign of Isolated FoundationTarunNoch keine Bewertungen

- Combined FootingDokument31 SeitenCombined Footingalbert_pathNoch keine Bewertungen

- Two Way Slab Design in MM FormatDokument5 SeitenTwo Way Slab Design in MM Formathardik_er29Noch keine Bewertungen

- Combined FootingDokument34 SeitenCombined FootingchakrapanithotaNoch keine Bewertungen

- Therefore Use, Therefore UseDokument4 SeitenTherefore Use, Therefore UseJason Teves DomasigNoch keine Bewertungen

- RCC DesignDokument41 SeitenRCC DesignDeenNoch keine Bewertungen

- Strong Col Weak BeamDokument2 SeitenStrong Col Weak BeamlaxmiNoch keine Bewertungen

- Anchorbolt For Pole DesignDokument3 SeitenAnchorbolt For Pole DesignJayNoch keine Bewertungen

- Base Plate Uc152x152x23Dokument2 SeitenBase Plate Uc152x152x23sonofalexanderNoch keine Bewertungen

- Cantilever RCC WallDokument15 SeitenCantilever RCC WallPraveen Kumar0% (1)

- Wall Footing Design For WaterDokument263 SeitenWall Footing Design For WaterRaju SainiNoch keine Bewertungen

- Design Beam For Shear & TorsionDokument332 SeitenDesign Beam For Shear & Torsionsidiq7Noch keine Bewertungen

- Flat Slab 6 X 6 Ext PNLDokument5 SeitenFlat Slab 6 X 6 Ext PNLDarshan Shah100% (1)

- Purlin DesignDokument6 SeitenPurlin DesignAnonymous mcHqIfbnV1Noch keine Bewertungen

- Hindustan Construction Co. Ltd. Mumbai. Subject: DetailsDokument2 SeitenHindustan Construction Co. Ltd. Mumbai. Subject: DetailsHemant SonawadekarNoch keine Bewertungen

- Design of Isolated FootingDokument28 SeitenDesign of Isolated FootingmeenuNoch keine Bewertungen

- Strap FootingDokument30 SeitenStrap Footinganon_140586866Noch keine Bewertungen

- CANTILEVER SLAB DESIGN Latest CorrectedDokument6 SeitenCANTILEVER SLAB DESIGN Latest CorrectedBijendra PradhanNoch keine Bewertungen

- Anchor Bolt Design, IS Code LSDDokument33 SeitenAnchor Bolt Design, IS Code LSDamlan jyoti ChakravortyNoch keine Bewertungen

- Combined Footing Design CF4-2Dokument10 SeitenCombined Footing Design CF4-2Saugat ThapaNoch keine Bewertungen

- Combined Footing DesignDokument2 SeitenCombined Footing DesignnaveenaeeNoch keine Bewertungen

- Design of Strap Footing PDFDokument3 SeitenDesign of Strap Footing PDFVasanthakumarNoch keine Bewertungen

- Beam Load Calculation Fill The Highlighted Cells OnlyDokument14 SeitenBeam Load Calculation Fill The Highlighted Cells Onlyhary9100Noch keine Bewertungen

- Hetauda Raft DesignDokument92 SeitenHetauda Raft DesignSurendra MaharjanNoch keine Bewertungen

- Boundary Wall Design - Final For RFCDokument10 SeitenBoundary Wall Design - Final For RFCShubham KhareNoch keine Bewertungen

- 2way Slab DesignDokument10 Seiten2way Slab DesignHari Amudhan IlanchezhianNoch keine Bewertungen

- Slab Thickness : 0.92 KN 8.825kN/mDokument6 SeitenSlab Thickness : 0.92 KN 8.825kN/mhamza hanifNoch keine Bewertungen

- Two Way Slab DesignDokument1 SeiteTwo Way Slab DesignMuhammad FaisalNoch keine Bewertungen

- Footing DesignDokument37 SeitenFooting DesignnaveenaeeNoch keine Bewertungen

- Isolated Footing Design: Foundation Type: IFDokument7 SeitenIsolated Footing Design: Foundation Type: IFBhuwan JoshiNoch keine Bewertungen

