Beruflich Dokumente

Kultur Dokumente

Tuning BMC Sports Cars

Hochgeladen von

Michael Carnell100%(3)100% fanden dieses Dokument nützlich (3 Abstimmungen)

4K Ansichten82 SeitenBy Mike Garton from 1969. Covers the AH and MG Sprites, MGB and MGA. Covers engine and transmission maintenance and tuning.

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenBy Mike Garton from 1969. Covers the AH and MG Sprites, MGB and MGA. Covers engine and transmission maintenance and tuning.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

100%(3)100% fanden dieses Dokument nützlich (3 Abstimmungen)

4K Ansichten82 SeitenTuning BMC Sports Cars

Hochgeladen von

Michael CarnellBy Mike Garton from 1969. Covers the AH and MG Sprites, MGB and MGA. Covers engine and transmission maintenance and tuning.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 82

r

TUNING RM.C SPORTS CARS

by Mike Garton

PEl' » RT

MOrOs=>DKS

1"

T ,

v-

~.~ .,

rc .

«,»,

~'I •

r •

.:"

"

. ,

... ~

L

I

:f

I I

~

I I

I

I

this book first appeared as a series of articles in Cars & Car Conversions

~

.

Printed and Published by

-

I

.'

SPEED AND SPORTS PUBLICATIONS LTD

Acorn Housel Victoria Road;. Acton] London W.3.

@ Copyright 1 gee by S peed and S pons Publican on s Ltd. All ri9hr~ reserved

~ .

-- ..

r

I

CONTENTS

page

Introduction 7

CHAPTERl

Early Sprites 9

CHAPTER2

The l098cc Sprite Midget 21

CHAPTER 3

1275cc Sprite MK4! Midget MK3 25

CHAPTER4

MGA 27

CHAPTER5

It MGB 39

CHAPTER 6

MG Transmission 51

CHAPTER7

Tuning the Suspension 58

CHAPTER8

The Five Bearing Engine 65·

Charts 71 Thi - blank

us page lS .',,',' anx

4

,

I

Thi - blank

us page lS .',,',' anx

5

Thi - blank

us page lS .',,',' anx

6

I NTRODUCTI ON

Former technical editor of JAuto News' .Salss Manager for Marcos Cars and journalist, 33-year-old Mike Garton turned to four wheels after several years' success on motorcycles in scrambles and u ~tra·lightweight road racing, with a season's karting as waiL

'0 1958 the bug-eyed Sprite was introduced, the 1935 MG 'PA" then owned was changed for a Sprite in ~59~ An early Austin-Healey Club member! he has remained faithful to this marque.

'n 1962 a Ughtweight racing Sprite was built, MEG 1994'" which earned itself a formidable reputation and works support for Mike+ F;r~t winner of the John Gott Trophy annual award, Mike acquired the Donald Healev-built Le Mans coupe ('62 car) in 1963. With the encouragement of Geoff Hsalev, GeQff Price .. Stuart Turner and Peter Browning, private and works entries were to take him to successes on circuits at home, in Francel Belguim, Germanv, ~taly and America. These include 2nd overall in the "65 Brands Hatch 1000 Milesl class wlns at 1000Ks, Nurburgring in ·67 (3rd in "66) and Sebring 12 brs., '68. In 1966 Mike was efected a full member of the British Racing Drivels Club.

Since then assorted iron from Cooper S and single-seaters to lotus 238 have been campajgned~

Now a techrucal correspondent with thA Special Tuning Dept of British Leyland at Abingdonl Mike continues to race in long distance continental events.

•

.'

, .J •

,;J

~ .~

7

. ! 1

8

CHAPTER 1

B M C Sports cars are synonymous • • • with Abingdon1 a quiet Thameside town where the first M.G~s rolled fort h in the mid-1920s. We wiU confine this series to post .. ' 955 models however, but never lose sight of the fact that M.G. development was hammered round the banking at Brooklands.

SPRITE MK I

We will commence with the: mode! that brought an entiralv new concept of sports cars to the motoring public .. the AustinHealey Sprite, wh1ch first emerged in 1958. The Sprite M k I stem med from an idea by Donafd H ea ley', whose ag ile mi nd had been the birth-place of several brilliant designs. Much of its initial success was attributed to its "frog -I ike' a ppearance. a bitter sweet reaction! The ~bugeyed~ headhghts were .. of course, a compromise: to com ply w rth export regu lations.

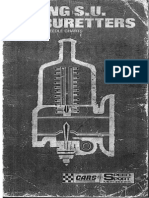

A simple 'punt' chassis with au-steel monocoq ue bodvwork, it h ad the A35 mec han leal components grafted to it. The 2.478~in. bore x 3 in. stroke power unit was unchanged tU«;spt for a sports car 'tweak': twin 1 ~ in. choke H1 S. U. carburettors. With the- very basic 8G712 cam (see chart l), output was all of 42 b.h.p. at 5,000 r.p.m. Cornpressi on was 8.3/ head capacity 24.5 C'C.j the pistons having a 4~2 c.c, dish, Valve sjzes ware as A35r Minor 1 JOOOI at 1 .095 in. inle-t. 1.005 in. exhaust. The 6! in. sinqle-plate .. six-

Early Sprites

spring clutch and standard gearbox ratios were u na lterad.

, st .- 3.628

2nd - 2.374 Top direct

3rd -- 1.412

Rev 4.664

The final drive ratio became 4.22 giving 15.37 m.p.h. per 1.000 r.p.rn. Wheels were , 3 ~ n. x 3 -! in. pressed steel, ventiJated 1YPIJ. Suspension was independent by coil-spring and wishbone at the front with rack-and-pinion steering. Some 200~OOO assorted 'Spridgets" later, this remains unaltered. At the rear, the normal jA' series

three-CI uarter floating axle was loea1ed bv 1 5·1801 q uarter- alii ptic spri ngs and radius arms. Lever-arm Armstrong shockers were fitted an round.

This AN-5 chassis series was in production from May 1958 until May 1961, then 'punsts' found that a conventional body line was introduced a-s the Sprite Mk II (H~AN6}j [ointtv with a cornmonlsed M.Gr Midget Mk I (G-AN1).

Performance was improved by gentng flat-top pistons giving 9 -1 compression (differen1 head cCipacity 26~ 1 c.c.) and a slightly' higher-lift cam, AEA 630. The cylinder head was similar to the 997 Cooper. with larger inlet valves (1.151 in.). Larger 11- in. choke H2 carburertors w.ere fitted} on a better ma n tford.

Three camshaft bearings were now fitted .. but clamp-bolt con-reds (2.A 654 r.h.-2A

9

inlet port

1",

make metal template to this shape and grind out

inlet port throat at section A.A. to allow pLate to just pass through

section through the inlet port

l'1l'-I1' ~ I

section through t he exhaust port

IMPROVING PORTS ON THE AUSTIN HEALEY MKl 10

6:56 l.h.) were retained. The gearbox acQtJ ired needJe-roller bearings with closer rat io 5, as fall ows: 1 st p 3.2; 2 n d j '.91 6 ; 3rd, 1 .357; Rev_ 4 .. ' 1 4,

B rakes were unchanged, with 7 in. drums all round, givi ng 70 sq. ins, total area.

The AN -5 chassis had power units with 9C prefix, th is became 9CG with the H ,AN6/G.AN1 series. it is important to get th ese correct.

A good set of A~F. ring and open-ended spanners, plus a socket set, ara a basic 1001 kitl toqet her with a II the usual screwdrivers, etc., and a n electric drill wrth flexjble drive, complete with a set of grinding mops and stones. Petrot a stiff brush and sultabta washi ng -tln are handy too; make one by chopping a 10 in. x 5 in. hare in a gallon tin. Don't forget to turn back the edges.

A word of warning. It is easy to go ahead and improve performance .. even by 100%_ but some cars have now endured 10 years r abuse, and it is essential to ensure it is baslcalfv sound. There is no point in spending hours on the power unit if brakes and suspension are not up to scratch. It is an too easy to "reave it ttll tater'. You and your vehicle win be tethaf.

Wna1 degree of tu nin g is r equ ired_ for what purpose 7

The 9C cylinder head will be improved bv carefuUy polishinq all costing marks, frezas. etc., from the combustion chamber, graduaUy raditlsing the central projection. Do not remove it altogether. Inlet ports should be enfarged and potished (illus~ tratlon A1). Make a template, and do not exceed this shape, as the wall is vary thin at this point. The compression ratio can be increased by fittin.Q the 9CG flat-top piston. to 9.3:1 or by removing approximatelv .065 in. from the head face. The head depth can vary tremendously and there is danger of penetra1ing the bottom oil way. A 'dodge' to check lhe available depth is to put a thin steel wire down the rocker feed hole; measure this depth. then deduct it from the measurement of the head-face-to- pillar-face depth. Remember to leave sufficient metal to prevent warping; tOS5/ .090 In, is normally a safe maximum.

To establish your actual compression ratlo you must obtain details .. some of which

can be regarde-d as constants. See Chart II. After working on the combustion cham bars you must also balance them. We can achieve this by placing the head face uppermost with plugs and valves in place (all polishi ng .. valve 9 rindi ng complet ad) , Place a piece of perspex totally covering the combustion chamber. but with a small ! in. hole j n its centre.

Using Redex a nd a burette. the capacity is soon found. Alternativelv, a crude but aquallv efficient method is to pack the combustion space with children's Plasticl n e, carefu lIy levelling it fl ush with the head face. Remove all of it (sha pe is un ~ important) and drop it into a measuring cylinder, graduated in c.c.s and containing it known quantity of wat.er. B store ~ andafter readings give the volume displaced. Most good chemists retail these glass cylinders.

