Beruflich Dokumente

Kultur Dokumente

VOLVO 2008 12-09-144753 EngineBrakeDesignandFunctionD13 2

Hochgeladen von

HorváthVargaLászló0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

290 Ansichten9 SeitenThis information covers the design and function of the Volvo Engine Brake (VEB) on the Volvo D13F engine. The engine brake operates by opening the exhaust valves during the inlet stroke. Compared with the earlier system, the mechanical loads are now shared by two rocker arms. Using the engine brake increases the gas flow through the cylinder which reduces the thermal stress on the injector spray nozzles.

Originalbeschreibung:

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis information covers the design and function of the Volvo Engine Brake (VEB) on the Volvo D13F engine. The engine brake operates by opening the exhaust valves during the inlet stroke. Compared with the earlier system, the mechanical loads are now shared by two rocker arms. Using the engine brake increases the gas flow through the cylinder which reduces the thermal stress on the injector spray nozzles.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

290 Ansichten9 SeitenVOLVO 2008 12-09-144753 EngineBrakeDesignandFunctionD13 2

Hochgeladen von

HorváthVargaLászlóThis information covers the design and function of the Volvo Engine Brake (VEB) on the Volvo D13F engine. The engine brake operates by opening the exhaust valves during the inlet stroke. Compared with the earlier system, the mechanical loads are now shared by two rocker arms. Using the engine brake increases the gas flow through the cylinder which reduces the thermal stress on the injector spray nozzles.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 9

D

Service Bulletin

Volvo Trucks North America

Greensboro, NC USA

Date Group No. Page

11.2006 253 66 1(9)

Trucks

Engine Brake

Design and Function

D13F

Engine Brake, Design and Function

W2005779

This information covers the design and function of the Volvo Engine Brake (VEB) on

the Volvo D13F engine.

Contents

Engine Brake page 2

Note: Information is subject to change without notice.

Illustrations are used for reference only and can differ slightly from the actual vehicle

being serviced. However, key components addressed in this information are

represented as accurately as possible.

PV776-20177446 USA23125.ihval

D

Volvo Trucks North America Date Group No. Page

Service Bulletin 11.2006 253 66 2(9)

Design and Function

Engine Brake

The engine (compression) brake operates by opening

the exhaust valves during the inlet stroke and just before

bottom dead center (BDC) on the compression stroke,

which utilizes the braking force of the compression stroke.

This is achieved mechanically with the aid of a camshaft

with an extra braking cam with two lobes, a brake rocker

arm and a control valve that regulates the lubricating oil

pressure to the rocker shaft. The control valve is located

on the cylinder head between cylinders three and four.

The inlet of the control valve is connected to a lubricating

oil channel in the engine block, and the outlet of the valve

is connected to the rocker arm shaft through a tube. If the

engine is equipped with an engine brake, this is shown

on the front engine identification label, on the left side of

the rocker cover.

Compared with the earlier VEB system, the mechanical

loads are now shared by two rocker arms, which

means that the braking power can be increased without

increasing mechanical stress. Using the engine brake

increases the gas flow through the cylinder which reduces

the thermal stress on the injector spray nozzles. The

increased gas flow cools the nozzles.

D

Volvo Trucks North America Date Group No. Page

Service Bulletin 11.2006 253 66 3(9)

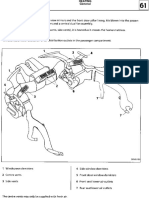

System Components

Camshaft

On engines with a compression brake, the camshaft is

designed with an additional cam at each cylinder for

operation of the VEB. There are now four distinct cams,

operating the intake valves, the unit injectors, the exhaust

valves and the VEB, respectively. The lift height of the

VEB lobes on the brake cam are very low compared to

that of normal exhaust cam lobes.

As mentioned, the camshaft (1) on an engine with a

compression brake has four cams for each cylinder; the

inlet cam, injection cam, exhaust cam and braking cam.