- End Plate DesignDokument26 SeitenEnd Plate DesignNitesh SinghNoch keine Bewertungen

- Design of Chajja (Sun Shade) Input:: Limit State Method Confirming To IS: 456-2000Dokument4 SeitenDesign of Chajja (Sun Shade) Input:: Limit State Method Confirming To IS: 456-2000MaheshNoch keine Bewertungen

- Moment Connection BBDokument8 SeitenMoment Connection BBanandNoch keine Bewertungen

- Water TankDokument89 SeitenWater TankDenishmakvanaNoch keine Bewertungen

- Combined FootingDokument5 SeitenCombined FootingKain Pasang Ruby IINoch keine Bewertungen

- Cantiliver Retaing WallDokument14 SeitenCantiliver Retaing WallMonjit GogoiNoch keine Bewertungen

- Isolated Footing DesignDokument5 SeitenIsolated Footing DesignMJ AbunagaNoch keine Bewertungen

- Analysis Report Tensile Canopy - HOCKEY STADIUM - R0 - ADokument23 SeitenAnalysis Report Tensile Canopy - HOCKEY STADIUM - R0 - ANeeraj KumarNoch keine Bewertungen

- Bracing Back To Back (Version 1)Dokument118 SeitenBracing Back To Back (Version 1)Tameem AnsariNoch keine Bewertungen

- Base PlateDokument15 SeitenBase PlatemaheshbandhamNoch keine Bewertungen

- Concrete Steel: Selected Design Case: 2Dokument25 SeitenConcrete Steel: Selected Design Case: 2venu manikantaNoch keine Bewertungen

- Design of Steel Plate - R0 - 20.04.21Dokument1 SeiteDesign of Steel Plate - R0 - 20.04.21Srishti Project ConsultantsNoch keine Bewertungen

- Design of RCC BuildingDokument5 SeitenDesign of RCC Buildingshreejay maneNoch keine Bewertungen

- Purlins & GirtsDokument10 SeitenPurlins & GirtsRaviKiranNoch keine Bewertungen

- BS 8110 Data Given: Calculation SheetDokument10 SeitenBS 8110 Data Given: Calculation SheetLee See VoonNoch keine Bewertungen

- Design of BeamsDokument14 SeitenDesign of BeamsNoor MohdNoch keine Bewertungen

- Steel Column FOR SCRIBDDokument8 SeitenSteel Column FOR SCRIBDdarshika.jaganiNoch keine Bewertungen

- Design of Splicing of RafterDokument3 SeitenDesign of Splicing of Rafterkeerthivasan_mrvNoch keine Bewertungen

- Staircase DesignDokument2 SeitenStaircase Designbkwagle100% (1)

- Wind Load Calculations As Per IS 875 Part 3Dokument9 SeitenWind Load Calculations As Per IS 875 Part 3RAVI PRAKASH SAININoch keine Bewertungen

- X Y and Partners: Steel Beam DesignDokument35 SeitenX Y and Partners: Steel Beam DesignAndré SantosNoch keine Bewertungen

- Beam Column Cleat Angle ConnectionDokument4 SeitenBeam Column Cleat Angle ConnectionsatyaNoch keine Bewertungen

- Isolated Footing DesignDokument14 SeitenIsolated Footing DesignDhandapany ArunNoch keine Bewertungen

- Fresh Air Stack FoundationDokument66 SeitenFresh Air Stack FoundationManan MansoorNoch keine Bewertungen

- RCC Beam Design Task-01Dokument29 SeitenRCC Beam Design Task-01Mohamed SaheelNoch keine Bewertungen

- Torsional Amplification Factor - Ax-For Response Spectrum Analysis (RSA)Dokument3 SeitenTorsional Amplification Factor - Ax-For Response Spectrum Analysis (RSA)George GeorgianNoch keine Bewertungen

- Omission Addition SR No. Description BOQ Ref. Unit Quantity Rate (AED) Amount (AED) RemarksDokument1 SeiteOmission Addition SR No. Description BOQ Ref. Unit Quantity Rate (AED) Amount (AED) Remarkslayaljamal2Noch keine Bewertungen