The volume of the compressed gasket is approxtmarelv 3 c.c. throughout "A' series. except for Cooper "S' and 1275 Sprite! M.G. at 3.8 C,C. The piston depth annular groove va ries a little; Chart II shows that some models diHer_ in particular the 1275 c.c, units and the 998 c.e. Cooper.

N ext we need to know what effect the piston has, e.g. ffat top. dished (volume of dish) or raised crown (vol u me displaced). Fin ally, we need the actual engine capacitv divided by fau r for the individual cylinder. Basic capacities are known but what if the unit 1S bored?

1. Geomstrv tells us Pi x radius2~Area ( Pi = 22/7 or 3.' 416 )

2, 948 c.c. bored ~ .030 in. = Sid bore 2 .. 478 -L .0-30 in.

3. ~2.508 In. bora diameter, 1.254 radius

4. (1 .254 in. x ·1.254 in.) x 3 .. 141 6 = 4 .. 965 sq. ins. x (stroke) 3 in.=14.985 cubic inches

Multi ply this bV 16.38 to give 244 c.c ... which is swept volume.

The combustion chamber capacity (std) is 24.5 c.c.

combustion. chamber vol = 24.5 C.C,

gasket vol _. 3~O c.c,

Annular groove - .8 c.c,

9C Piston (12A 145) dish = 4.2 c.c. Unswept volume Tatar =32.5 c.c,

Add this figure to the swept volume 24"1- c.c. and divide this total by 32.5 for the correct com prsssi 0 n ratio.

11

L.

~

.

..

~. (.

•

;~

J

.r

.~

. ,

,

.. , :

e. g. u nswept vol -t. swept vol ume

.. - _.-- -

unswept volume

244 = 276.5

32.6 ·r- 32.5 32.5 = 8.5 = 1

By using this formula and Chart 'I~ you can obtain compression to suit, without machi ning heads. AU the cylinder heads can be interchanged .. but head clearance differs, with the result that larger valves overlap the bores and the brock must be relieved for cteerance by at least .060 • n . This manifests aself to a grealer extent wnen d iffar-ent CB ms are used (Chart , ). AEA 400 exhaust valve in KE 965 materia! should be used in the 'A" series heads except for Cooper S B nd oth er 1275 c.c , units.

To obtain a moderate power increase on the 9C engine .. therefore. we must polish and bala nee the head and fit 9CG Piston 12A 187 (or mach ined head) ~ To take full advantage of the raised compression. the Cooper 997 camshaft SSG 229, has higher lift with j ncreased v.alve period. The cam profile determines the varvecrash point, relative to spring strength ana weight of valve gear, There is no advantage in rars'ng the valve-crash point by fitt1ng too strong a spri ng.r or combination of springs.

The onlv result ~s excessive load on the cam followers and lobes.

Alwavs use the 12G 793 oil-pump when rebu iid ing; it is th e most effie ient for th is type. As, initiallv, we have retained the damp-bolt rods and, we assume .standard crankshaft {balanced as an assembly with f/ywhe-e[ and clutch pressure pla1e) AEA 311 valve spr. ngs shou Id be retain ed . These will restrict r. p.m. to ap proximately 61400 with the 8SG 229 cam.

Use the Mk rI (9CG) inlet manifold and H2 carburettors. carefully rnatchinq the manifold to the head ports. R eplaci 09 the production exhaust manifold by a good three~ branch type is beneficial in scavenging the cvl inders .. and worth two to three additional b. h.p, The standard distributor is unsu itable, and should be replaced by 1he special competitions one. C-27H 77Gtl with matched advance curve. This is also ioeal for the seml-race cam C-AEA 731. Static setting for the ign ition should be one or two degrees before T. D.C.r using N6Y

plugs. Carburettor nssdles should be V3 with blue springj AUC 4587 .

Power output should now have increased from its normal 42.5 b.h.p. at 5 .. 000 to around 55 b.h.p. at 5 .. 800j more than the standard Mk. U 9CG unit. For ~ further increase fot competition it is wiser to increase capacity. At the same time we can use the fully floating gudgeon pins. There is a choice of pistons for tnis purpose; ideally, the 9CG bfock is a better basis. with bearings for all camshaft journals. Crankshafts have been available which enabled high r.p. m. to be used safely. C·AEA 406 was an improved-materia I s pee i f cat, 0 n wit hid e nt lea J me as u re men ts to standard; this was the 'red crank'. A safe maximum with this was .a round 7,500 when correctly balanced. (This is essentia I to the Jife of the cornponeot.) Always balance the crank with th~ flywheel and crutch. C-AEA 461 was a more expansive nitrided component for Formula Junior engines. Due to its th icker webs, t he centre mai n casting of the block had to be red uced in width by .063 in, either side. At the same time the centre cap was 'strapped' ~ This Js useful when buirding any rA' series brock .. and is simply a matter o-f rnachininq the cap flat and fitting a steel billet .5 ill. thick on top. Reta i n this by '0 nger high~ tensile studs and Nvlcc, or si milar. nuts,

If you are fortunate to obtain one of these cranks your r.p.rn. limit is considerably extended. A new Tuftrided crankshaft C-AEA 792 is now available from B. M,e =r probably safe to 7 .. 500 r,p.m. For a maximum- power unit the standard con-rods should be discarded. RepLacements are a choice of the standard 9FA Cooper type, 12G 123/' 26r wh ic h can be fitted with 12A 674 original pistons to a 2 .. 543 in, bore (.065 in, oversize), The Formula Junior pistons, C~AEA 639, have a slrghtlV domed top, requ iri ng special rods C -A EA 620 and 621 as the gudgeon pin diameter is larger tha n standard at .687 in. Bore size is 2.538 in. (4060 in. o/size). W~th the 3 in. stroke crankshaft the respective capacities would be 99B c.c. and 995 c.c: The con rods should be carefuHy weighed end-toend. Usjng the rig htest one a s standard, reduce the other to identical limits.

At this stage we require a more efficient cylinder head. The 12A 184 (9CG) is a

i

1

I l

i

~

12

,.. u

~

...,.J

(;aj

~

).,

(f)

"'-.I

h

rc

:,

Q

U

':>.

Ct:l ~ ~

CD ~

C£

.c(

LL1 ;,

f.!) ",

~

~ i

;

JIIIM I

Ul j

~

~ I

.-.... 1

~

Q.

,.. Ul

• &\ o

13

~. I

:1-.

''''I"

,~ ,

': ..

, ,

'j

~

, ....

,

~

", , ,

, , .

. , "

, ,

~

-c z a:: lLJ lX LU

I.aJ Z

-

o

Z IJJ

IUJ C!)

C

-

2:

"lLI I--

-

a:

a.. CIJ

-

~

14

improvement on the 9C type. Its capacity is greater at 26.1 c.c. and this wou Id give approxi matalv 9.8 compression witt, the - 0' top Cooper piston.

Much better stiU 'S the MG 11 CO/Cooper 998 head, 28G 222. lts inlet valve head is larger .. 1 .21 9 in. and the general castinq, is much better too.

Inlet ports should be carefullv polished to a good fin ish, and exhaust ports can also be polished to remove casting marks, etc. Carefu ~ Iy smooth the combustion chamber leaving no sharp edg es. The spark pi ug orifice is .a favou rite point to overlook; radi US the peak awav, and if va lve seats have a 'sunken' aope arance. blend them to the profile. Check that the ports blend smoothly to t he val ve seat and cut this to leave min irnu m area of co ntact: "kn tfe~ edge~ the valves in fact. Radius the noncontact areas of the insert. Unless one is extremely skilled, the production valves 12G 296 inlet. AEA 400 exhaust. should be polished but left alone.

This head has 28.2 c. c. capac ity and th is would provid e 9:1 wit h the 1 2A 674 pistons. The C .. AEA 639 piston does, howevert rise .020 in. a pproxi mate Iy above the com pressed gasket he ight, displaci ng all the neutral volume except the combustion chamber. With these, the compression ratio would be 10:1 approximately, A similar ratio can be obtained by machining the head as detailed earlier. to reduce its capacity; approximatelv .. 045 in. should suffice. A compression ratio of 11 : 1 should be regarded as optirn urn for tractability, and this would requi re a 22 c.c. head capacity with 12G 674 piston. 25 C.G. head with C-AEA 639 pistons; these, would be in relation to a pproxi rnatelv .095 in. and .050 in. from the head face.

Alternatively, th e latest Sprite M k I V (H AN9). M,G, Midget III (G AN4) head, 38G 399~ c:ou Id be used, with the 1 2A 674 piston. Its capacitv, at 21.4 c.c. standard, is approximately correct, and it would require only Hght potishinq. Valve sizes are increased to 1 .307 in let, 1 ~ 156 exhaust. This head would have to be relieved to be suitable with the C-AEA 639 pistons, thouph: compression woufd be 12.7;1 as standard.

The valve springs fitted to the 12A 184/ 2aG 222 heads are AEA 311 outer .. AEA

15

, L !

I

401 inner. The inner is fitted with d ~fferent col r a rs (AEA 402) at til e top and a Iso ona is fitted at die bottom (AEA 403),

With these springs/ with the C·A EA 731 and C .. AEA 648 race camshatts. you will not experience valve-crash until 7_000. The springs fttted to the 3aG 399 head (12G 1136 ou1ar/12G 1'37 inner) have a slightly increased rate. but this would be cancelled by the weig ht of the valves to some extent.

CAMSHAFTS & CARBURATION.

The increased cam lift and spring load renders the standard.ttming chain unsuitable

at high r.p.m. Convert to DUp~8X by using JS' type components; B.M.C, make a kit (C-AJJ 3325) which includes the countersunk hardened screws for the front plate, A lightened steel camshaft sprocket. to suit tho Duplex chai n, is C-AEG 578. Early rocker gear of the pressed -steei type should be discarded in favour of the forged rockers. C urre nt prod uction Cooper ·S· models have a new, I ighter forged type, 12G 1221. These have adequate strength for all purposes, and can be lightened still further by lightly radiusinq the bosses and valve contact area shoulders.