The brake cam has two lobes, the charging lobe (3) and

the decompression lobe (4) which lifts the exhaust valves

at the appropriate time to eliminate the power stroke

driving power and fully utilize the braking power.

Inside the exhaust valve rocker arm (5) are two pistons,

the pump piston (7) and the power piston (14), along

with a non-return valve (6), another piston (10) and a

spring (13). The power piston is located directly above

the exhaust valve bridge and it is the power piston that

presses down on the bridge to open the exhaust valves.

The pump piston is located directly underneath the engine

brake rocker arm (9) and is what the brake rocker arm

pushes against. The exhaust rocker arm (5) is shaped so

that the brake rocker arm is positioned above the exhaust

rocker arm. When the lubricating oil pressure is sufficient,

the clearance between the rocker arms is taken up by

the pump piston. Both pistons in the exhaust rocker arm

are linked by an oil channel. When the pump piston is

pressed down, the oil underneath the piston is pumped

to the power piston. At the same time, the non-return

valve closes and the higher oil pressure causes the power

piston to be pressed down to open the exhaust valves.

W2005932

D

Volvo Trucks North America Date Group No. Page

Service Bulletin 11.2006 253 66 4(9)

Control Valve

The control valve is mounted on the cylinder head under

the valve cover and is connected to the oil system ahead

of the rocker arm shaft. Its purpose is to reduce oil

pressure to the rocker arms while the engine is operating.

There is always full system oil pressure to the control

valve inlet. A seal connects the inlet to the lube oil gallery

in the cylinder head. Oil pressure to the rocker arm shaft

can be increased by the solenoid valve which is a part

of the control valve, from about 100 kPa (14.5 psi) while

the engine is operating to over 200 kPa (29 psi) during

compression braking. The control valve regulates the

oil pressure to the rocker arm shaft assembly and is

controlled by the Engine Electronic Control Unit (EECU).

1. Locking Ring

2. Sleeve

3. Valve Slider

4. Balance Spring

5. Spring Seat with Ball Holder

6. Valve Ball

7. Cylinder

8. Rod

9. Solenoid Coil

10. Piston

11. Electrical Connection

12. Pressure Regulation Hole for Flow Control

13. Return Hole

14. Calibration Hole

15. Hole for Oil Flow to Rocker Arm

W2005933

D

Volvo Trucks North America Date Group No. Page

Service Bulletin 11.2006 253 66 5(9)

Neutral

The VEB valve is shown in its neutral position, which

means that the engine is stationary. The solenoid coil (9)

is not energized and the valve slider (3) is up against the

locking ring (1).

Normal Driving

During normal engine running, the solenoid coil (9) is

not energized. The solenoid valve is in regulation mode

and forces oil through the hole (15) to the rocker arms

while allowing oil to flow through the calibration hole (14)

and onwards to the return hole (13). This reduces the

oil pressure to 100 kPa (14.5 psi), which is enough to

lubricate the camshaft bearings and valve rocker arms.

Engine Brake Activated

When the engine is running and the engine brake is

activated, the solenoid coil (9) is energized and the

valve slider (3) is forced to its end position which is fully

open. The trapped oil acts as a hydraulic lock. Full oil

pressure is now delivered to the rocker arm shaft and the

compression brake comes into action.

Engine Brake Deactivated

When the engine is running and the engine brake is

released, the solenoid coil (9) is de-energized. The

high pressure oil inside the rocker arm shaft causes the

valve slider (3) to quickly move and open the oil return

connection (13) so that the oil can drain out. When the oil

pressure has fallen to approximately 100 kPa (14.5 psi),

the valve slider returns to its regulation position.

Exhaust Rocker Arms

The exhaust rocker arms on an engine with a compression

brake are larger than those of a conventional engine.

The rocker arm is equipped with a non-return valve and

a piston with a pressure-limiting valve. Its purpose is to

regulate oil flow during compression braking.