- 3Dokument4 Seiten3George GeorgianNoch keine Bewertungen

- PC 7r1Dokument6 SeitenPC 7r1George GeorgianNoch keine Bewertungen

- 2Dokument1 Seite2George GeorgianNoch keine Bewertungen

- General Details RoofingDokument1 SeiteGeneral Details RoofingGeorge GeorgianNoch keine Bewertungen

- SDokument1 SeiteSGeorge GeorgianNoch keine Bewertungen

- DetailDokument1 SeiteDetailGeorge GeorgianNoch keine Bewertungen

- Seismic Design Manual (SEAOC) Vol 1 - Code Application ExamplesDokument171 SeitenSeismic Design Manual (SEAOC) Vol 1 - Code Application Examplesmgrubisic60% (5)

- T1Dokument1 SeiteT1George GeorgianNoch keine Bewertungen

- T2Dokument1 SeiteT2George GeorgianNoch keine Bewertungen

- TensionDokument1 SeiteTensionGeorge GeorgianNoch keine Bewertungen

- Nitoproof 600Dokument4 SeitenNitoproof 600sandeepuaeNoch keine Bewertungen

- B4Dokument1 SeiteB4George GeorgianNoch keine Bewertungen

- Tower Crane Found.Dokument1 SeiteTower Crane Found.George GeorgianNoch keine Bewertungen

- B 2Dokument1 SeiteB 2George GeorgianNoch keine Bewertungen

- B3Dokument1 SeiteB3George GeorgianNoch keine Bewertungen

- Water TanksDokument1 SeiteWater TanksGeorge GeorgianNoch keine Bewertungen

- Safe Out PutDokument9 SeitenSafe Out PutGeorge GeorgianNoch keine Bewertungen

- Foundation Level - 1M From Road LVL Is Less Than Required in Soil Report - 1.5M As Minimum!!Dokument15 SeitenFoundation Level - 1M From Road LVL Is Less Than Required in Soil Report - 1.5M As Minimum!!George GeorgianNoch keine Bewertungen

- Thick PlateDokument1 SeiteThick PlateGeorge GeorgianNoch keine Bewertungen

- Thermal LoadsDokument1 SeiteThermal LoadsGeorge GeorgianNoch keine Bewertungen

- Sub-Grade Is Less Than Required in Soil Report 26,250 kn/m3..!!Dokument1 SeiteSub-Grade Is Less Than Required in Soil Report 26,250 kn/m3..!!George GeorgianNoch keine Bewertungen

- BDokument1 SeiteBGeorge GeorgianNoch keine Bewertungen

- Tower CraneDokument1 SeiteTower CraneGeorge GeorgianNoch keine Bewertungen

- Raft LevelDokument1 SeiteRaft LevelGeorge GeorgianNoch keine Bewertungen

- 0.85m (-0.55mm FROM ROAD: Missed Road Base Layer 25Cm As Per The Soil ReportDokument1 Seite0.85m (-0.55mm FROM ROAD: Missed Road Base Layer 25Cm As Per The Soil ReportGeorge GeorgianNoch keine Bewertungen

- PunchingDokument1 SeitePunchingGeorge GeorgianNoch keine Bewertungen

- Moduls of Rapture..Dokument1 SeiteModuls of Rapture..George GeorgianNoch keine Bewertungen

- Miss Matching Model 1.48M, Drawings 1.15M, (More Pressure On Raft in Actual)Dokument1 SeiteMiss Matching Model 1.48M, Drawings 1.15M, (More Pressure On Raft in Actual)George GeorgianNoch keine Bewertungen

- CHEN 200 Homework Problems 1: Problem 1: (3 Marks)Dokument2 SeitenCHEN 200 Homework Problems 1: Problem 1: (3 Marks)Amy MillerNoch keine Bewertungen

- Laboratories With EquipmentDokument10 SeitenLaboratories With Equipmentabd devNoch keine Bewertungen

- Vibration Control Techniques During Turn PDFDokument22 SeitenVibration Control Techniques During Turn PDFAhmed EzzNoch keine Bewertungen