The shaft should be changed to C-AEG 399: this req u i res a n additional tapped pillar on which the locating screw has been sawn off fl ush with the threads, The pu rpose of this is that the locating hole, which can cause failure with excessive l oadinq, is movsd in to a point where it is supported on both s ides. At th e same ti me, the springs should be changed to specers (C~AE G 392) a nd washers (A EG 1 68) adj usted 10 locate each rocker c antrallv over the valve stem.

Whichever head is chosen, with a compression ratio around 11:1 you will now req uire better breathl ng .

The choice is between a pair of 1! in. S.UT (.090 in, jets, blue spring AUC 4687 and AM or CP4 (race) need les) or a 45DCOE9 Weber. The 1 tin. S,U.s could be mounted on the Sprite Mk IV manifold opened out and matched to the head ports.

H the Weber 1s used. the approximate

settings are: Choke 36

Main Jet 1,50/1.55

Correct jon Air Jet 1.75

Idling Jet .50/1.55

Pump Jet .60

Emulsion F2

Auxiliary 3.5 m.m.

Hoa t 7.0 m.m.

With either C·AEA 731 or C-AEA 648

earns. the C-27H -7766 distributor is suitable, as is the Cooper is'' distributor .. 12G 445_ with no vacuum advance. Stati-c setting should be T.O.C. and power should be around 75 b.h.p. at 6,500 T.p.m.

If the ign1tion and carburettor are carefully set, there should not be any overheating problem- It IS just as well to throwaway the thermostat and replace it with blanking sleeve 1 1 G 176. This does have a purpose r It prevents coolant rushing through the head withe ut circulati ng a fOU nd valve seats, etc.

When the bonnet is back on. irs just as weU to check there are no gaps between the cowling and radiator on Mk 1"5 or forward opening bonnets. In particular, the bottom of the radiator matrix should be checked.

Place your oil cooler (alwavs a wise invest-

ment) alongside the radiator .. not in front, a nd feed it with tne fresh a ir ~ ntakes, TRANSMISSION & SUSPENSION. What do we do with the power now? Welt, there is no point in wasting it with a sUpping clutch and ruining the flywheel into the bargain. The flywheel itself should be lig htened to the limits as shown (HI ustra1ion B). Don't attempt to exceed these limits. A fractured flywheel is expensive, .a nd you may never be the sa me agai n.

The standard six -spring clutch is useless for competition. Automotive Products can supply a 61 in. competition nine-spring assembly, under the foUowing part numbers:

Cover Assembly, 50333 ~ Drive Plate/ 45585/41 ; Re~ease Bearinq. 50345: This uses spacer was hers (six off) 50332. A 'deep bowl' version has also been available

..

which eliminated the necessity for spacers. Th is (;1 utch is perfectly su it~ bl e for most competition work, but specia I applications may need different d rtve n plates and in th is respect you should contact A.P. Competitions Department at leamington Spa. Little can be done with 9C gearbo)(es other

than to bring it to the 9CG closer ratios. The following table shows the com-

parison: 9C 3.628 1 st 9CG 3 .. 2

2.374 2nd 1 .916

1 .41 2 3rd 1 · 3 57

4.664 Rev 4~114

The conversion was ach ievec by usi ng the followfng pa rts : 1 st Speed gea r, 22A 426 ; Reverse gear, 22A 204; Lay Gear. 22A 207; , st Motion Shah, C-22A 228; 2nd Speed g~tu .. C~22A 226; 3rd Speed gear, C-22A 227. Top is direct in all cases. These gears are no longer available.

There are no alternatives for the 9CG box. The stronger spur-qears cannot be fitted, as the 1098/'275 c.c, gearbo~es have larger diameter mainshafts. The layshaft ShQV ld a I ways be replaced by the stronger. later type, 22G 673. The most satisfactory answer is to utilise the 1098 c.c. gearbox, 38G 374. Baslcally stronger (the 12G 673 ~ayshaft sh ou Id still be fitted}, th is box enables you to fil1he noisier but stronqer spur-gear set. C .. AJJ 3319. Ratios on them are as fall 0 ws: 1 st, 2.573; 2nd, , t 722; 3rd, 1 .255-

Fitting this box also enables the 7 i in. 1098 competition clutch, C~ B HA 4448_ with driven plate C~BHA 4449, to be used, as the bell housing has more room. This requires the th icker mou nti ng plate. 0 bviouslv the larger flywheel from the 1098 model has to be used, only 12G 180.

The ~A' Series fear axle serves its purpose well a nd has a wid e choice of ratios:

Assembly Part No.

ATA 7239 ATA 73~3 ATA 7326 ATA 7093

2A 72:10 ATA 7230 ATA 7073

Riley 1 .5 Competition Std Sprite Minor 1000 A.35

Post Office Post Off,ce Minor 1000

Some of these can no lonqer be obtained.

other than as complete cliff assemblies, or secondhand. It is rare for the actual crownwheel and pinion to be damaged so a search round breakers yards often provides them cheaply.

Later Sprite axles, after HAN 7 ·24732/ M idg et G ~ANZ 1 61 84, have a different diff-assem b'v. with the filter on the case The nose assembly is interchangeable. (onlv 4.22, 3.9 and 3.7 can be obtained for this carrier assembly) but this would result in no levef plug. The older assemblies can be fitted in later axles whsn there is a su rfeit of fillers. I f yo u are i nterchangi ng a

. crown-wheel and pinion onlv, you must beware of the difference in s-ome pinion

3.727 3.9 4.22 5.55 4.875 5.3 5~3

16

17

~ .. .. .

~>:':

~.

shahs. The inside diameter of the pinionbearing can be either 1 ln. or 1 • , 875 in.

In all cases the HAN9/GAN4 axle-shafts .. B T A 607, shou Id be fitted. A speci al competitio n shaft is also available In Hmited quantlties. under part number C- BTA 940~ Limited-slip differentials, while expensive, red uce the strain on drive -shafts over bumpy surfaces, and eliminate power lost

throug h spinning wheels: These were obtained from 8.M.C. (e-BTA 696 or C-BTA 881 part numbers) I or the I atest type eve il ~ able C - BTA 1226.

Suspension was always good with AN5 series a nd their early I ig hter bodies. It is not wise to lower the car too much If it is used for normal roadwork. Cornpetltionwise, the fro nt can be lowered by usi ng spacers above the spring pan; these in-

crease the fitted length and reduce the pre-load of the spring. The springs fjtted to latsr 1098/1275 models are increased in rate by 50 lbs whichr with spacers .. would not lower the car qu ite so much .. yet be stiffer. It is possi ble to get them cut and groundj thus lowering the car without spacers at all but this should not be attempted wi~ Iy· n illy. The coils must be ground accuratslv to stress the working coils correctly; approximately 0.2 in. reduction would reduce the rate bV 50 Ibs. A number of roll bars can be obtained varying in diameter from 9/16 in. to i in, Remember that stiffening and/or lowering the front increases understeer. This can correct cverstser caused by lightened bonnots. etc. Dri II the bottom links fo r the fittingSj or altarnativelv, you can obtai n bottom Ii nks ready ddlled.r AH A 7029/7030. Competition shock absorbers are availabte that effectively control the stro ng er fat e s p r i n 9 s. R epl ace m ent val V9:S can be obtained but 1hese should only be used when the oriqinal equipment is in good condition. Mount the shocker upright, and pump it a number of times to e:.tpel all air.

Jt ls not possible to get lowered springs tor the rear quarter elliptics, A stiffer. heavyduty type, AHA 5468/ is available with thicker but fewer leaves. A popular 'mod' is to reduce the number of leaves on the standard sprinq, ag ai n especiall V when Ught fibreglass rear ends are used. Wedges

'j.

~" ....

~. ~.

..

f.

18

to change the ride heiqht, by .angling the springs up or down, are available (AHA 6456). Adjustable shock absorbers were svai I able for quarter elliptic models after HAN5-4333. C-AHA 6453/6454. At this point the mountings changed. These shock ~a bsorbers are no tonger ava ila ble but later 7906/7 type can be used by changing the links (43 in. on early models) and using a 5/32 in. spacer between the shocker and chassis.

The axle loc~te~ it$elf quite well but owners often sxpanance wheel lift In corners, attempting to combat this by conti n uously stiffeni ng the shockers. Practice often proves that the opposite wUI effect a cure .. more so with softer springs.

Whe-els present a problem .. in that the rim- width continuos throug hout the range at 31 ln., both disc and rim type. 8.M.C. only make a 60~poke wire wheel (C-AHA 7573) with 5 in. rim for competition, Stronger 3! in. disc wheels .wlthout perforation. were introduced under part number AHA 6455. The practice of cuttinq and weldi ng wheels ~s undesirable ... as there is no way of checking the stress limits or accuracy ~ for 1969. suc~ w~eels will in any case not be permitted by scrutineers The expansive alternatives are allov Or magnesium wheels. These can provide rim widths to choice which do not require spacers. Spacers are always undesirable. as they lncrease the load shared by studs. and hub bearings ~ a 1 in. spacer can in ~ crease such stress by 25 per cent. A 5 in. rim is a good medium for ths all ... purpose owner, but for a fun circuit car. the lowprofile Form ula 2-style tyres req u ire 7 in. or 8 in. rims+ These present problems peculiar to themselves! not 1east being premature failure of hub bearings. There are no eccsotable mods for the front bearlnqs, but it is wise to fit the later stub axles BTA 744/745. which have a stronger specificati on.