W2005872

D

Volvo Trucks North America Date Group No. Page

Service Bulletin 11.2006 253 66 6(9)

Non-Return Valve

The non-return valve, consisting of a piston, spring and

ball is located in the exhaust rocker arm. When oil from

the rocker arm shaft is forced into the valve, the spring

force and the oil pressure determine movement of the

piston.

When the oil pressure is low, about 100 kPa (14.5 psi),

the control valve is in its engine operating position. During

this time, the piston will not move out of its rest position

because the oil pressure cannot overcome the spring

force. The piston pin prevents the ball from seating and

the oil can flow freely through the valve in both directions.

When the control valve begins compression braking, oil

pressure to the non-return valve increases. The spring

force in the non-return valve is such that when the oil

pressure exceeds about 200 kPa (29 psi), it overcomes

the spring force and moves the piston to where it no

longer controls the ball. The spring forces the ball against

its seat and the oil contained above the piston cannot

flow past the ball. As a result, high oil pressure is formed

above the piston.

W2005888

Rocker Arm Piston

The rocker arm (pump) piston is located in the arm

offset, facing upward and aligned with the VEB rocker

arm adjustment screw. The purpose of the piston is to

eliminate all valve clearance during compression braking

which it does by closing the gap between the exhaust

rocker arm and the engine brake rocker arm.

1. Rocker Arm (Pump) Piston

2. Non-Return Valve Location

W2005873

D

Volvo Trucks North America Date Group No. Page

Service Bulletin 11.2006 253 66 7(9)

Normal Engine Operation No Compression Braking

While the engine is running, the control valve reduces the

oil pressure in the rocker arm shaft to approximately 100

kPa (14.5 psi). The non-return valve is kept open by the

piston being pushed forward. The oil channels fill, but

the low pressure is not able to push the pump piston to

its upper position. The brake rocker arm does not contact

the exhaust valve rocker arm (5). In this situation, the

exhaust valves are not affected by the cam lobes on the

engine brake cam.

W2005889

Compression Braking

During compression braking, the control valve raises

the oil pressure to system oil pressure in the rocker arm

shaft. The piston is moved back, but the non-return valve

is held open by the oil flow. The higher pressure is able

to push the pump piston to its upper position. When the

pump piston is pushed to its upper position, the clearance

between the engine brake rocker arm and the exhaust

valve rocker arm is taken up.

Oil pressure pushes the pump piston to its upper position

and fills the volume beneath the piston. Once the oil has

filled the system and no longer flows, the non-return valve

closes. When the brake rocker arm travels over one of the

two lobes, the pump piston is pushed down and the oil

volume beneath the piston applies pressure to the power

piston. The piston is pushed down and the exhaust valves

open. The non-return valve is kept closed by the high oil

pressure while the exhaust valves are open.

After the exhaust valves close and the brake rocker arm

is no longer exerting pressure on the pump piston, the

oil that was pushing the power piston down runs back

to the pump piston. The system then refills because the

non-return valve opens to allow the amount of oil that

leaked out during the previous cycle to come through.

Deactivation takes place when the oil pressure in the

rocker shaft falls to approximately 100 kPa (14.5 psi). The

non-return valve piston opens the non-return valve so that

oil can flow back to the rocker arm shaft. The pump piston

spring forces the pump piston back to its lower position

and the brake rocker arm cannot come into contact with

the pump piston.

W2005900

D

Volvo Trucks North America Date Group No. Page

Service Bulletin 11.2006 253 66 8(9)

Control System

The engine brake is associated with accelerator pedal

movement and is activated when the pedal is completely

released based on the selection made with the engine

brake switch on the instrument panel.

The selection made with this switch also regulates engine

braking activated by the cruise control.

Note: The engine brake functions as long as the engine

control system has received signals from engine sensors

indicating that the required preconditions for engine

braking have been met. For example, the engine speed

must be greater than 1100 rpm, the vehicle speed must

be greater than 12 km/h (7.5 mph) and the engine coolant

temperature must be above 70 C (160 F).