- Compressed Air: Stäubli Invents Active SafetyDokument12 SeitenCompressed Air: Stäubli Invents Active SafetyAlper SakalsizNoch keine Bewertungen

- Flywheel ExperimentDokument4 SeitenFlywheel ExperimentNasim Mammadov67% (3)

- HTO AssignmentDokument5 SeitenHTO AssignmentMadhumita KumarNoch keine Bewertungen

- 05-1 N T4 Hydraulic Section Rev1Dokument128 Seiten05-1 N T4 Hydraulic Section Rev1Fútbol y más100% (1)

- Hi-Lo and PRO-1 Pan Feeder PartsDokument86 SeitenHi-Lo and PRO-1 Pan Feeder Partssergiu20Noch keine Bewertungen

- Pump System Labby 2015Dokument6 SeitenPump System Labby 2015Azril DahariNoch keine Bewertungen

- SP 1212 Check SheetDokument5 SeitenSP 1212 Check SheetDaniel MartinezNoch keine Bewertungen

- Operator'S Manual: ListedDokument152 SeitenOperator'S Manual: Listedmantencion CRINoch keine Bewertungen

- Electric Motor EE ST and L - EEA Comment Attended 22 July 2015Dokument193 SeitenElectric Motor EE ST and L - EEA Comment Attended 22 July 2015gomeraNoch keine Bewertungen

- Formulas To RememberDokument6 SeitenFormulas To Remembermr.xinbombayNoch keine Bewertungen

- Amca 211-05 (Rev 6-12)Dokument61 SeitenAmca 211-05 (Rev 6-12)Call MeNoch keine Bewertungen

- Volvo Edc III Tad 1241 2 Workshop ManualDokument7 SeitenVolvo Edc III Tad 1241 2 Workshop Manualmary100% (55)

- Railways: Railway IntroductionDokument9 SeitenRailways: Railway IntroductionIkram ArifNoch keine Bewertungen

- BS 7448-3 - 2005 (2007)Dokument62 SeitenBS 7448-3 - 2005 (2007)Артем ТитовNoch keine Bewertungen

- Steam Systems Product Offerings: For Industrial / Commercial SystemsDokument2 SeitenSteam Systems Product Offerings: For Industrial / Commercial SystemsDavid C TalledoNoch keine Bewertungen

- Cromax 42CrMo4 4140Dokument3 SeitenCromax 42CrMo4 4140Iñigo Fernandez de LabastidaNoch keine Bewertungen

- Fig. 900 Fig. 940: Safety ValveDokument36 SeitenFig. 900 Fig. 940: Safety ValveJesús Santiago QuijadaNoch keine Bewertungen

- Noc18 Ce23 Assignment2 PDFDokument4 SeitenNoc18 Ce23 Assignment2 PDFrichard kwofieNoch keine Bewertungen

- RR Avon 1534 2Dokument3 SeitenRR Avon 1534 2frdn100% (1)

- PHD Thesis Optimization of Bow Shape For Large, Slow Ships by NordåsDokument84 SeitenPHD Thesis Optimization of Bow Shape For Large, Slow Ships by NordåsPrasad PatilNoch keine Bewertungen

- Plane Stress Model: Transforming Stress Components and DirectionsDokument7 SeitenPlane Stress Model: Transforming Stress Components and DirectionsEngr Aizaz AhmadNoch keine Bewertungen

- Lecture Powerpoints: Physics: Principles With Applications, 7 EditionDokument45 SeitenLecture Powerpoints: Physics: Principles With Applications, 7 EditionBsc CivilNoch keine Bewertungen

- 15 CH 4 Columns and StructsDokument22 Seiten15 CH 4 Columns and StructsgNoch keine Bewertungen

- 3M Sample CalculationDokument7 Seiten3M Sample Calculationsagar kolhe100% (1)

- Filcord C: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsDokument2 SeitenFilcord C: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsPavelNoch keine Bewertungen

- 6 Energy Balances Problems4Dokument12 Seiten6 Energy Balances Problems4Snow Drop0% (1)

- Emp 006Dokument2 SeitenEmp 006Brian FreemanNoch keine Bewertungen