Rear hubs also present a problem. They must always have the bearing lock nut absol utely tight. Any play will resu It in the bearings turning on the casing and in the hub itself. This will fracture the half-shaft flange under s~d~ thrust, Various mods have been tried, including special hubs with an additional inner bearinq. White

~ ~~~~~~~~~ r 9

•

-

L&J Z

-

(!) Z LU

I-I.JJ (!)

o

-

:J:

"w .....

-

a:

Q.

m

.'

_.

I _

I'~ 1-, :~ .-.::

~

19 ~

~

..

~

r- ~ .".: ' ..

~'

these do stiffen the hub they introduce greater stress on the casinq, leadinq to failure' You can't win.

Brakes are quite suitable for normal roadwork but hopeless for competition work, Ferod 0 VG 95 li n In gs help red uce fade, but require m ore pedal effort. This was dealt with On the Warw.ck-built 'Sebri ng' cars by he mologati ng a Girl i ng 8 iii, disc/B in. drum system for use with wire wheels only. All the works entries were so equipped. This had separate rnaster-cvli nders for cl utc hand brakes.

The sta ndard system has a lwavs been Lockheed, and Healev's also introduced a Lockheed conversion for AN5-6/GAN 1 models, This was a good improvement for disc wheel cars, using PL capltiers. The com bin at io n master - cyl ind er h ad an extension fitted. and the resid ual valve cha ng ed. 0 iscs were 8475 in. di a meter, larger th a n the Girl i ng system, and it was much cheaper. To convert early models now presents no difficulty. for the production disc brakes introduced with HAN7/ GAN 11 models easily adapt. The mastercylinder should be changed to BHA 4365, as well as the calli pers, discs, hoses .. etc, You must ensure the hoses do not foul when the wheels are turned, lock to lock. Special OS 11 pads (C-AHT 16) are readily available for these. but you should retain t he standard I ininqs on the rea r for balance. The swept area of these discs ts some 25 per cent. greater than the special GirHng set- up.

During these early vears, apart from the Warwjck.-built ~Sebring' (so named after their successive class wins and identified from normal production cars by the special Donald Healey chassis- plates) there were also limited producn on specials by Speedwell, Doug Wilson- Spratt's Hea ley Centre (W,S.M.) and the Abingdon-built Midgets campaig ned successfully by D ick Jacobs. These appealed by having pretty aluminium bodies grdfted on to the Sprite platform. The Donald Healev and M,G.

" " ~,

· ' , ,

•

"

~,

~.

·

I

·

,

u

"

r, ~

•

20

cars were in some cases homolog ated within Appendix "J" requlations, as were the Speedwell versio ns.

Various special engine capac ities were introduced In these competition versions for particutar events, B.M.C. u nits from t"ei r development had the XS P prefix, with various strokes and bores, some of which are now in private owner's hands. Dimensions are as follows ~

960--= (948 .. 020 in.) 2.498 in. x 3 in. 995~ (946 .060 In.) 2.538 in, x 3 in. 9B9-=- 2 .. 82 in. x 2.438 in.

, 098=·· 2 .. 667 in. x 3 in. (short stroke) 1.75 in. mains

1138- 2.59 in. x 3.3 in. 1293= 2.8 in. x 3~2 in,

2 in. mains 2 in. maills

Speedwel! also had their own developments; of notable interest was an 1100 un it with si x-port alloy head and uSing fO('11 motor-cycle AMAL carbs. With dual pumps operating a scavenge system, they were supplied by a weir principle. Alexander E ng lnes also introduced a spacial version complete with 'speed I stripe in tuned and super-charged form,

Alloy h esds ware avail a bl e in norma I or six-port form, most of which were liable to either warping or porosity, Biggest power gain from a single item was th e crosstlow head, also in allov and very expensive. Unfortun()te1Yl these were liable to lose guides at inopportune moments, leading to even more expensive repairs.

The supercharging method is often adopted since it can be cheaper than advancsd conventional t uni ng, but I feel you should still strip and fully balance the power u rut. The C 7 5 B 02 Shorracks was a fou r- va n e type unit, d riven at u nder era n kshaft speed. This had a displacement of 730 c.c per revolution. Using a single H.4 , ! in. S, U. wit h 1 00 in. Jet and R . F, need le. the power output was around 68 b.h.p. The "Sebrinq' models also offered one on a race-tuned engine, giving around 90 b,h,p,

CHAPTER 2

The l098cc Sprite Midget

Durjng production of the Austin Healey Mk 11/MG 1 at HAN6-24131JGAN'~ 16183. a larger power u njt and baulk-rinq synchromesh gearbox was introduced. These HA N7/GAN 2 versions also h ad the disc brakes (referred to eartisr and still current) and nalt-etllptic rear springs. WJre wheers beca me a factory option instead of the specialised conversion.

These early 1098 models (10CG Prefrx) had 2.543 Bore "/ 3.296 j n. stroke, sti" retain.ng 1475 in. majnb~arjngs: no special crankshafts were available. Unsuited to tuning .. a peculiarity was locet overheatinp .. causing the core-plugs to pop out with increasing regularity.

Other than mil dly pol ishJ ng t he cornbustion chambers. these units are best 1 eft untouched.

Introduction of the H~AN8/GAN3 models. in March, 1964.. with smoother body tine/" curved Screen. wind-up windows and reposition ed instrument pa net also brought the 1 0 C.C I 1 098 en gi ne which, with 2 in. main bearinqs, was much more robust. Basic compression ratio 8.9 .. wjth the same- head capacity as the 10eG at 28 .. 29 c.c, in let valves were Iarqer, h OW~ ever. at 1.219 in. diameter. the head being basicalIy identical to the 998 Cooper 28G 222.

The efficiency wHI be irn proved by carefully pOlishing and radiusinq sharp edges~ N EV E R raoius the combustion chamber I head face angle. The throat width In iii ustration A 1 can be take n (0 11 /32 in.

.~

on this head .. with extreme care. It is stiU possible to obtain the domed competition inlet valve (C-AEA 628) of 1.280 in. diameter to fit this head. with the seat suitably ground out.

Special crankshafts are no longer available for these models .. but suitablv balanced as a complete assemblv, with crutch, lightened flywhee! complete, it shou Id be ·safe" to 7.000 r.p.rn. If you have a clank reground undersize or change any reciprocal parts (clutch, flywheel) you must rebalance the whole assembfy. R ~ p.m, should be rest ricted with undersize cranks also.

Pistons present a oroblem due to their very small compression height (Chart U ). What we need are rods .15 in. shorter between centres, but they don't exist r

For all- round use, the compression can be lncreased to 10:1 by removing appr-o:(i~ rnatetv .060 in. from the head. To get the full benefit, fit the SSG 229 cam (the block has three bearings as standard); this requires the com petition distributor, C-27H -776. With ignition at T. D.C. and sta ndard need~es, the power. will be over 65 b. h.p. at 6rOOO r.p, m.

Pernovinq the air cleaners w;U need a mixture correction which i nvolves fjtt~ng AH2 needles and red springs AU C4387. Replace the cast exh a ust manifold wjth a three-branch type, as before. The earlier valve spr~ng and tuning gear points still apply. Competition valve sorinps. increasIng the total rate to 165 Ib:S. . s wiH enable

21

(J)

a::

LLJ

I-

~ to-

W

,.

J rx

UJ

OJ

It:

-c

u

:J

en

z

-

~

t-- •

I

I

I

j

1

v

~

.....

en

L..".

0

:::...

~

, §

\ a

u

\ ;:....

r::Q

I

)

/

-- 22

------ ....... ,. - 8! J DIA --~-~ __ ~

MACHINING LIMITS FOR LIGHTENING 948cc FLYWHEELS

23

the valve bounce point to rise from 6.250 to 7,350 r.p.rn, (part no's C-AEA 494/ C· A fA 524). lig hte ned cam fel lo wers C-AEG 579r help to lessen the load. too. The competition clutcb rnenti oned eari~el" sho uld be fitted, bu t for spec i al pu rposes .. a more suita ble driven - plate (cemented and rivetted) would be advisable. Refer to Automotove Products .. Leamington Spa.

Sea rchi ng for more power p wit h the bottom end des It with as before (fu' ~yfl oati ng sma 11- end con - rods sta ndard) th e competitions C-AEA 731 and C-AEA 648 camshafts are ave i I a ble. Com pression shou Id be 10.5 (23 c.c. head) or 1 1 ;, (21.3 head), Ideally one can use the latest HAN 9/GAN 4 cvl inder head; the capacity will gi\le 1 1 :1 exactlv, and you have the i mmed i ate ben efit of larq e r inlet a nd exhe ust valves,

With the 731 and 648 earns, in particutar the latter r it will be essential to check each valve on lift. W-th the head fitted (using an 01 d gasket) obtai n at I east .060 in _ clearancs by relieving the blocks with a cutter, Check valve sprin-gs too ~ adequate clearance between the centre cads when the springs are compressed ~s .060 in.

These amounts may seem excessive. but at h ig hr. p, rn. with valve float occu rring and heat expansion effects. it is possib Ie for cont act to occ u r between va Ive and block. Th is imposes considerloads on va I ve gear, push rods, ca m followers and ca m 10 beg , Val ve spri nqs becoming 'solid' at fun lift have the same results.