Switch

The compression brake is controlled by a switch located

on the dash.

A typical switch can have the following selections:

0 Compression brake not engaged

1 LO Half compression braking power

2 HI Full compression braking power

T2006953

D

Volvo Trucks North America Date Group No. Page

Service Bulletin 11.2006 253 66 9(9)

VEB Induction (Charging) Phase

The induction phase begins at the end of the intake stroke

and continues just before BDC on the compression stroke.

The piston travels downward toward bottom dead center

and the VEB cam charging lobe opens the exhaust valves

long enough to fill the cylinder with exhaust backpressure

caused by the turbocharger.

When the charging lobe closes the exhaust valves,

the cylinder has a backpressure at the start of the

compression stroke. This backpressure increases

compression considerably during the compression stroke

which, in turn, creates a powerful braking effect when the

piston moves upward.

T2006830

VEB Decompression Phase

At the end of the compression stroke, as the piston

approaches top dead center, the engine brake cam

decompression lobe opens the exhaust valves and

releases the built-up pressure from the cylinder. Shortly

before bottom dead center, the ordinary exhaust lobe

opens the exhaust valves.

T2006831

Das könnte Ihnen auch gefallen

- Sprinter Adding Additional BatteriesDokument4 SeitenSprinter Adding Additional BatteriesHorváthVargaLászlóNoch keine Bewertungen

- 3239a Abs Speed InformationDokument14 Seiten3239a Abs Speed InformationHorváthVargaLászlóNoch keine Bewertungen

- Volvo Trucks Parts Catalog 2015Dokument412 SeitenVolvo Trucks Parts Catalog 2015HorváthVargaLászlóNoch keine Bewertungen

- RM Futes Hutes 61 62Dokument34 SeitenRM Futes Hutes 61 62HorváthVargaLászlóNoch keine Bewertungen

- Technical Note 3426A Je0 K - Je0 S: Basic ManualDokument52 SeitenTechnical Note 3426A Je0 K - Je0 S: Basic ManualHorváthVargaLászlóNoch keine Bewertungen

- Whirlpool Adp4535 IncoredDokument1 SeiteWhirlpool Adp4535 IncoredHorváthVargaLászlóNoch keine Bewertungen

- Irf 5305Dokument9 SeitenIrf 5305Mali RamoneNoch keine Bewertungen

- Tecra A11Dokument238 SeitenTecra A11alma23Noch keine Bewertungen

- DBW 2010 DBW 2016: Water Heaters Workshop ManualDokument78 SeitenDBW 2010 DBW 2016: Water Heaters Workshop ManualAndzej LazovskijNoch keine Bewertungen

- Hydronic d5wsDokument27 SeitenHydronic d5wsHorváthVargaLászlóNoch keine Bewertungen

- External LightDokument149 SeitenExternal LightHorváthVargaLászlóNoch keine Bewertungen

- Wiring Diagram B12B B12M B9B B7B PDFDokument90 SeitenWiring Diagram B12B B12M B9B B7B PDFAbdelhak EzzahriouiNoch keine Bewertungen

- Volvo d12 Workshop Manual Less Specifications Abby PDFDokument709 SeitenVolvo d12 Workshop Manual Less Specifications Abby PDFkoaa8592% (37)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 2013 Honda CB500F Owners Manual EngDokument125 Seiten2013 Honda CB500F Owners Manual EngEmanuel RusuNoch keine Bewertungen

- Mercedez Benz Mbe 4000 PDFDokument20 SeitenMercedez Benz Mbe 4000 PDFMaria AndinoNoch keine Bewertungen

- Ford - Truck - Construction Series - GCC - ENG - 2017 PDFDokument17 SeitenFord - Truck - Construction Series - GCC - ENG - 2017 PDFyodiumhchltNoch keine Bewertungen