When reboring bear in mind that 4060 in - oversi Z8 is 11 44 c. c. To exceed this takes you out of the popular 1150 c.c, Class,

To get rnaxirnu m power, fit 1 ~ In. S, U. carbu rettors to the sta ndard rna n ifold having carefutly polished it to the correct

diameter and matched it to the head ports; kits C-AU D 194 and C-AJJ 3304 provide all necessa ry parts, Flare pipes in pi ace of the air- cl eaner will aid t he venturi effect. Use No, 6 need1es, No.7 with th e 648 cam. Using t he competition distributor and a static timing of 2 ·~-3·~ B_T. D.C. a useful 80

b.h.p, at 6.000 r.p.m should be available, dependent on the camshaft used. For absolute maximum use a 45DCOE Weber carbu rettor. B, M. c. can su pply a manifold a nd kit (less carb) for this pu rpose {C -AJJ 3360} and although it will be- necessary to experiment a bit suitable setti ngs should be as fo 11 ows ~

Choke 38 rn.m.

Main Jet 1 .85 1 .90 rn.rn,

Air Correction 2.10 m.m

Slow Running 50 F2

Pump Jet .60 m.m:

Auxil iarv 3.5 rn.rn.

Float 5 rn.rn.

A rae i ng exhau st man ifold, with rna K imum extractor effect. and I a rge bore o uti et sh ou Id be used ( C - AH T 11), The HAN 9/GAN/4 pi pe and silencer will match up with this for road use. M eximu m power, with careful attention to timil1g and carbs, should be a peak 85 b. h.paround 7,000 r.p.m,

Front suspension is dealt wit h as before, but the rear sprinqs, be i ng half-ell i ptlc. can be repl aced by lowered on 85 (C. A H A 8272) for racinq. The rear sprinqs were U prated 50 I bs. just before the 1 275 versi on was i ntrod u ced. an d thi S shou Id be remem bered when a ti breg lass rear is fitted, for insta nee. Adjustable rear shock a bsorbers for these mod els 1:1 re part num hers C-AHA 7906 R/H .. C-AHA 7907 L/H.

No changes are necessary to the standard braking system. Retain the normal linings on the rear, and fit D, S. 11 Pads (C~AHT 16) to the front discs.

24

CHAPTER 3

1275cc Sprite MK4/Midget MK3

From October 1 966 these ever- popular models grew up a little more. The HAN 9jGAN /4 acq u ired a I arqer, de - rated version of the Cooper ~S' power unit/ allied to the previous model's features- Block design differed in that th-ere were no covers 9 ivi ng access to ca m followers (u nchanged). Main bearing diameter remained 2 in.

Cvlinder dimensions are bore 2~78 in. x stroke 3 .. 2 in. ; smaller valves were used t ha non the · S' at 1 .309 in, i n let and 1 .21 9 in. exhaust. These 1275 units have 8.8:1 compression as standard. using a piston wit h extremely larg 8: dish f 11 .. 1 3 c.c, A power output of 65 b. h. p. at 6/000 t, p. m. is obtained in standard form,

Early models came out with standard rnatertal c r ankshafts, this quickly being amended by a special batch of nitridedtype marked AEG 517. These were replaced in production with a nitrid ed production crank (AEG 565) and this continued until late 1967. when a t uftrided version. with ths same markings. was introduced. Th ls Is considered to be perfectly satisfactory for air purposes. The con-rods (AEG 520) are extremely goodactually an improvement on the Cooper ·sr types, Other than earsfullv matchlne them for weight/ no problems should occur and nothing else need be done to them.

Remove the head and ca refu lIy polish the combustion chamber and ports, do not alter the shape. CarefuUy blend the inlet manifold and head ports, retaining

'j

the sleeves, Polish out the manifold to accept the 1! S.U.s C- AU D 194 (No.6 needles blue springs) with fitting kit (C-AJJ 3334 for this model) and use flare pipes C-AEA 485 (or C -AHT 10), Fit the 'arge bore exh a ust man ifold (C~AH T 11),

Static ig n ition sho uld be set arou nd 8;) 8,T. D.C. This should provide another 10 b.h.p, to give a total of 75 at 6fOOO r.p.rn. Va!ve bounce with the standard springs occurs around 6~ 700 r.p .. m.

To gain more power we require G cam, and the opportunity should be taken to strip the power unit. H ave the tightened flywheel (C -A HT 7Q) fitted f with the competition crutch (C-AEG 546L drivenplate C-AEG 547 (6; in. diaphragm type) and balance the complete assembly.

Carefully match the connecting-rods AEG 520, These now su persede the earlier 'S' type. as mentioned earlier.

The Cooper ~ S' pi sto n ca n be used in e it he r dish ed ( 9 .75 ~') 0 r fl at top < 1 2 : 1 ) form, The dished- type (8G 2434) are possibly best. Bored i .020 in. gives '293 eTC', while to exceed this would go out of the 1300 c.c. class (.040 in 1311 c.c.). When rebu ild i ng use VP3 materia I (Vandervell) for rnai n and big - end beari nqs, The lightened cam-whee's (C-AEG 578) and cam followers (C-AEG 579) should be used-

The camshafts in the 12CC series differ from normat B, M.e, practice. in that a 'spider' drive replaces the older pin-type to the oil pump. This eli mi nates drive

;

.

\':'.

-

\

.J

25

failure, A drive flangar 12G 7291 is necessary for the end of the cam.

Choosing C·AEG 567 for road and competition use, use distributor C-27 H- 7766. and T.D.C_ static ignition. Remove .060 in. from the head face to get 16.4 c.c, com bustion c ha mber capacity a nd a com ~ pression ratio of 1 1 tS : 1. Power is increased to 83-85 b.h.p. at 61000 r.p.rn . .! and is usabl e to 6.500 r.p.rn.

Fittinq a Cooper 'S' head (larger inlet and exhaust valves). similarly polished and mach [ned, wou Id give arou nd 90 b. h ,PJ at 6j500_

Usinq the C-AEG 529 cam provides no power below 3jOOO r.p.rn. but pulls "from 4.500 to a peak 95 b.h.p. around 6t500 with 85 b.h.p., still usable. at 71500 r.p.m The longer cam penod puts less stress on the springs and thereby extends their valve bounce figure with C-AEA 652/524 springs.

To obtain maximum power, still using the 529 cam and 8G 2434 pistons. have

the standard head modified to accept the rarger C-AEG 544 inle1 valve 1 .. 406 in. CarefuUy match the combustion chambers and polish them thoroughly; capacity should be reduced to 16.4 c.c, (.060 ln. from head face). (Altarnativelv, a race head can be purchased. C-AHT 2211 with this work completed.) Use Cooper JS' head gasket AEG 226 (3.8 c.c.). With ignition and distributor as before, replace the S.U.s with a 45 DCOE Webert settings:

Choke 38

Main Jet 1,95

Air Correction 1 .. 75

Idling 50 F2

Pump Jet 60

Emulsion F2

Auxiliarv 3.5

Float 7 rn.m

Maximum power should be 104 b.h.p.

at ',.000 r.p.m. evenly rising from 5jOOO r.p.rn. odd,

These results can only be obtained by careful attention to detail in preparatio n.

26

r

I·

:.I

CHAPTER 4 1

----------~--------~~M~G-A---~

,~

''I

The first production sports car from Abingdon with a B_M .C, power unit was a very pretty roadster which departed completely from the traditional MG. Available in coupe form also, this model was desiqnated MG A, By 1962 over 1 10,000 models in various "forms had ganeto owners around the world,

The co nventiona I box section chassis was retain ed and gijven a new -look stream & fined bod v- The 1489 c.c. power unit was borrowed from the Austin A50/Morris Oxford range, output being increased by stepping up compression to 8.3:1, An improved cast exhaust manifold, twin 1 ~ j n. S- U, carbu rettors and ca rnsh aft (chart B,1) with Increased I tft and period. contrlvec to produce 68 b.h.p. Bore and stroke were 2.88 in. Y 3.5 in, The head capacity was 38.7 coco nominal and piston dish 4.85 c.c, Valve sizes were unchanged at 1.5 in, inlet. 1 .281 in. This output was transrnittad through an 8 in. single plate clutch to the gearbox with ratios:

3rd 11374

2nd 2.214

1 st 3.£4

Top gear being direct of course. These did not change and indeed were current to the MG B until the Mk II alt-svnchrornesh gearbox was introduced .The three-quarter f~ oati ng rea r ax I e was fitted with a 44 3 f~nal drive (4.55 optional) relative to 17 rn.p.h. per 1 fOOO r.p.m. (16 :4 m.p.h 4.55),

Braking was via 10-inch drum brakes wit h a total area of 1 34.4 sq uare inchss : nevertheless, these proved efficient.

OriginaUy the powef units had narrow throats and ports, the earfy version having mods to tappets r push rods and piston. after 15GB 38484. These later pistons have stiffer gudgeon pins.

15G D units have atl these modifications plus a new gearbox with repositioned starter motor and the slid ing spli ne prop shaft replaced by a Hardy Spicer jolnt, output then being around 72 b.h.p. at Df700 r.p.m.

Before you attempt any modifica1ions

carefulty examine the vehicle .. some have 15 birthdays and probablv as many owners' You must ensure it is basically sound. Tile. MG slogan has atways been 'Safatv Fasf/" let's keep it that way,

Reference to the ea rlier 'Spridgef sections will find suggestions of suitable equipment, Most car enthuslasts soon gather a good selectio n of tools a nyway I N ever waste rna ney on tools, buy top quality every ti me,

The first step is to remove the cylinder head, strip it and clean all parts. P055ib~y it may show signs of being modified previously, this work should be checked,

Early versions should have their inlet ports opened out as illustrated in diagram Ba. 1. Also grind out the exhaust throat to 1.170 in. --- 005 in, a nd shorten the exhaust guide by .094 in-, grinding away the boss 10 flow the port.

This would bring t he motor I nto line with the later production versions. A special material exhaust va1ve was fitted to some models (' H 1025). and shou Id

-

•

27

.~ .... "i:

,

I

I

inlet port

1~6in make metal template to this shape and grind ou.t inlet port throat at section A.A. to allow pLate to just pass through

, -,

it"

if -II

,

!

I ~

,.

!.-.

t:

:oc"

e

r

t'

remove by grinding

shorten this end of guide by 332 in

bore exhaust throat to ~ :~;~ in DIA

ENLARGING PORTS ON EARLY MGAs 28

always be fitted as this. has an improved surface finis h,

We are I ooki ng fOr sornethi ng more. but the snag is that no special crankshafts exist for these models. The standard one carefully balanced is safe to around 6.500, but continuous running above 6,000 r.p.rn. is not really on. Con - rods a lso li mit the r.p.rn. as they are the clamp bolt type/ but here at least, an alternative exists.

For a mild increase the head should be polished a nd all surface i rreg u la riti as removed, Where valve seats have been -fitted, blend them into the combustion chamber roof, The valve seats in the port should be gently blended back also, The centre peak which creates turbulence should be gently ground to a 3/16 In. radius and a ny sharp edges radiusad away. Do not spoil the ch a rnber walls or g asket overlap. or fail u re will result, Balance the chambers (see Sprrdg et sectio n) and return to t he nom i na I 38.7 c.c, capacity by lightly grinding the face (.01 0 in =- 1 c.c, a pprox.}. The face shou Id be lightly tinlshed in an y case to ensu re it is absol utalv fl at. Match th e inlet ports carefully to the manifold and smooth out the manifold without increasing its diameter, Using a slightly richer needle. the CG. and keeping tile standard ignition. th is stage wi II show ami Id inc rease to around 75 b.h.p at 5.750 r.p.rn,

Fitt~ng the aid Riley 1 .. 5 camshaft (4aG 184) wah red uced cam I ift and ti ming (see chart B 1) i ncrB~S8S power in the low and mid range at the expense of performance above 5.000 r.p.m. Tappet clearance .015 in, and iqnition should be around 4 It B_T_D,C.

Assuming that we are aiming to get the maximum possible for road use. then remove the power unit. H avj ng st ri pped it and cleaned all parts carefully, examine the block and cam baa ri nqs:

The crankshaft should be exarni ned and scrapped jf indo u bt. Regrou nd cranks are not a good prospect I Better to start with a new one and have it fully balanced with flywheel and clutch pressure plate, The strongest era n K is t ha t fitted to tile 1622 c.e. versio fl. but this req uires the centre main housing to be machined to reduce its width.

Con-rods should be carafullv matched and weighed end to end. A hig hly pol ishad

29

fi nish increases surface strengt h.

For increased co mpression for road use.

British Leyland Special Tuning can supply the flat top piston C-l H-1178 to suit the standard rods, Th is wou I d give 9: 1 compression, Static iqnition at 4 ~ B.T.D.C_ and the standard cam would increase output to around 80 b.h.p,

Harder N3 plugs would be required for fast motoring,

A higher compression is obtained by using the special C ~ 1 H -11 80 pisto ns (cha rt 111) that are also avail able from Special Tu ning. As these are competition pistons th ev h ave extra tolerances .8 nd should only be fitted to bores with minimum wear. Oversizes are available If reboring is necessary.

These pisto ns must be fitted correctly with the deflector face towards the plug and req u ire the spec i a I Twi n - Cam rods with large diameter solid small ends, C .. AEH-S42/644. The rods are difficult to obtain, remain~ng stocks being disposed of as matched sets (C -AJJ 3357). If you can get these they are superior to any other type, Aga in they should be carefully balanced.

With the pistons fitted, check their hsight by putting plasticine on the crown a nd pi acin 9 th e head in nositio n (use an old gasket), Clearance should not be less than .060 in, Maxi mum power she uld now be around 85 b.h.p.: bU1 can be further increased by larger carbs.

The MG B manifold 12H 911 is an im .. provement on the sta ndard version a~ it has a larger diameter bafance pipe (t in.). Match this: to the cylinder head first and then fit 1:i in. S.U, HSs {C-AU D 229). Use studs long -enoug h to fit the thick Neoprene gasket C -AHT 178 and retain the carbs with double coil spring washers and two locking nuts- This method absorbs vibration and reduces frothing in the float cham bars at h rg h r .p. m. Use the ra m pipes C - AH H 7209 to red uce turbu Ie nee and create a vent uri effect.

Competition and higher revving will demand additional fuel flow. The standard pu m p shouJd flow at 9 g s lions per hour but if it's clapped, then it may only pass 6 gallons_

In maximum racing tune the units could easily require 7 -8 gaUons per hour; thus

~ .j

,,",

. :.

~ f.

~. I t .. .... :

~' ..

. ,

30

W ....J )(

-c

~ ~ w a:::

CD C!)

:2:

~

a:: <C LLI

01 c( (!)

2:

fuel starvation and weakened mixture could result. Pump AUA 73 has ample -flow rate but may need alteration to the bracket to fit.

Static ig n ition woutd be a oprox. 2 0 B.T, D+C- The 1 i in. varbs should have .. 100 in. Jets with KW needles. Maximum should be just below 90 b. h. p. at 6,000 r.p.rn, Tappet clearance in all cases should be 1015 in. Maximum power being davsloped around the adopted rev Ii mil of 6,,000 r.p. m.

Other camshafts should be considered with care as the power is always higher in the rev range. Ths C~ AEH 714 camshaft would give another 5~8 b.h.p. at the expense of torque b8~OW 3,500 r.p.rn.

Don't fit heavy valve springs unnecessadly: the standard 1 H 722 outer/1 H 723 inner suffer bounce around 5.800 normally, The different profile of the 48G 184 cam restricts performance above 5_200 whatever springs are used,

On the other hand the C-AEH 714 .. as used ~n the 1961 Sebring cars win not encounter valve crash until approx. 6 .. 400 r.p.rn As this .5 about the tolerance we want, stronger springs would only load camshaft and foflowers for no reason or gain.

With the standard SSG 252 camshaft the standard outer 1 H 1111 .. with C·1 H 1112 inner (total load 174 I bs.). wou Id extend valva crash to a similar fig ura (6 .. 400 r.p.rn.).

It should be borne in mind that careful attention to the valve gearr reducing the operative weight ov grJnding surplus metal from rockers, will also postpone the valve crash point. A 10 per cent. reduction would enable the standard springs to be retained in this instance, There are phys~cal lirruts though so do not go mad with the grinder (down .. Myrtle, down ') and have .a rocker shear under load.

Fitting the 1 H 1111 /C-1 H 1112 springs with the race cam would extend the valve crash point 1:0 around 6.800 r.o.rn. A very shortterm prospect that would be l

The later 1 SOO Mk n had a 1622 c.c. unit and the head has sliqhtlv larger velves: porting is also lmproved, This hsad could be fitted to earJier models where every ounce of power is sought. By the wav, its combust jon chamber is 43 c.c. and

"1 ,I

c

1

1

f

~

approximately .045 ~ n, wou ~d need rernovi ng from the head face to obtain the: 1500/1600 M GA volu me of 38.7 c.c, nom i na I. With th is I arger varve head the r ace oa mshaft 714 a f"I d ign ition at 2 ~ B.T_D.C. It should be possible to achieve 100 b.h.p at around 6,000 r.p.rn.

""

~

Having dealt with the: power unit we move to the clutch, Agal n we beg In by checking it carefully.

Early cars up to 1 5G B 16225 were fitted with Black/Yellow pressure springs; replace these with Cream/Green 1 H 1024s lncreasinq pressure by some 15 lbs. The cornpetltion clutch plates are no ~ anger obtai nable throu gh B riti sh t.evla nd _ but Borg and Beck usually have the answer to most clutch problems,

The gearbox can be improved by converti ng to c lose ratio gea rs us~ng the fallowi ng parts:

Lay Gear C-1 H-3298

F~rst Motion Shaft C -1 H ·3297

2nd Speed Gear C·22H-1094

3rd Speed Gear C-1 H -3300

C -22H -'094 is a modified version of the superseded second speed gear C-1 H-3299 and must be fitted with 22H-249 b.aulk rtng.

Ratios would now be:

3rd 1 + 268 (1.374)

2nd 1. 65 (2.214

1 st 2 . 45 ( 3 . 64 )

2 nd 1 ~ 65 ( 2.21 4 )

Standard rati os ~n brackets ~ top being direct.

For cornpetltion and acceleration the 40-55 final drive ratio tS best unless the MG B wheels are fitted to obtain wider rims. These are smaller olarneter and even though the wider rims permit larger section of racing rvres. the speed red uction may prOVB too 9 rea t.

Final drive ratio's have been available as

foUows:

4~55 : 1 SSG 284

4.3:1 (std) SSG 243

4 .. 1:1 (1600 Mk II) C .. ATB 7240

3 .. 9 :1 BTB 414

Possibly ths standard 4.3 ratio will be a happy medi urn. For road work the 4.1 or ear!y MGB touter 3.9 ratio would prove best.

I

j

01

~

,

I

i L\

"

-

•

.j

31

M G B wheels fitted as sta ndard are:

4J x 14 Steel 0 isc (correct (p.c.d.) AHH 6132 5J x 1 4 Steel 0 isc (correct (p.c.d.) AHH 8112 4j-J x 14 Wire (60 Spoke) AH H 6487 5;-J y 14 Wire (70 Spoke)

C-AHH 8530

For road work the speedometer will need to be correct ec. Retu rn it to Messrs. Smith ~ ndustries through your distributor. quoting the tyre si ze and f n a I d rive ratio.

The standard braking system should bethoroug h I Y overh a u led, repl ace the hoses on pri nciple, Exernl ne all met al pipes for possible chafing or rust, replace any questionable leaks .. exchange cylinders are preferable to bodge jobs with kits of rubbers.

BRAKES & SUSPENSION.