- Liebherr D934 936 946Dokument90 SeitenLiebherr D934 936 946bagus hutomo100% (4)

- Engine Manual OM460 KM OM460 E 00Dokument247 SeitenEngine Manual OM460 KM OM460 E 00HANAFI YUSUF100% (1)

- 00 017695Dokument4 Seiten00 017695Walter LazoNoch keine Bewertungen

- Volvo Auto ShiftDokument350 SeitenVolvo Auto Shiftsengottaiyan100% (6)

- Function: APS, Air Processing System - FunctionDokument20 SeitenFunction: APS, Air Processing System - FunctionSvara 889Noch keine Bewertungen

- cbr250rr 2021Dokument115 Seitencbr250rr 2021Sam SamiNoch keine Bewertungen

- Overhaul A240eDokument140 SeitenOverhaul A240eSamuel83% (6)

- Allison at MT HT Transmission Operators ManualDokument50 SeitenAllison at MT HT Transmission Operators ManualWiston CastroNoch keine Bewertungen

- Engine: Technical TrainingDokument70 SeitenEngine: Technical TrainingNova kurniawan 34Noch keine Bewertungen

- Scania Opticruise Transmission Fault Codes DTC & TroubleshootingDokument84 SeitenScania Opticruise Transmission Fault Codes DTC & Troubleshootingfrank mutale100% (10)

- Engines: Symbolisation 062356 B3 Symbolisation 062045 B5Dokument52 SeitenEngines: Symbolisation 062356 B3 Symbolisation 062045 B5Hamid edris100% (2)

- DETROIT DIESEL SERIES 60 Operator's ManualDokument154 SeitenDETROIT DIESEL SERIES 60 Operator's ManualAndreyNoch keine Bewertungen

- 6 Cylinder MBE906: Engine PerformanceDokument2 Seiten6 Cylinder MBE906: Engine Performanceguillermo meza huamanNoch keine Bewertungen

- Volvo D16-500V - 2050-Xe PDFDokument2 SeitenVolvo D16-500V - 2050-Xe PDFDIONYBLINK100% (1)

- Options T880 044-19Dokument200 SeitenOptions T880 044-19Abdelkader Draï67% (3)

- Service Manual: Multi Unit Manual OM352 OM353 OM362 (A, LA) Diesel Engine, Turbocharged, Lntercooled TurbochargedDokument7 SeitenService Manual: Multi Unit Manual OM352 OM353 OM362 (A, LA) Diesel Engine, Turbocharged, Lntercooled TurbochargedOscar González0% (1)

- t8. Fault CodesDokument33 Seitent8. Fault CodesjuanNoch keine Bewertungen

- What Is A RetarderDokument10 SeitenWhat Is A RetarderAsheNoch keine Bewertungen

- Toyota U151E-U250E Zip Kit: Electronic CautionsDokument8 SeitenToyota U151E-U250E Zip Kit: Electronic CautionsMajdy Alsobhi100% (2)

- Opticruise W.S.MDokument100 SeitenOpticruise W.S.MVincent Price50% (2)

- 32MJM8001 VFR800XFDokument141 Seiten32MJM8001 VFR800XFPradipta TejaNoch keine Bewertungen

- HRD k3v k5v Series Parts DiagramsDokument12 SeitenHRD k3v k5v Series Parts Diagramsيحيى بن يحيىNoch keine Bewertungen

- Volvo D16 Engine Family: SpecificationsDokument3 SeitenVolvo D16 Engine Family: SpecificationsJicheng PiaoNoch keine Bewertungen

- 2020 - YZF - R1 - Kit Manual - ENDokument82 Seiten2020 - YZF - R1 - Kit Manual - ENMr. TNoch keine Bewertungen

- enDokument84 SeitenenRegistr Registr100% (11)

- 706 15 PDFDokument25 Seiten706 15 PDFHelloNoch keine Bewertungen

- AtDokument366 SeitenAtEduardo Junior Obando RomeroNoch keine Bewertungen