The brakes can cope with the extra performance but brake fade will be noticed. Prevent this by usi ng the Ferodo VG 95/1 lined shoes (C~8 G 821 5) st ill avai Is ble through Special Tuning. These require more pedal effort which a servo will compensate for, but servo assistance is a matter of inoivid ua I preference on a hig h psrfurmancs car.

The MGA's most appealing factor to the enthusiast was its handli ng _ Relative'v stiff all round. it was designed with oversteer which is easily corrected. This warns the over- indulgent before thsv can lose it completely.

The only change to the front was that the early springs were changed after 15GB 15152. The coil and wire diameter were increased and the free length reduced; fitted length and load remained the same. This spring AH H 5546 was fitted to aU MGAs1 except the Twin-Cam and Its push rod version. the 1-600 De Luxe. The rear sprj ngs rerna ined sta ndard t hro ug h the series also; the part number is AH H 5461 .

Modern radial and racing tyres extend the limits of adh-esion so that for fast motor! ng or competition a more 'neutral I handling is required. We can achieve this. by stiffeni ng the front end. Additiona I shock absorbers are available for the 1500; 1600 models, C-AH H 5609 for dght hand drive; C-AH H 5610 left hand. Theserequire spacer blocks C-AH H 5570 and

mounting brackets C-AH H 5608;5609~ stocks of which are exhausted. Drawings of these are sti II suppli ed by t he Special Tuning Department at Abingdon with the shock absorber, Existinq shock absorbers can be stiffened by fitting the MG B valves, part number C-AH H 7218.

A sim ilar eHect is obtained by fitting ali anti-roll bar. Under no circumstances fit both bar and tweaked shockers. Check all the steering parts carefully at the same time as you are work ing on the suspension.

For competition or motorway conditions an oil cooler-if not fitted already-should be obtameo.

Concurrently built with the push rod model was the 1 588 c.c. double overhead cam Twin-Cam. This project was not entirely su ccessfu I. As it was co nsidered to be developing maximum pefformance at a pproxi mately 110 b.h. p. at 6.700 no specia I parts were avail able.

Some two thousand were bui It between , 958-60 and they stil! give service around th e wo rid. An enthusiast in America recently purchased a brand new power un it in its orig inal craie I Another innovation was all round disc brakes by Dunlop and centre lock dJSC wheels. The front suspension spri ngs were numbered AH H 5789~ and are now fitted to the B GT to cou nteract adoiucna: vveig ht. Later chassis appeared as 1600 De Luxe models using the 1588 push rod unit but still having the all round disc brakes and centre lock wheels.

I n May. 1959, the normal production MGA was given increased capacity with a 1588 c.c. version of the 1489 c.c. unit. Virtually it was bored out and little else. It is pos-sible to overbore the early model 10 2.97 in, and fit the 1600 pistons 12H 178, at least gaini ng additional torque. Standard output was 80 b.h.p. at 51600 r.p.rn.

Lockheed front disc brakes appeared on this model" with the I Ovinch drums remaining at the rear, using sliqhtlv narrower shoes. Apart from capacity it was identical 10 the previous model and all the previous mods apply with correspond rngly lncreased performance. The early head improvements were standard to th is unit, but carefu I polishi rig wil ~ give a round 82 b. h.p

32

34

36

The ftat top pistons for the 1600 (9.25:1) to suit the Twin-Cam rods part n u m b a r ~ C - 1 2 H - 1 73 a re no Ion 9 er a va i 1- a ble. I t is possible to obtai n a 9 : 1 (14986) or 9.5:1 (15059) piston to sua the standard rods from Heo olite stockists. With the former piston and preps ratio n si mila r 10 the 1500 rnodet. output would be approximately 85 b.h.p,

Fit the 11 in S. U. 's with Me needles. .1 00 in. jet and st at i c i g n I tio n at 8~· B. T. D . C . pl1lnj~g ~prox~mate~y .020 in. from. the he.ad face with the 15059· piston would give 10:1 compression. The combustion chamber shou ld be modified as d i ag ra m Ba II and the head could then be modified (Ba JI,) to accept the M G B valves, 12H 436 exhaust. 12 H 435 inlet, by grlndrng out throats and ports. It's simpler by far to acquire the 1622 head, 48G 21 5~ and correct the combustion cham ber vol ume by machining the face" approximately .050 in.

Frtting the C~AEH 714 cam and again pointing out the rev limit power can be increased to around 1 05 b.h.p,

All transmission mods are as the 1500 except where the brakes are concerned. The 1600 has Lockheed discs; for competition work the DS 1 1 pads sho uld be obtained by sending to Messrs. Ferodo for deta i Is. I f this transfers a bias to the rear, causing them to lock. up prernaturelv. then fit VG95j1 !injng material.

MGA 1622

In Apr!l, 19611 the 1600 Mk II was introduced, this carried on the same styling with an uprated power unit. This actually was a new unit with a stiffer crankshaft, improved cvundsr head with larger inlet 1 .565 in. (forrnerlv '.5 in.) and exhaust 1.345 in. (formerly 1 ~281 in.) varves and i ncre ased combustion volume at 43 c.c,

The hrgh compression version (8.9 ~1) had flat .. top pistons .as standard and developed around 90 b. h.p. at 51500. This was a new block and not an oversize 1600; t he stand ard bore size is. 3 ~ n.

The difficulty is that no special pistons sxist for this mode~ from any source. nor are we helped by the fact that the small end diameter was increased to .75 in. from .6869 in,

Head machining arter polishtng and ba lancinq eha mber volume dsta i led ear'li~r

could increase cornnresslon to approximately 9.5 but at .060 in. removed this . would b'B on the limit.

Frtti ng the 1: • n, 5, U. on th~ 1 2 H 911 manifold and usiuq the race C-AEH 714 cam shou Id ach i eve 1 05 b. h. p. at about 6,.000 r. p. rn,

The standard valve springs fitted were 6K 873 outer and 1 H 723 inner, with a total load on full rift of 163 Ibs. These need not be changed; with the standard cam valve crash occurs around 61200. With the 714 cam around 6,600 r.p.rn is more than ample.

The transmission mod! apply alth.,ugh the f. na I drive rati 0 was 4.1 on this model. The clutch had h-ght grey springs increasing the pressure to 205 Jbs

All the previouslv suggested modificati a ns to gearbox.. wheel s. brakes a nd so o n, also appt y.

If a power unit has been damaged beyond repa i r the owner sh OU Id co nsider fitting an MG B power unit, wjth or without gearbox. One has to be prepared to modify parts to some extent but it is not too difficult. Using the B powsr un it you must first ensure that the first motion shaft has the sam e number of splines as the centre of the cl utch driven plate to be used. A point also to watch here is that the 18GB (5 main bearing) M GB power unit has a la rger diameter crankshaft bush. I f the M GA small diameter first motion shaft is used than a smaller diameter bush must be made. Alternat ivelv the larger dla meter first motion shaft co u Id be fitted to the gearbox. The pump unit is longer and the water pump is too close to the radiator. The easiest answer is to space the radiator approximately 5/16 in, further forward.

It is possible to use the MGA water pump, part number 12H 839 but this does not have the same capacity a nd can lead to overheatin g. If this pu m p is fined, the correct pulley 8G 742 must also be fitted to keep the fan pull ev in Ii n e. It's better to use the MG B pump 12H 766 with pulley 12B 174.

If the MGB unit is fitted complete with gearbox the first motion shaft problem does n at arise. The rear m au nting is different and the MGA rear gearbox extension must be fitted in pJace of the MG Bone.

J

37

-:

,

'I 1

Fit the speedometer drive gear to the output shaft also-

Retain the MGB starter motor .. as the MG A one may find it too much; the B starter is I arger and the flo or will have to be modified.

H ave a free flow ex ha ust fabricated, the MGA one is restrictive and the M GB one requires too much modification to fit With the additlona l weig ht at the front

hand ling will be affected, and it may prove useful to fit the stronger AH H 5789 front springs to compensate.

A useful hint "or all M GAs is that B oi I cooler fits with ~ittte trou ble :

1 2 Row a u cooler Block adaptor Pipes

38

ARO 8909 AHH 6701 (AHH 8536 (AHH 8637

CHAPTER 5

All good thi ngs h av-e to end so matime (don't cry Myrtle f) and after seve n year~ of the M GA production ca me th e final move away from M G traditions, Sports car purists ace ept~d certai n i nconven iences for years as necessities but the MGA had buried many of them (tradiricns not purists) ,

! ntrod uct io n of the M G Bin Octo ber "62 saw the demise of a separate box' section chassis=-the B falling into line with modern techniques by being unitary co ... - struction, Some felt this to be a retrograde step but the B proved itself to be no mobile blancmange. I n fact smooth lines and increased comfort were contained within a smaller pac kagE1. l.enqth and heig ht had been reduced while more important still, so had we~9ht.

Other th an this body change basic essentials remained as the MG A 1600 M k U. Front discs were slrghtry smaller diameter, 1 OJ- in., with increased pad area; rsar drums remained at 10 in, diameter but with wider shoes. front suspension geometry was sl ightly ~Itered a I1d softer rater longer spri ngs fitted. R ear leaf springs and shockers were hasicallv unaltered.

Not only were creature comforts catered for with wind-up windows and so on. but a new power unit exclusive to the- MG B effect ivelv increased the power to wei 9 ht ratio from 100 b.h.p, ton to 117 b.h.p, ton.

MGB

,

!

J

j

1 ;

•

j

~

FoUowing established B Me practice i1 was a conventional three mai n bearing job with a 3.16 in, bore. 3,,5 in. stroke .. qivinq 1 798 c.c tnta I capacity. Derived from the 1 6 GA un it it retai ned the cv!i nder head una hered ~ Main bearings were increased in journar dia meter to 211 67 in I with t hei r length r-ed uced by .25 in,

The 43 c .c. ca pa city comb usti on cha mber and 6.25 c.c. piston dish gave a compression ratio of 8.8:1, The camshaft was also un altered in specification (eSG 252) while 111e carburettors changed from H4s to the improved H S4s with no change in choke size. Nett output for this power u nit was 95 b. h.p I at 51400 r. p.m, nett with maximum torque up to 110 lbs.Zft. at 3.000 r.p.m.

The unit was completely new and not a bored out 1622, and had the prefix 18G. A diaphragm clutch replaced the six" spr, ng M GA type; althoug h it rematned at erght in. diameter.

The gearbox ratios were unchanged but gojng from 15 in+ to 14 in. wheets had neciss.atated reducing the axle ratio from 4.1 to 3.909. Overdrive was an optional e xtra. grvlng a .82 red ucnen.

CYLINDER HEAD.

As we are dealinq with the early models it is again emphasised that the condition of the vehicle. bodllv anQ mechanically. is

39

,.

.~

{J

~

......

ill

IJ..

0

).,..

I f2

10-...

rc

::,

0

W

:::...

Q:J I 1-

~

I

0...(

~~

..,

, ,

...,.

.. -,

..

en tZ LLJ Z a Q..

~ a u

a C(

IJJ :x:

0::

LIJ o Z

"

-

...J

> U

m C)

%

i .

I

e f

~

..

I

~

I

J

P"

40

9

332 ----

3/R rn n

/4 I" C

constant radius of~ between points AandB

varying radii

cc

MODIFYING THE 'B~ SERIES COMBUSTION CHAMBER 41

rnaehin ing d imen 5 ions - enlargement of cyl i nde r head combustion space NOTE-·020in,(-50Bmm.) may be removed from the standard cylinder head face

,

I

L.

·2

..

all important, It would not be unreasonable for some of these m odets to have exceeded 60,000 rnites-cnot without a few incidents eit her r

Unless the car's history is well known it should be thoroughly examined. Any extensive tu ni ng wi II in valve stri ppinq cornporients and the owner would be wise to obta i n t he workshop rna nual (AKD 3529) which details any special tool s that may become necessary.

First steps tJr~ to remove and strip the eyli nder heao. Exa mi ne a II va lves, havi ng first removed all carbon Then IighUy polish their sterns, neck and heads. Any I~ght pittinq in the seat or face may be removed by g ri nd iog j n ; you shou Id check the stem d iamete r for wear with a micrometer and at 'east chec k it i n a n~w guide. Si mil arJy if the valve guides themselves are worn t replace them, Assuming the head is as standard and shows no sign of cracks or warping by carefully polishing out the combustion chambers, Remove all possible sharp edges from the pluq orifice and also radi us the 0 uter wa lis to reduce the peaks intruding in the kidney profile. Don't remove them ccrnpletelv. smooth 1he canto ur of the smaller ridge near the pi ug a nd take the pea k between inlet and exhaust valves back by approximately . 25/3 in. R ad i us from this point on the profile round ,fading out around the centre line of the two valves. Do not chamfer the edge of the com bustio n cha m bar or this w til lead to burnt 9 askers, just I ig htly leve I the edges. Check gasket clearance with an old gasket. Attention to the valve ports can remove casting errors or burrs from seat areas and in the throats. Inlet ports should be carefu I~y polished without destroyi ng the orig inal throat or port diameters. I think its important to be 'extremely careful wh-en poHshing the inlet ports so as not to weaken the structure between the valves, ca usi ng cracki ng, Also this br~dge point encloses the water passage cooling the valve seats; too much enthusiastlc gri nd ing results ina ru in.ed head,

This work will have increased the capacity of each combustion chamber, The head face will have to be machined accord-

.

..

, .

.J.

.~

..

,.

f;!.

i-

~!

~:

,

i

-

f

j ng Iy to correct this, T he standard ca pac itv is 43 C.G. and for the normal compression ratio you must return to this,

Measu rin g comb ustio n cham bers has be~n dealt with earlier. but to recap you req uira a quantity of IIg ht oil (R edex is ideal), a piece of tlat Perspex 10 entirely cover the combustion chamber with a .5 In, hole j n t he centre and a measuring cylinder,

With valves ground in and lifted together with the usual sparking plug1 the head sh ou ld be mou nted with the head f~ce horizcntallv uppermost. Srart with a known quantity of oil in the rneasuri ng cylinder and gradually pour through the hole in the Perspex which seals off the cham ber. Whe n oil closes t he bottom of the hole- you ca 11 read th e cap ac ity from oil reduction in the measuring cvlinder : if you spill any start again, Sometimes small corrections Can be made by light Iy grinding the valves deeper i(110 the head but on no account let the valves become 'pocketed", The largest capacity chamber becomes your 'datum' so red uce the head face to return the chamber to the required capacity. About .009 in. from the head face .5 approximately equal to 1 c.c, The other combustion chambers should then be polished out so that they are all within .5 c.c .

H avin 9 com pi ete d this wor k a small 2·3 b.h. p. inc rease wi II result, a greater benefit will result from taking the opportu nity at th is stage to increase the compression ratio.

A completely pol i shed cyli nd sr head is available- from British Leyland Special Tuning through dealers under part number C~AHT 100. This will increase the compression to 9.5 :1 : the combustion chamber capacity is approximately 38.5 c.c.

B efore replaci n 9 any cylinder head wh ich has b~e.... mod ified to give hig her cornpression, or where high compression pistons have been fitted, counter sink the head stud holes. this prevents any tendency for the b lock to I itt a rou nd th e base of the stud. ca using gasket failure, Head nuts should be torqued down to 50 Ib./ft, and more rigid high tensile steel washers used,

42

•

;' ~----- - .... -

l/~ 18 R 4

I

..

~

,

I

'.

~

.j

•

~

# ;,

~

.j

j

l

~

.t

-,

;1

I

~

~

i

i

I

~ inlet port

- ----...1_

"II f

MACHINING LIMITS FOR LARGER VALVES- B SERIES

43

!

, ,

j

~

J

~

•

•

1

,

'i.

:.

a minimum thickness of .100 in., with an outside diameter . 75 i n. is recommended, Always. use the competit ion head gasket (C~AEH 768); this is well worth the additional cost, as it red uces the risks of gasket failure with thicker copper facing a nd rei nfnrced water way holes- H ig h compression not only increases potentia I output, it also reo u [res a greater volume of air ffue I. 0 pen out the sta ndard inlet rna n i ~ fold carefullv. mate hi ng it to the cvl i nder head. Also fit 1'1 in. S.U. HS6 carburettors, C-AU 0 229. usin 9 the kit, C-AJJ 33211 which has all the necessary spacers and gaskets. TZ needles with red springs should be correct and static ignition remains at a ro u n d 1 0 o B. T,D ~ C.

Power output should be just over 100 b.h.p, at 5.500 having torque progressivety Increased through the range.

At this stage It would not be wise to fit stronger valve springs, The standard sprtngs 1 H 1111 outer/1 H 723 inner bounce at 6,200 r.p.rn. which is wall within the rotatinq parts' I imitations.

Before continu ing t he engine should be removed and stripped.

The 18G and later 18GA (closed circuit breathing) three bearing units are renowned for long distance reliebltlrv but this depends on preparation and keeping to rev limits.

If the cranksh-aft shows no signs of scoring or wear outside normal tolerances it may be acceptable. if its seen a heavy mileage i1 would be more prudent to replace it. Use a n-ew crank if possible as each regrind has some weakening effect. If you do have a crank reground it must be balanced, even if it had been balanced prsvtcuslv. tdeallv of course you should use' a n itrided shaft (C- 1 2H 1 1 67); un ~ fortunatetv stocks have long been exhausted. The crankshaft should be balanced as an assembly with its rotating parts, i.e.. cl utch assernblv, front pullev and flvwheel which should be lightened by .a reputable firm.

When reassembling use bearings in Vandervell VP 3 material. but if it is to be

built as a competition unitthen use the main bearings set C-8G 8843_ with big end bearings {complete set) C-8G 2259, These have greater cleara nces (more noise starting from cold l) bU1 are essential; a

relativs lv small mileage is required for -

running In.

Connecting rods are best replaced by the Twin-Cam type fo r competition. (C~AEH 642/C-AEH 644) or set number C-AJJ 3357-if yo u ca n obtai n them r Caretullv balance the rods. obtaininq equalltv of we~g ht at the end s. whichever type von proceed with, Polish to reduce surface cracking and ~ightly rub a file over the cap/rod mating surface edges.

Twin - Cam rods have a larger diameter with ~ in. small ends (fully floating) which will require special oiston C-AEH 0736. Th is can on Iy be su ppl ied as .040 in - oversize (C .. A E H 073643) givi ng 1840 c ,C . engine capacity; but more important this piston is flat topped resulting in a cornpression of 1 0 ~1 with standard head capacity, The C .. AHT 100 cylinder head would give 11 :1 ,

The standard rods. 12H 997/998 (12H 426/424) on early 1 8G units) have sma II ends which anchor the gudgeon pins with a clamp bolt. the pin diameter ts i in. British Leyland do not make a flat top piston to suit these rods though it is possi ble to obta ~n one from H epolite, part numbe-r 16225. This should be acceptable for road use but is not recommended for cornpetiti on.

B ala nci ng consi derably extends the I ite of components in any state of tune, so jf the engin e is rebu i It at this stage with flat top pi stons a nd the Sports ca rnshatt C .. AEH 714, the result would be a smooth pu~ljng engine with constderabtv improved output. Maximum b.p.h, would be a pprox i rnatetv at 6" 000 r.p.m.